Barrier mechanism

A bearing mechanism and hollow technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of reduced production efficiency, uneven thickness of the coating layer on the surface of the lens, etc., and achieve the effect of uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The carrying mechanism described in the present invention is suitable for coating or transporting the lens, and it is connected to a vacuum pump through a valve.

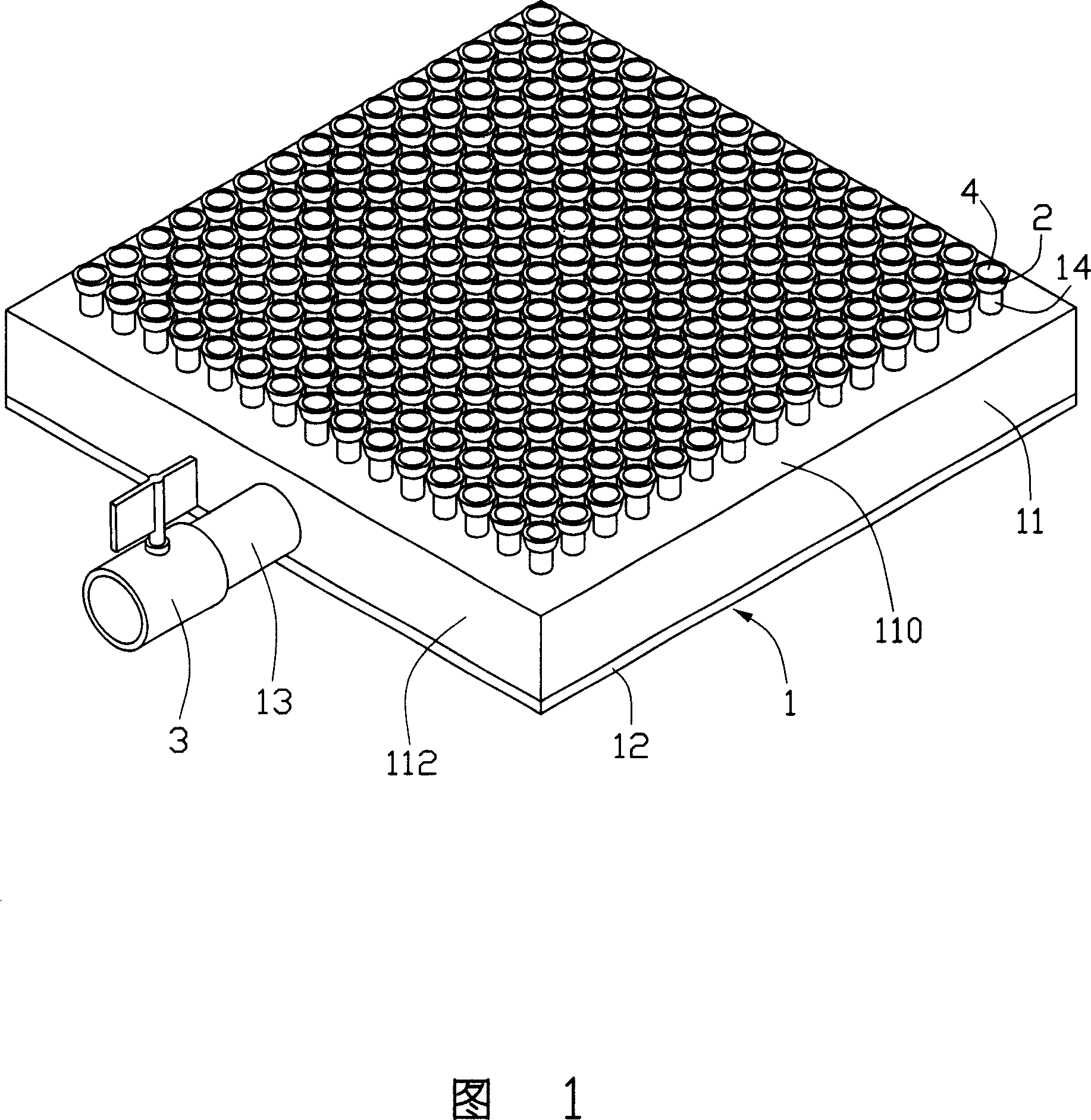

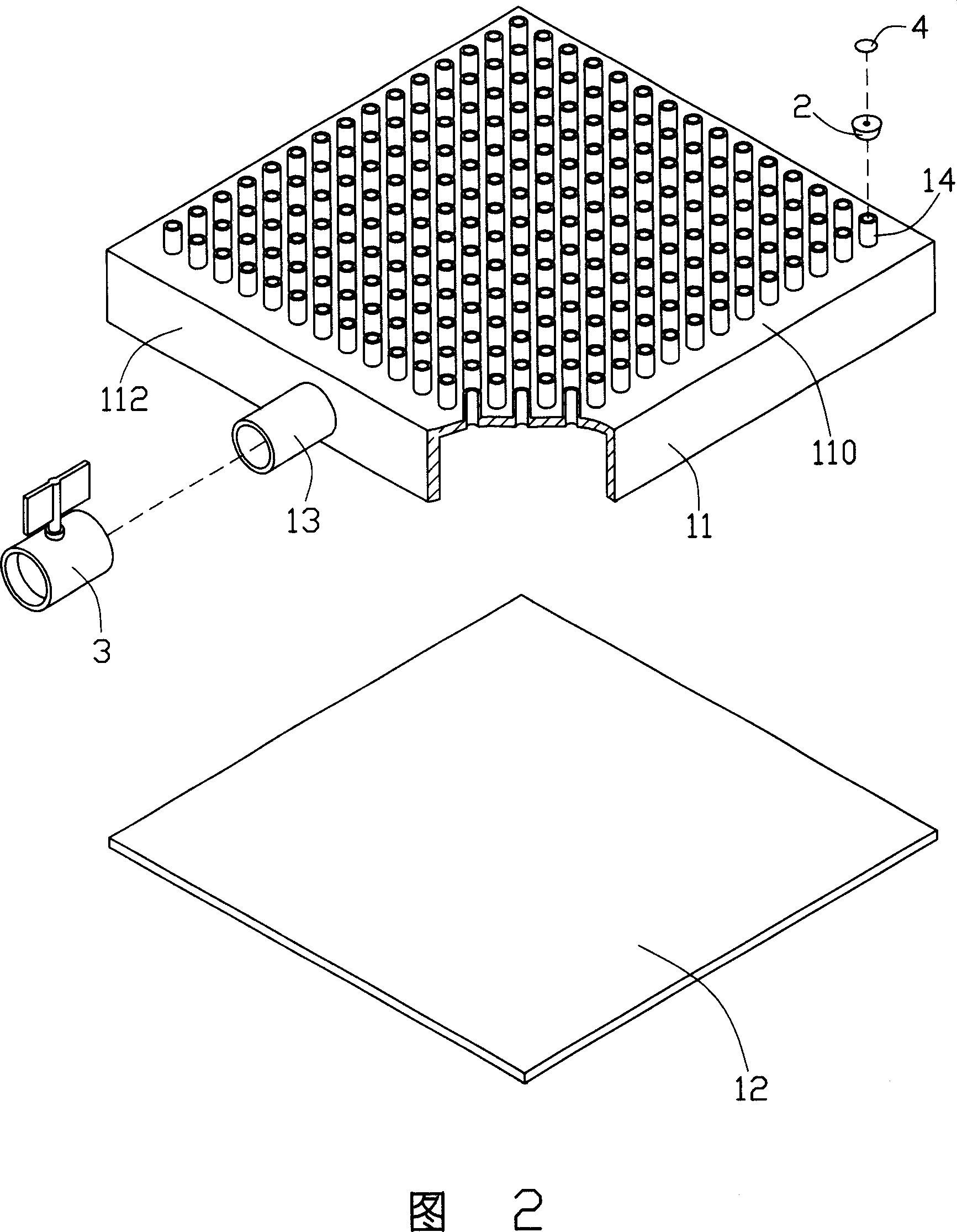

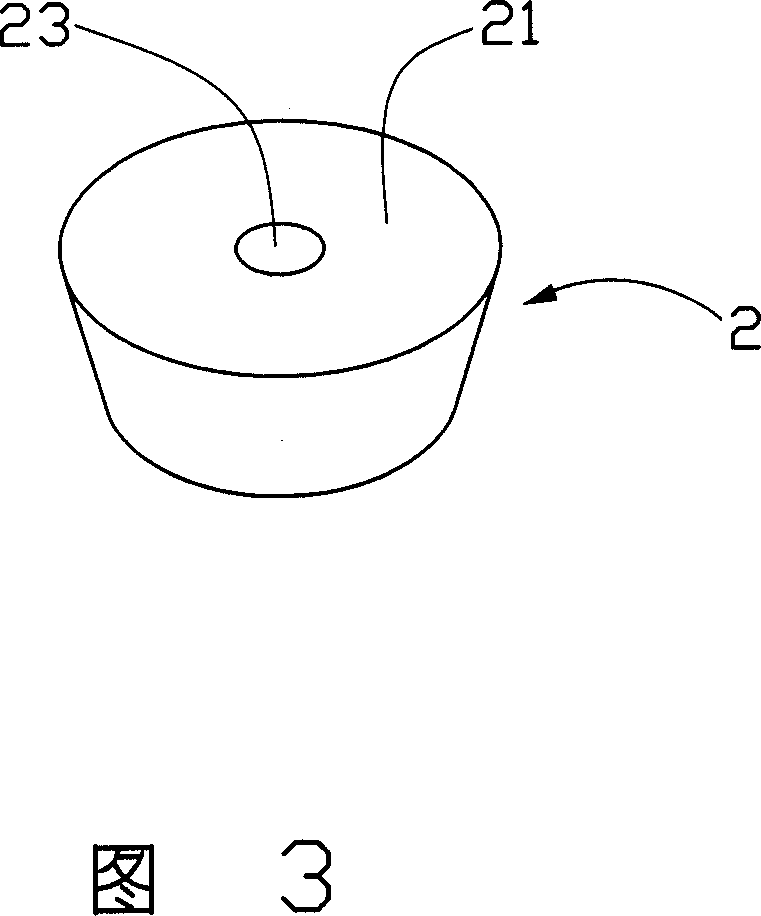

[0013] Please refer to FIG. 1 , the carrying mechanism described in the preferred embodiment of the present invention includes a hollow box body 1 and a plurality of suction heads 2 .

[0014] Please also refer to FIG. 2 , the hollow box 1 includes a body 11 , a cover 12 , an air outlet 13 and a plurality of suction nozzles 14 . The main body 11 is a semi-closed metal box structure, which has a working surface 110 and a side surface 112 adjacent to the working surface 110 . The cover 12 is a metal plate, which is welded together with the main body 11 to form a closed metal box, and a hollow cavity is formed between the main body 11 and the cover 12 . The air inlet 13 is a tubular body, which is disposed on the side surface 112 and communicates with the hollow space between the body 11 and the cover 12 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com