Patents

Literature

104results about How to "Avoid plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

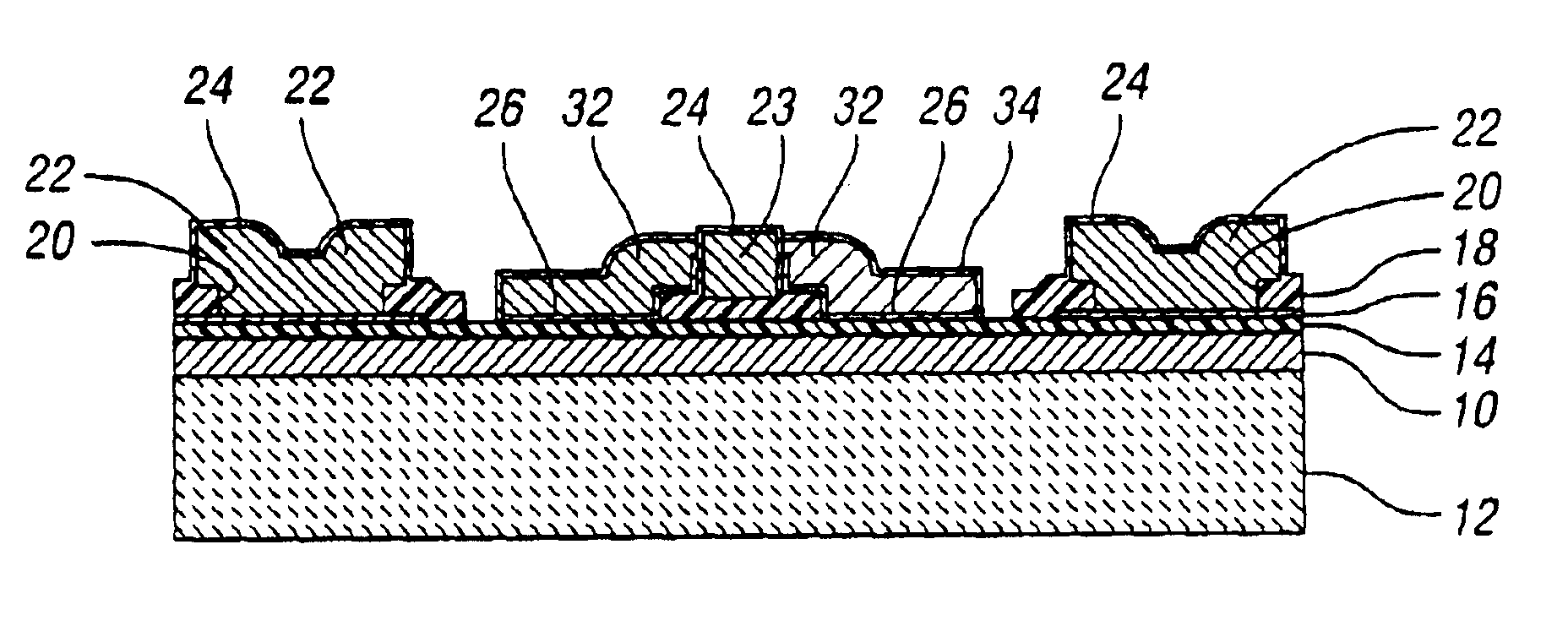

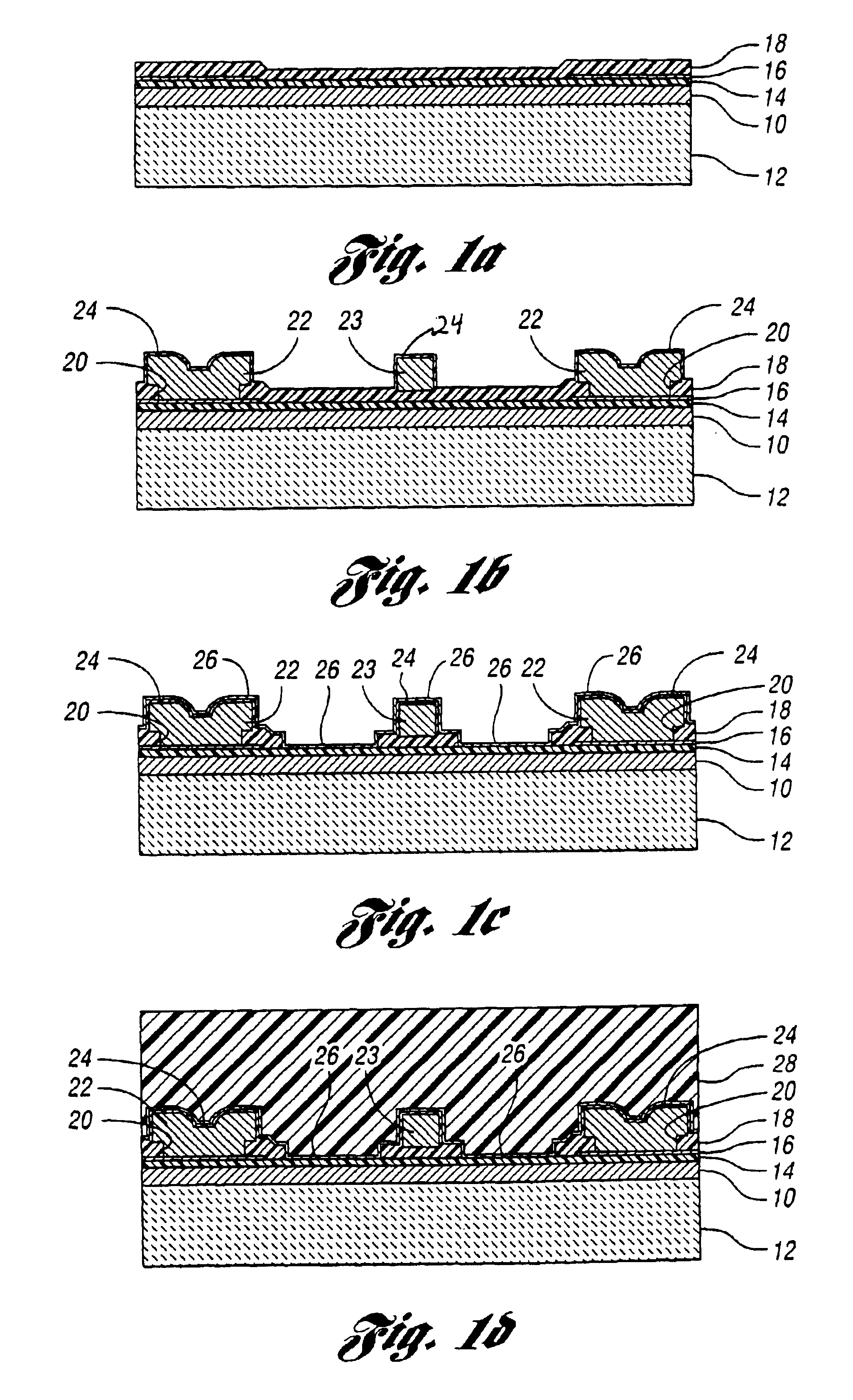

Process for forming MEMS

ActiveUS7264984B2Provides structural stabilityAvoid platingSemiconductor/solid-state device manufacturingMicrostructural device manufactureResistPhotoresist

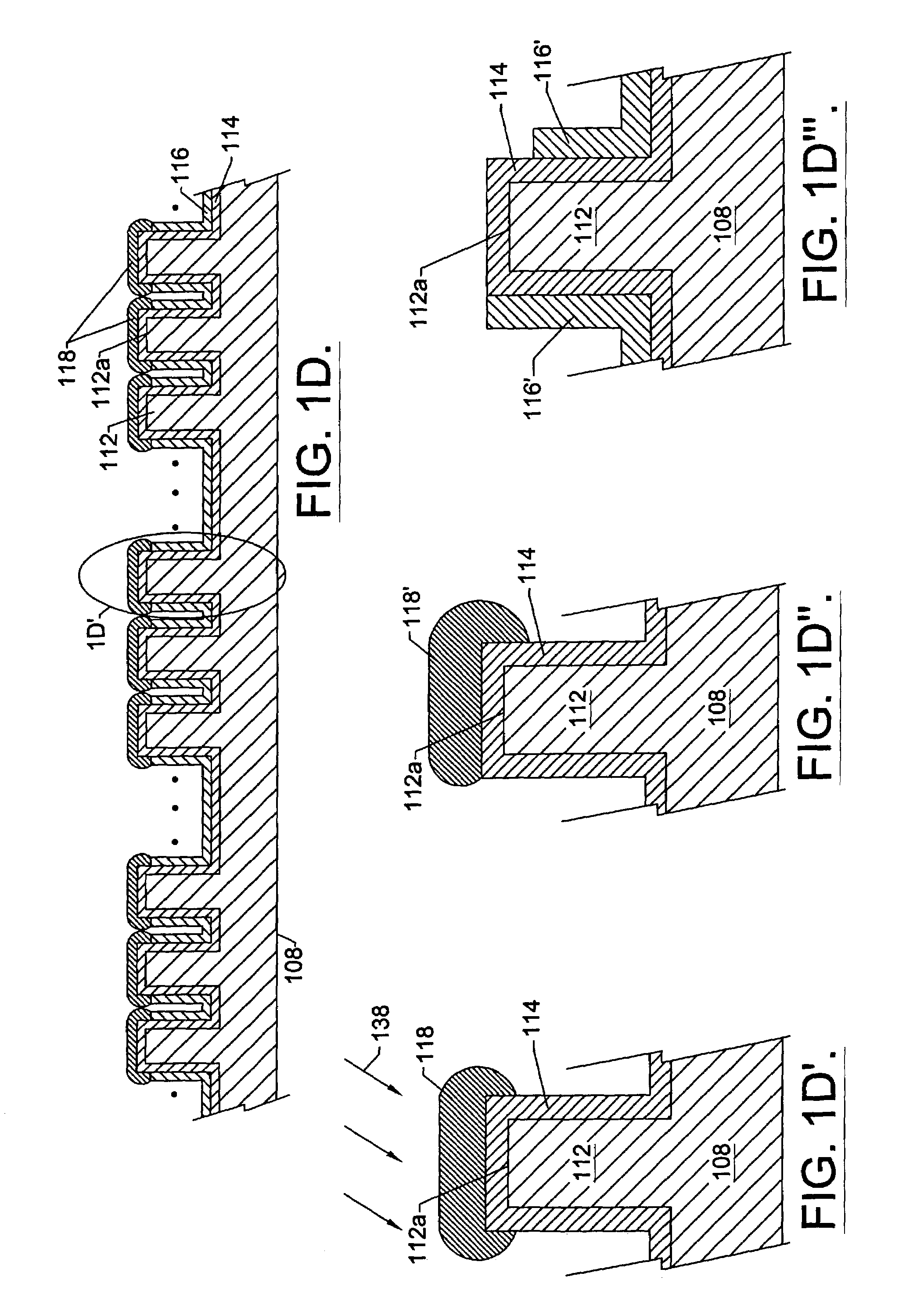

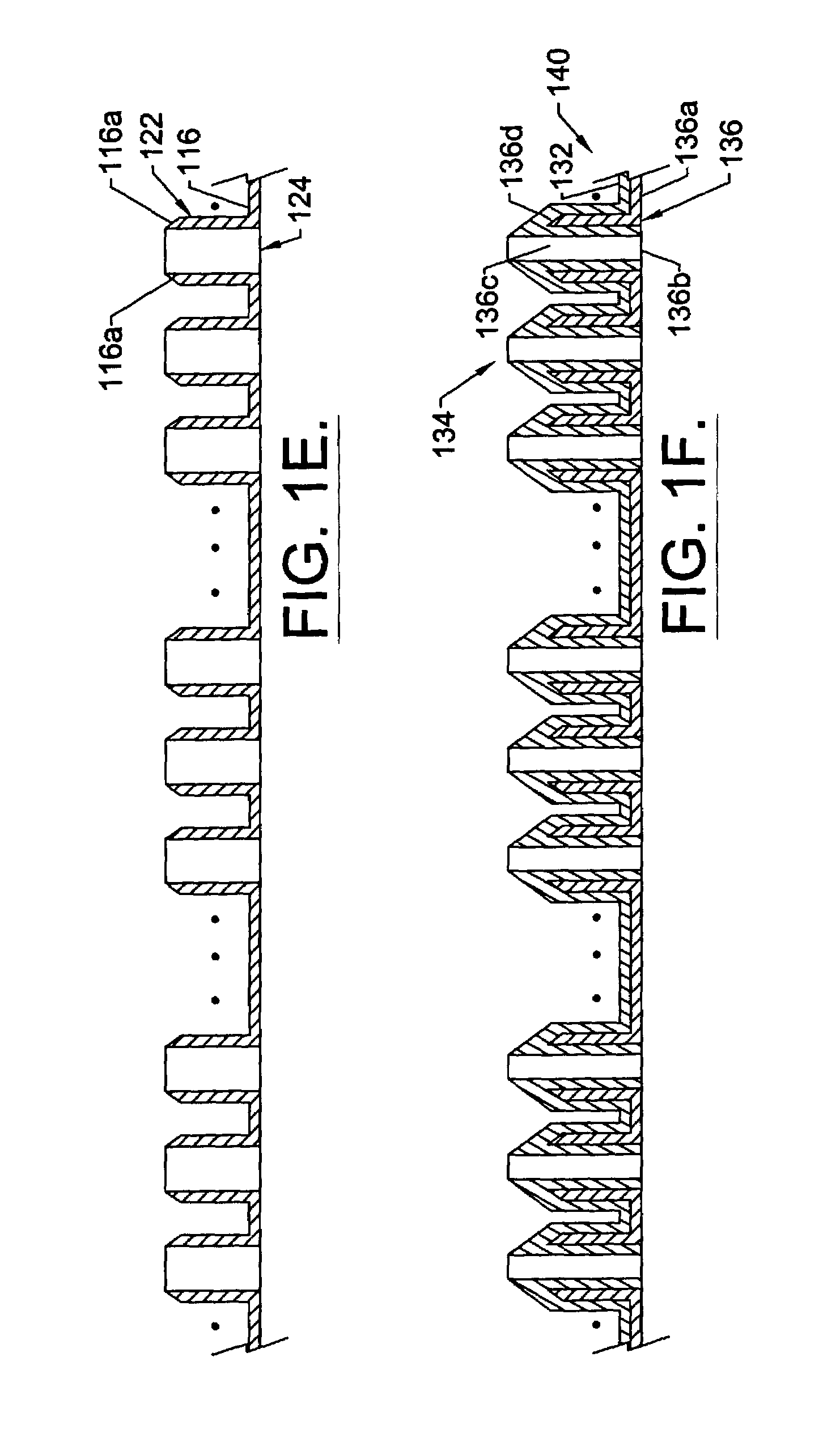

The present invention relates to a process for forming microstructures on a substrate. A plating surface is applied to a substrate. A first layer of photoresist is applied on top of the plating base. The first layer of photoresist is exposed to radiation in a pattern to render the first layer of photoresist dissolvable in a first pattern. The dissolvable photoresist is removed and a first layer of primary metal is electroplated in the area where the first layer of photoresist was removed. The remainder of the photoresist is then removed and a second layer of photoresist is then applied over the plating base and first layer of primary metal. The second layer of photoresist is then exposed to a second pattern of radiation to render the photoresist dissolvable and the dissolvable photoresist is removed. The second pattern is an area that surrounds the primary structure, but it does not entail the entire substrate. Rather it is an island surrounding the primary metal. The exposed surface of the secondary metal is then machined down to a desired height of the primary metal. The secondary metal is then etched away.

Owner:FORMFACTOR INC

Methods of fabricating microneedle arrays using sacrificial molds, and microneedle arrays fabricated thereby

InactiveUS7332197B2Low cost manufacturingLow costLiquid surface applicatorsMicroneedlesElectroplatingMaterials science

Microneedle arrays are fabricated by providing a sacrificial mold including a substrate and an array of posts, preferably solid posts, projecting therefrom. A first material is coated on the sacrificial mold including on the substrate and on the array of posts. The sacrificial mold is removed to provide an array of hollow tubes projecting from a base. The inner and outer surfaces of the array of hollow tubes are coated with a second material to create the array of microneedles projecting from the base. The sacrificial mold may be fabricated by fabricating a master mold, including an array of channels that extend into the master mold from a face thereof. A third material is molded into the channels and on the face of the master mold, to create the sacrificial mold. The sacrificial mold then is separated from the master mold. Alternatively, wire bonding may be used to wire bond an array of wires to a substrate to create the sacrificial mold. The first material preferably is coated on the sacrificial mold by plating. Prior to plating, a plating base preferably is formed on the sacrificial mold including on the substrate and on the array of posts. The inner and outer surfaces of the array of hollow tubes preferably are coated with the second material by overplating the second material on the inner and outer surfaces of the array of hollow tubes.

Owner:MEMSCAP

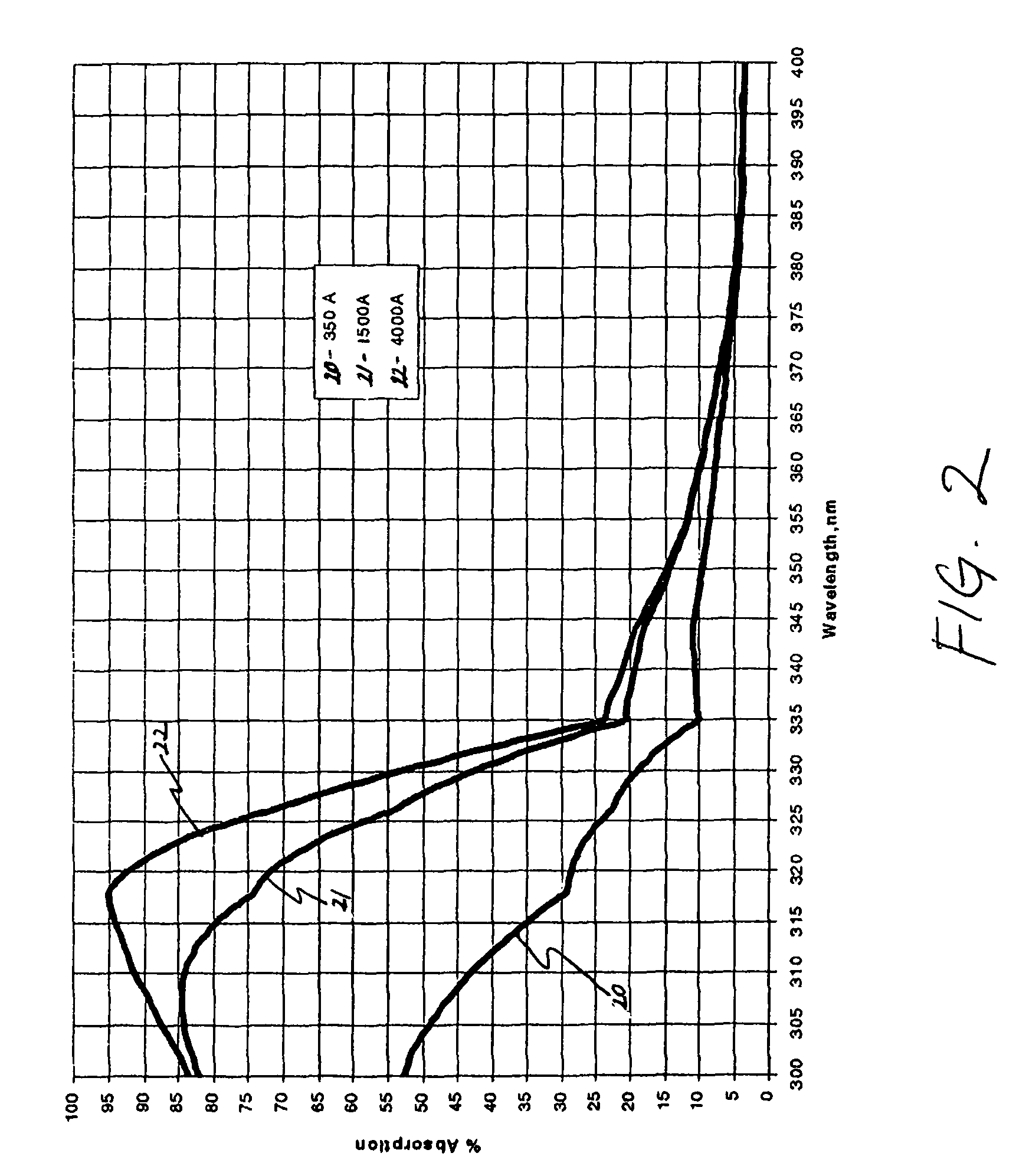

Durable silver mirror with ultra-violet thru far infra-red reflection

InactiveUS7838134B2Excellent Environmental DurabilityAvoid platingVacuum evaporation coatingSputtering coatingGalvanic cellUltraviolet

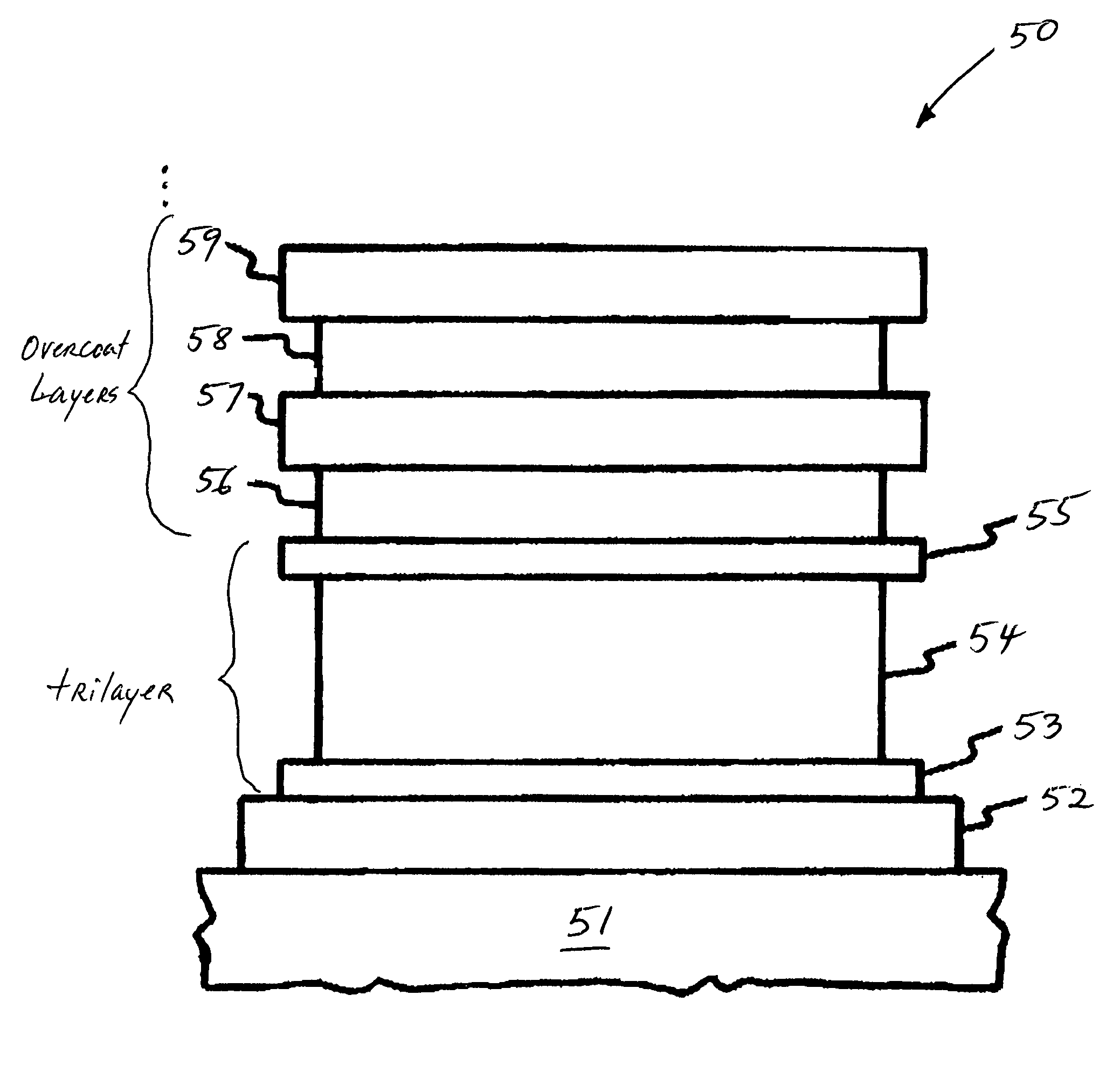

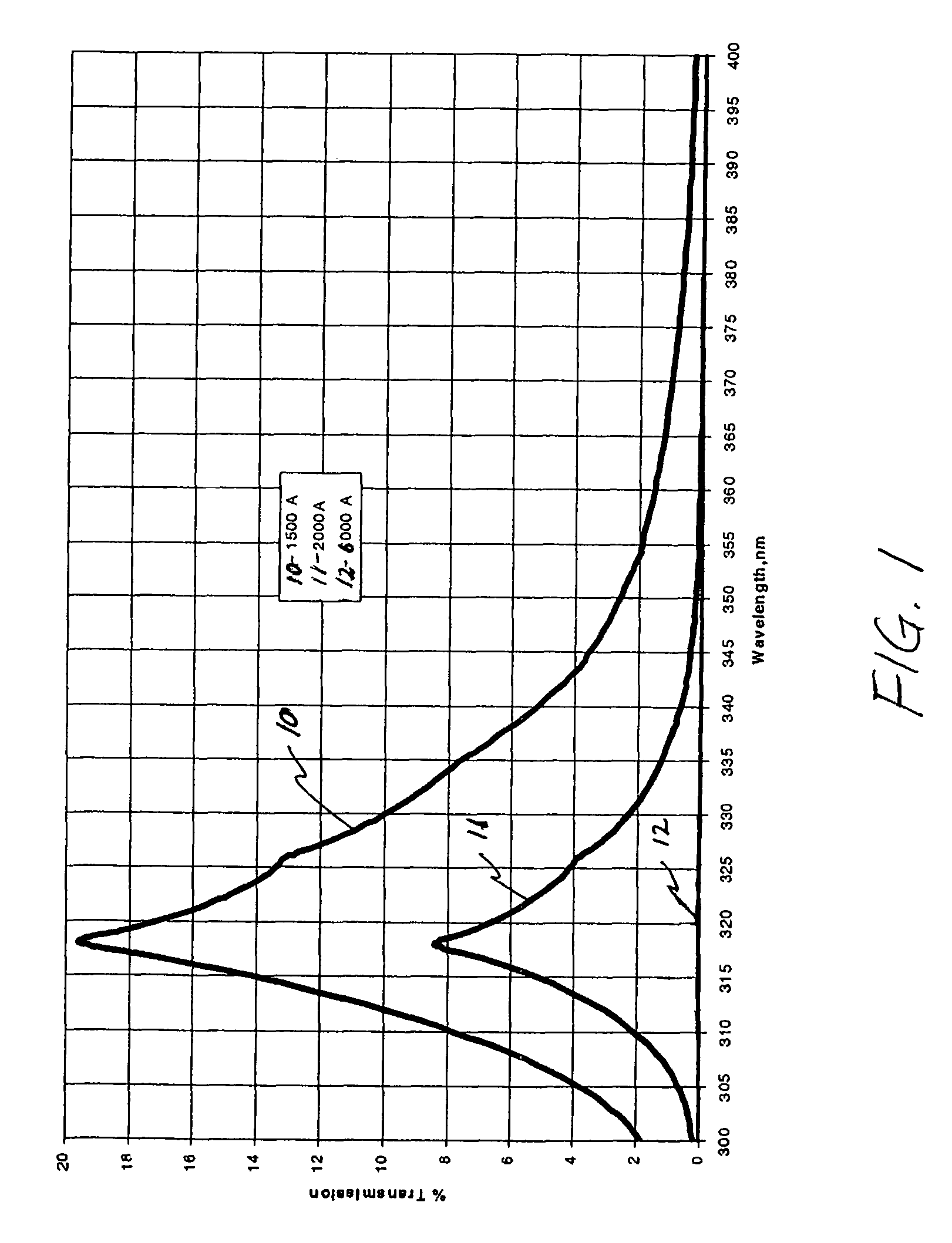

A durable highly reflective silver mirror characterized by high reflectance in a broad spectral range of about 300 nm in the UV to the far infrared (˜10000 nm), as well as exceptional environmental durability. A high absorptivity metal underlayer is used which prevents the formation of a galvanic cell with a silver layer while increasing the reflectance of the silver layer. Environmentally durable overcoat layers are provided to enhance mechanical and chemical durability and protect the silver layer from corrosion and tarnishing, for use in a wide variety of surroundings or climates, including harsh or extreme environments.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

