Spring clamping piece and carrier device of elastic clamping silicon slice

A technology of spring clips and shrapnel, applied in the direction of climate sustainability, gaseous chemical plating, coating, etc., can solve the problems of low output per unit time, low production cost, pinholes in the film, etc., and achieve back passivation , Guarantee the demand for mass production, and avoid the effect of coiling and plating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

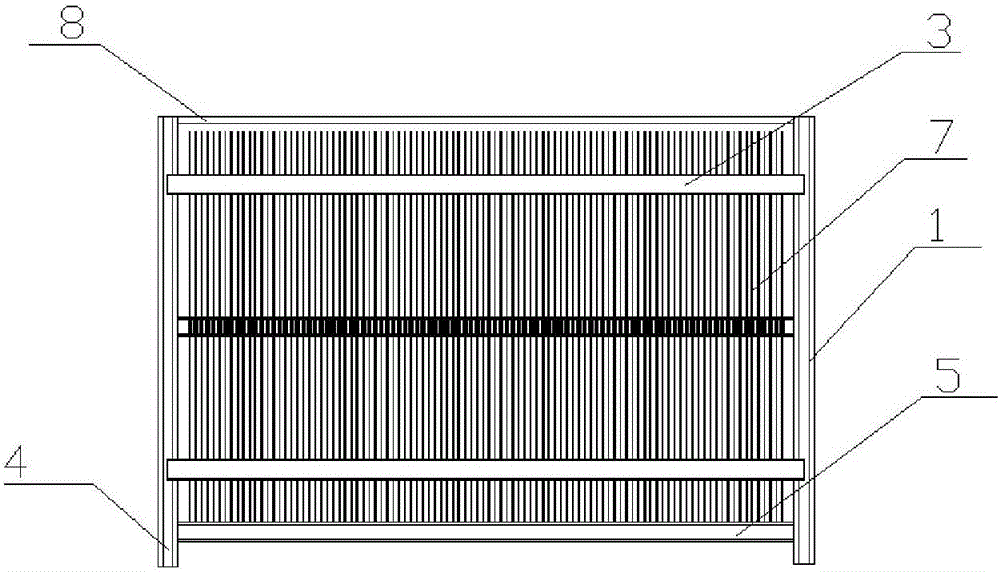

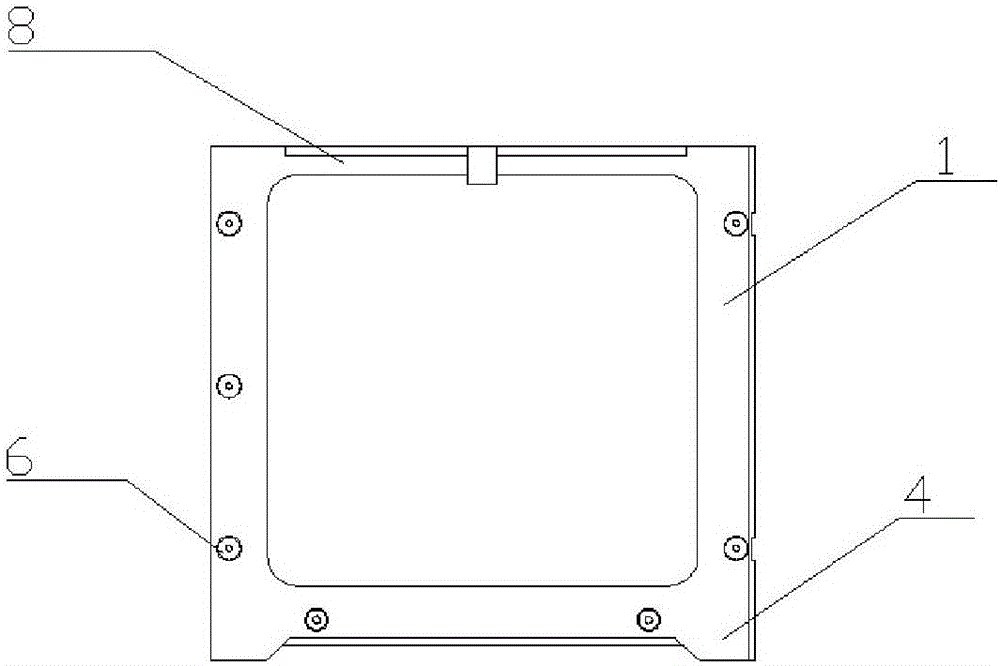

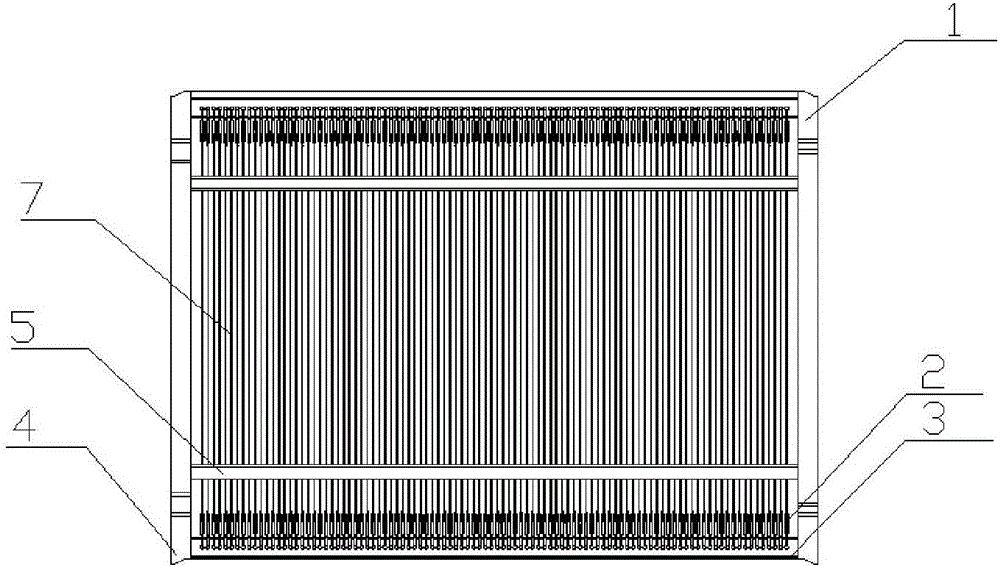

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 4 As shown, the spring clip 2 is composed of a connecting end and a pair of elastic pieces extending outward from the connecting end, the two elastic pieces are arranged opposite to each other, and the elastic pieces are close to each other on the side away from the connecting end to form a clamping portion 10; The elastic pieces approach each other along a certain arc in the clamping portion and the part with the smallest distance is not at the end of the elastic piece. The end of the clamping portion has a curved arc concave toward the middle of the two elastic pieces, and the silicon chip 7 is clamped in the clamping portion.

[0034] A clamping portion 9 is provided on the connecting end of the elastic piece close to the spring clip 2 , and the clamping portion 9 is clamped to the base 3 .

[0035] Such as Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com