Graphite boat pretreatment substitution piece and graphite boat pretreatment method

A graphite boat and pretreatment technology, applied in coating, gaseous chemical plating, metal material coating process, etc., can solve problems such as affecting process performance, high cost, silicon wafer bending, etc., to reduce costs and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific implementation plan

[0024] The objectives and effects of the present invention will be described in detail below with reference to specific embodiments and drawings.

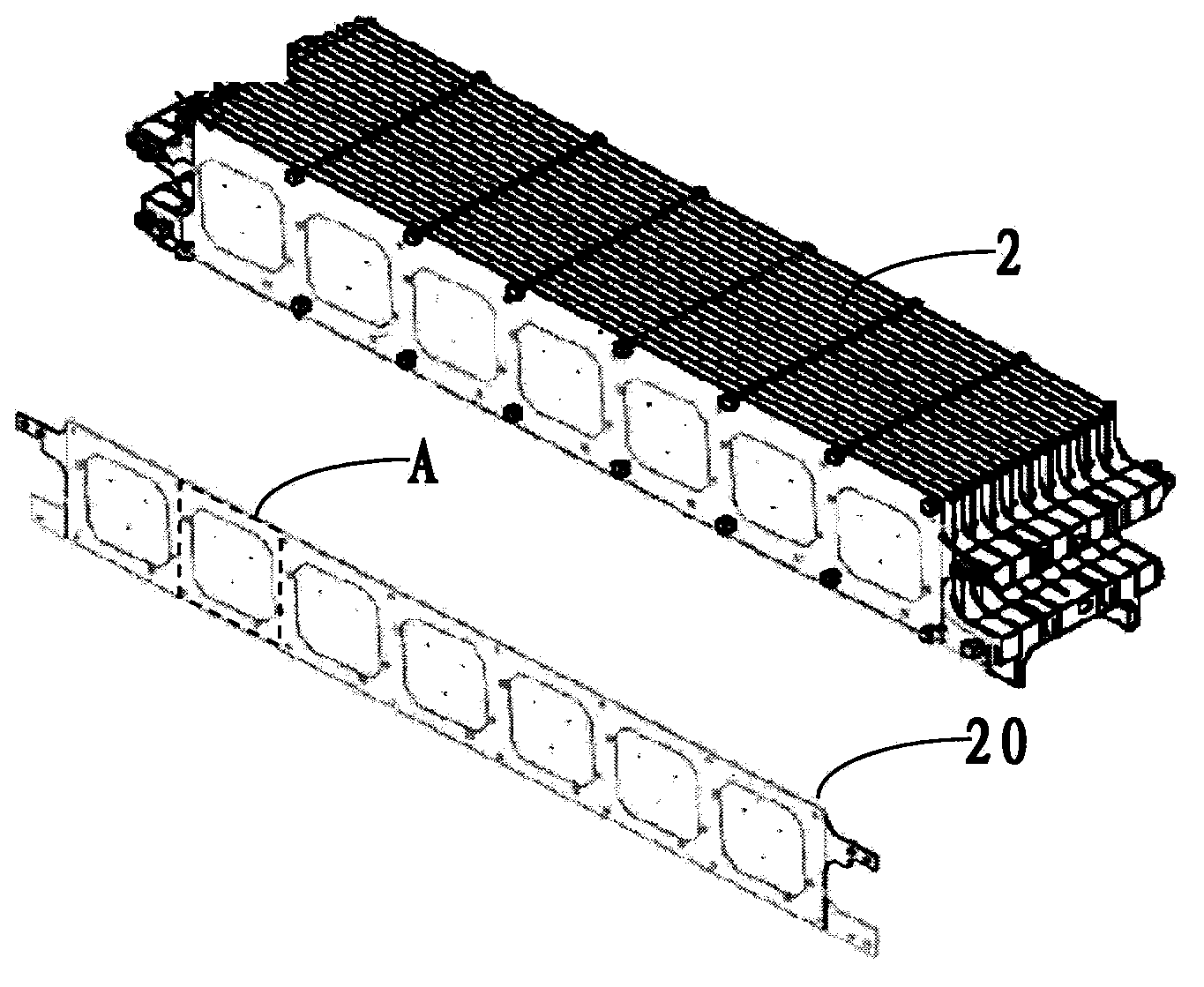

[0025] See Figure 1 to Figure 4 The graphite boat pretreatment replacement sheet 1 of the present invention is used for the pretreatment after the graphite boat 2 is cleaned. The graphite boat 2 includes a plurality of stacked boats 20, and each boat 20 includes a plurality of The process card points 200 carrying the workpiece piece, the shape of the graphite boat pretreatment replacement sheet 1 matches the process card points 200, the thickness of the edge area is 100-300 μm, and the thickness of the center area is 1 to 3 mm, The material of the graphite boat pretreatment replacement sheet 1 is graphite or carbon fiber and other materials resistant to high temperature and corrosion. In this embodiment, the graphite boat pretreatment replacement sheet is a square with a side length of 125 mm or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com