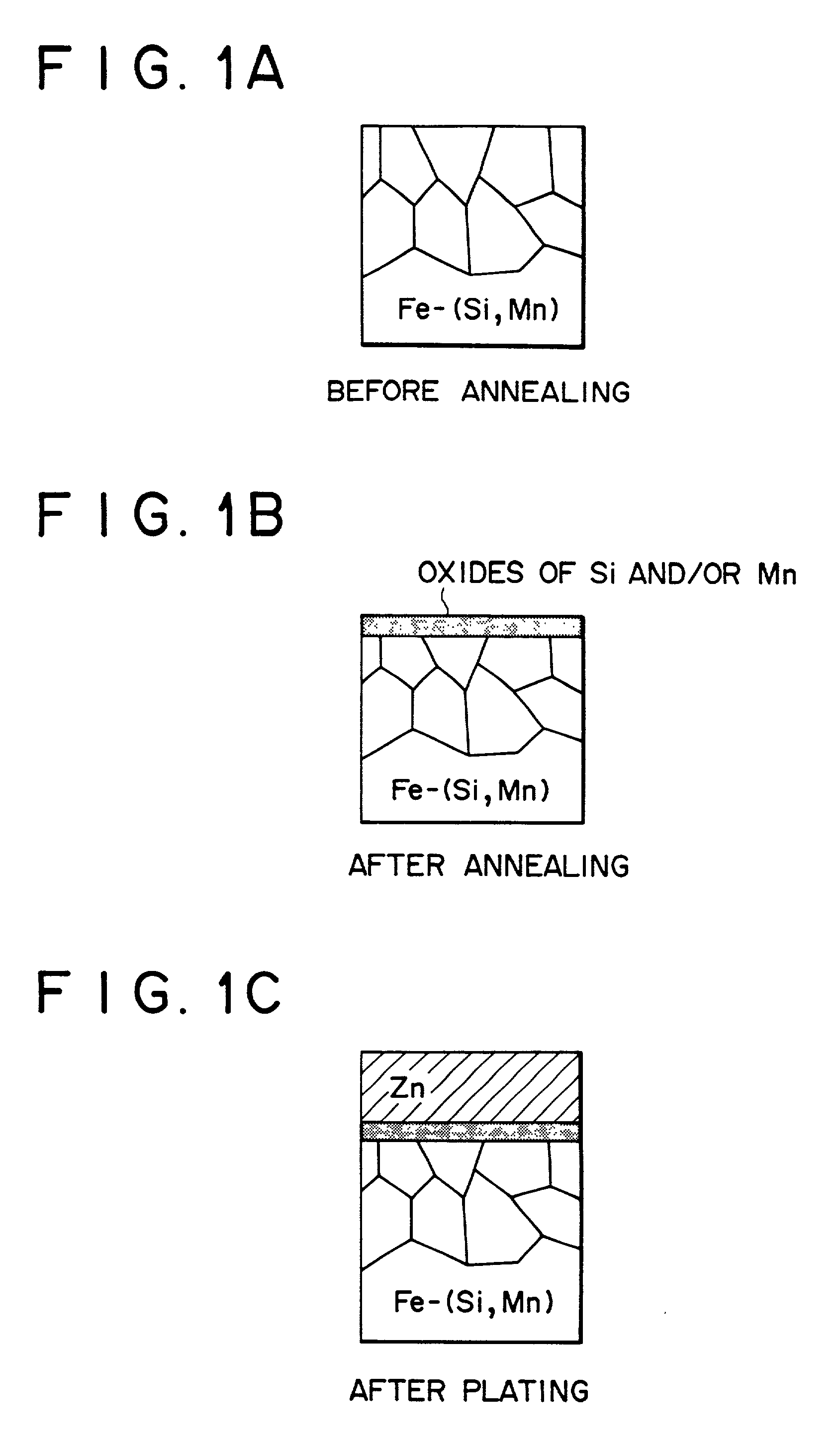

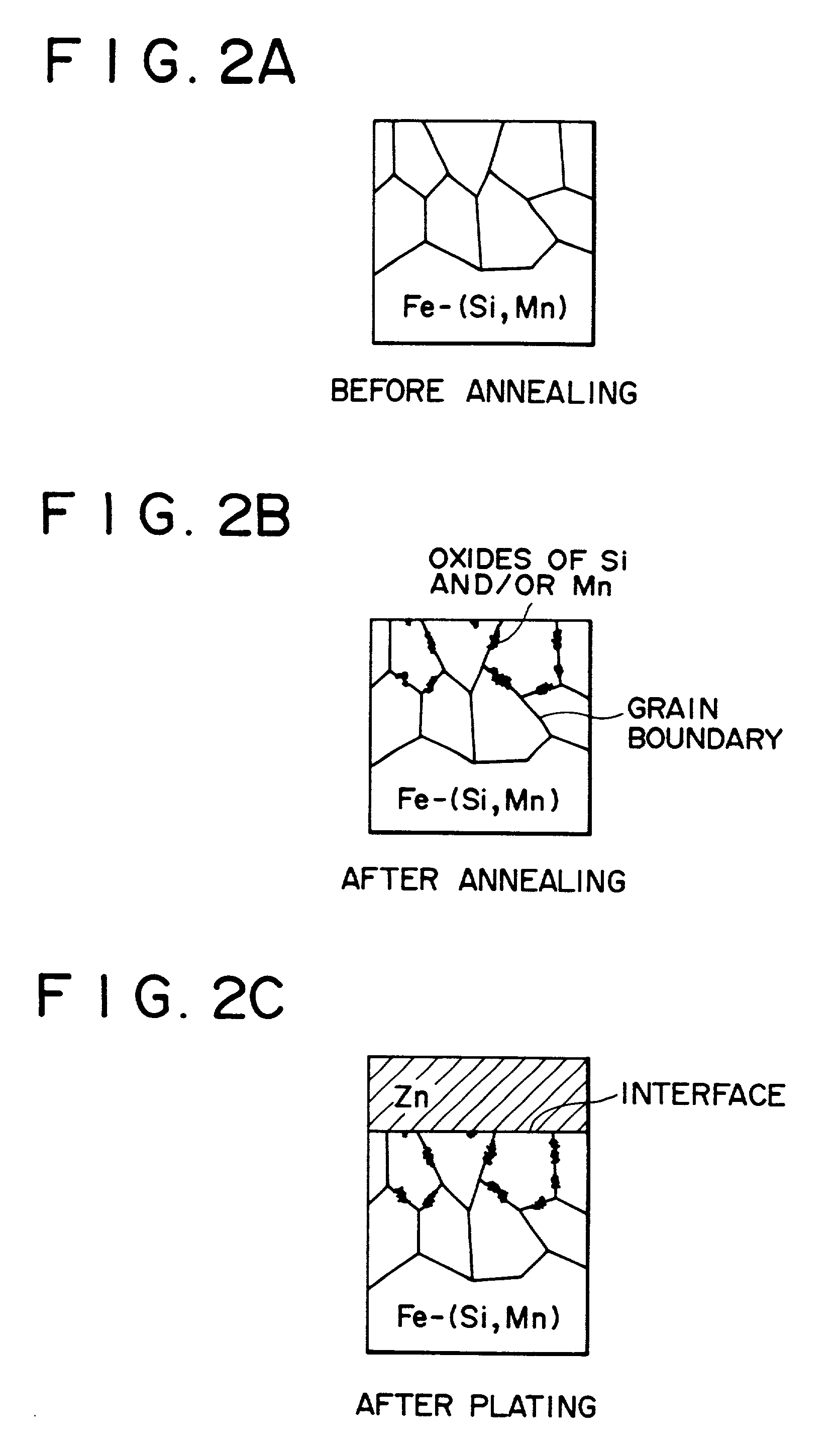

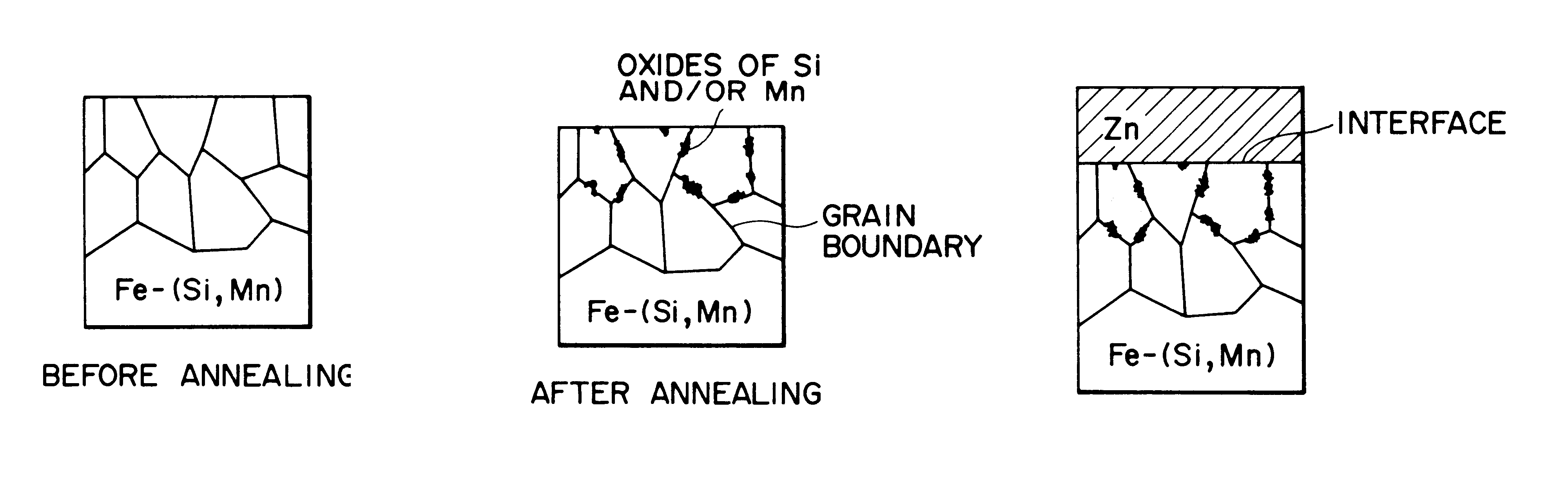

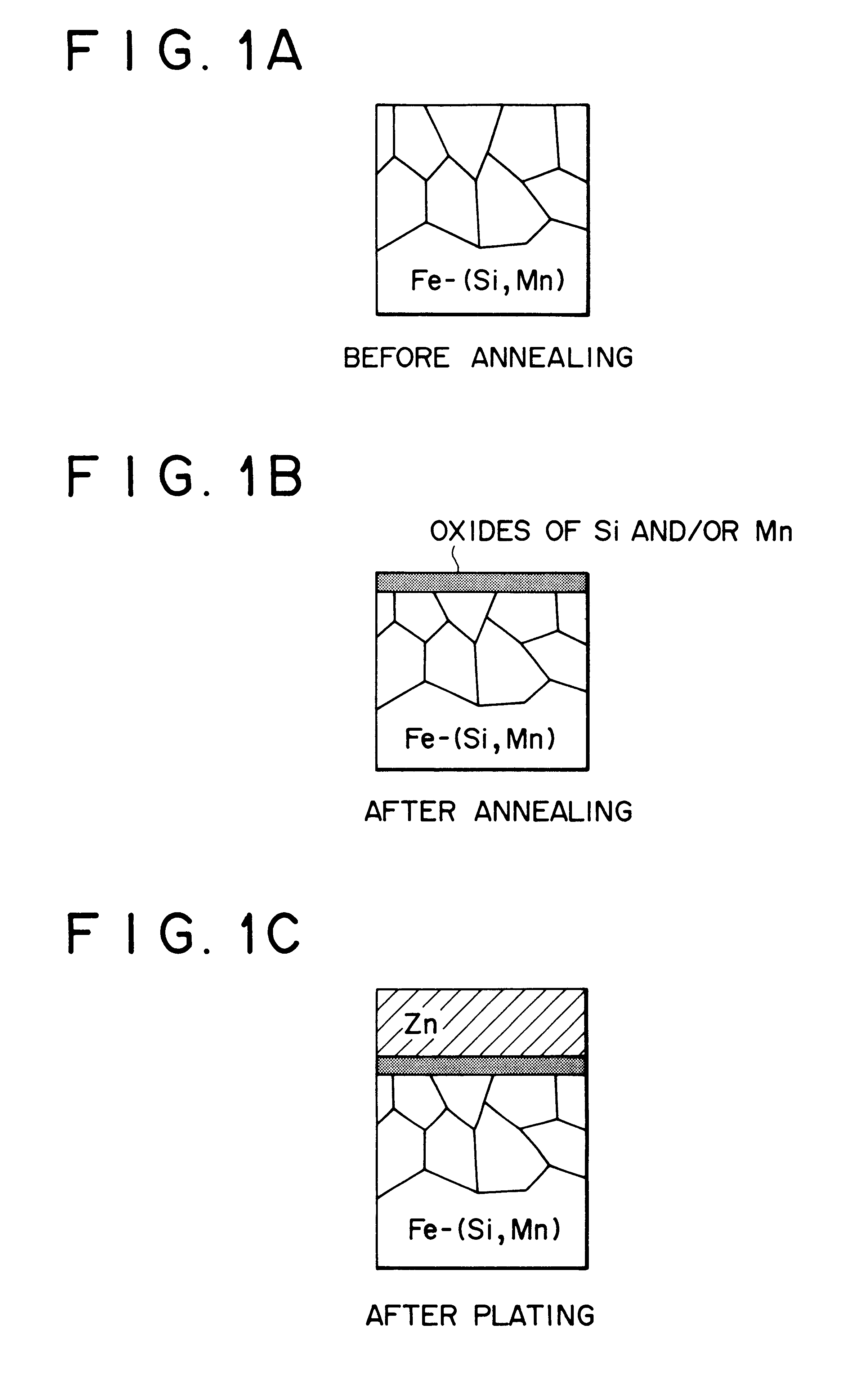

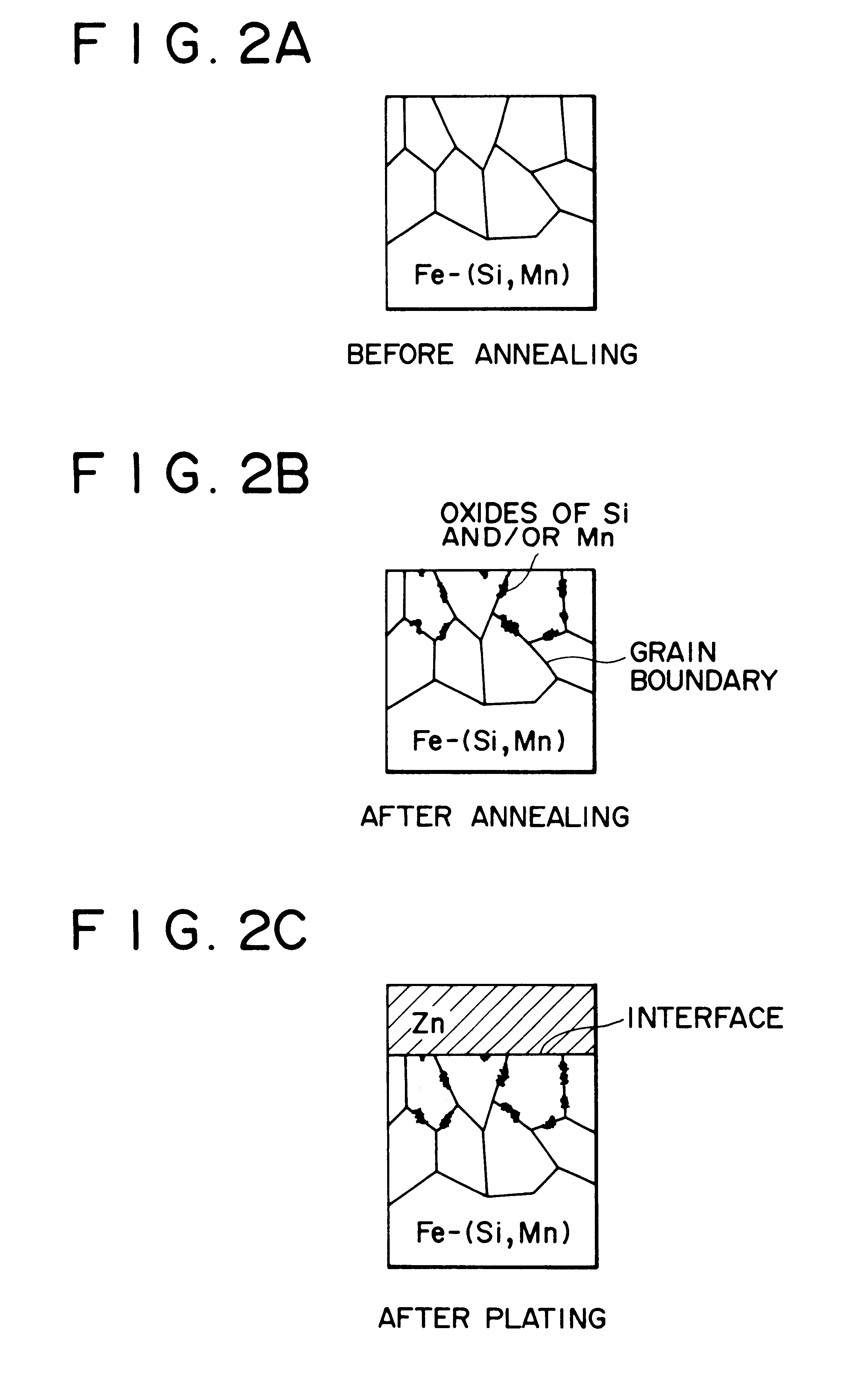

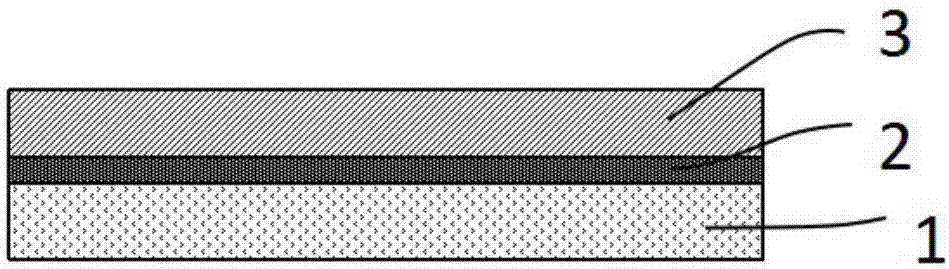

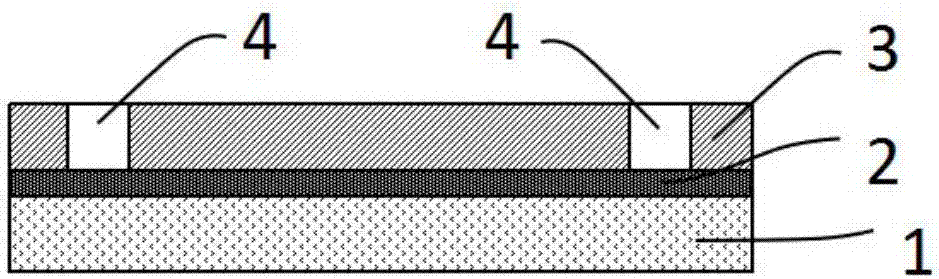

Hot-dip galvanized steel sheet

InactiveUS20010031377A1Improve surface conditionHigh tensile strengthHot-dipping/immersion processesDomestic articlesSheet steelScanning electron microscope

A hot-dip galvanized steel sheet composed of a basis steel sheet containing Si in an amount of 0.05-2.5 mass % and Mn in an amount of 0.2-3 mass % and a hot-dip galvanized zinc layer formed on the surface thereof, wherein said hot-dip galvanized zinc layer is formed in such a way that there is an Si-Mn enriched phase which is found, by observation under a scanning electron microscope or a transmission electron microscope, in the vicinity of the interface in a region no shorter than 50 mum in the cross section perpendicular to the interface between the basis steel sheet and the hot-dip galvanized zinc layer, said Si-Mn enriched phase containing more than twice as much Si and / or Mn as the basis steel sheet and extending over a length no more than 80% of the length of the interface observed. This hot-dip galvanized steel sheet is free of bare spots even in the case where the basis steel sheet contains Si and Mn in a comparatively large amount and hence is liable to suffering bare spots.

Owner:KOBE STEEL LTD

Process for forming MEMS

ActiveUS20060134819A1Provides structural stabilityAvoid platingSemiconductor/solid-state device manufacturingMicrostructural device manufactureEngineeringPhotoresist

The present invention relates to a process for forming microstructures on a substrate. A plating surface is applied to a substrate. A first layer of photoresist is applied on top of the plating base. The first layer of photoresist is exposed to radiation in a pattern to render the first layer of photoresist dissolvable in a first pattern. The dissolvable photoresist is removed and a first layer of primary metal is electroplated in the area where the first layer of photoresist was removed. The remainder of the photoresist is then removed and a second layer of photoresist is then applied over the plating base and first layer of primary metal. The second layer of photoresist is then exposed to a second pattern of radiation to render the photoresist dissolvable and the dissolvable photoresist is removed. The second pattern is an area that surrounds the primary structure, but it does not entail the entire substrate. Rather it is an island surrounding the primary metal. The exposed surface of the secondary metal is then machined down to a desired height of the primary metal. The secondary metal is then etched away.

