An airtight control device and method applied to electroplating grinding wheel

A control device and airtight technology, applied in the direction of electrolytic coating, coating, etc., can solve problems such as electroplating failure and inability to ensure airtight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

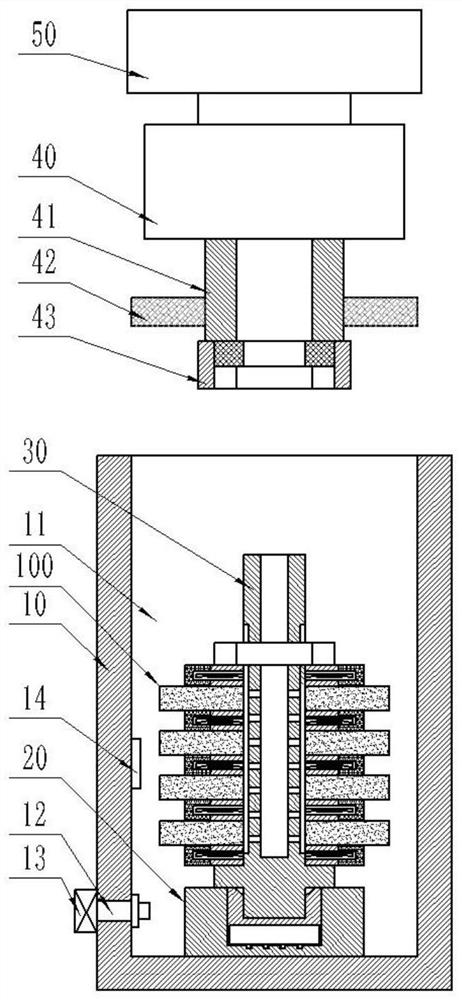

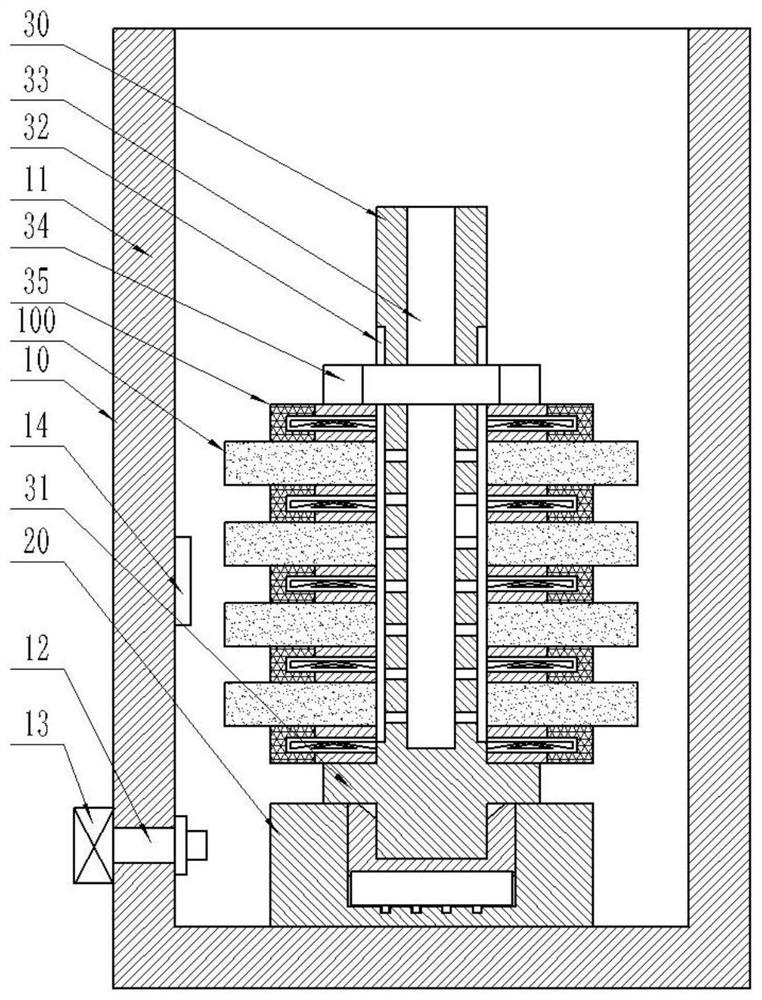

[0072] An airtight control device applied to electroplated grinding wheels, wherein, such as Figure 1-5 As shown, it includes: an airtight control cylinder 10 , an engaging seat 20 , a mandrel mechanism 30 , a telescopic docking mechanism 40 , and a driving motor 50 .

[0073] The airtight control cylinder 10 has: an airtight cavity 11 , a booster port 12 , a booster pump 13 , and an air pressure sensor 14 .

