Preparation method of passivation contact structure

A technology of contact structure and diffusion method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve problems such as appearance and electrical performance degradation, improve cell efficiency, reduce parasitic absorption, and simple process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

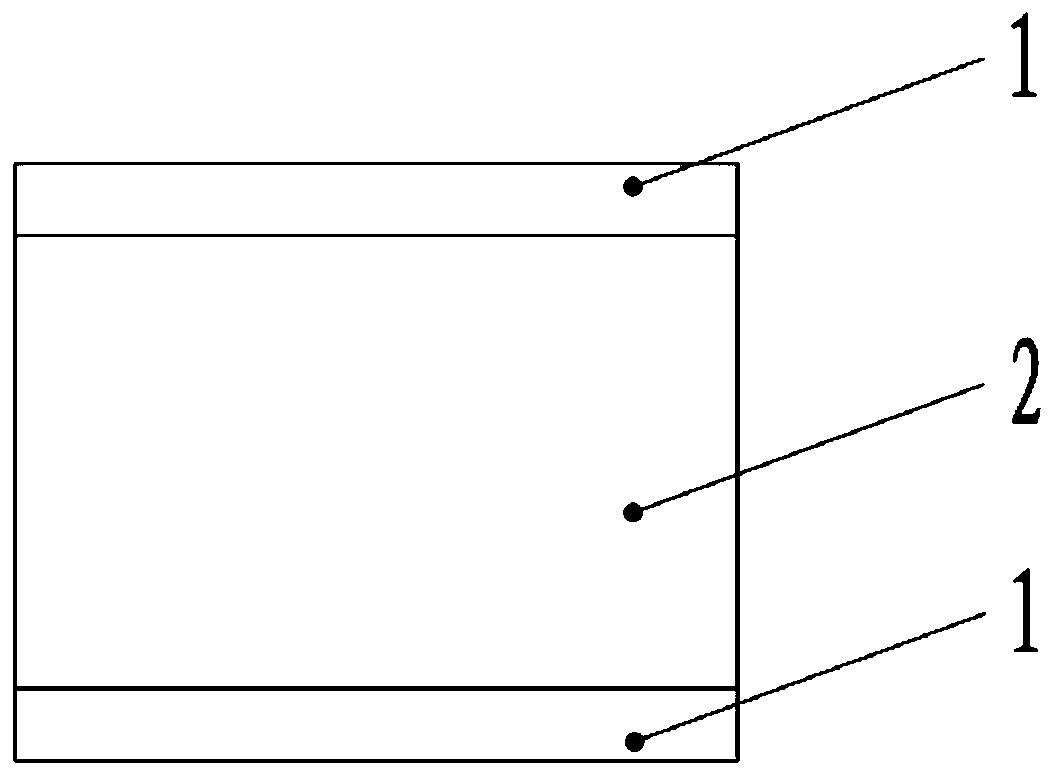

[0046] A method for preparing a passivation contact structure by physical vapor deposition (PVD) provided in the present embodiment 1 adopts the multi-source magnetron sputtering method in the physical vapor deposition to prepare a passivation contact structure, which specifically includes the following steps:

[0047] Steps (1), (2), (3), (4) and steps (1), (2), (3),

[0048] (4) the same;

[0049] (5) The multi-source magnetron sputtering method firstly fixes the N-type silicon substrate 2 in the reaction chamber of the magnetron sputtering coater, then fixes the doped target material phosphorus or boron, and finally fixes it after the treatment in step (4). The N-type silicon substrate 2 is placed so that the side with the oxide layer faces outward and is opposite to the target, and the distance between each target and the N-type silicon substrate 2 is controlled to be 15-300mm; finally, the entire vacuum chamber is evacuated, Make its vacuum degree not higher than 1.5×10 ...

Embodiment 2

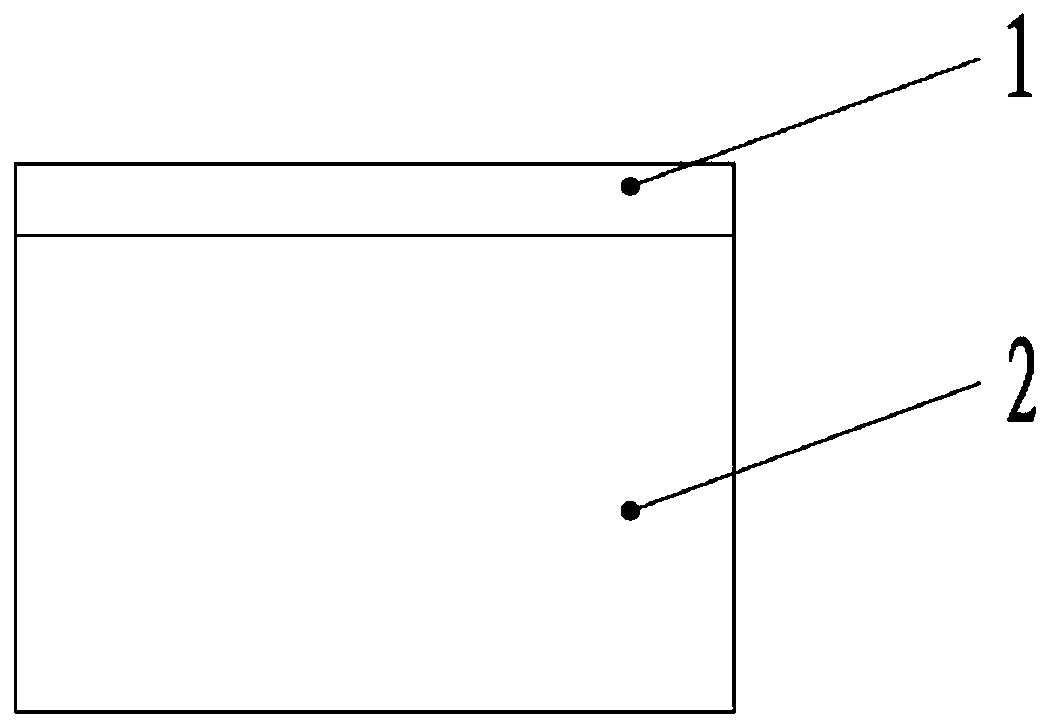

[0053] The second embodiment is to obtain a phosphorus-doped amorphous silicon layer by vacuum evaporation, and then combine with rapid thermal annealing to obtain an n-type doped passivation contact structure, which specifically includes the following steps:

[0054] Steps (1), (2), (3), (4) are the same as steps (1), (2), (3), (4) in Comparative Example 1;

[0055] (5) Multi-source co-evaporation method First, place the base evaporation source monocrystalline silicon or polycrystalline silicon powder with a purity of 99.9999% in the molybdenum boat, and then place the doped evaporation source phosphorus powder or boron powder with a purity of 99.9999% in the appropriate amount. In another molybdenum boat, each evaporation source is sequentially fixed in the vacuum coating machine, and after the end, the substrate silicon wafer processed in step 4 is fixed, so that the side with the oxide layer faces outward and is opposite to the evaporation source; finally, the substrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com