Owner:FORMFACTOR INC

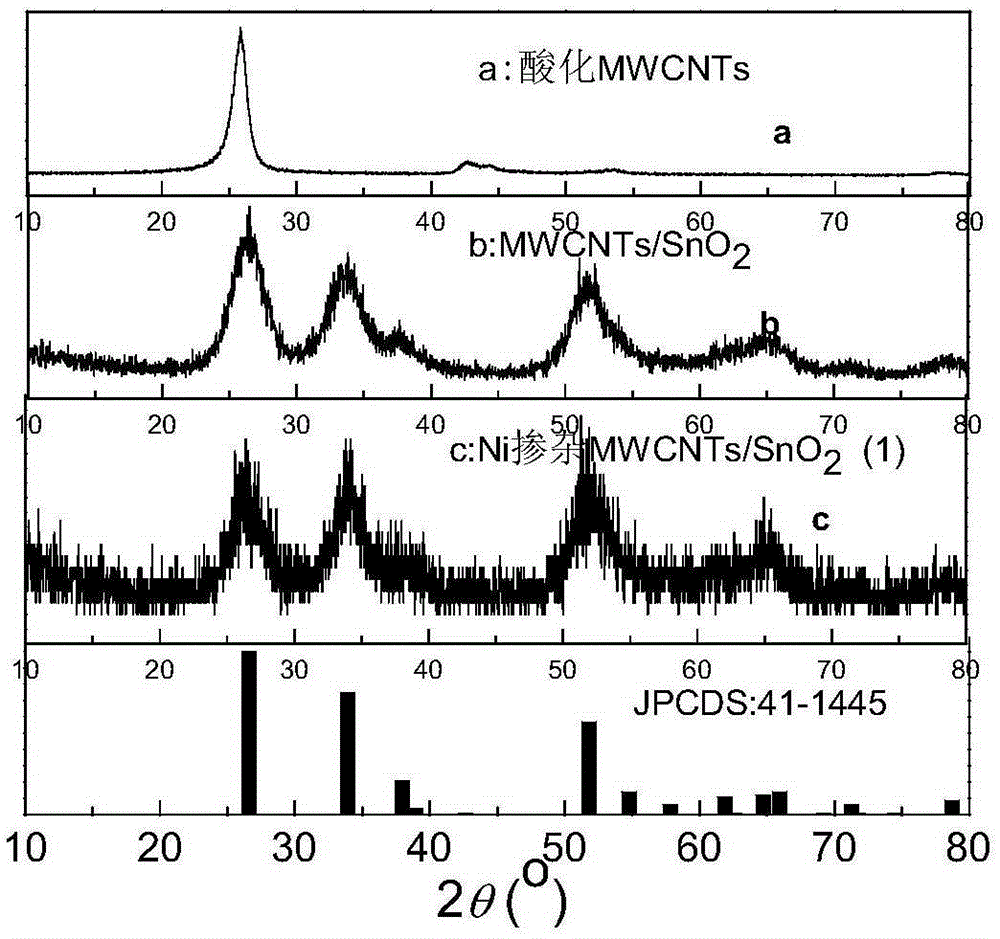

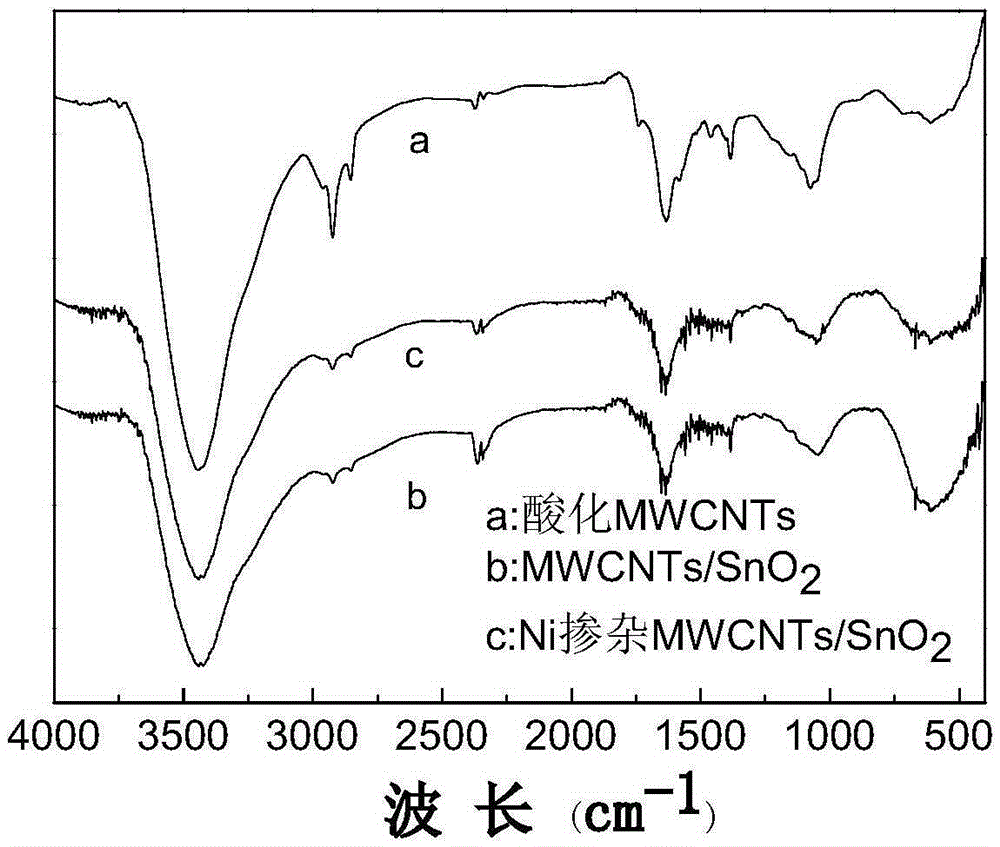

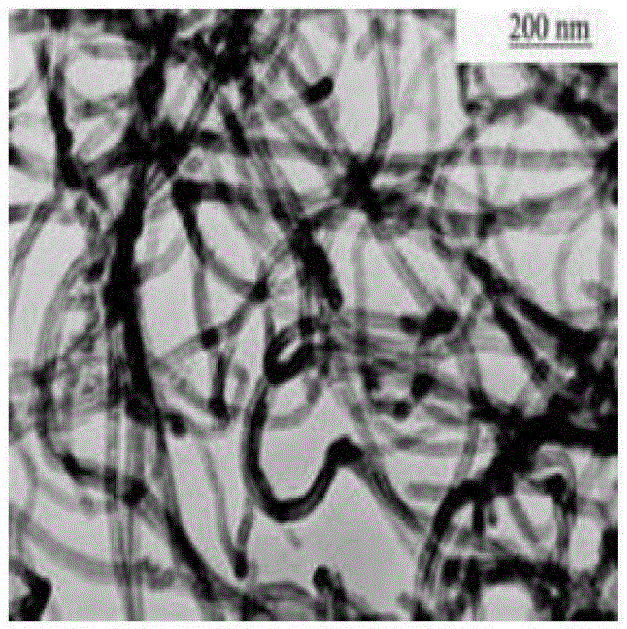

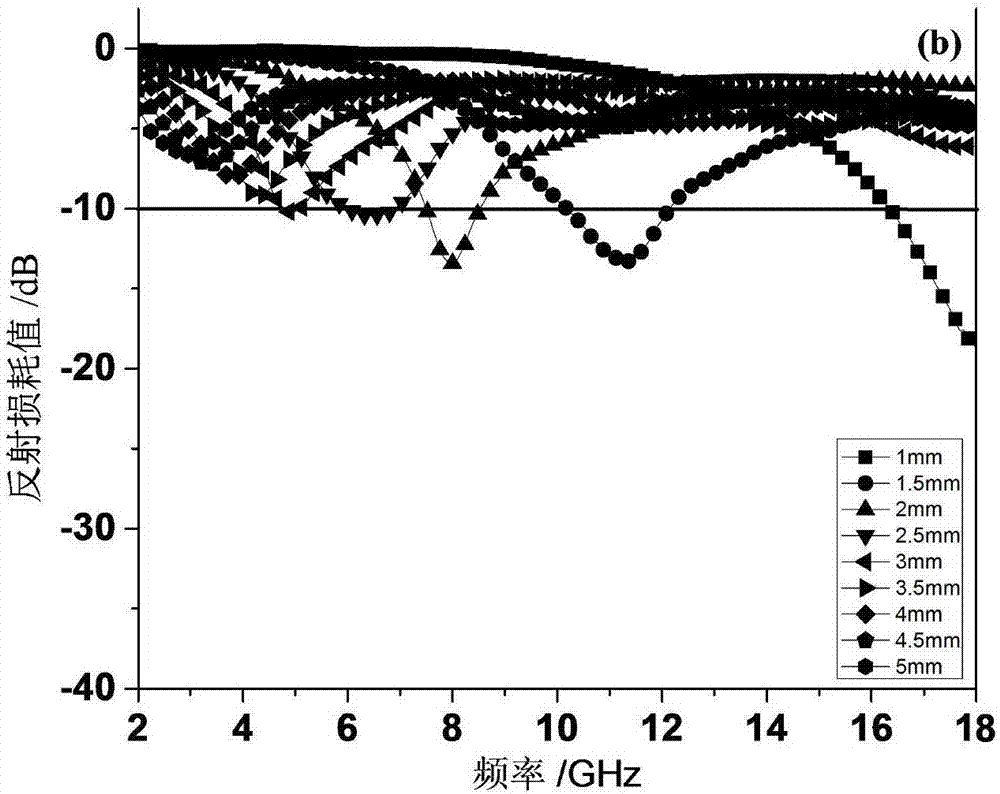

Nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes/tin dioxide

ActiveCN105338799ALight weightImprove conductivityMagnetic/electric field screeningTin dioxideNanocomposite

The invention discloses a nanocomposite made of magnetic-metal-doped multiwalled carbon nanotubes / tin dioxide, and the nanocomposite can be widely applied to the aspect of electromagnetic wave absorption. A preparation method of the nanocomposite comprises the following steps: 1, conducting acidificaiton on multiwalled carbon nanotubes; 2, dispersing the acidified multiwalled carbon nanotubes treated in step 1 into water, obtaining dispersion liquid of the multiwalled carbon nanotubes, adding tin tetrachloride pentahydrate, then adding nickel nitrate hexahydrate or ferric nitrate nonahydrate or cobalt nitrate hexahydrate, then adding acid, then slowly adding stronger ammonia water, adjusting pH to be 7-10, conducting a reaction for 8-24 hours at the temperature of 120-180 DEG C, and obtaining the nanocomposite made of the magnetic-metal (M)-doped multiwalled carbon nanotubes / tin dioxide through aftertreatment, wherein M represents Fe, Co and Ni, and the massic volume ratio of the acidified multiwalled carbon nanotubes to the tin tetrachloride pentahydrate to the nickel nitrate hexahydrate or the ferric nitrate nonahydrate or the cobalt nitrate hexahydrate to the acid is 0.04 g: 1-4 g: 0.5-3 g: 0.5-4 mL.

Owner:ANHUI UNIV OF SCI & TECH

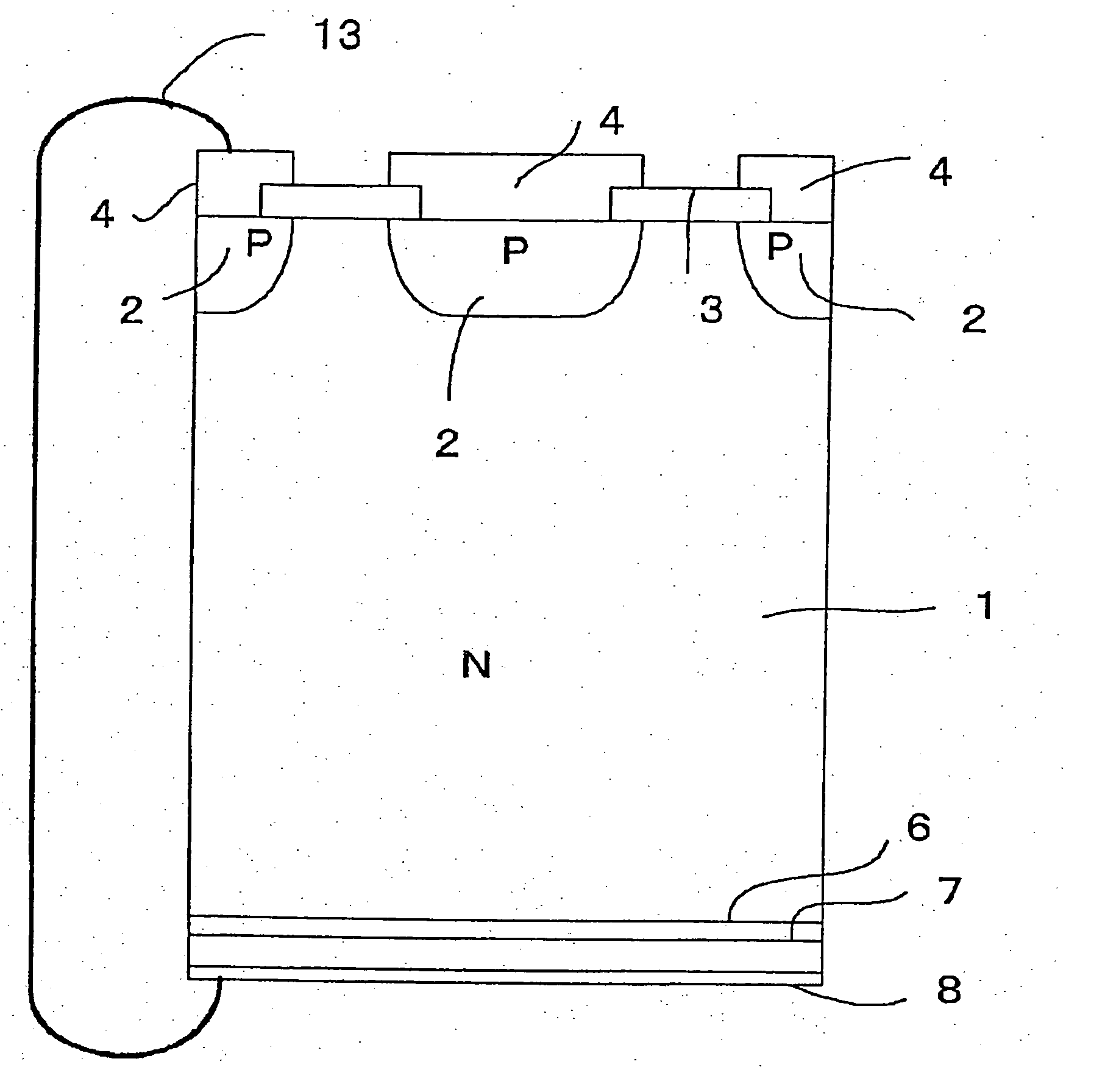

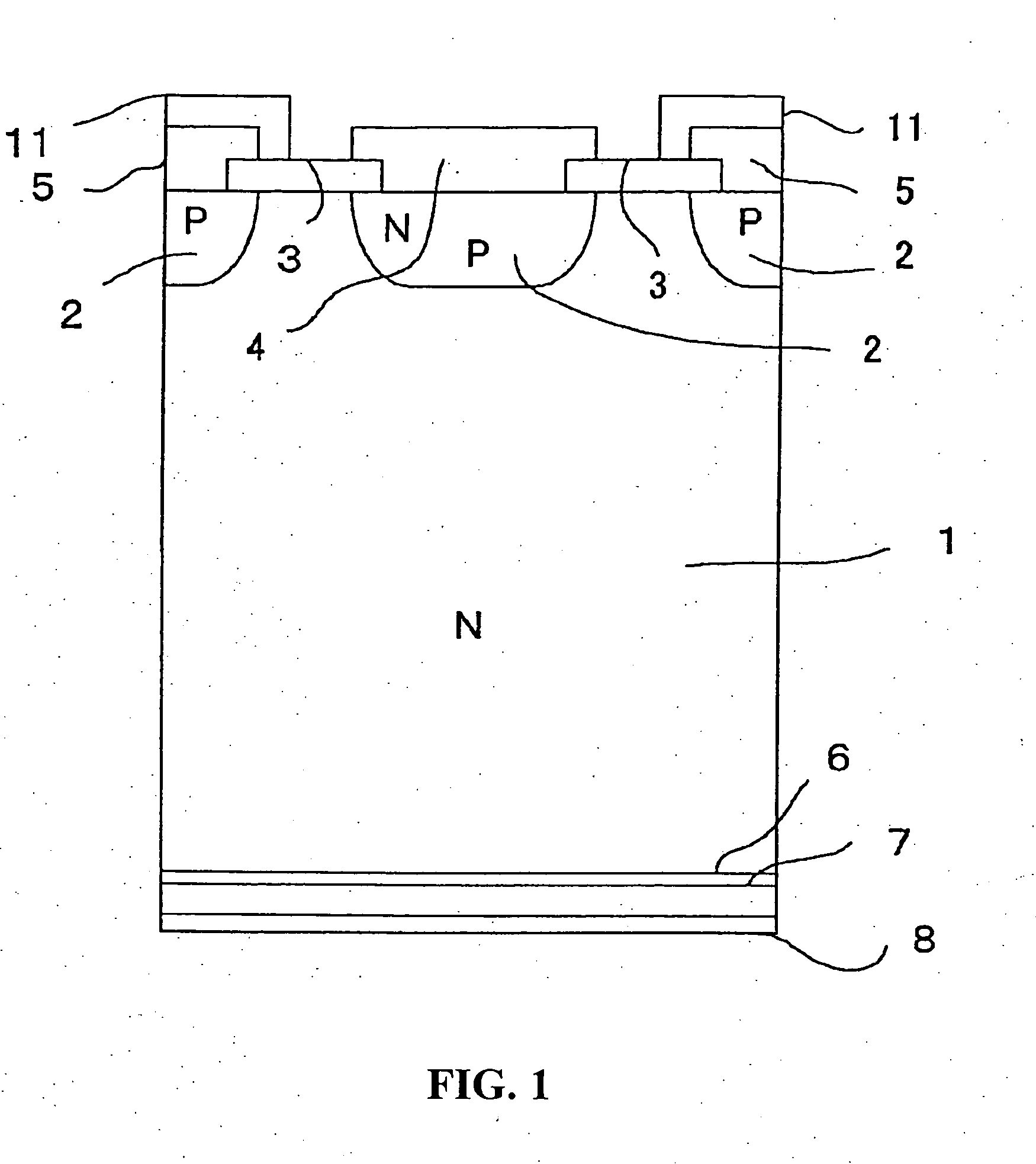

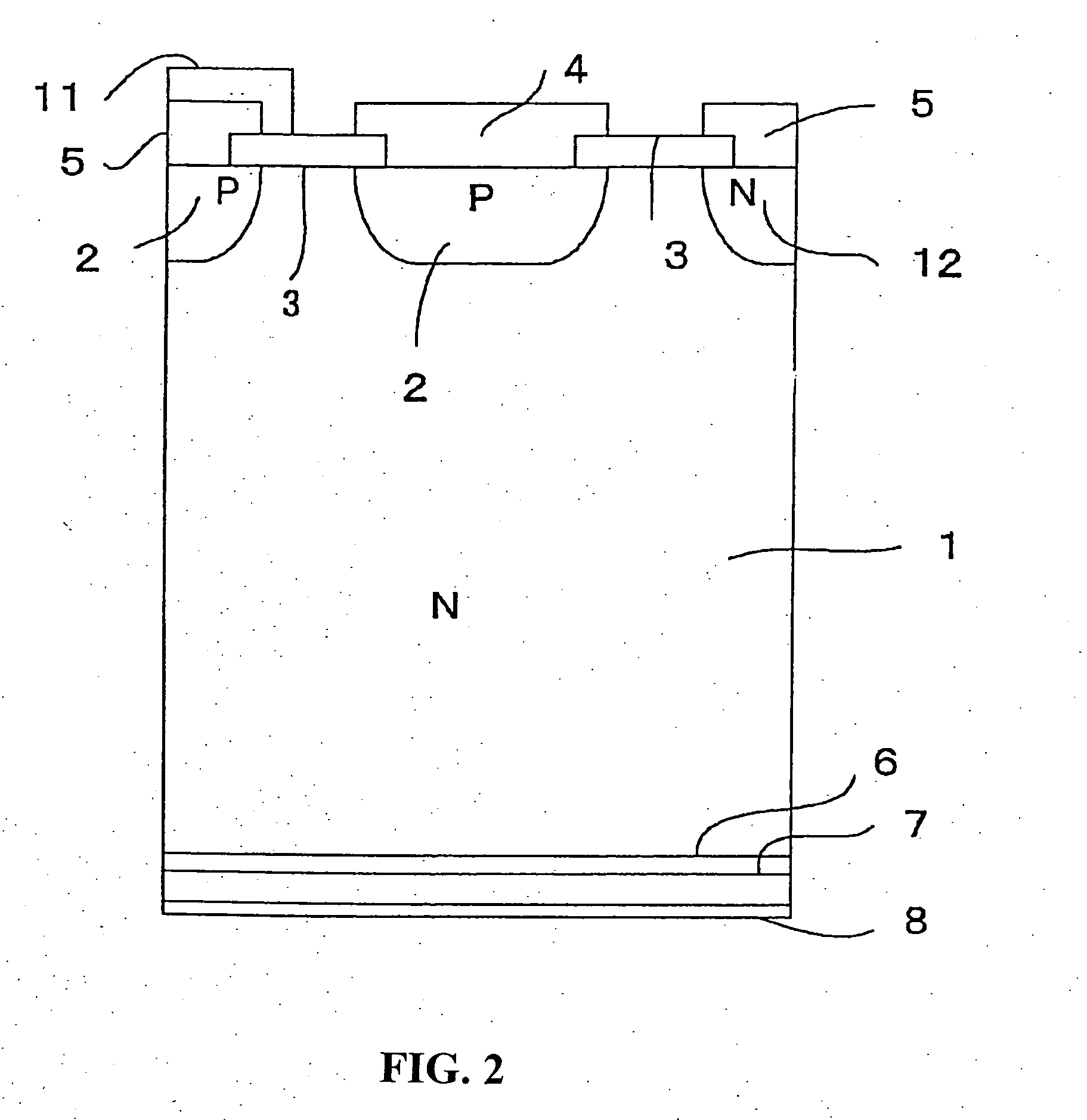

Method of manufacturing semiconductor device

ActiveUS20050158979A1Small variation in film thicknessAvoid platingSemiconductor/solid-state device detailsSolid-state devicesDevice materialSilicon

A method of manufacturing a semiconductor device is disclosed in which a metallic deposit is stably formed on the anode side with small variation in film thickness, and plating is prevented on the cathode side without carrying out any additional processing on the cathode side. The processed anode side causes no interference in subsequent processing. Insulator films are used to cover a scribe line, as well as a field plate or an open electrode provided on a surface of a silicon substrate before Ni electroless plating of an aluminum electrode is performed to form a metallic deposit on the electrode.

Owner:FUJI ELECTRIC CO LTD

Hot-dip galvanized steel sheet

InactiveUS6342310B2High tensile strengthGood molding effectHot-dipping/immersion processesLiquid surface applicatorsSheet steelScanning electron microscope

A hot-dip galvanized steel sheet composed of a basis steel sheet containing Si in an amount of 0.05-2.5 mass % and Mn in an amount of 0.2-3 mass % and a hot-dip galvanized zinc layer formed on the surface thereof, wherein said hot-dip galvanized zinc layer is formed in such a way that there is an Si-Mn enriched phase which is found, by observation under a scanning electron microscope or a transmission electron microscope, in the vicinity of the interface in a region no shorter than 50 mum in the cross section perpendicular to the interface between the basis steel sheet and the hot-dip galvanized zinc layer, said Si-Mn enriched phase containing more than twice as much Si and / or Mn as the basis steel sheet and extending over a length no more than 80% of the length of the interface observed. This hot-dip galvanized steel sheet is free of bare spots even in the case where the basis steel sheet contains Si and Mn in a comparatively large amount and hence is liable to suffering bare spots.

