PCB manufacturing method and PCB

A PCB board and manufacturing method technology, which is applied in the manufacture of printed circuits, the formation of electrical connection of printed components, and the electrical connection of printed components, etc. The problem of unstable electrical connection between the pin and the internal copper layer of the non-plug hole can improve the accuracy of judgment, improve product reliability, and increase the area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

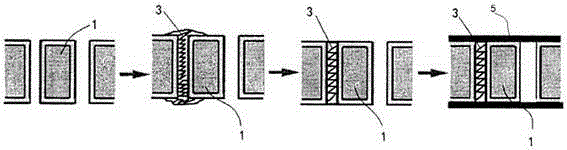

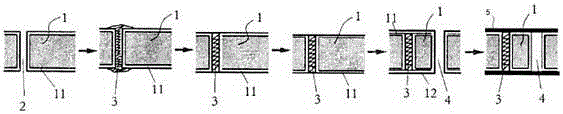

[0047] The present embodiment provides a kind of manufacturing method of PCB board, such as figure 2 shown, including the following steps:

[0048] 1) Take the substrate 1, and drill the plug hole 2 on the substrate 1;

[0049] 2) Perform the first electroplating on the substrate 1, so as to plate the first copper layer 11 on the surface of the substrate 1, and plate copper on the inner wall of the plug hole 2;

[0050] 3) Use an aluminum sheet with a through hole, then fix the aluminum sheet on the substrate 1, and make the through hole correspond to the plug hole 2, then place the resin 3 on the aluminum sheet, use a scraper on the aluminum sheet with a certain pressure and The speed is scraped back and forth, so that the resin 3 on the aluminum sheet is filled into the plug hole 2 until the resin 3 protrudes from the orifice of the plug hole 2; during this process, the viscosity of the resin 3 is controlled to 400psi, and the blade The pressure is 4Kg / cm 2 , the speed i...

Embodiment 2

[0065] This embodiment provides a method for making a PCB board, which is an improvement on the basis of Embodiment 1, and the difference is that it includes the following steps:

[0066] In the above step 4), the above-mentioned first copper layer 11 is subjected to material reduction treatment, and the part of the resin 3 protruding from the above-mentioned first copper layer 11 due to the material reduction treatment is subjected to material reduction treatment again, so that the resin 3 protrudes The surface of the opening of the plug hole 2 is again flush with the surface of the first copper layer 11 in height.

[0067] The advantage of the manufacturing method of the PCB board provided in this embodiment is that since the manufacturing method of the PCB board provided in Embodiment 1 needs to perform copper plating on the surface of the substrate 1 twice, the first copper layer 11 is plated in step 4). The material reduction treatment can avoid plating an excessively thi...

Embodiment 3

[0070] This embodiment provides a PCB board, which is manufactured by the manufacturing method described in Embodiment 1 or Embodiment 2.

[0071] The PCB board provided by this embodiment is made by using a specific manufacturing method, so it has all the advantages brought by the above-mentioned specific manufacturing method at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com