Electroplating apparatus

An electroplating device and electroplating technology, which is applied to circuits, electrical components, electrolytic processes, etc., can solve problems such as uneven screw fastening pressure and deterioration of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail herein, referring to the accompanying drawings as necessary.

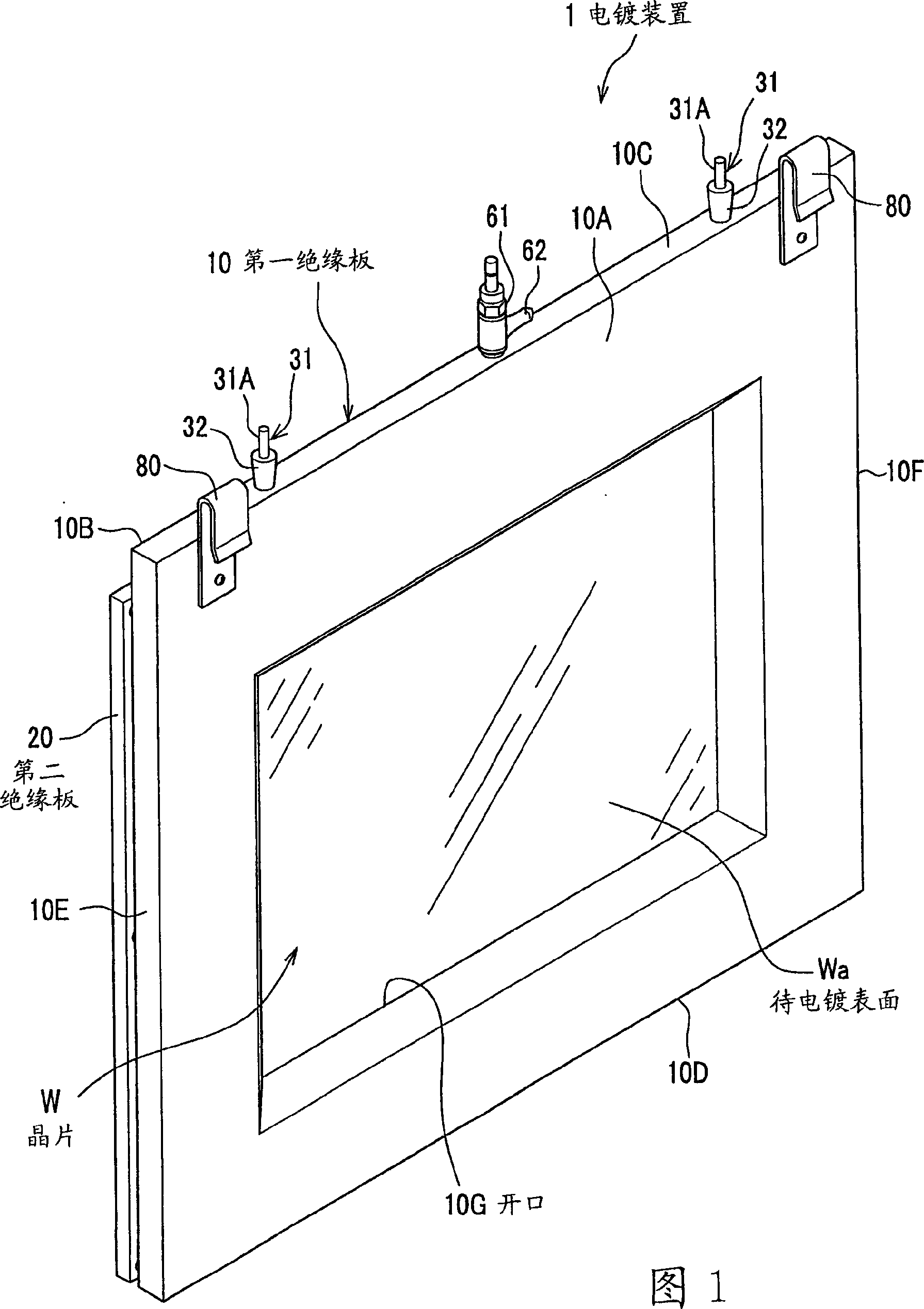

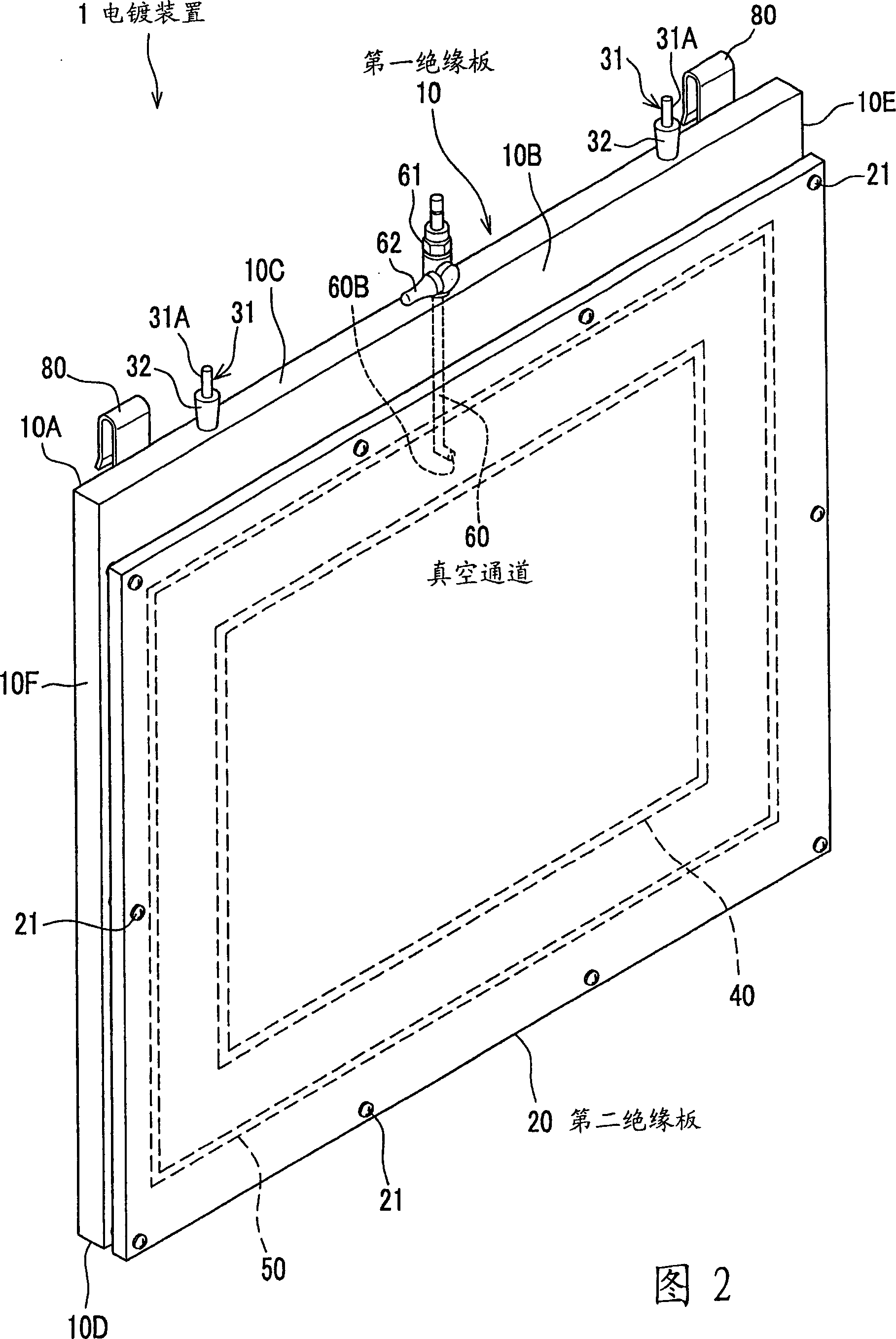