Owner:KOBE STEEL LTD

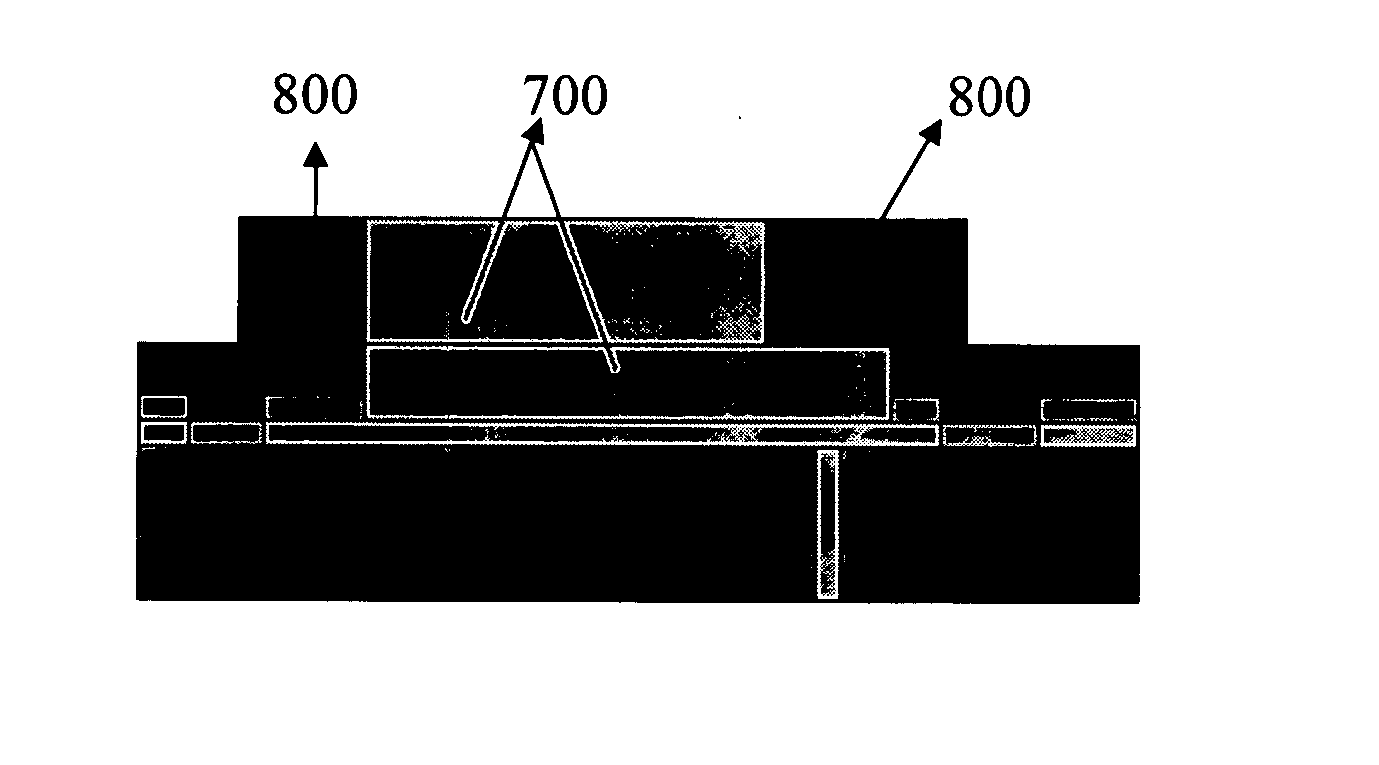

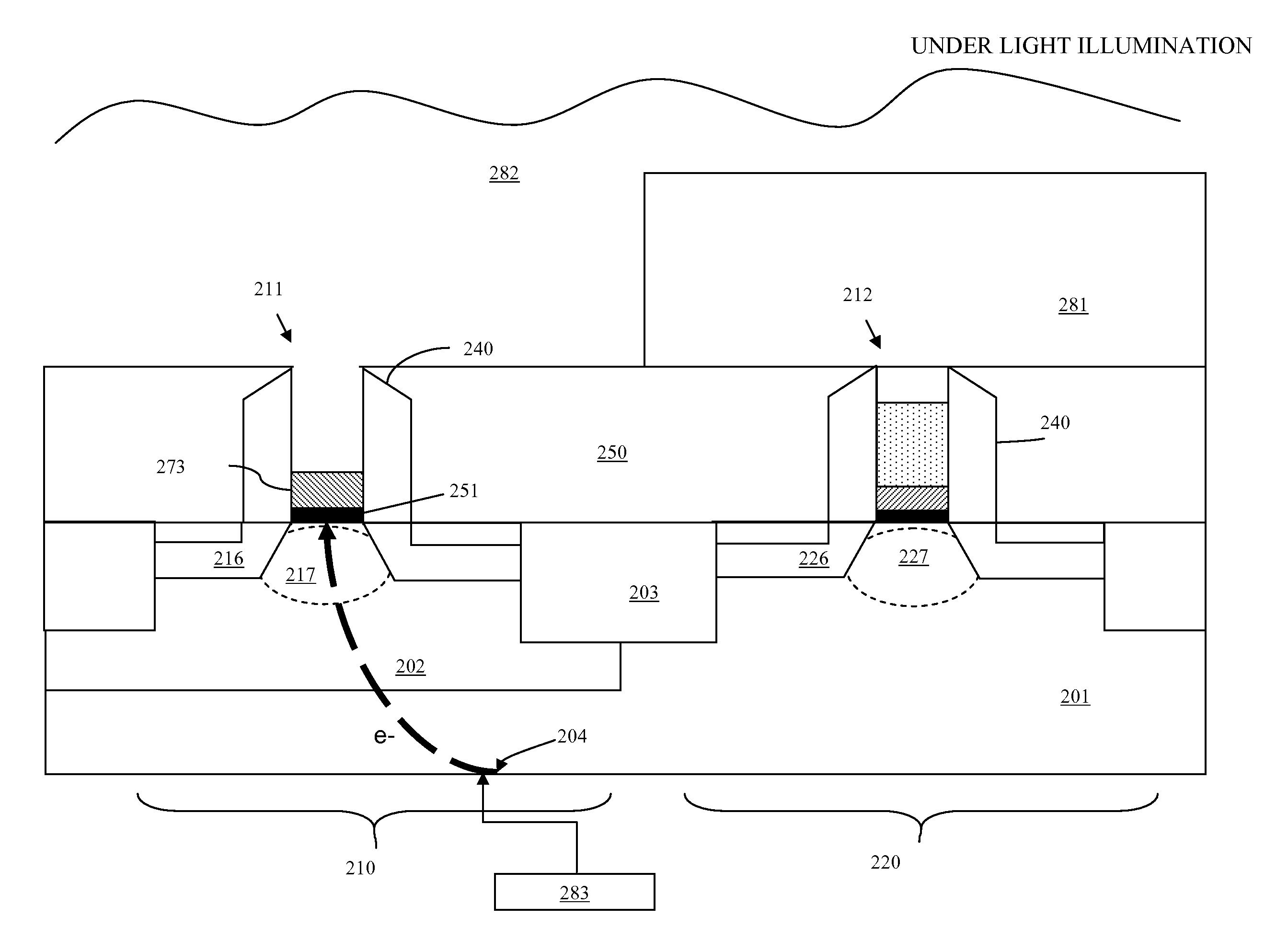

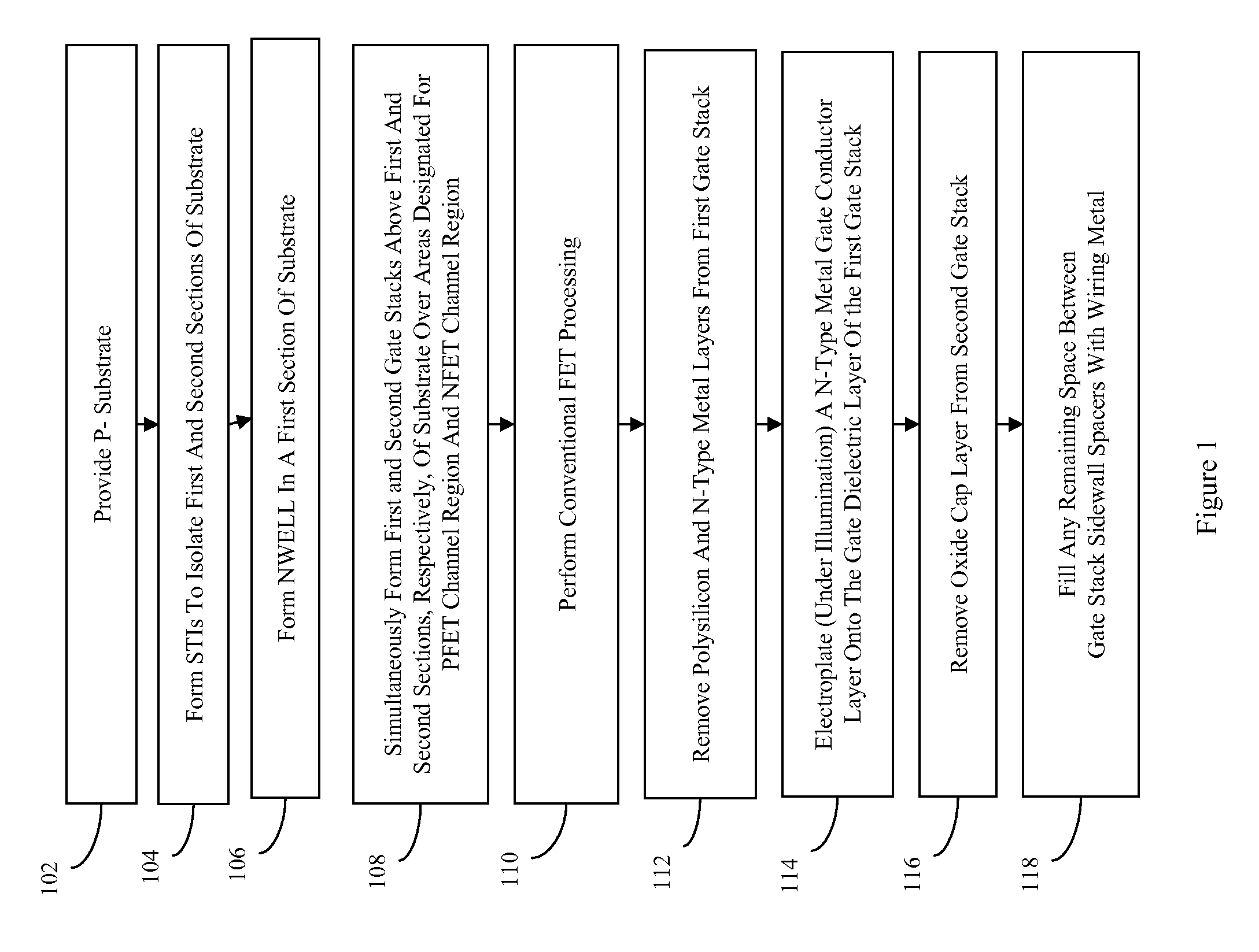

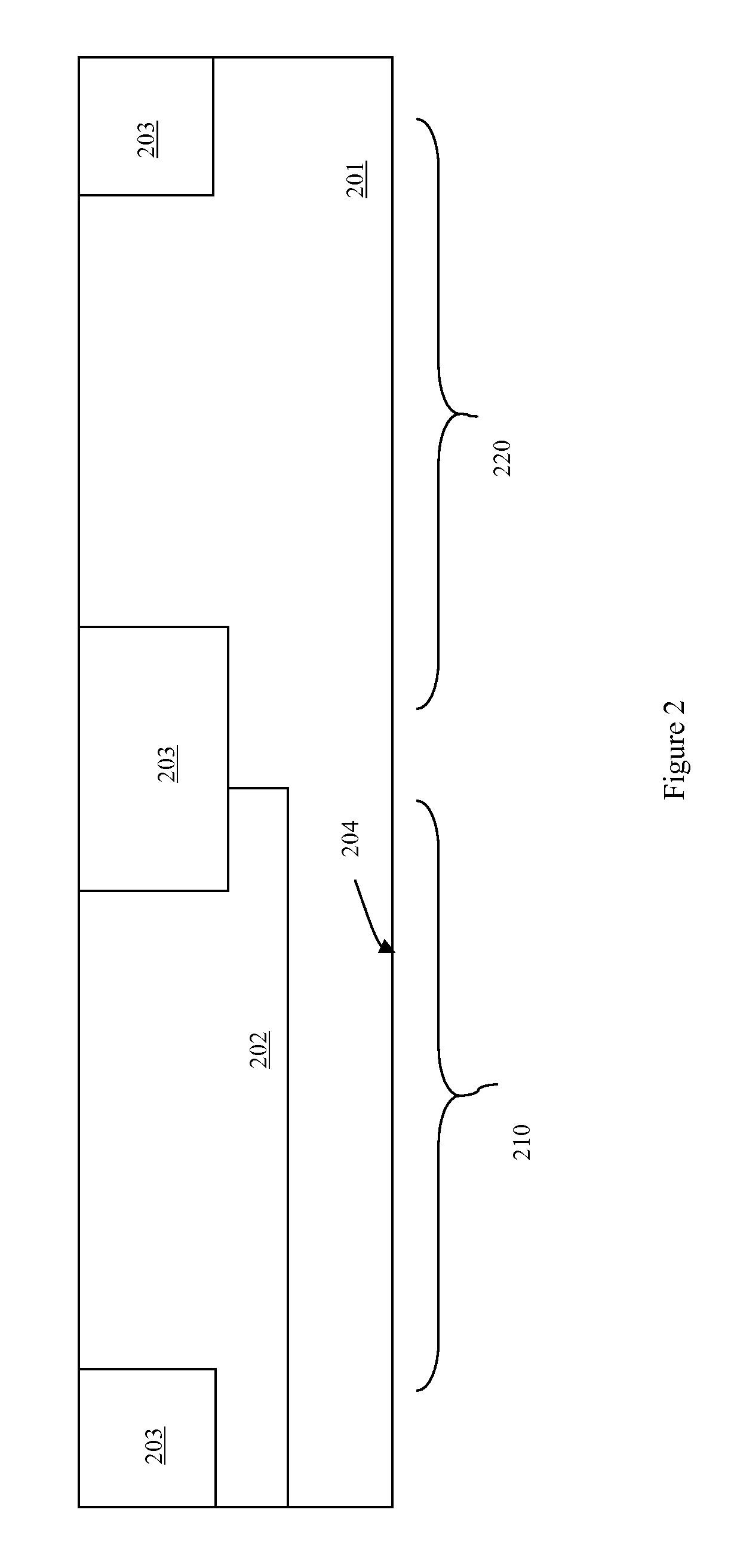

Complementary metal oxide semiconductor device with an electroplated metal replacement gate

InactiveUS7776680B2High trafficEasy to PlatingSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorGate dielectric

Disclosed herein are embodiments of a method of forming a complementary metal oxide semiconductor (CMOS) device that has at least one high aspect ratio gate structure with a void-free and seam-free metal gate conductor layer positioned on top of a relatively thin high-k gate dielectric layer. These method embodiments incorporate a gate replacement strategy that uses an electroplating process to fill, from the bottom upward, a high-aspect ratio gate stack opening with a metal gate conductor layer. The source of electrons for the electroplating process is a current passed directly through the back side of the substrate. This eliminates the need for a seed layer and ensures that the metal gate conductor layer will be formed without voids or seams. Furthermore, depending upon the embodiment, the electroplating process is performed under illumination to enhance electron flow to a given area (i.e., to enhance plating) or in darkness to prevent electron flow to a given area (i.e., to prevent plating).

Owner:GLOBALFOUNDRIES INC

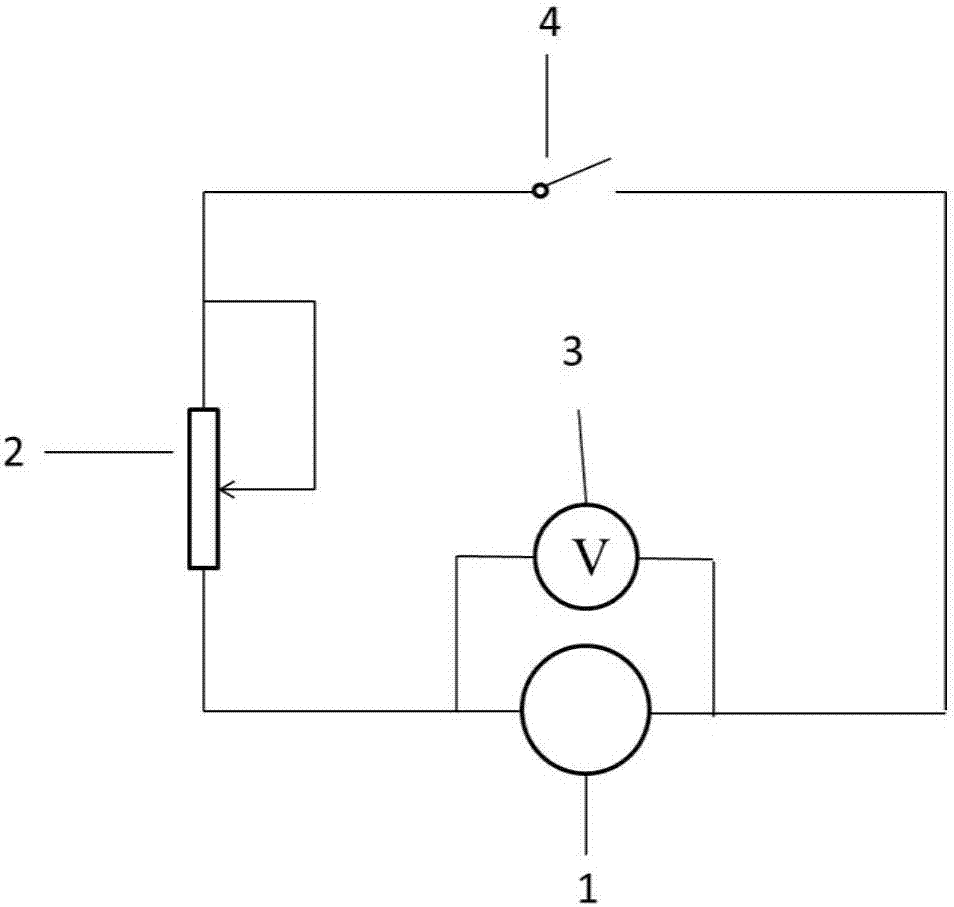

Method for pre-lithiation of cathode pole piece of lithium ion battery

InactiveCN107464919AAvoid consumptionAvoid platingCell electrodesSecondary cells charging/dischargingPolymer electrolytesEngineering

The invention discloses a method for pre-lithiation of a cathode pole piece of a lithium ion battery. The method comprises the step of forming an external short-circuited circuit between the anode and the cathode of a button battery. According to the invention, a solid polymer electrolyte film is formed on a cathode surface in advance in the manner of pre-lithiation, so that the lithium ion consumed in the process of firstly charging the whole battery can be avoided and the first coulombic efficiency of the battery is increased.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for performing chemical nickel plating on surface of capacitive touch screen

The invention provides a method for performing chemical nickel plating on the surface of a capacitive touch screen. The method comprises the step that an ITO thin film is sequentially subjected to ungrease treatment, corrosion treatment, activation treatment, reduction treatment and chemical nickel plating; an activating agent used in the activation treatment step is prepared according to the following steps: PdC12, deionized water and concentrated hydrochloric acid are mixed and heated at the temperature of 50 DEG C to obtain H2PdC14 solutions; diethylenetriamine is added into the H2PdC14 solutions to keep for 4 hours at the temperature of 50 DEG C; solvents are evaporated and removed to obtain a palladium compound; the palladium compound is dissolved into N-methyl pyrrolidone to obtain NMP solutions of the palladium compound; the NMP solutions are mixed with diethylene glycol monoethyl ether and diglycidyl ether to obtain activating agents. Compared with the prior art, the activating agents prepared by using the method are used for activating, thereby avoiding the plating of conductive substances on the part with no need of nickel plating between the electrodes in a chemical nickel plating step, and a good nickel plating effect is guaranteed.

Owner:FUJIAN FEIYANG OPTRONICS

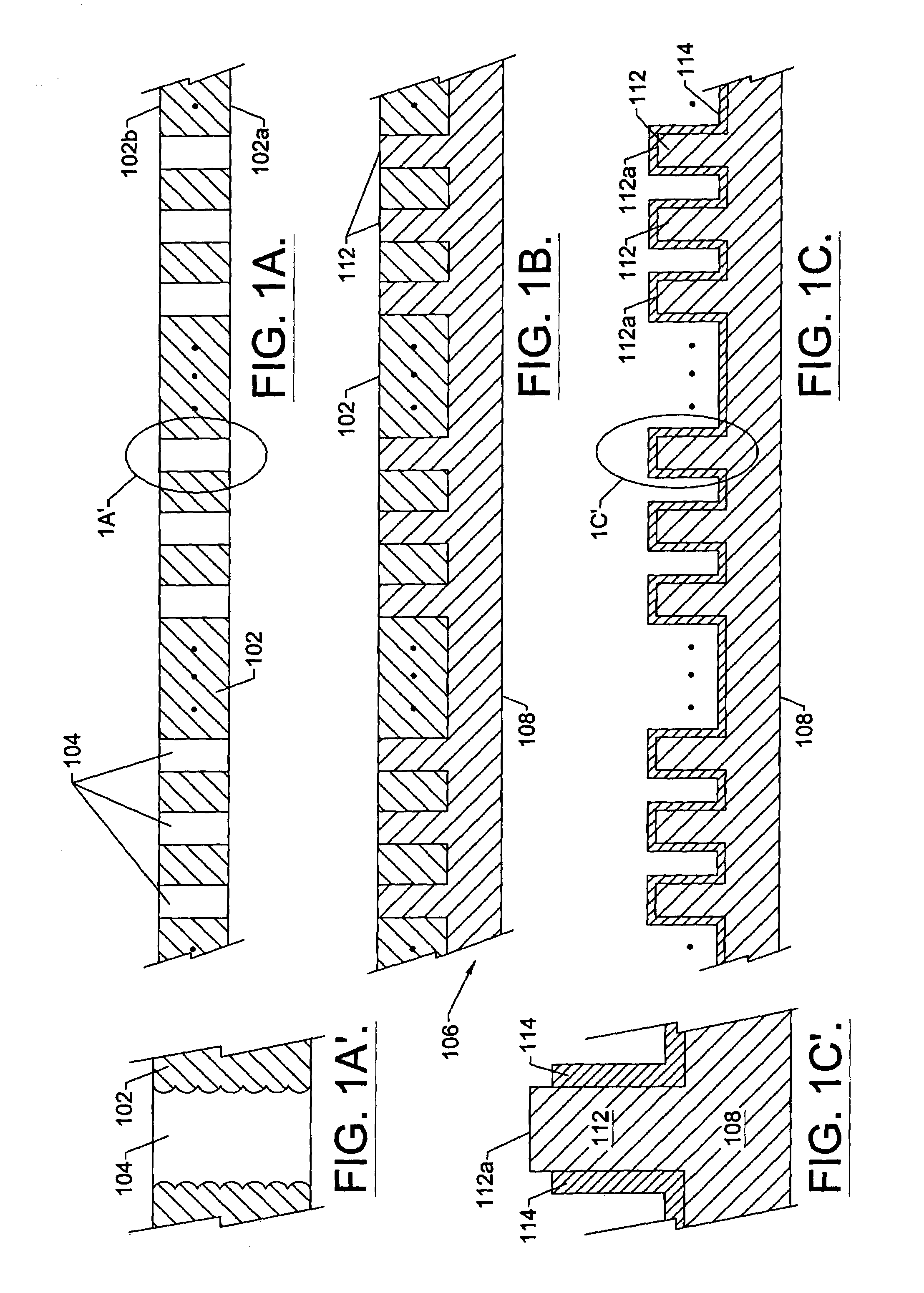

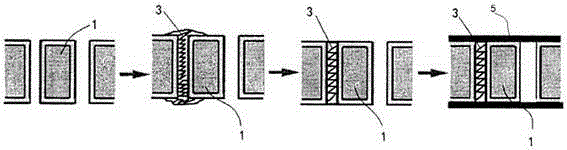

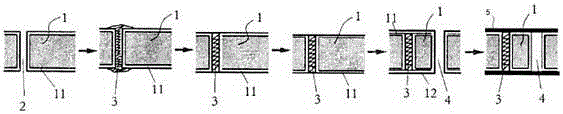

Method for making micromechanical structures having at least one lateral, small gap therebetween and micromechanical device produced thereby

InactiveUS6846691B2Avoid platingEnhanced couplingImpedence networksSolid-state devicesEngineeringMetal electrodes

A method and resulting formed device are disclosed wherein the method combines polysilicon surface-micromachining with metal electroplating technology to achieve a capacitively-driven, lateral micromechanical resonator with submicron electrode-to-resonator capacitor gaps. Briefly, surface-micromachining is used to achieve the structural material for a resonator, while conformal metal-plating is used to implement capacitive transducer electrodes. This technology makes possible a variety of new resonator configurations, including disk resonators and lateral clamped-clamped and free-free flexural resonators, all with significant frequency and Q advantages over vertical resonators. In addition, this technology introduces metal electrodes, which greatly reduces the series resistance in electrode interconnects, thus, minimizing Q-loading effects while increasing the power handling ability of micromechanical resonators.

Owner:RGT UNIV OF MICHIGAN

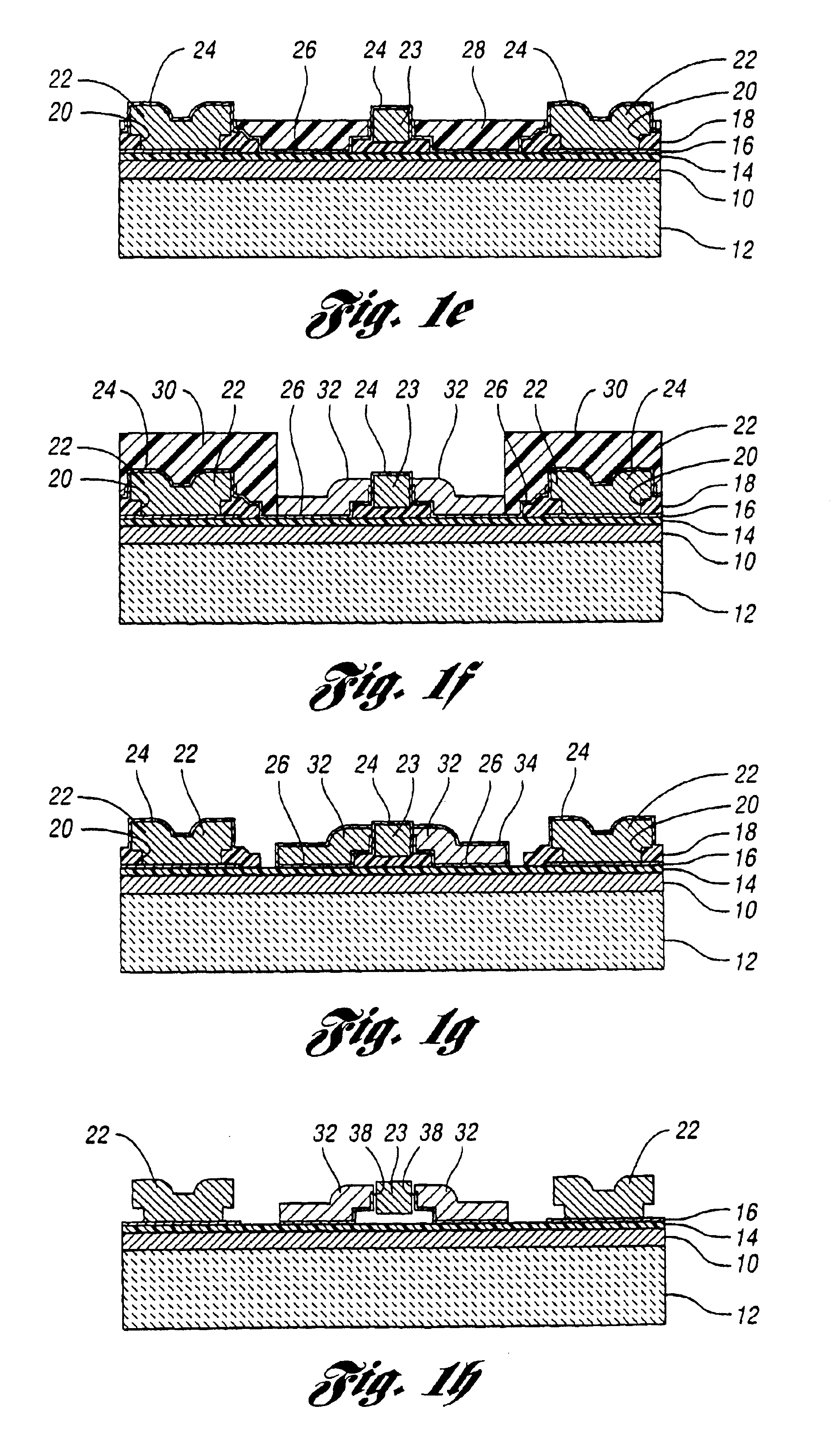

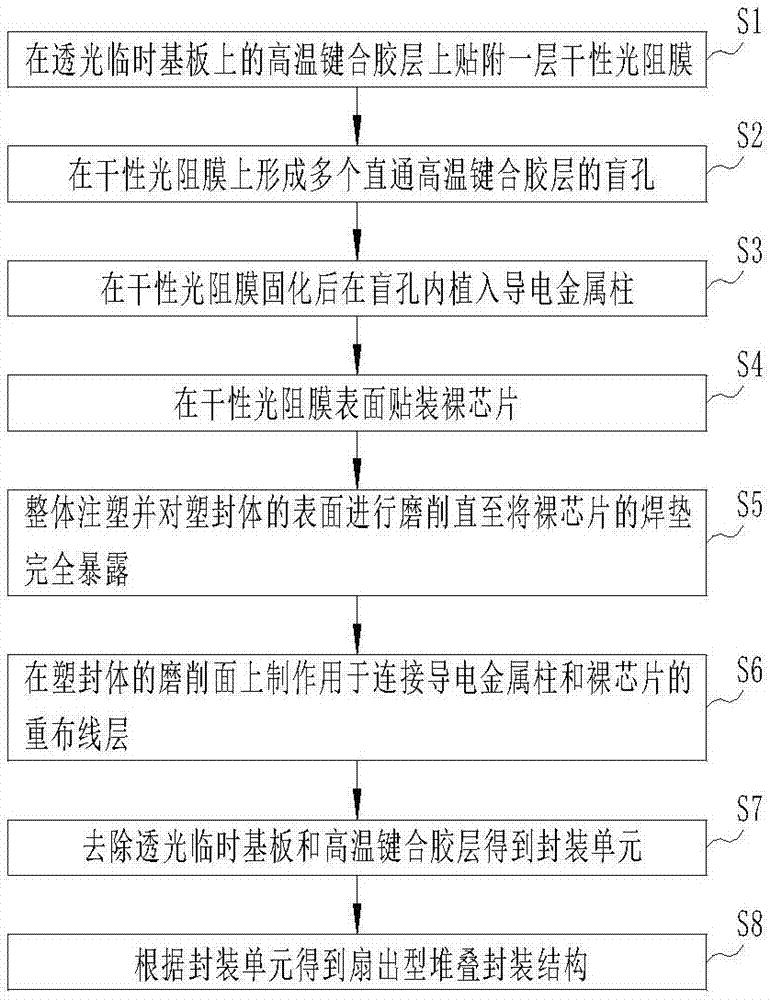

Wafer-level fan-out type stack package process method

ActiveCN107481945AReduce thicknessSimple processSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyInjection moulding

The invention discloses a wafer-level fan-out type stack package process method, and the method comprises the following steps: pasting a dry photoresistive membrane on a high-temperature bonding glue layer on a light-transmitting temporary substrate; forming a plurality of blind holes, which are directly communicated with the high-temperature bonding glue layer, on the dry photoresistive membrane; implanting conductive metal poles in the blind holes after the dry photoresistive membrane is solidified; pasting an unpacked chip on the surface of the dry photoresistive membrane; carrying out the integrated injection moulding, and carrying out the grinding of the surface of a plastic packaged body till the bonding pad of the unpacked chip is completely exposed; manufacturing a rewiring layer, used for connecting the conductive metal poles and the unpacked chip, on the grinding surface of the plastic packaged body, wherein the rewiring layer is provided with miniature salient points obtained through reballing and reflow soldering; removing the light-transmitting temporary substrate and the high-temperature bonding glue layer, and obtaining a package unit; and obtaining a fan-out stacked package structure according to the package unit. The method simplifies the manufacturing technology of a fan-out type stack package, and reduces the manufacturing cost of the stack package.

Owner:NAT CENT FOR ADVANCED PACKAGING

PCB manufacturing method and PCB

InactiveCN105208772AImprove the accuracy of judgmentAvoid pollutionElectrical connection printed elementsPrinted element electric connection formationMechanical engineeringMaterials science

The invention provides a PCB manufacturing method and a PCB. The method comprises steps that, a substrate is drilled to form a plugging hole; a first copper layer is plated on a surface of the substrate, and copper plating on an inner wall of the plugging hole is carried out; the plugging hole is filled by employing resin till the resin projects out of the plugging hole port; material decrease processing on the resin projected out of the port is carried out to make the resin project out of the surface of the port and be level with the surface of the first copper layer; the substrate is drilled to form a non-plugging hole; a second copper layer is plated on the first copper layer, and copper plating on the inner wall of the non-plugging hole is carried out; a substrate graph is shifted; the substrate is etched to form a conductive line. The PCB is manufactured through the PCB manufacturing method, the non-plugging hole quite near the plugging hole is quite clean internally, when on-off tests on the PCB are carried out, after the non-plugging hole is detected by a probe, the probe can tightly contact with the conductive copper layer of the hole wall of the non-plugging hole to realize conduction, and thereby efficiency for determining functions of the PCB can be greatly improved.

Owner:ZHUHAI FOUNDER TECH HI DENSITY ELECTRONICS +1

Golden finger plate processing technology

ActiveCN105960113AAvoid misalignmentPrevent goldPrinted element electric connection formationEngineeringNickel electroplating

The invention discloses a golden finger plate processing technology. A primary dry film is provided at the position of a golden finger graph, an acidic CuCl2 etching solution is utilized to etch the position for golden finger plating, a problem of diffusion plating on leads caused by incomplete dry film coverage for lines on a same plane and gaps among the lines because of inaccurate alignment during anti-plating dry film operation can be prevented, non-plating areas except a PCB plate golden finger graph area is provided with secondary dry films, plating of a nickel layer and a gold layer is sequentially carried out at an etched golden finger graph area, after dry film removal, no lead residual on golden fingers is realized, a problem of short circuit at the golden finger position because of diffusion plating can be effectively avoided, and quality of products is improved.

Owner:DIGITAL PRINTED CIRCUIT BOARD CO LTD

Graphite boat pretreatment substitution piece and graphite boat pretreatment method

InactiveCN103824795AAvoid platingImprove performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon chipPre treatment

The invention provides a graphite boat pretreatment substitution piece and a graphite boat pretreatment method. In the prior art, a graphite boat is pretreated through no-load pretreatment or silicon chip fully-loaded pretreatment, which causes relatively-high cost or bad pretreatment effect. The shape of the graphite boat pretreatment substitution piece is matched with process clamping points; the marginal area thickness range of the substitution piece is 100-300 mum, and the central area thickness range of the substitution piece is 1-3 mm; and thus the substitution piece can be reused many times. The graphite boat pretreatment method is characterized by, to begin with, providing a graphite boat for pretreatment, the graphite boat being provided with a plurality of process clamping points; next, providing a graphite boat pretreatment substitution piece, the number of which is matched with that of the graphite boat; then, arranging the graphite boat pretreatment substitution piece on the process clamping points of the graphite boat; and at last, arranging the graphite boat to chemical vapor deposition equipment to deposit silicon nitride. Therefore, the cost of pretreatment can be reduced, and the performance of the pretreatment is improved.

