Device and method for avoiding rotary coating of two-sided solar cell silicon nitride coated film

A technology of solar cells and silicon nitride, which is applied in the field of solar cells, can solve problems such as chromatic aberration, and achieve the effects of simple design, wide application range, and increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

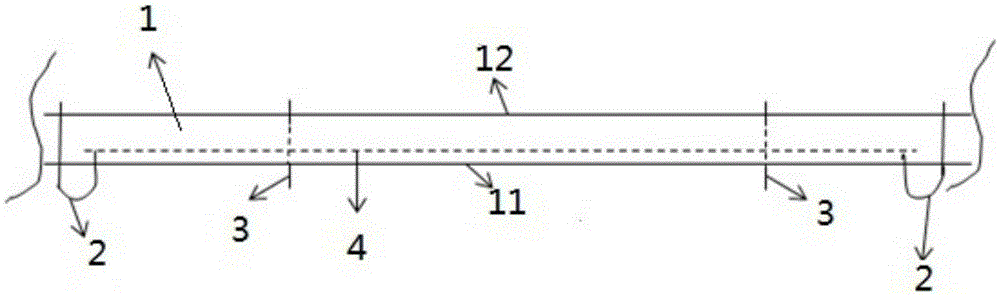

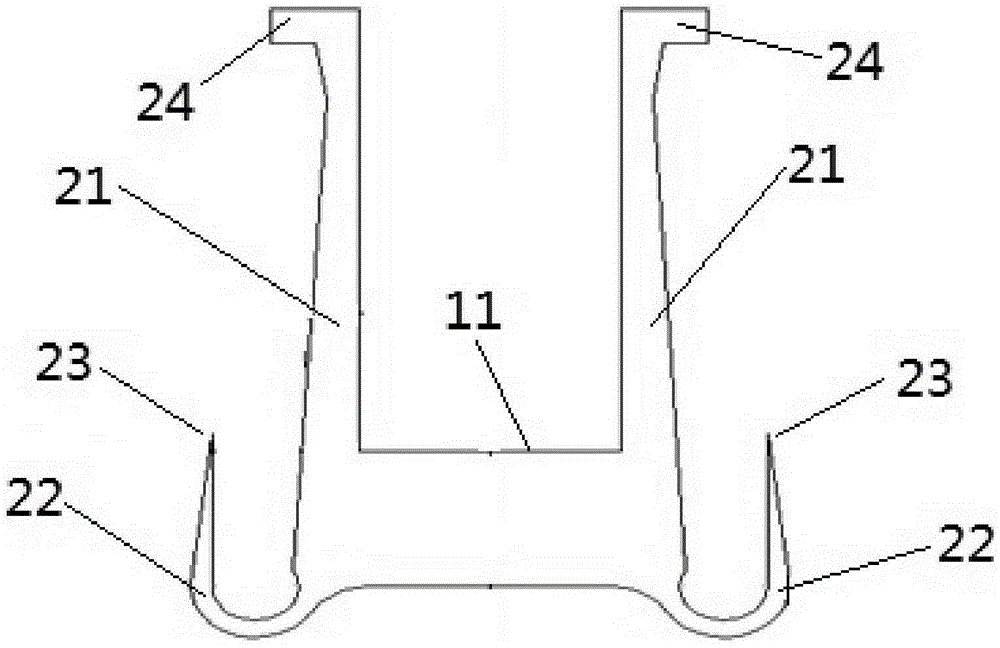

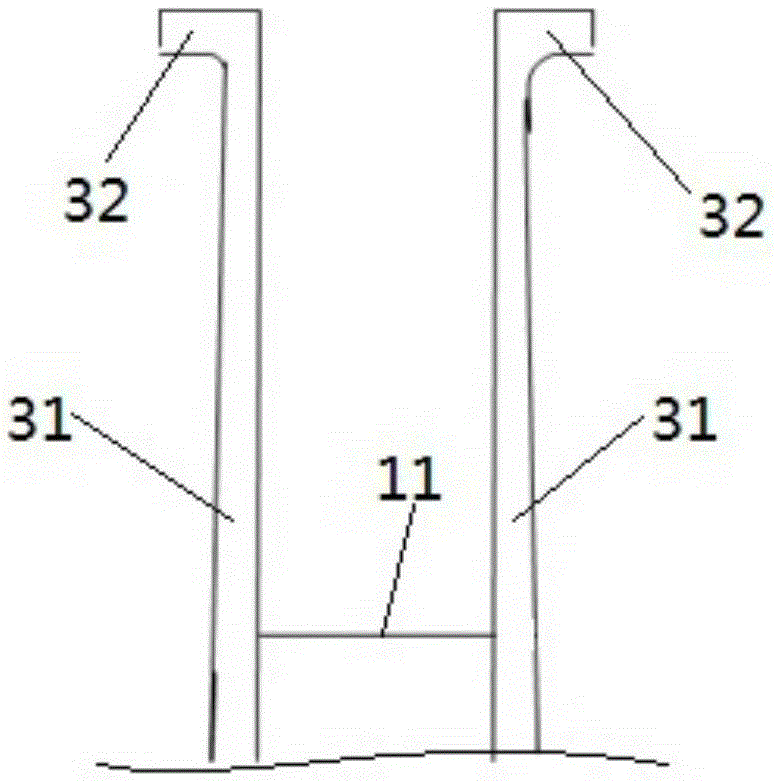

[0037] A kind of device that solves double-sided solar cell silicon nitride coating wrapping plating, such as figure 1 As shown, it includes a graphite frame 1, several support hooks 2, stop rods 3 and gaskets arranged on the graphite frame 1. Wherein support hook comprises support hook body 21 and hook body 22, as figure 2 As shown, the support hook body 21 is U-shaped, and the two free ends of the top are turned outward by 90° to form a support hook protrusion 24. The bottom is straight, and the two sides are respectively connected to the hook body 22. The hook point 23, the distance from the hook point 23 to the bottom of the support hook body 21 is 4.5mm, the transition at the hook point 23 is smooth, and the bottom of the hook body 22 of the support hook 2 has a suitable rounded corner, so that the hook point and the support hook body 21 The distance is appropriate, so that the hook body 23 is not too close to the edge of the silicon chip 4 or the hook point 23 is too c...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, except that the hook point 23 is flush with the lower surface 11 of the graphite frame in this embodiment.

Embodiment 3

[0047] This embodiment is basically the same as Embodiment 1, except that the hook point 23 is set 1 mm above the lower surface 11 of the graphite frame in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com