[0074] The booster port 12 communicates with the airtight chamber 11 , the booster pump 13 communicates with the booster port 12 , and the air pressure sensor 14 is installed on the side wall of the airtight chamber 11 .

[0075] The joint seat 20 is installed at the inner bottom of the airtight cavity 11 . The joint seat 20 is coaxial with the airtight control cylinder 10 .

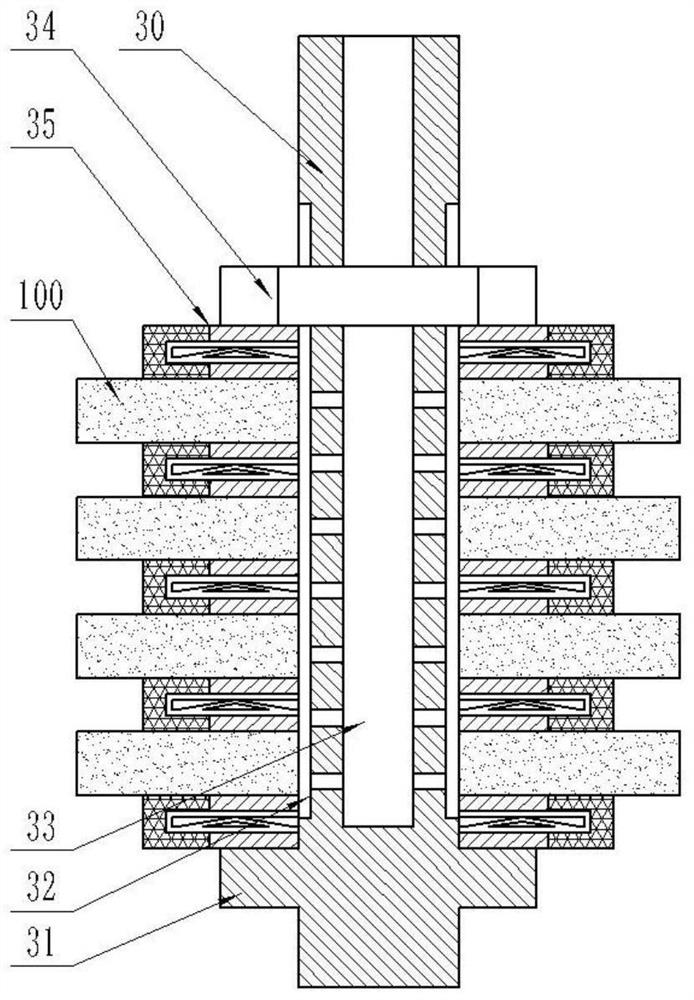

[0076] The mandrel mechanism 30 has: a mandrel, a fixed block 31 , a sealing protection pad 35 , and a locking nut 34 .

[0077] The mandrel is snapped into the joint seat 20, and the outer sur...

Embodiment 2

[0093] An airtight control device applied to an electroplated grinding wheel, wherein it has the same characteristic structure as that of Embodiment 1, such as Figure 7-9 As shown, the joint base 20 is composed of a docking base 21 and a protection base 22 , and the protection base 22 is movably installed in the docking base 21 .

[0094] The bottom of the docking base 21 has an annular groove 211 and a vertical groove 212 communicating with the annular groove 211 . A coil spring 23 is provided under the protection seat 22 , and a sliding block 231 slidingly connected with the vertical slot 212 is provided under the coil spring 23 .

[0095] When the lock nut 34 exerts pressure on the sealing protection pad 35, the mandrel is subjected to rotational stress, and the mandrel transmits the stress to the protection seat 22, and the protection seat 22 transmits the force to the coil spring 23, and the sliding block at the bottom of the coil spring 23 231 is blocked by the vertica...

Embodiment 3

[0097] An airtight control method applied to an electroplated grinding wheel, comprising the following steps:

[0098] Loading, set the electroplated grinding wheel 100 and the sealing protection pad 35 on the mandrel, so that the sealing protection pad 35 is arranged between two adjacent electroplating grinding wheels 100 and axially outside the outermost electroplating grinding wheel 100;

[0099] Clamping, insert the bottom end of the mandrel into the joint seat 20 at the bottom of the airtight chamber 11 in the airtight control cylinder 10, and rely on the locking nut 34 corresponding to the axial upper end of the mandrel to seal and protect each electroplated grinding wheel 100 The pad 35 is axially clamped, wherein the fixed block 31 at the axial lower end of the mandrel restricts the sealing protection pad 35 on it;

[0100] Docking, start the telescopic docking mechanism 40 above the airtight control cylinder 10 to drive the telescopic shaft 41, the sealing piston 42 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com