Owner:선테크파워컴퍼니리미티드 +1

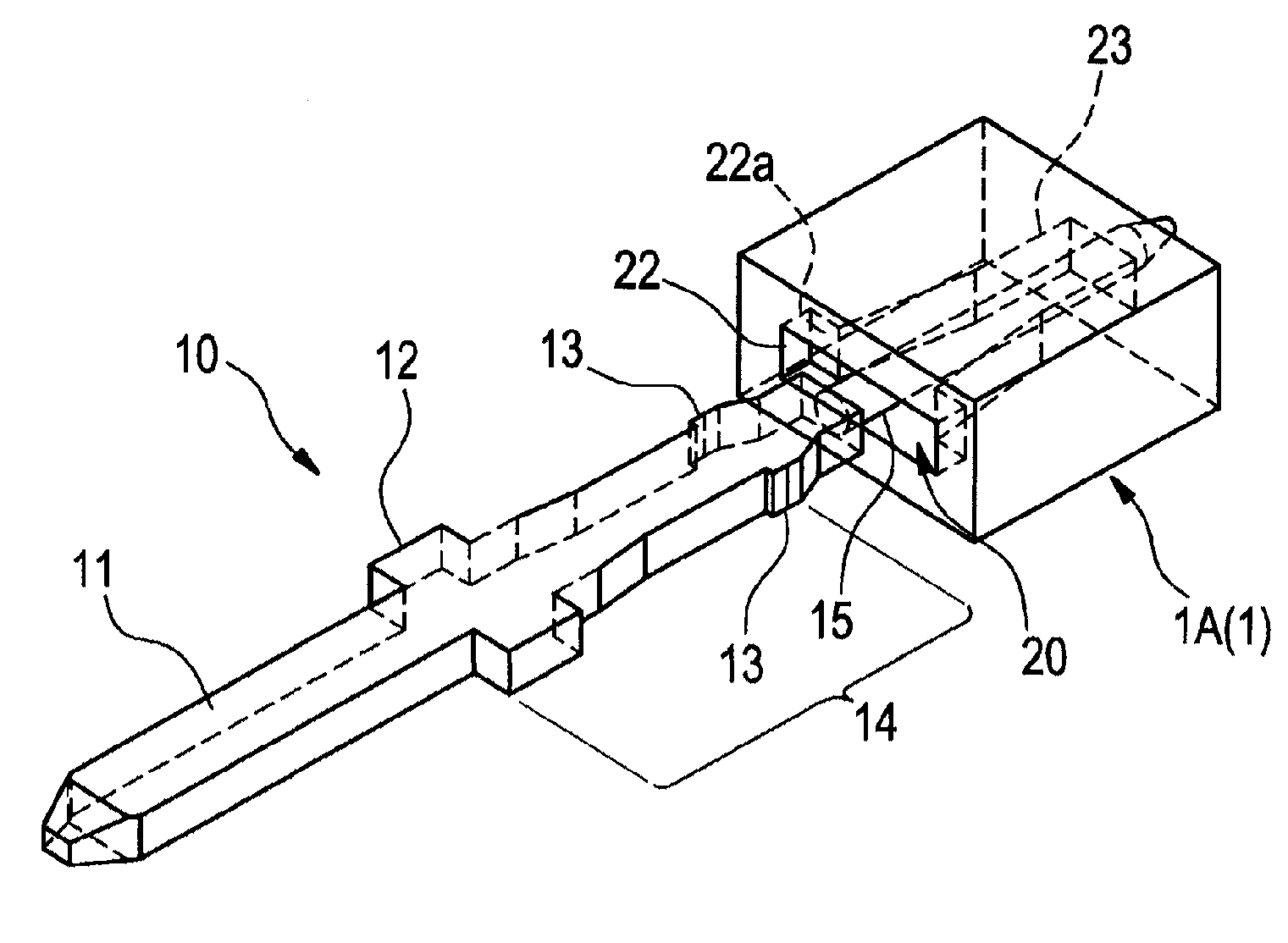

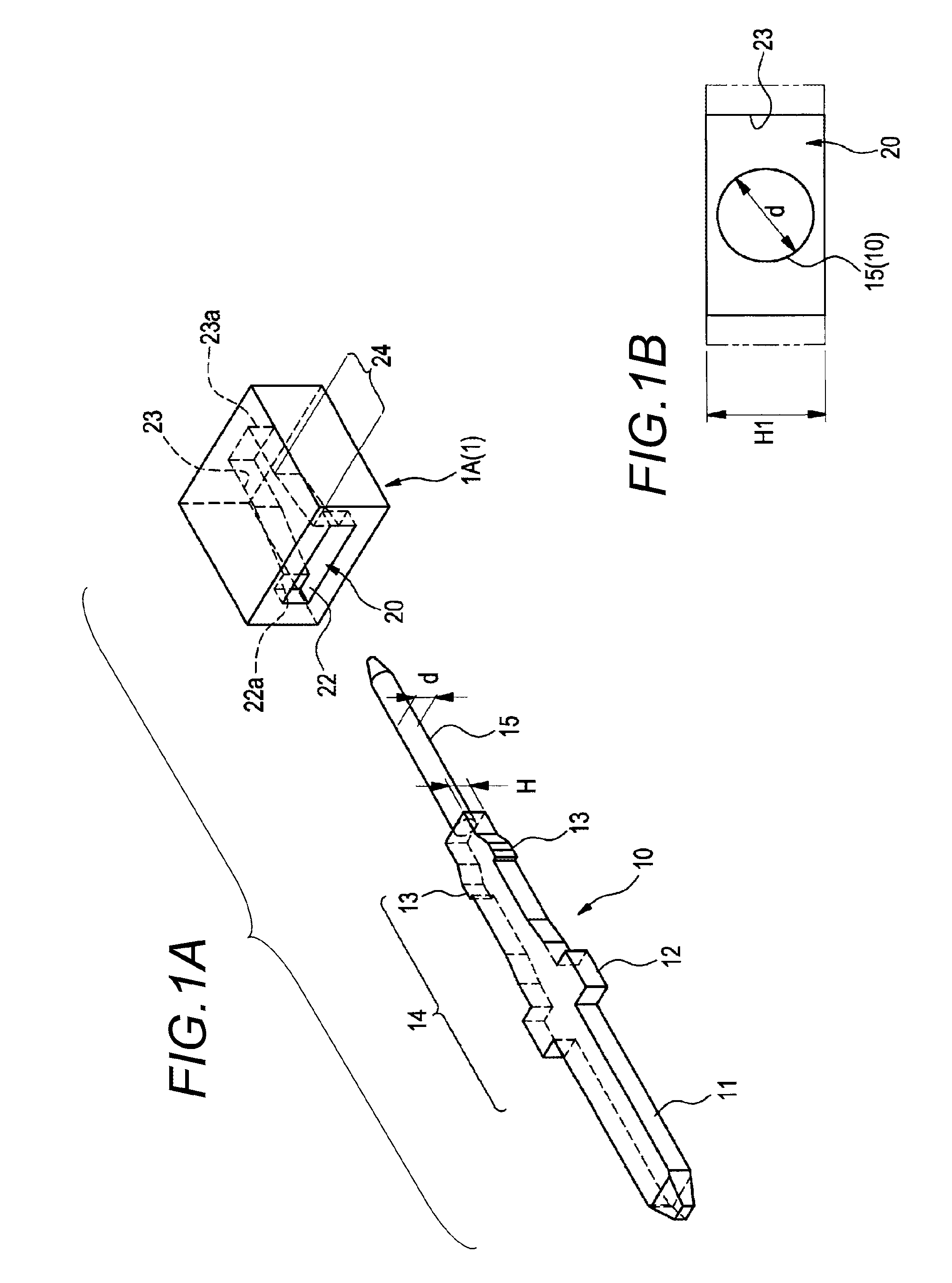

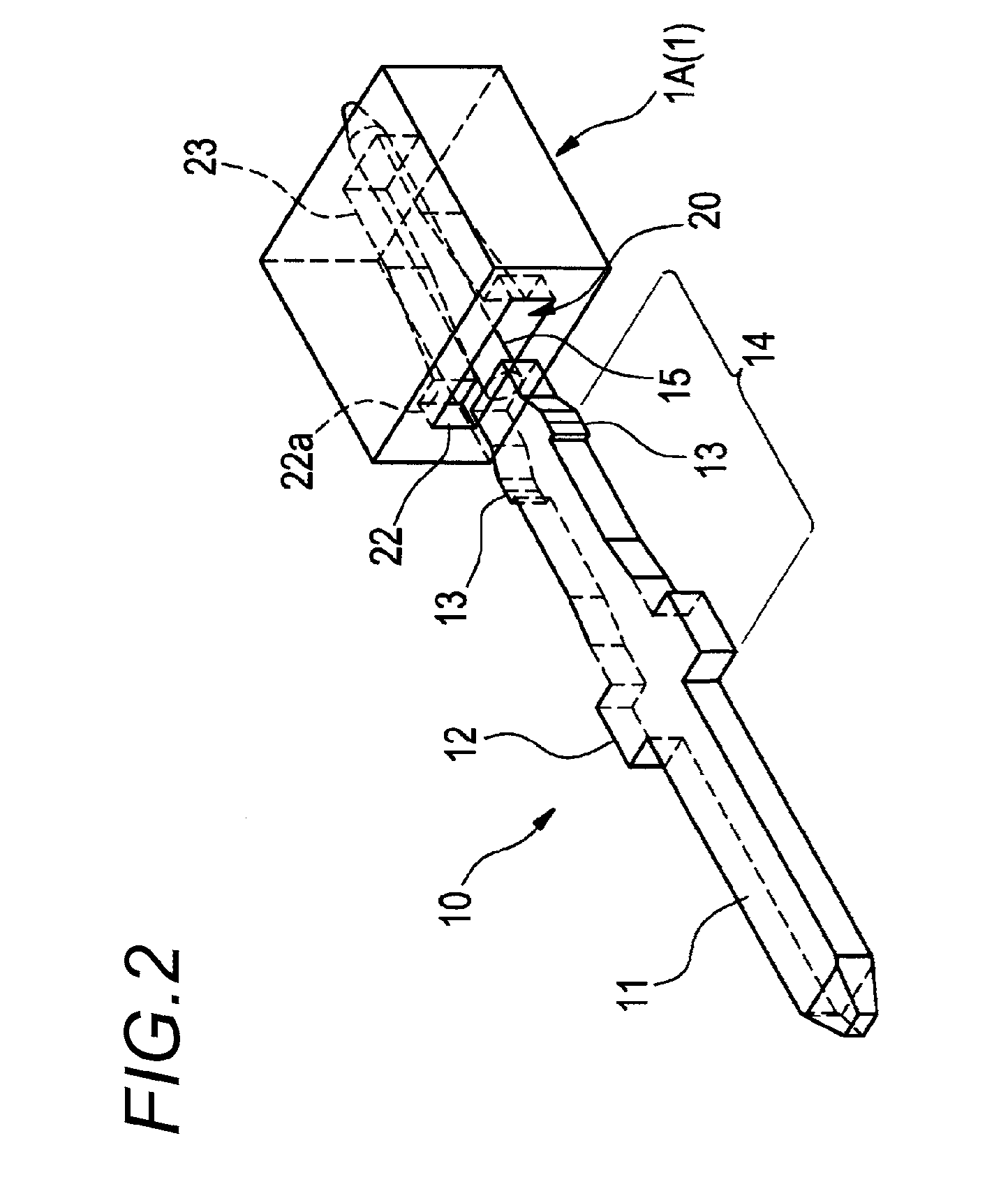

Press-fit terminal for board connector and fixing structure of press-fit terminal to connector housing

InactiveUS20140179173A1Small diameterReduce spacingSecuring/insulating coupling contact membersMating connectionElectrical and Electronics engineering

A press-fit terminal includes an electric connecting part provided in a front part of the press-fit terminal to be electrically connected to a mating connector terminal; a rear leg part provided in a rear part of the press-fit terminal to be inserted and fixed to a through hole of a circuit board; and an engaging part provided in an intermediate part between the electric connecting part and the rear leg part to be press-fitted to a press-fit hole of a wall part of a connector housing. The rear leg part is formed in a shape of a round pin having a circular form in cross-section. The rear leg part may be designed to have a diameter in cross-section being smaller than a minimum dimension between opposed inner wall surfaces of the press-fit hole of the connector housing.

Owner:YAZAKI CORP

CeO2/MWCNTs composite and preparation method and application thereof

InactiveCN107384310ADisordered growthAvoid platingOther chemical processesChemical platingSURFACTANT BLEND

The invention discloses a CeO2 / MWCNTs composite and a preparation method and application thereof. The CeO2 / MWCNTs composite is synthesized by a simple chemical method, and CeO2 nano-particles orderlessly grow on the surfaces of MWCNTs and in MWCNTs. By adoption of a hydrothermal method, no surfactant is added; a traditional electroplating or chemical plating method is avoided; the pollution is small; and the preparation method is simple and convenient, green and environment-friendly and easy for reaction control, does not need expensive equipment, and can be used for industrial production.

Owner:ANHUI UNIV OF SCI & TECH

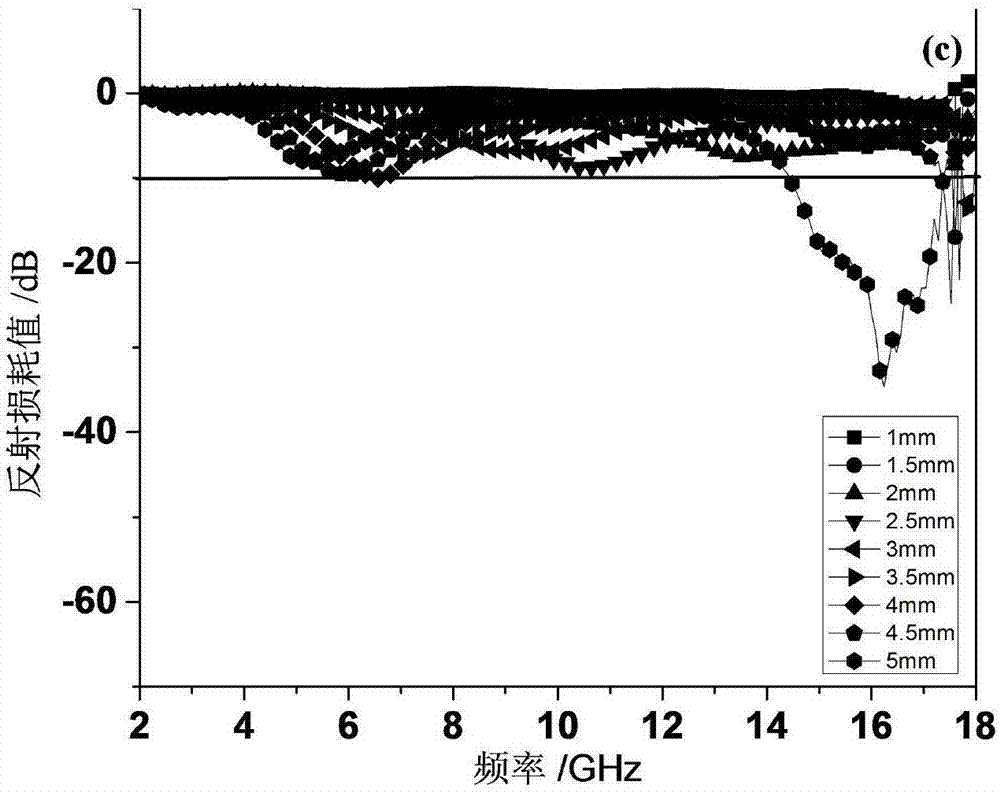

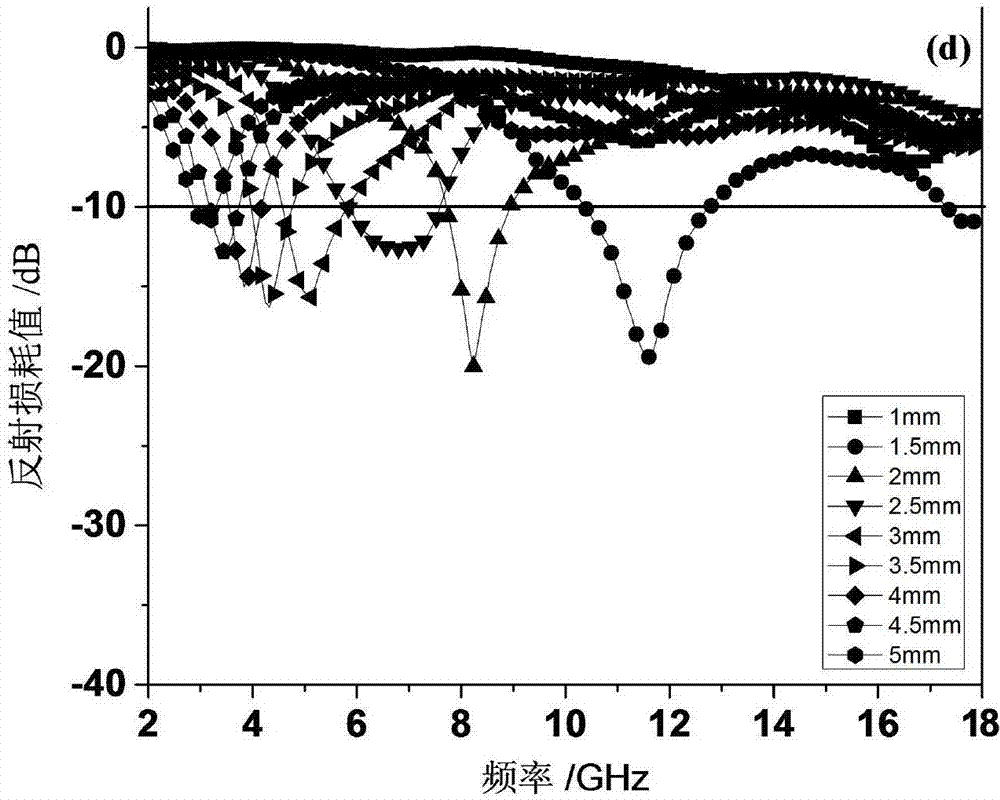

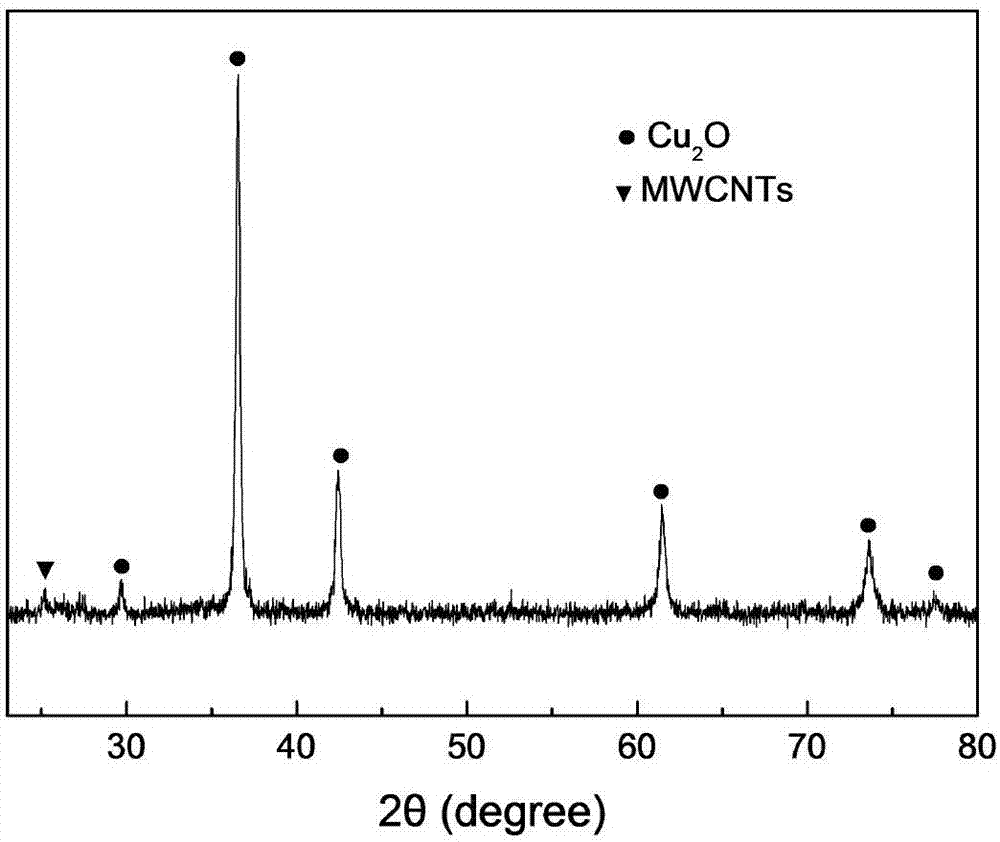

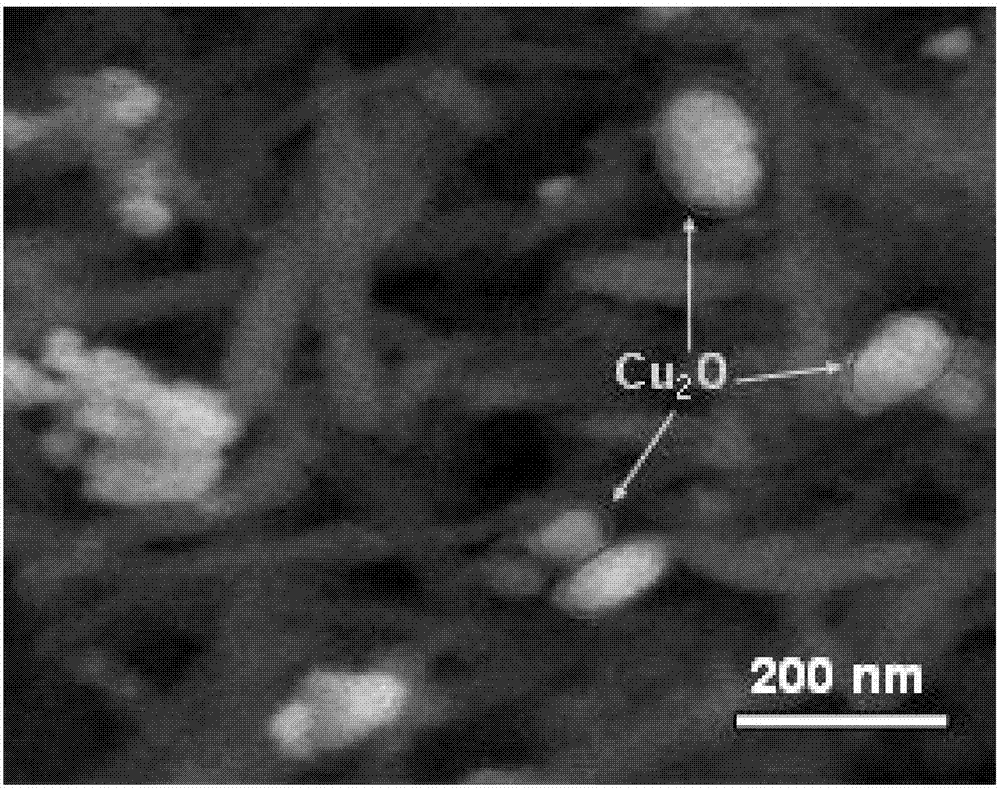

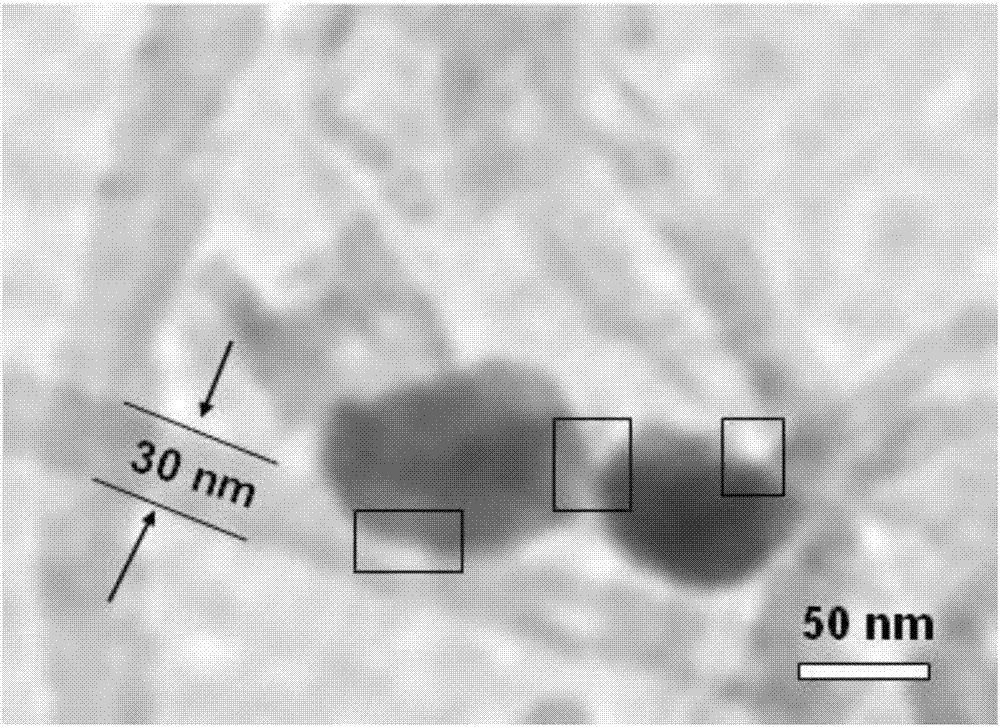

Cu2O/multi-walled carbon nanotubes (MWCNTs) composite material, preparation method thereof and electromagnetic absorption application

ActiveCN107454815AIncrease the conductive pathPromote absorptionCarbon compoundsMagnetic/electric field screeningChemical platingNanoparticle

The invention discloses a Cu2O / multi-walled carbon nanotubes (MWCNTs) composite material, a preparation method thereof and electromagnetic absorption application. The Cu2O / MWCNTs composite material is synthesized by a simple chemical method, and Cu2O nanoparticles are disorderly grown on surfaces of the MWCNTs and in the MWCNTs. A hydrothermal method is employed, no any surfactant is added, a traditional electroplating or chemical plating method is prevented, pollution is relatively small, the preparation method is simple, green and environmental-friendly, reaction is easy to control, expensive equipment is not needed, and the preparation method can be used for industrial production.