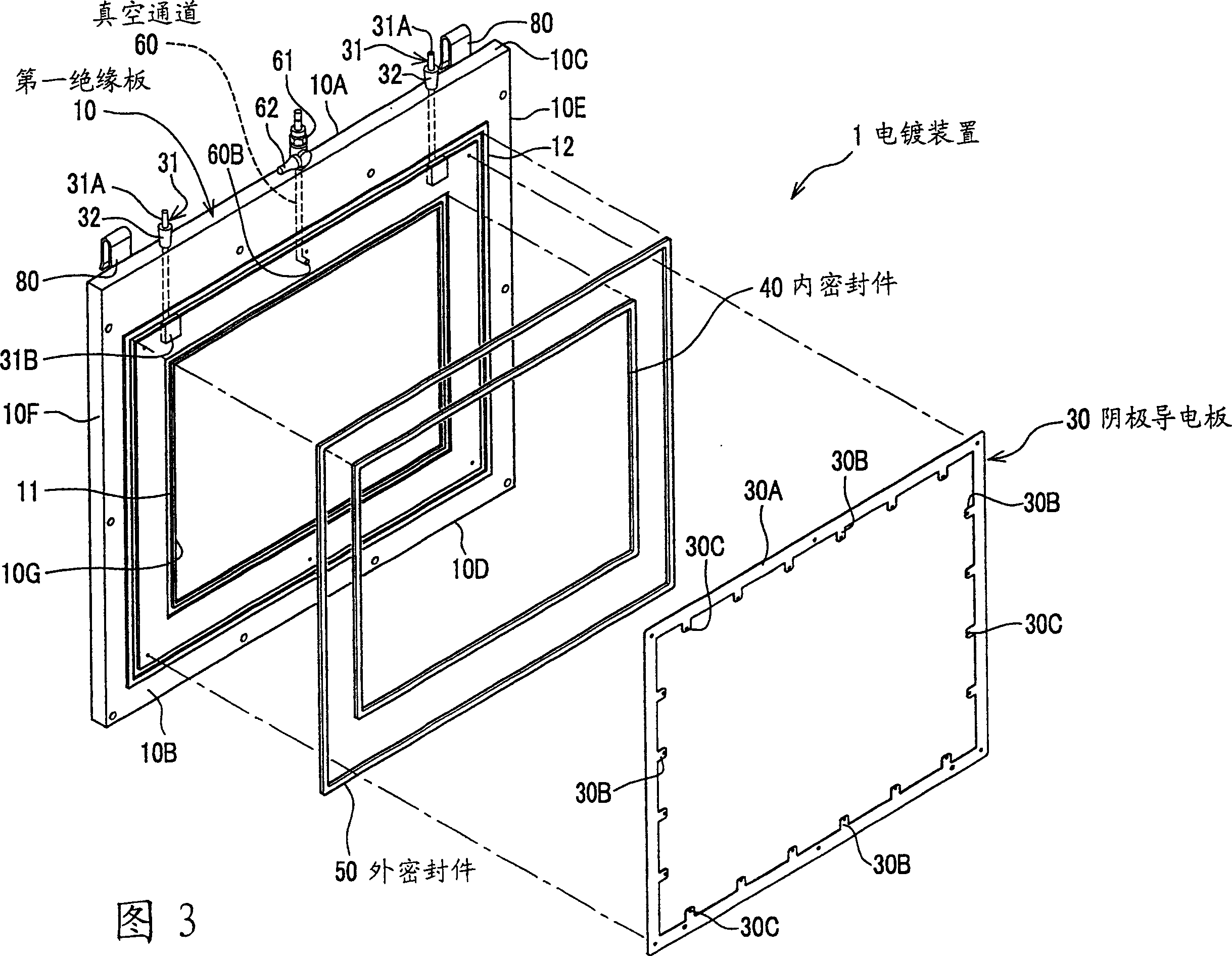

[0027] Figure 1 to Figure 4 As shown, the electroplating device 1 generally includes: a first insulating plate 10 , a second insulating plate 20 , a cathode conductive plate (conductor) 30 for conducting current, an inner seal 40 , an outer seal 50 and a vacuum channel 60 .

[0028] The first insulating plate 10 is, for example, a flat plate made of an insulating material such as an acryl plate, and is formed in a substantially rectangular shape. As shown in FIGS. 1 and 2 , the first insulating plate 10 has a front surface 10A, a rear surface 10B, a top surface 10C, a bottom surface 10D, a left side 10E, and a right side 10F. An opening 10G having a substantially rectangular shape is formed in the first insulating plate 10 . A surface Wa to be plated of a wafer W (described later) is exposed through the opening 10G. Further, as shown in FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com