Owner:ANHUI UNIV OF SCI & TECH

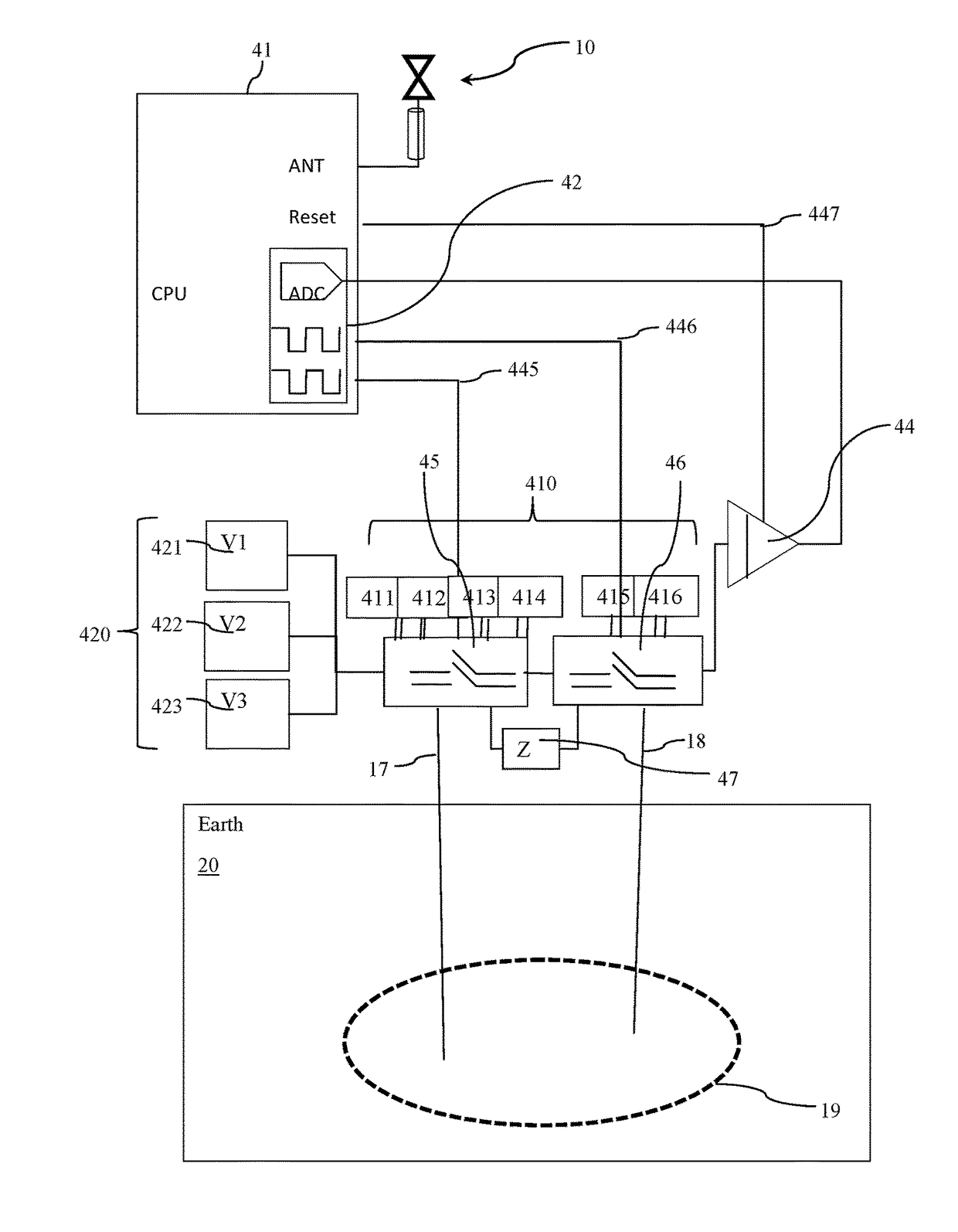

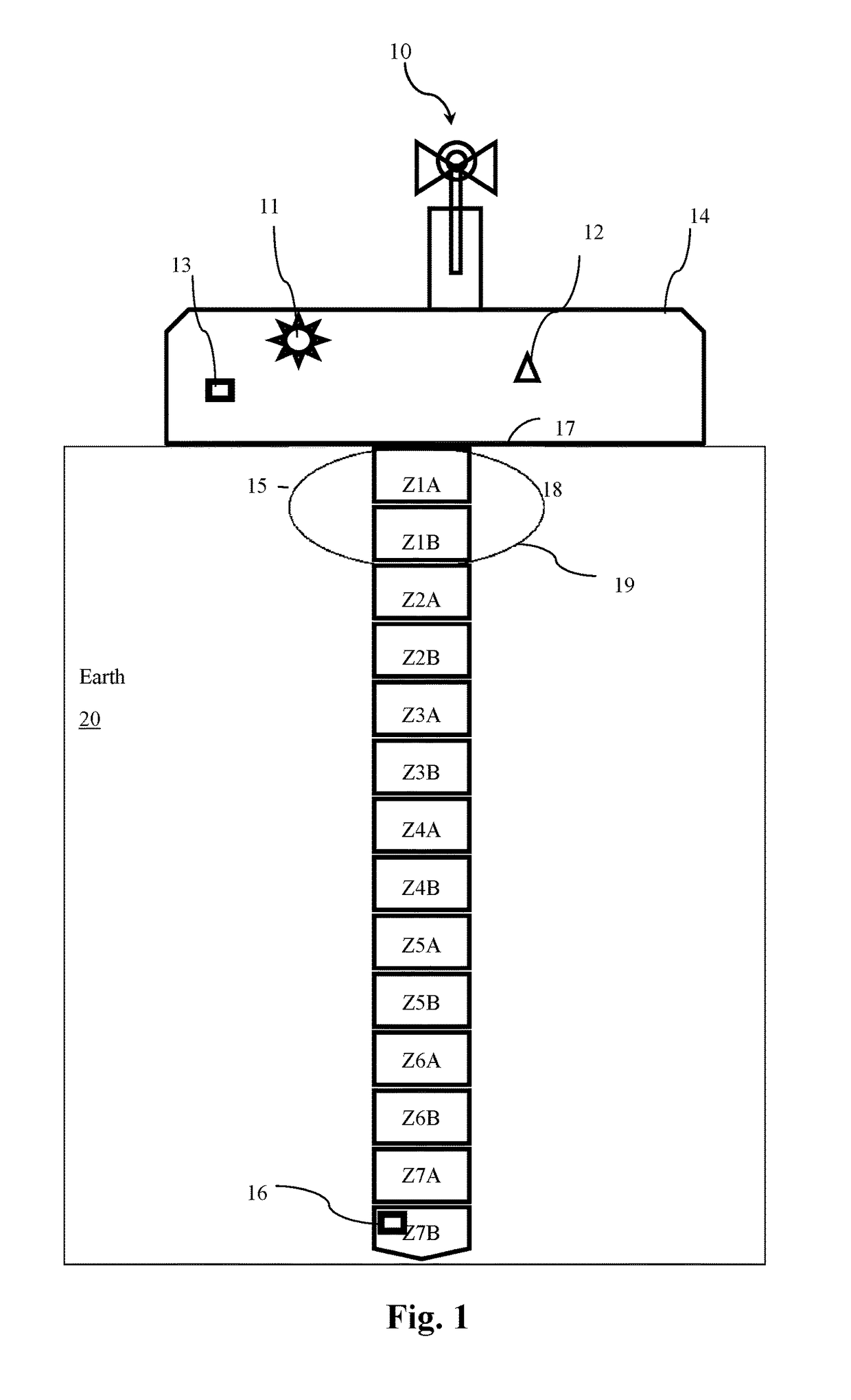

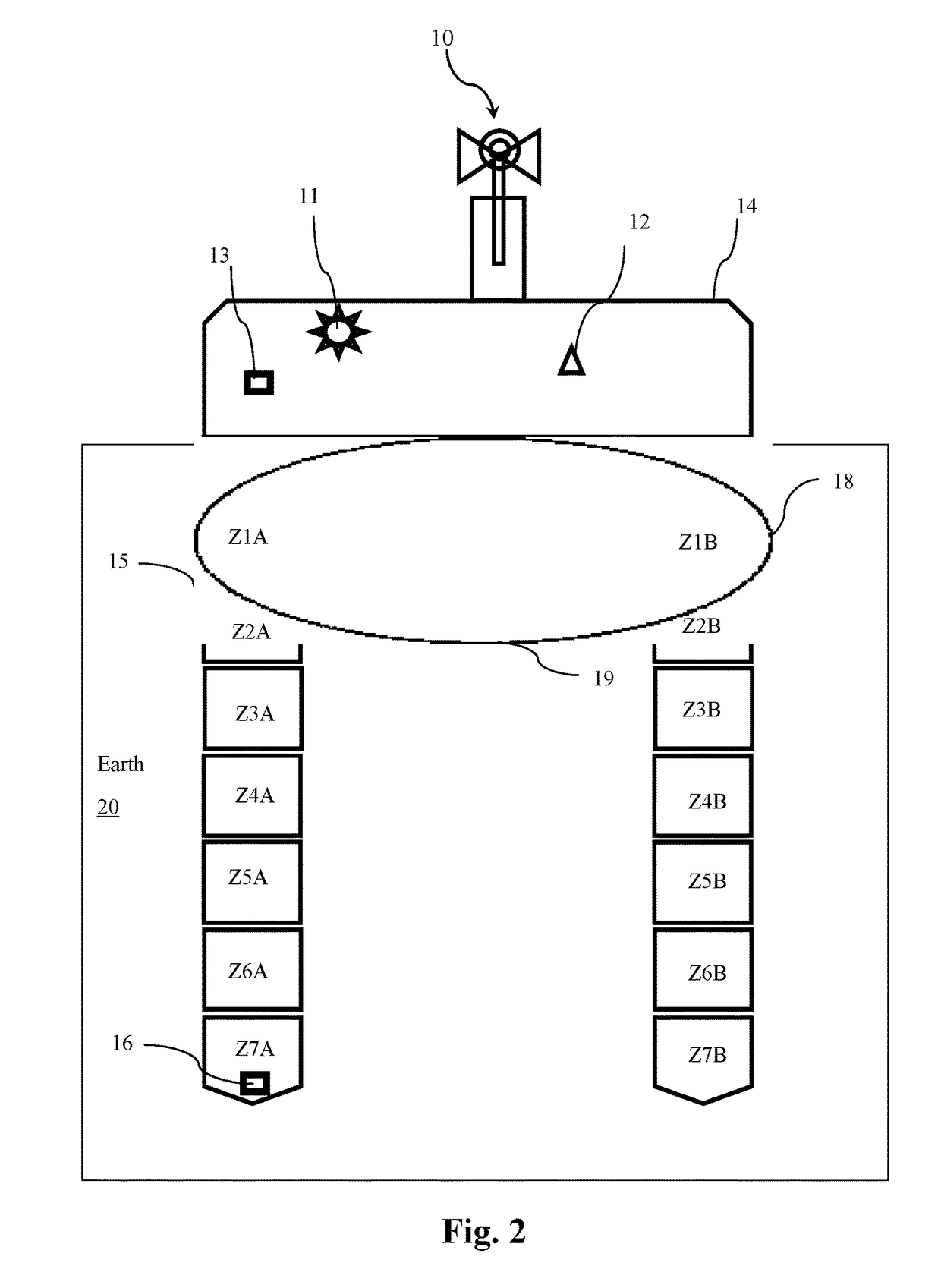

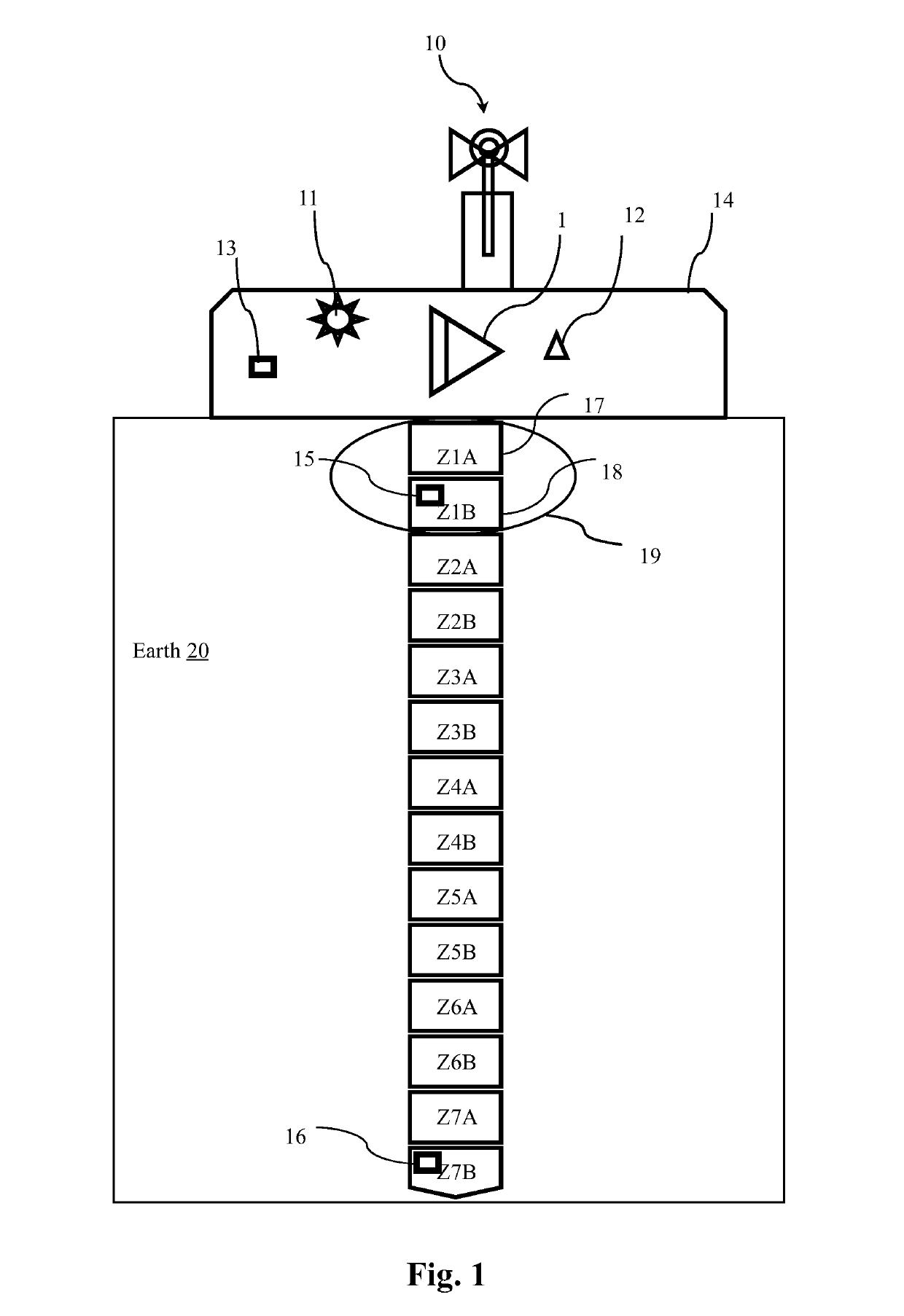

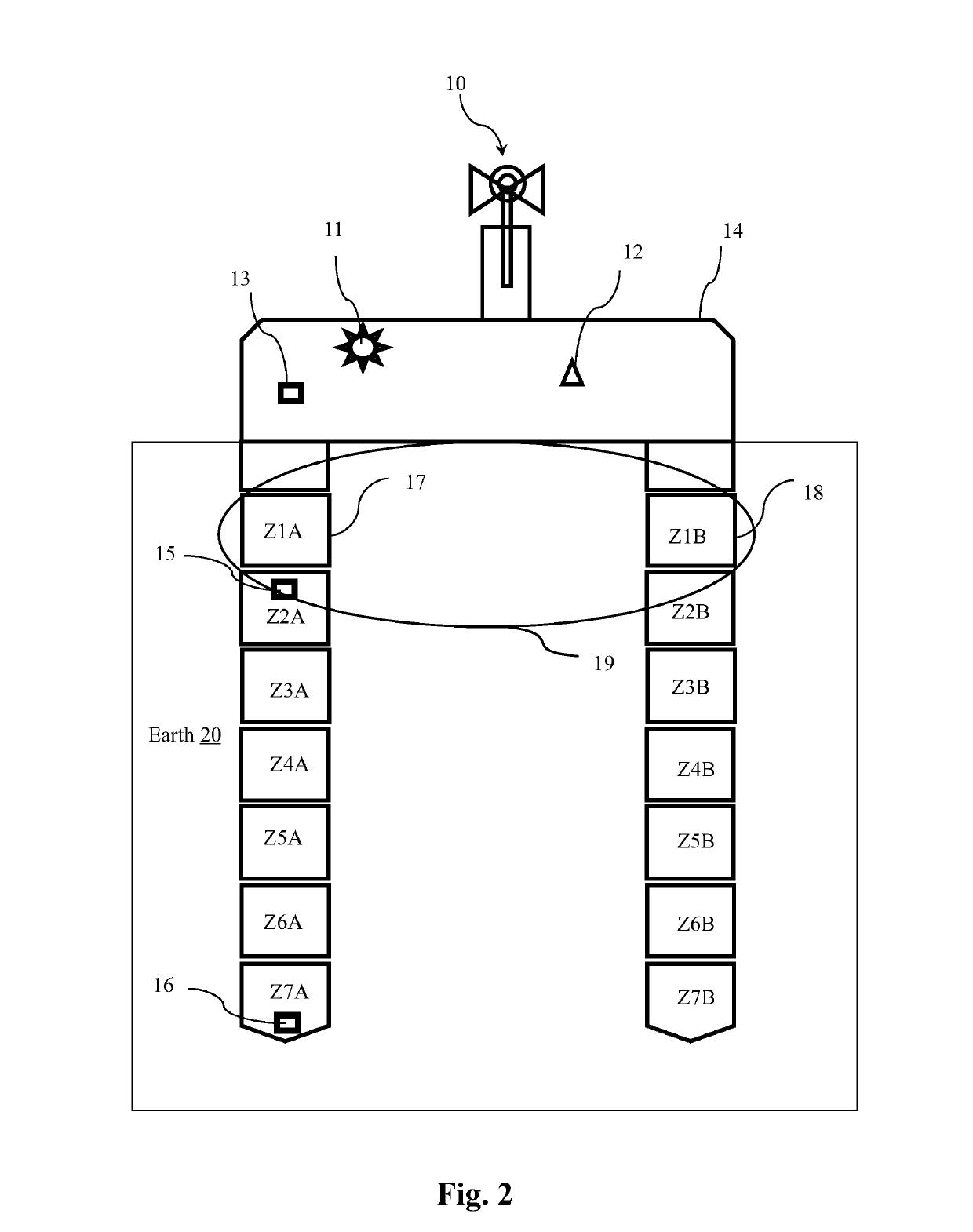

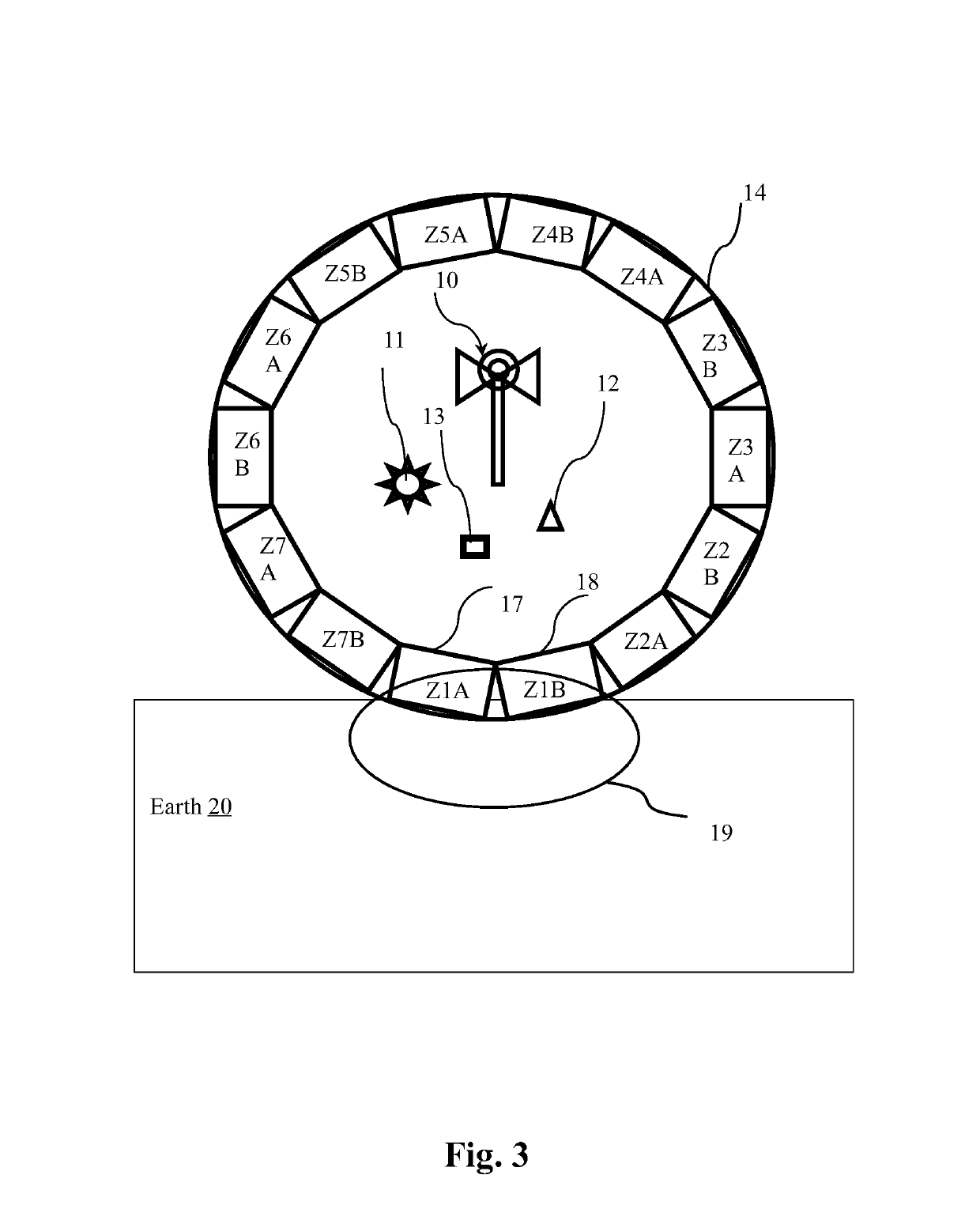

Wireless soil profile monitoring apparatus and methods

ActiveUS20170328854A1Excessive water useAvoid water damageWireless architecture usageMaterial capacitanceUltra low powerElectronics

An in situ ultra-low power contactless measurement apparatus and method suitable for micro-electronics in big data applications for continuously reporting a soil moisture profile at various zones.

Owner:PAULSEN KEITH LYNN

Environment-friendly high-phosphorus chemical nickel plating solution for airtight glass-sealed binding terminal, and applications thereof

InactiveCN103938193ARefined grain sizeFast platingLiquid/solution decomposition chemical coatingChemical platingBULK ACTIVE INGREDIENT

The invention discloses an environment-friendly high-phosphorus chemical nickel plating solution for an airtight glass-sealed binding terminal. The environment-friendly high-phosphorus chemical nickel plating solution comprises the following active ingredients according to concentration: 25-27g / L nickel sulfate, 19-22g / L sodium hypophosphite, 20-23g / L sodium hydroxide, 41-44g / L lactic acid, 1.5-2.3g / L trisodium citrate, 13-15g / L malic acid, 8-12g / L glycine, 0.2-0.4ml / L OP-10, 0.26-0.3g / L stannous chloride, 0.26-0.34g / L maleic anhydride and 3-5mg / L N,N-diethylaminopropyne. The invention discloses a method for performing chemical plating by adopting the chemical nickel plating solution. A stainless steel needle and an iron cover can be simultaneously subjected to chemical nickel plating and be evenly plated, no nickel nuclear generated on sintered glass can be guaranteed, and the difficulty in keeping the smoothness and cleanness of the surface of glass can be solved.

Owner:深圳市迪凯鑫科技有限公司

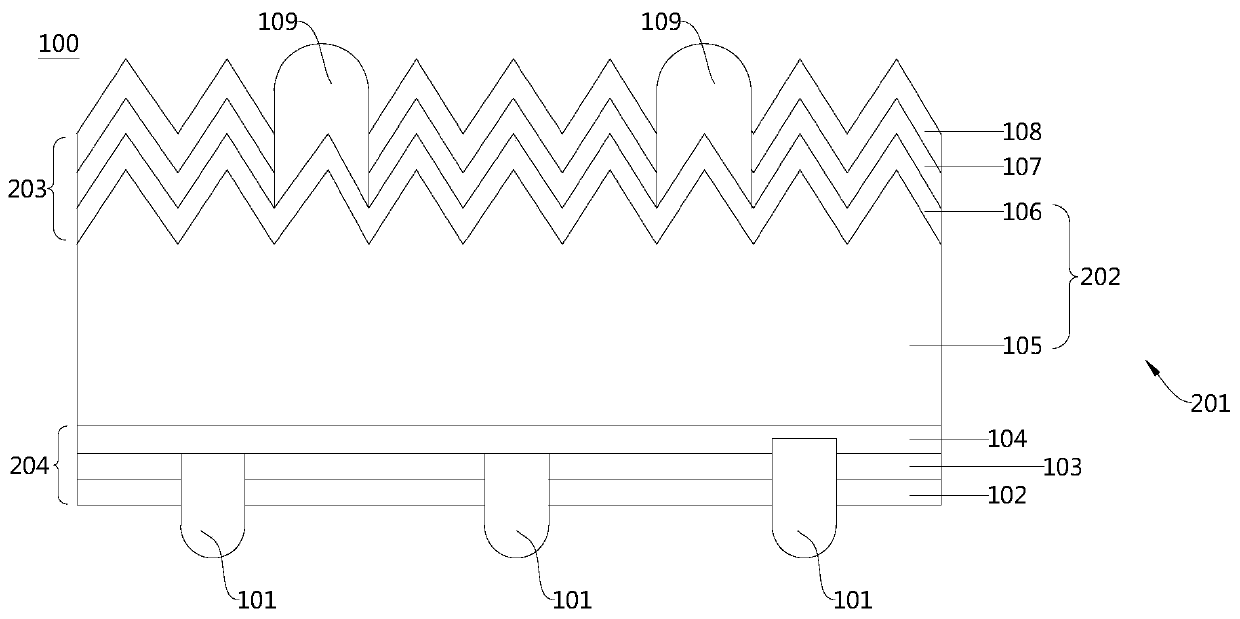

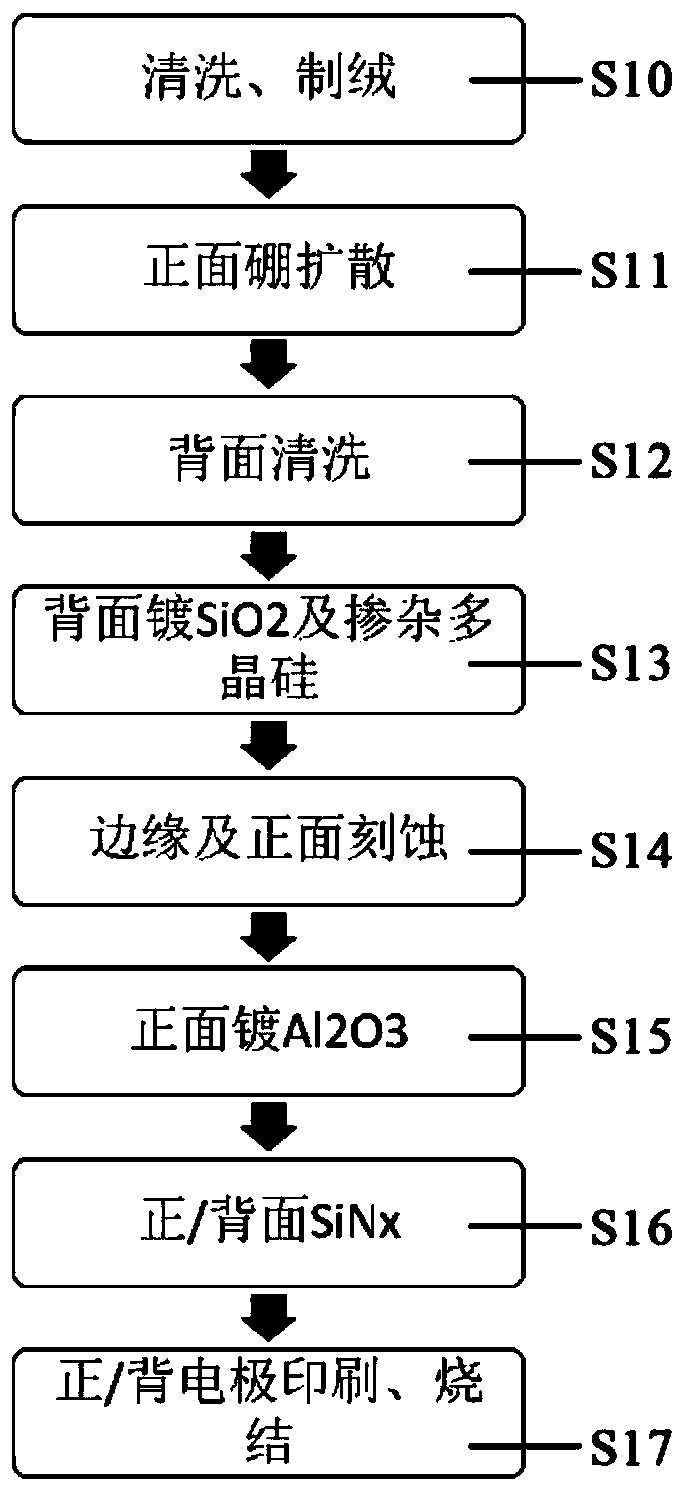

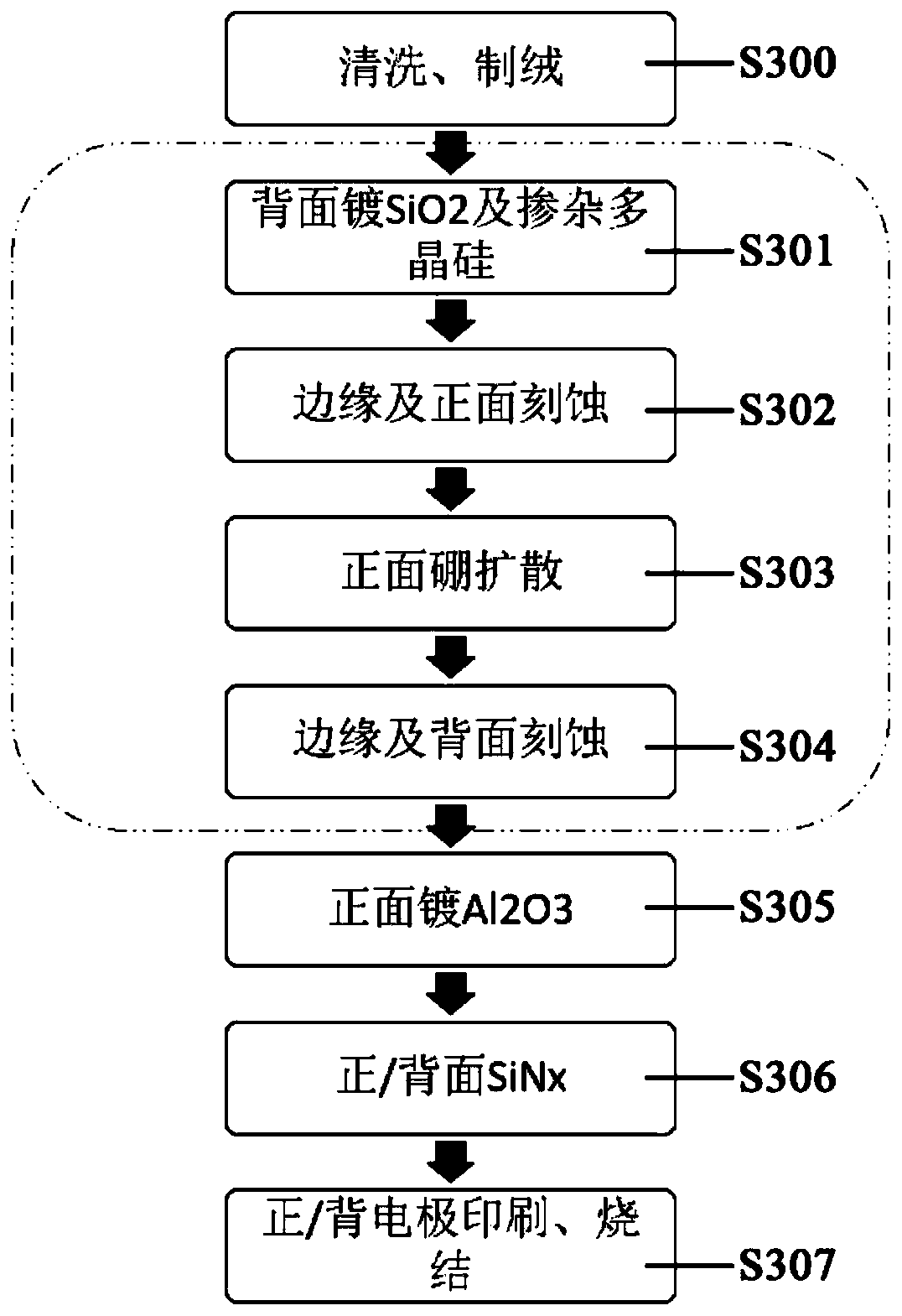

Preparation method of crystalline silicon solar passivation contact cell

InactiveCN111599895AAvoid platingImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationEngineeringCrystalline silicon

The invention discloses a preparation method of a crystalline silicon solar passivation contact cell, and belongs to the field of solar cells. The preparation method comprises the steps of manufacturing a tunneling layer on the back surface of N-type crystalline silicon to obtain a first structure body; manufacturing an n+ doped polycrystalline silicon passivation layer on the back surface of thetunneling layer, and then performing edge and front surface etching to obtain a second structure body; performing p+ doping on the front surface of the second structure body to manufacture a P-type layer, and then performing edge and back surface etching to obtain a third structure body; manufacturing a passivation film on the front surface of the third structure body to obtain a fourth structurebody; manufacturing anti-reflection films on the front surface and the back surface of the fourth structure body correspondingly to obtain a fifth structure body; and respectively manufacturing electrodes on the front surface and the back surface of the fifth structure body. The cell is simple in manufacturing process and high in photoelectric efficiency.

Owner:TONGWEI SOLAR ENERGY MEISHAN CO LTD

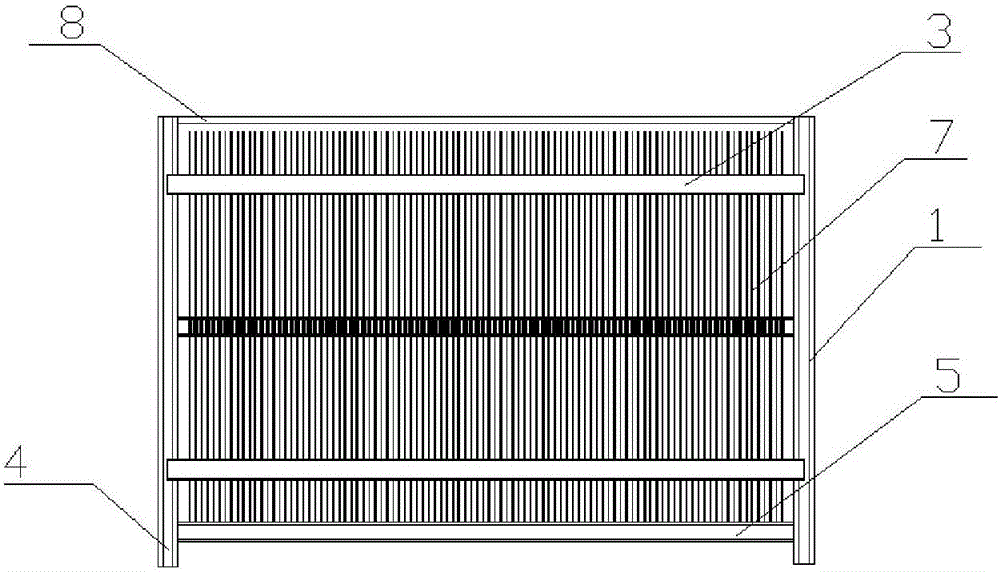

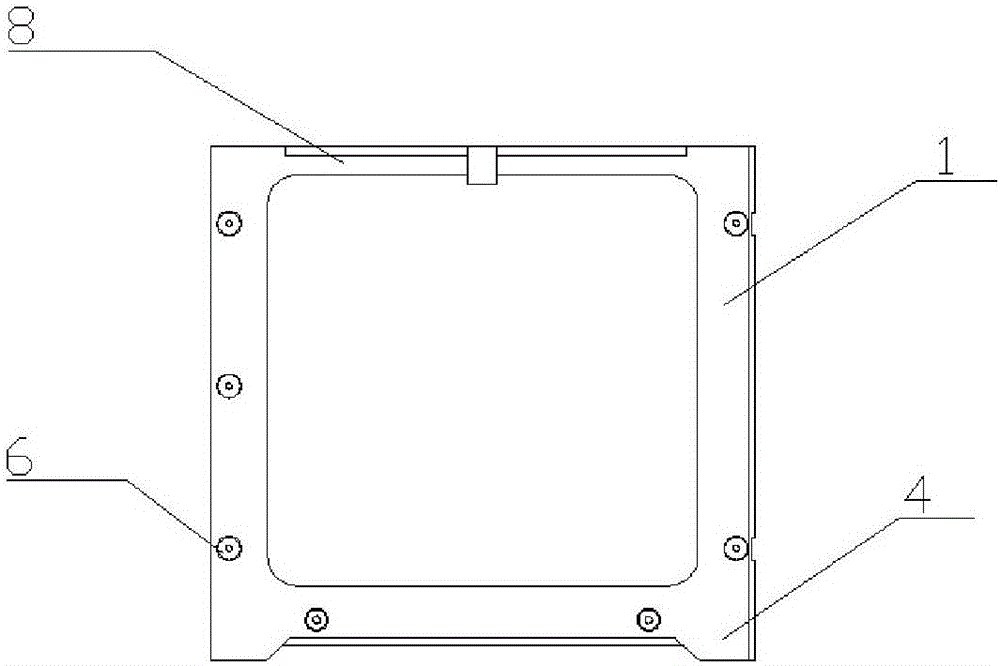

Spring clamping piece and carrier device of elastic clamping silicon slice

InactiveCN106119810AAchieve back passivationAvoid platingFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a spring clamping piece which consists of a connection end and a pair of elastic slices extending from the connection end to the outer side, wherein the two elastic slices are opposite to each other, and the ends, far away from the connection end, of the elastic slices get close to each other to form a clamping part; and the elastic slices get close to each other at the clamping part along a certain radian, and the positions, the distance between which is smallest, are not located at the end parts of the elastic slices. The invention discloses a carrier device for clamping a silicon slice with the spring clamping piece. The carrier device consists of side plates, a base and the spring clamping piece. Two ends of the base are fixed to the side plates, and the spring clamping piece is connected into the base in a clamping manner. The device disclosed by the invention is arranged in atomic layer deposition equipment, so that a high-quality thin film plated by an atomic layer deposition film plating technology can be obtained, and the problem of circle-plating caused by the atomic layer deposition film plating technology can be solved.

Owner:JIANGSU MICROVIA NANO EQUIP TECH CO LTD

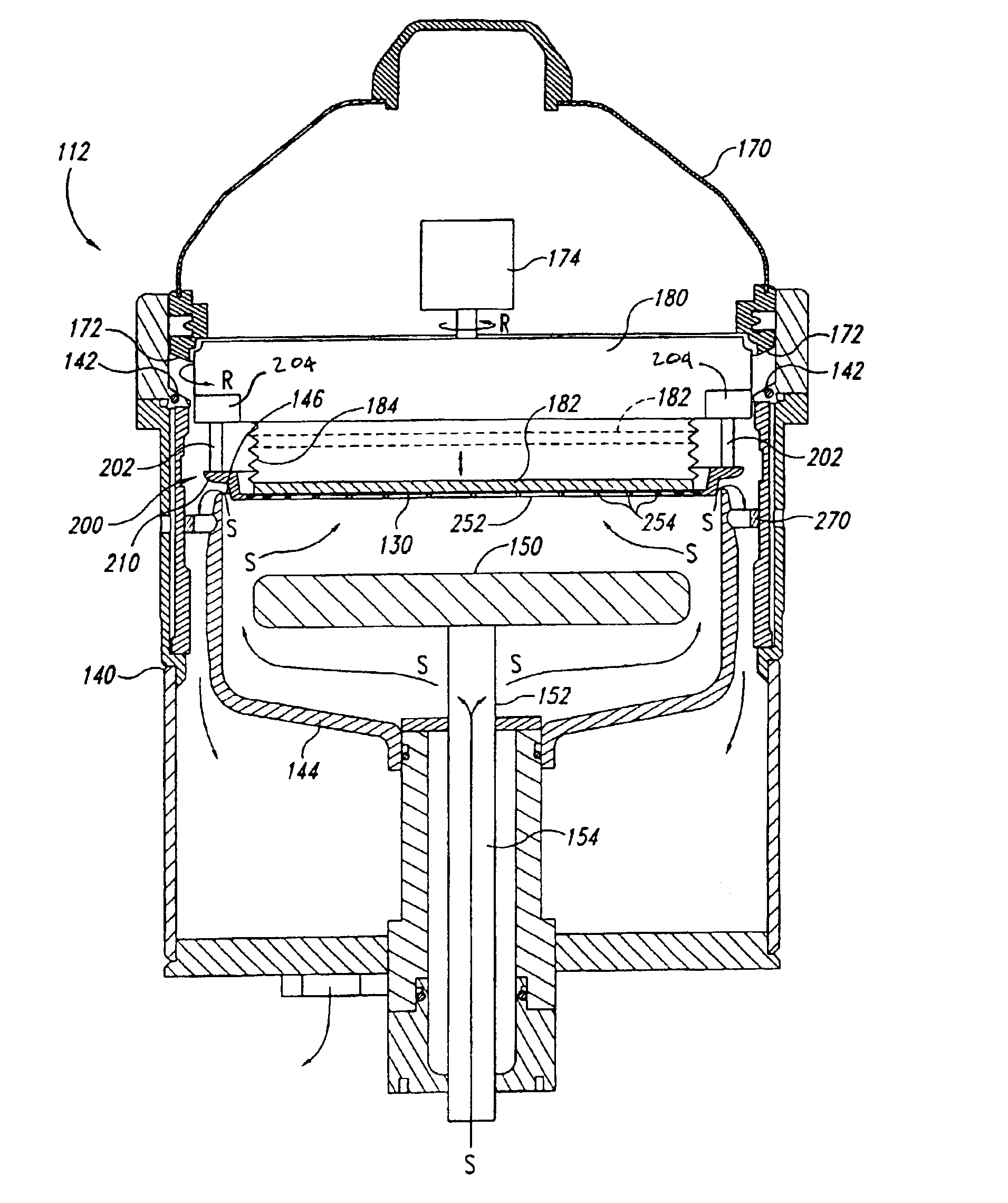

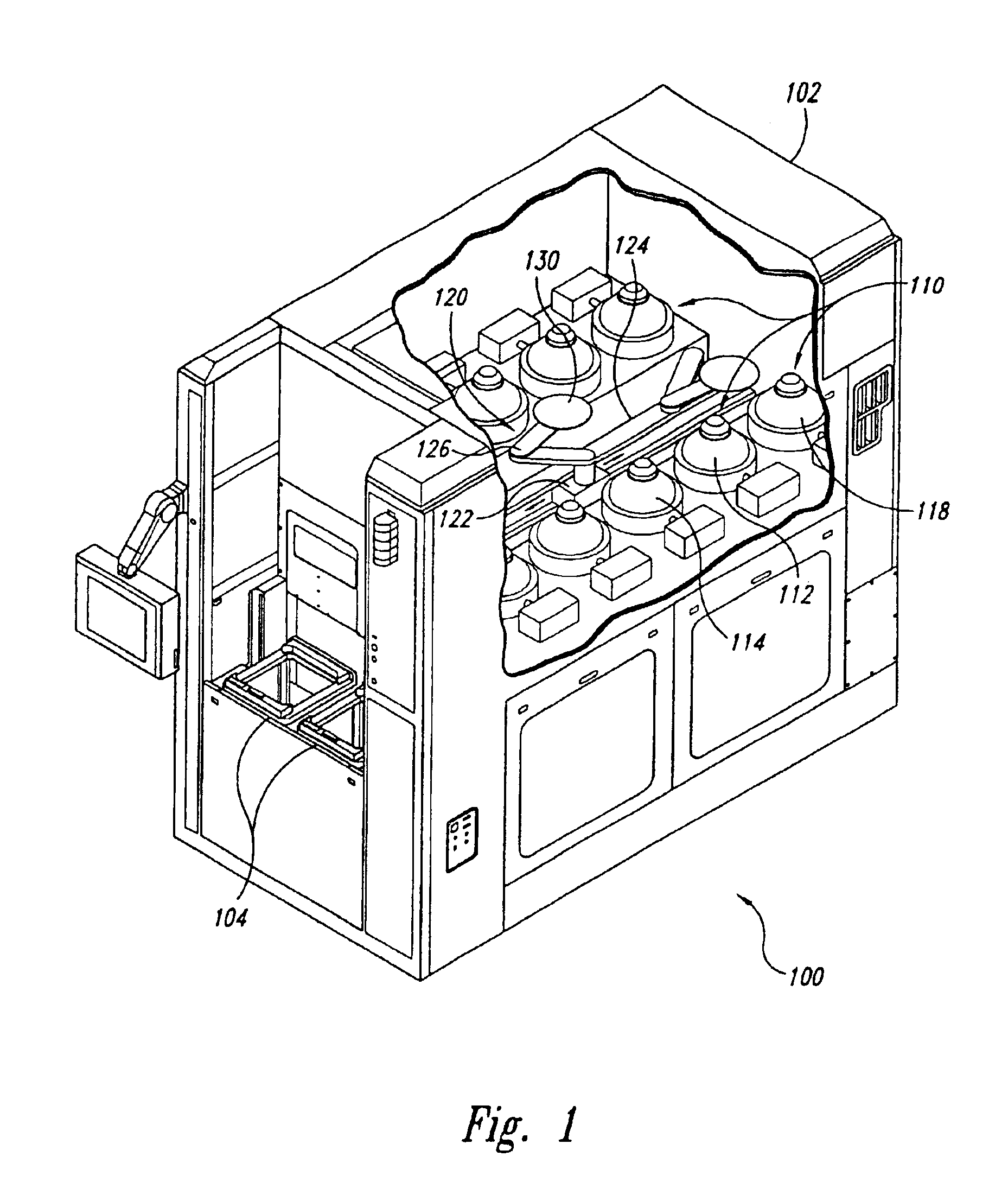

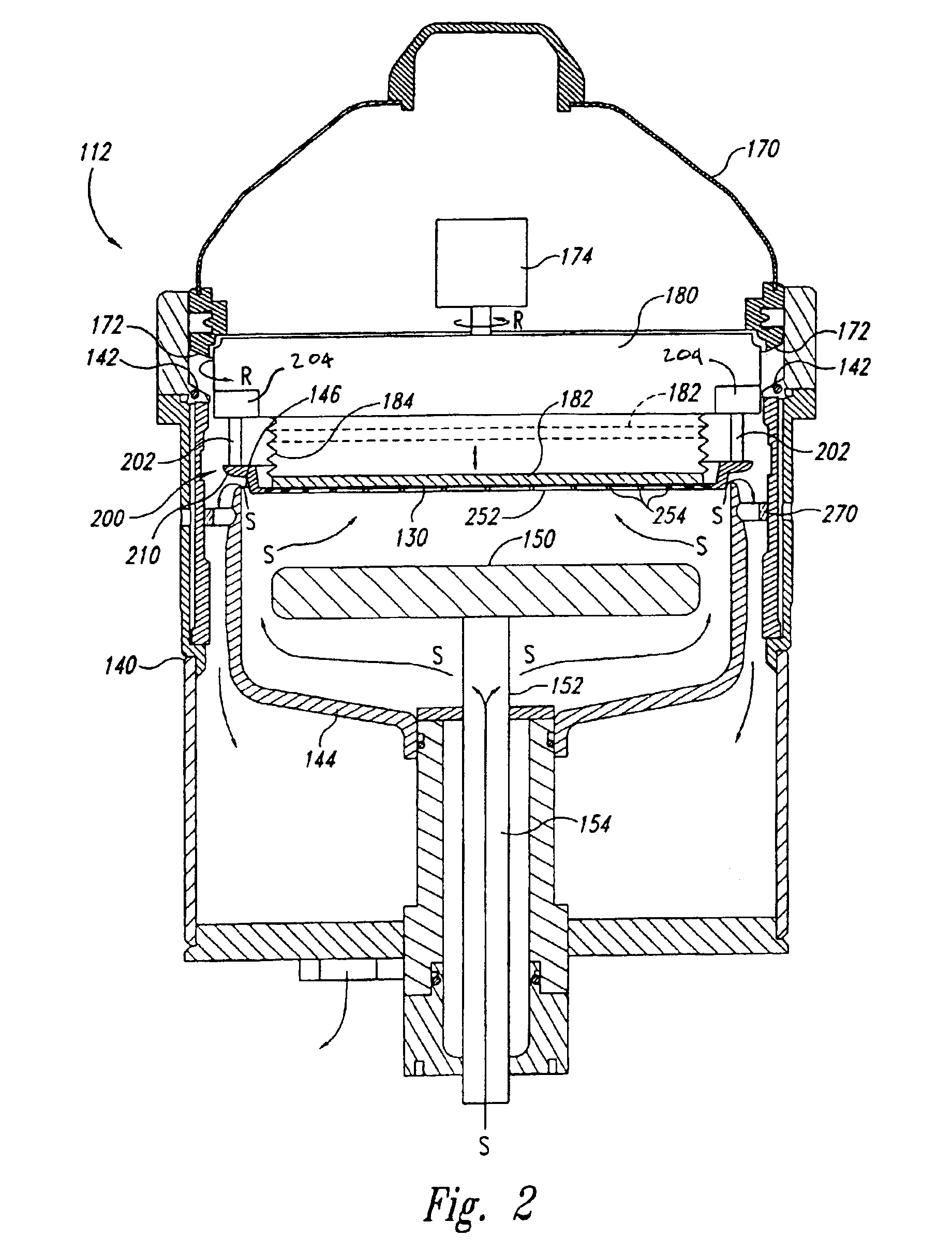

Contact assemblies, methods for making contact assemblies, and plating machines with contact assemblies for plating microelectronic workpieces

InactiveUS6939448B2Mitigates galvanic etchingReduce exposureMachining electrodesCellsEngineeringContact system

Contact assemblies, electroplating machines with contact assemblies, and methods for making contact assemblies that are used in the fabrication of microelectronic workpieces. The contact assemblies can be wet-contact assemblies or dry-contact assemblies. A contact assembly for use in an electroplating system can comprise a support member and a contact system coupled to the support member. The support member, for example, can be a ring or another structure that has an inner wall defining an opening configured to allow the workpiece to move through the support member along an access path. In one embodiment, the support member is a conductive ring having a plurality of posts depending from the ring that are spaced apart from one another by gaps. The contact system can be coupled to the posts of the support member. The contact system can have a plurality of contact members projecting inwardly into the opening relative to the support member and transversely with respect to the access path. The contact members can comprise electrically conductive biasing elements, such as fingers, that have a contact site and a dielectric coating covering at least a portion of the biasing elements. The contact members can also have a raised feature configured to engage the seed-layer on the workpiece for conducting the current to the seed-layer.

Owner:SEMITOOL INC

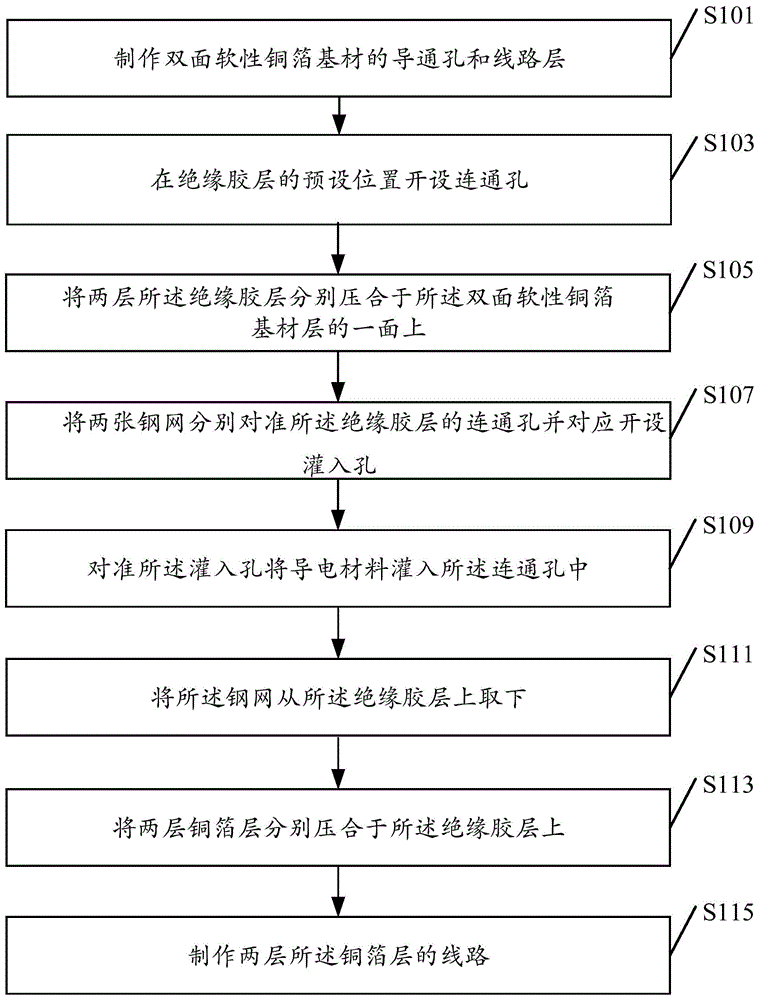

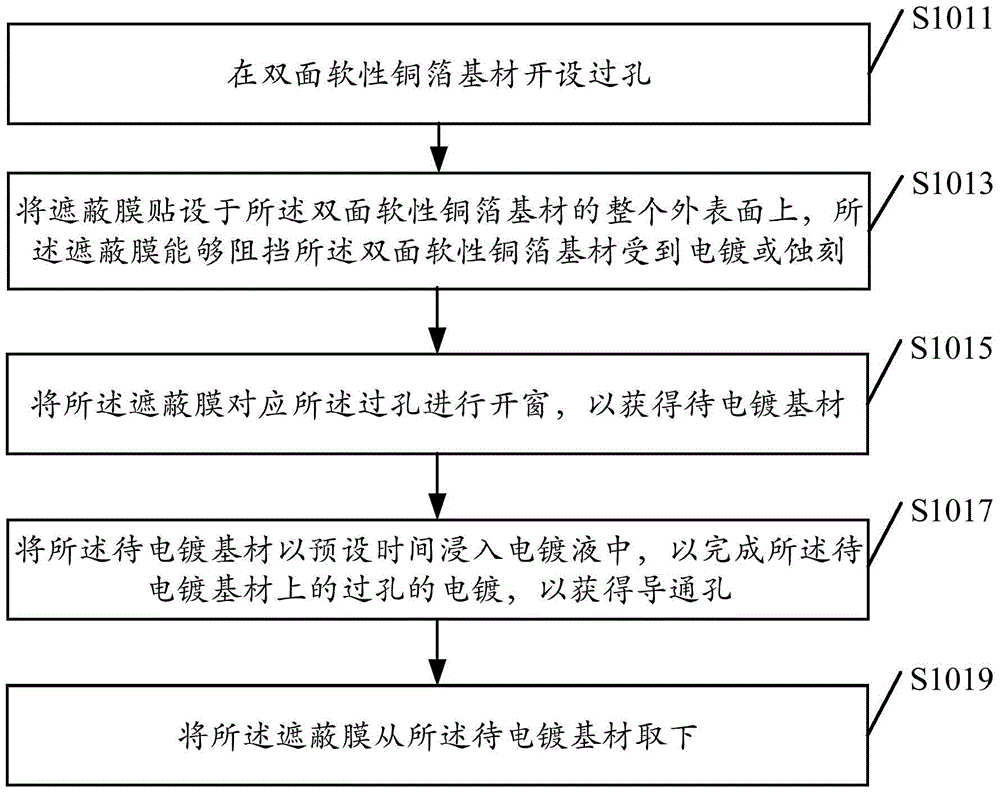

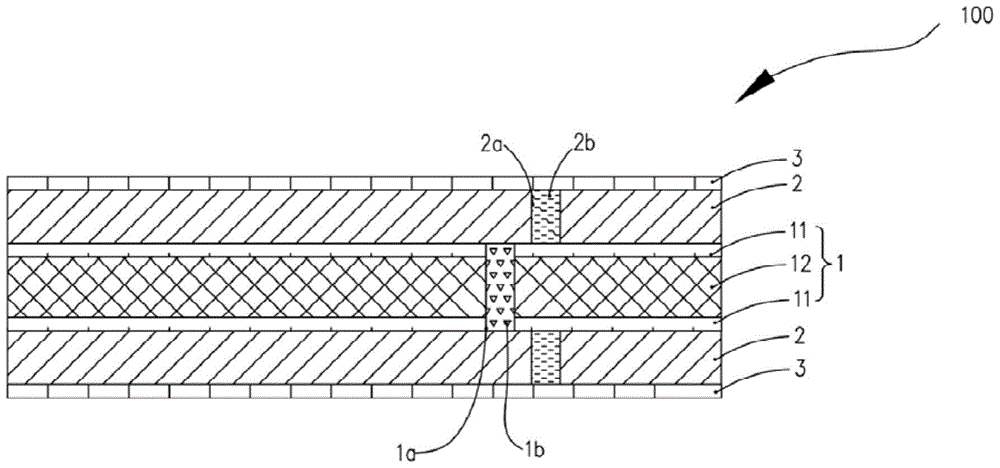

Manufacturing method of multi-layer flexible circuit board, multi-layer flexible circuit board and mobile terminal

InactiveCN105792544AUniform thicknessRealize the electrical connection relationshipPrinted circuit aspectsMultilayer circuit manufactureFlexible circuitsElectrical connection

The invention discloses a manufacturing method of a multi-layer flexible circuit board. The method comprises the following steps: manufacturing via holes and circuit layers on a double-sided soft copper foil substrate; forming interconnecting holes in preset positions of insulating adhesive layers; laminating each insulating adhesive layer on one surface of the double-sided soft copper foil substrate; making two steel meshes aligned with the via holes of the insulating adhesive layers respectively and correspondingly forming injection holes; injecting a conductive material into the interconnecting holes through aligning with the injection holes; taking down the steel meshes from the insulating adhesive layers; laminating two copper foil layers on the insulating adhesive layers respectively; and manufacturing a circuit with the two copper foil layers. According to the manufacturing method of the multi-layer flexible circuit board, the electric connection relationship between the copper foil layers of the multi-layer flexible circuit board is achieved by forming the interconnecting holes in the insulating adhesive layers and injecting the conductive material into the interconnecting holes; and electroplating again after holes are formed in the copper foil layers is avoided, so that uniform thickness of the multi-layer flexible circuit board is ensured; and welding of a precision device is facilitated. The invention further provides the multi-layer flexible circuit board and the mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Preparation method of passivation contact structure

InactiveCN111063764AAvoid platingImprove efficiencyFinal product manufacturePhotovoltaic energy generationThin membraneSolar cell

The invention relates to a preparation method of a passivation contact structure. The preparation method comprises the steps of (1) cleaning a silicon wafer substrate; (2) preparing a single-sided n<+> or p<+> doped layer on the surface of the cleaned silicon wafer; (3) depositing a tunneling oxide layer on a non-doped surface; (4) depositing a layer of doped polycrystalline silicon film on the surface of the tunneling oxide layer by adopting a PVD method. Therefore, the passivation contact structure is prepared. The method disclosed by the invention has the main advantages that the doped polycrystalline silicon film is prepared by adopting the PVD method, so that the components of the film can be well controlled; the optimal doping ratio can be debugged according to actual process requirements; the polycrystalline silicon film prepared through single-side film forming is high in deposition rate and good in compactness; and the problems that in the industrialization process of an existing solar cell in an N-type passivation contact structure, the front face appearance is poor, and the electrical property is reduced can be well solved.

Owner:江苏杰太光电技术有限公司

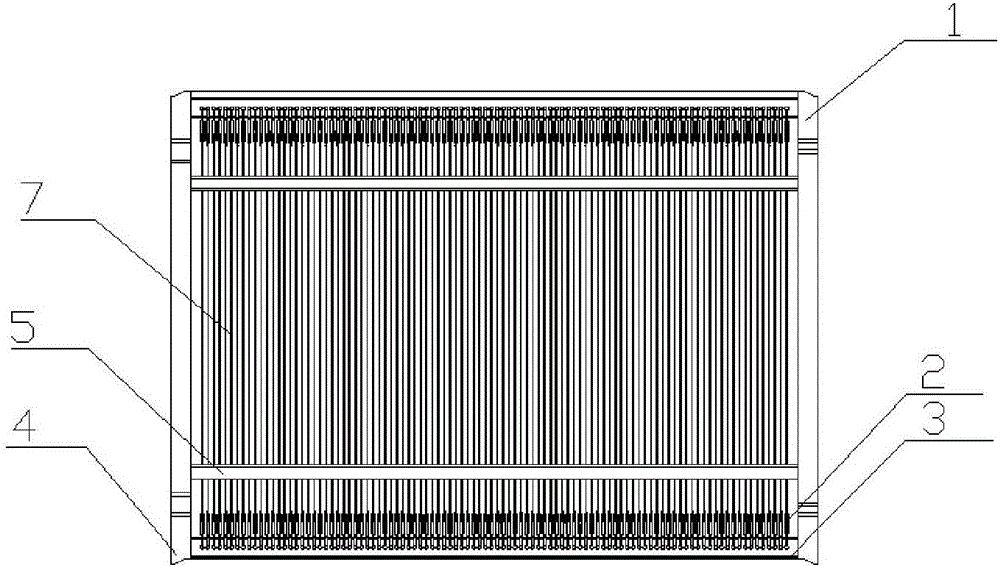

Device and method for avoiding rotary coating of two-sided solar cell silicon nitride coated film

InactiveCN106756874ASimple designIncrease resistanceChemical vapor deposition coatingGraphiteSolar cell

The invention relates to a device and method for avoiding rotary coating of two-sided solar cell silicon nitride coated film. The device comprises a graphite frame and a plurality of supporting hooks arranged on the graphite frame. Each supporting hook comprises a body and a hook body, wherein a hook point is formed at the free end of the hook body and is not lower than the lower surface of the graphite frame but not 1 mm higher than the lower surface of the graphite frame. The hook points of all the supporting hooks are located on the same horizontal plane. During two-sided coating, a to-be-coated silicon wafer obtained through earlier stage processing of a two-sided solar cell technique is put on the supporting devices of the device, the silicon wafer enters the device, one surface of the silicon wafer is coated, and then the silicon wafer with one surface coated is turned by 180 degrees, so that the other surface is coated. Compared with the prior art, the device and method have the advantages that the application range is wide, safety and reliability are achieved, the stability performance is good, overhauling is convenient, the maintenance frequency is low, the technical performance is good, and the problem of edge chromatic aberration caused by rotary coating of the plate-type coated film can be solved.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Wireless soil profile monitoring apparatus and methods

ActiveUS10499573B1Excessive water useAvoid water damageThermometer detailsAgricultural machinesEngineeringMoisture

Owner:PAULSEN KEITH LYNN

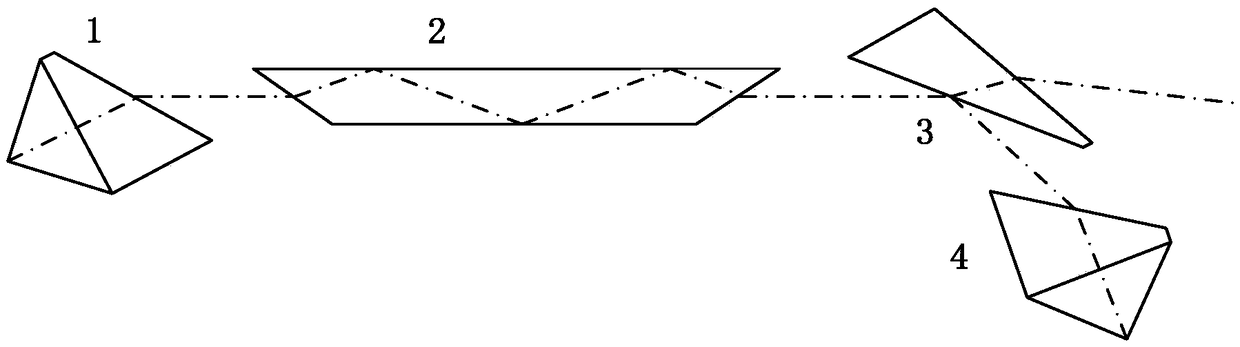

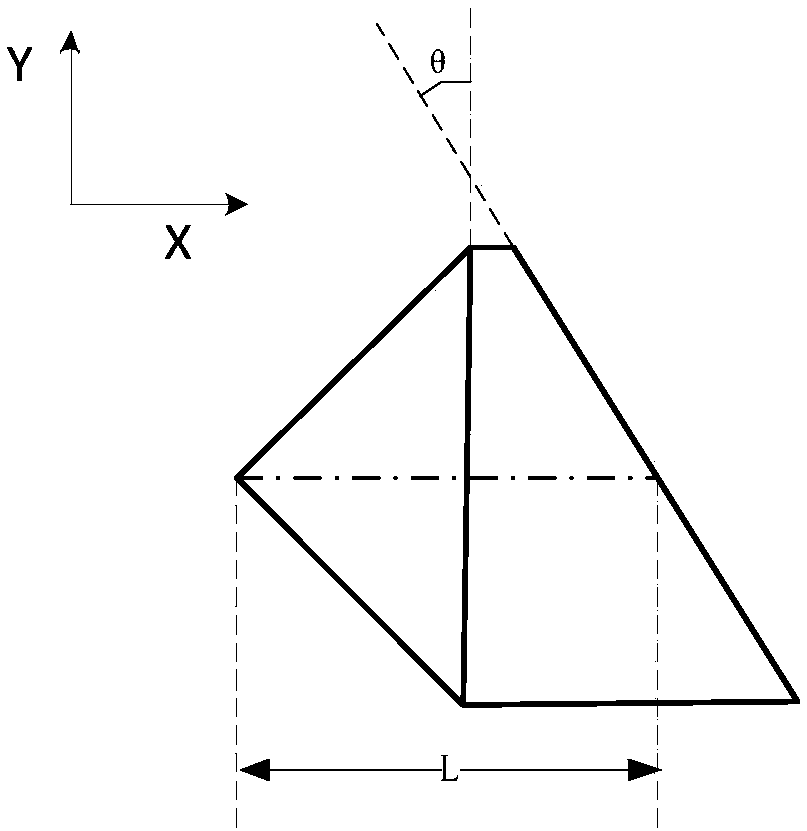

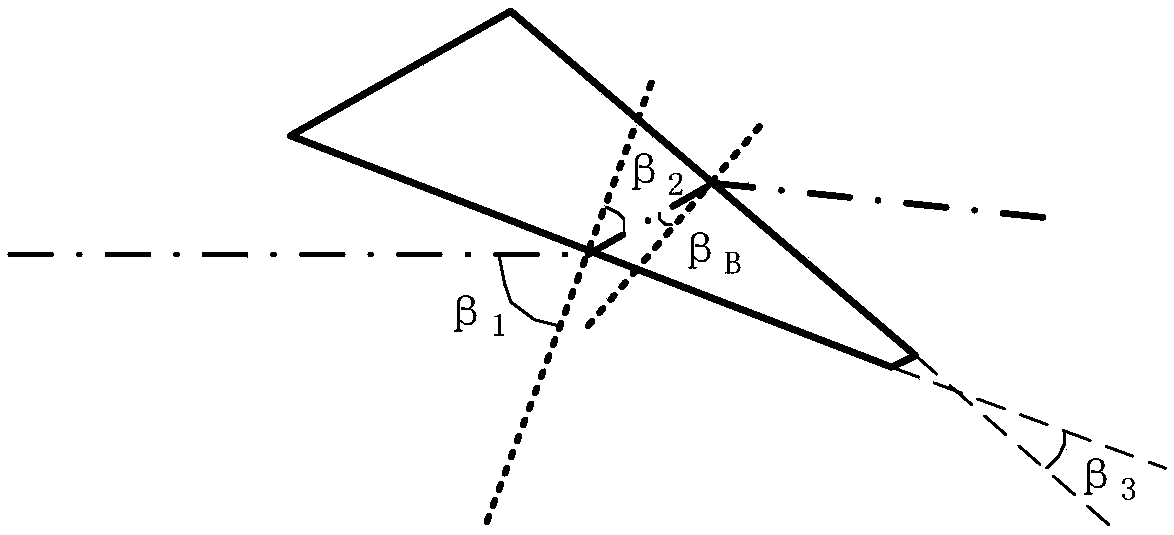

A laser-damage-resistant solid-state laser resonator

ActiveCN109167240AHigh damage resistance thresholdAvoid platingPrismsOptical resonator shape and constructionResonant cavitySpecial design

The invention relates to a laser damage resistant solid-state laser resonator, comprising a first total reflection prism (1), a laser gain medium (2), a coupling output prism (3), and a second total reflection prism (4). In order to solve the problem that the reliability of laser is not high due to the damage of optical element film, The invention adopts all optical elements which are not coated as resonant cavity elements, realizes high transmission, high reflection and specific proportion transmission of laser light through special design material and incident angle, thereby realizing oscillation output of laser light, so that laser damage threshold of laser light can be greatly increased, and laser reliability can be further improved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

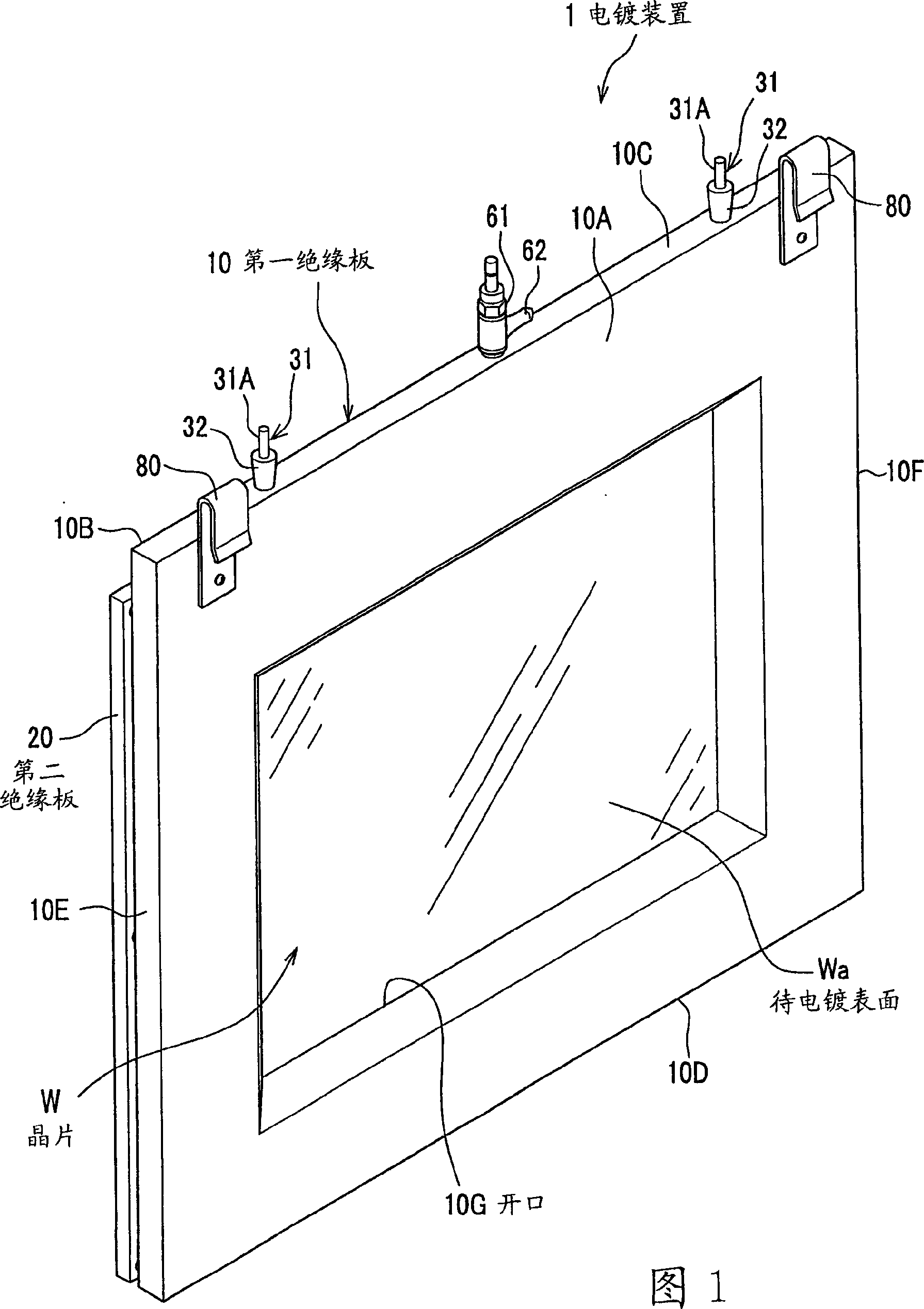

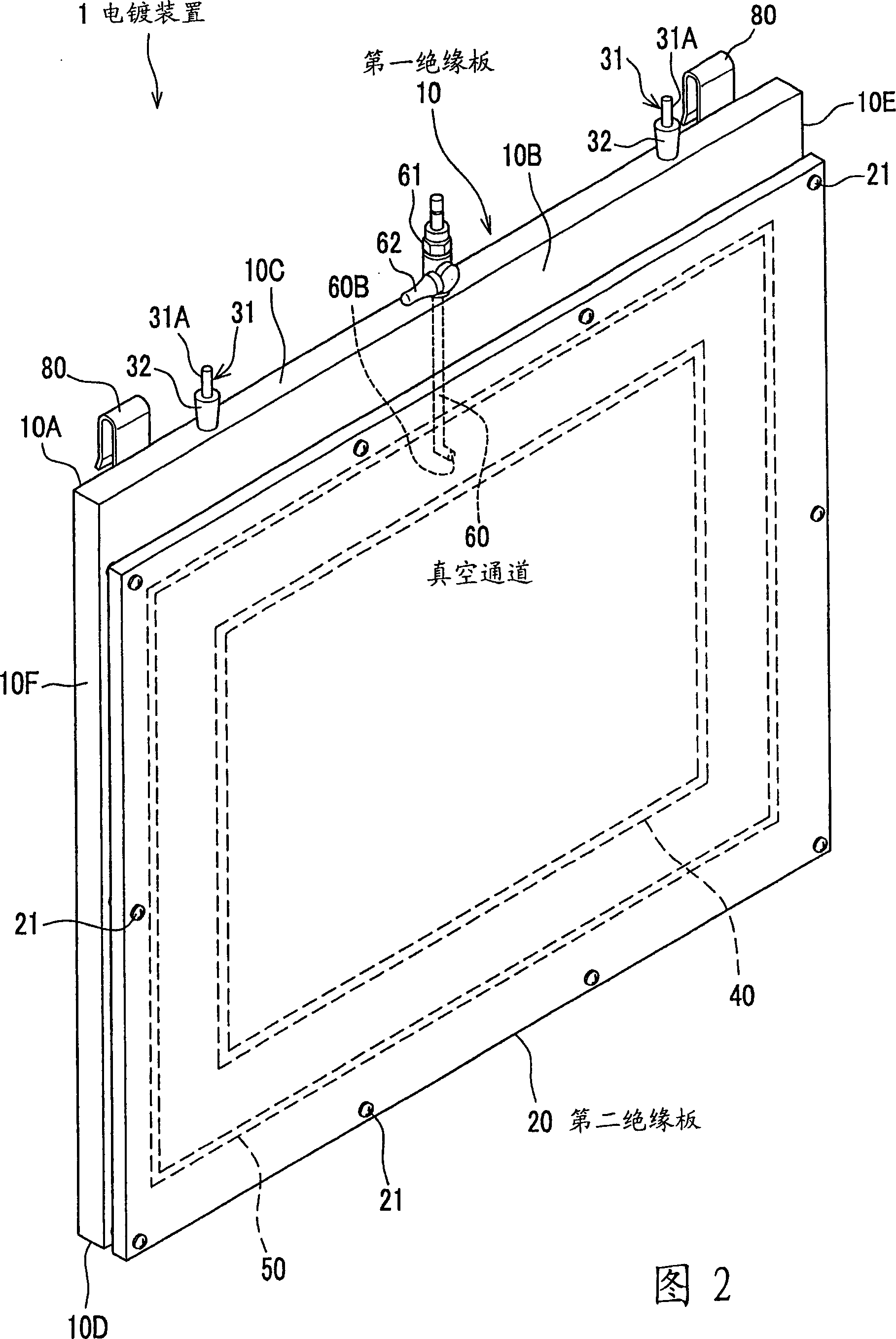

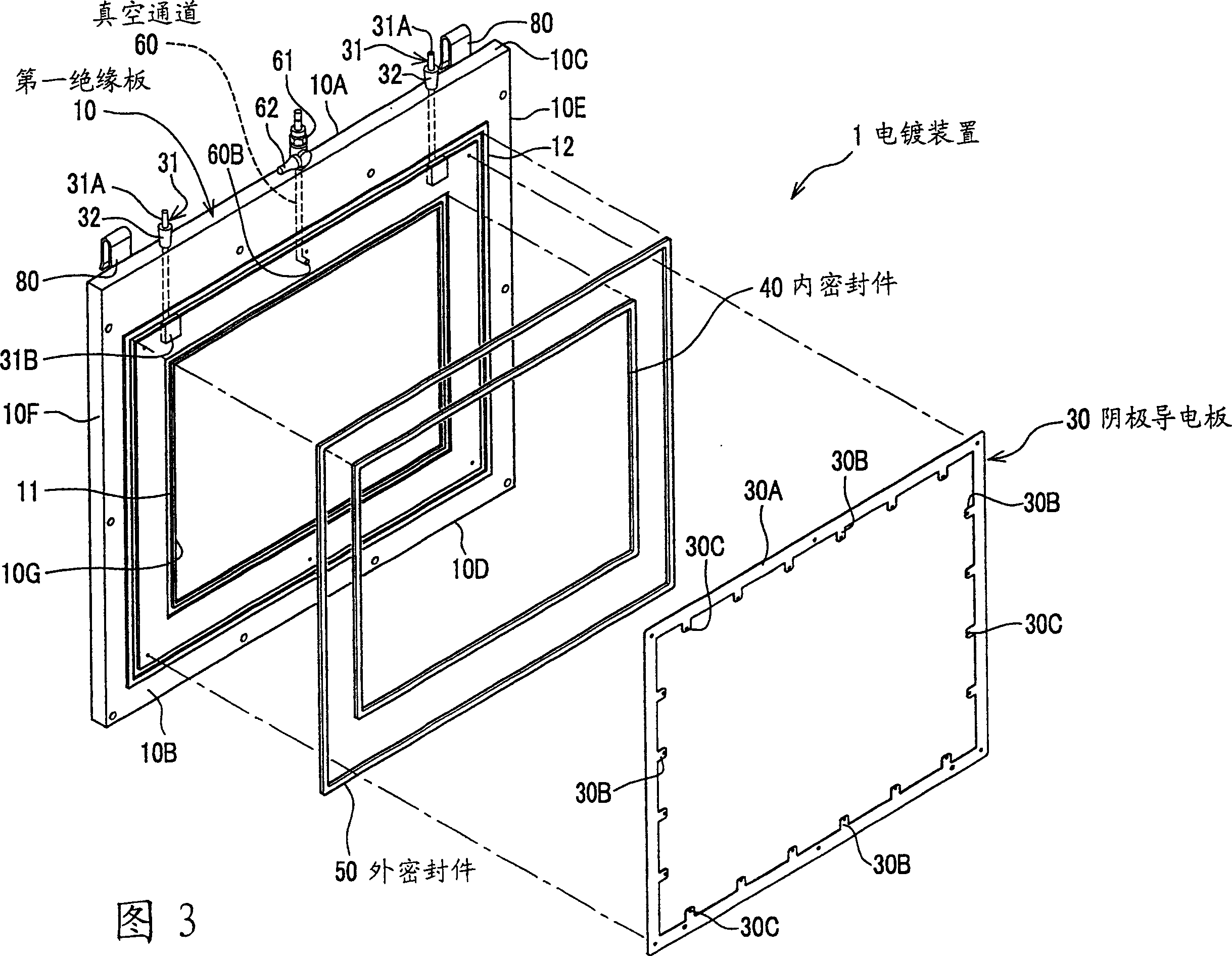

Electroplating apparatus

ActiveCN1831209AAvoid platingImprove performanceElectrolysis componentsPrinted circuit manufactureElectrical conductor

An electroplating apparatus including a first insulated plate which has an opening, a second insulated plate which holds an object to be electroplated between the first insulated plate and the second insulated plate in such a way that the object to be electroplated is exposed through the opening, an inner seal which is provided around a periphery of the opening between the first insulated plate and the object to be electroplated, a conductor which is provided between the first insulated plate and the second insulated plate surrounding the object to be electroplated so as to conduct electricity to the object to be electroplated, and an outer seal which is provided between the first insulated plate and the second insulated plate surrounding the conductor, in which a vacuum passage is formed inside the first insulated plate and / or the second insulated plate in order to make and keep air pressure in a space surrounded by the first insulated plate, the second insulated plate, the inner seal, and the outer seal, negative.

Owner:YAMAMOTO MS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com