Semiconductor electroplating clamping steel strip

A technology of semiconductors and steel strips, applied in semiconductor devices, circuits, electrolysis processes, etc., can solve problems such as poor conductivity and waste of liquid medicine, achieve stable current, avoid contact, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

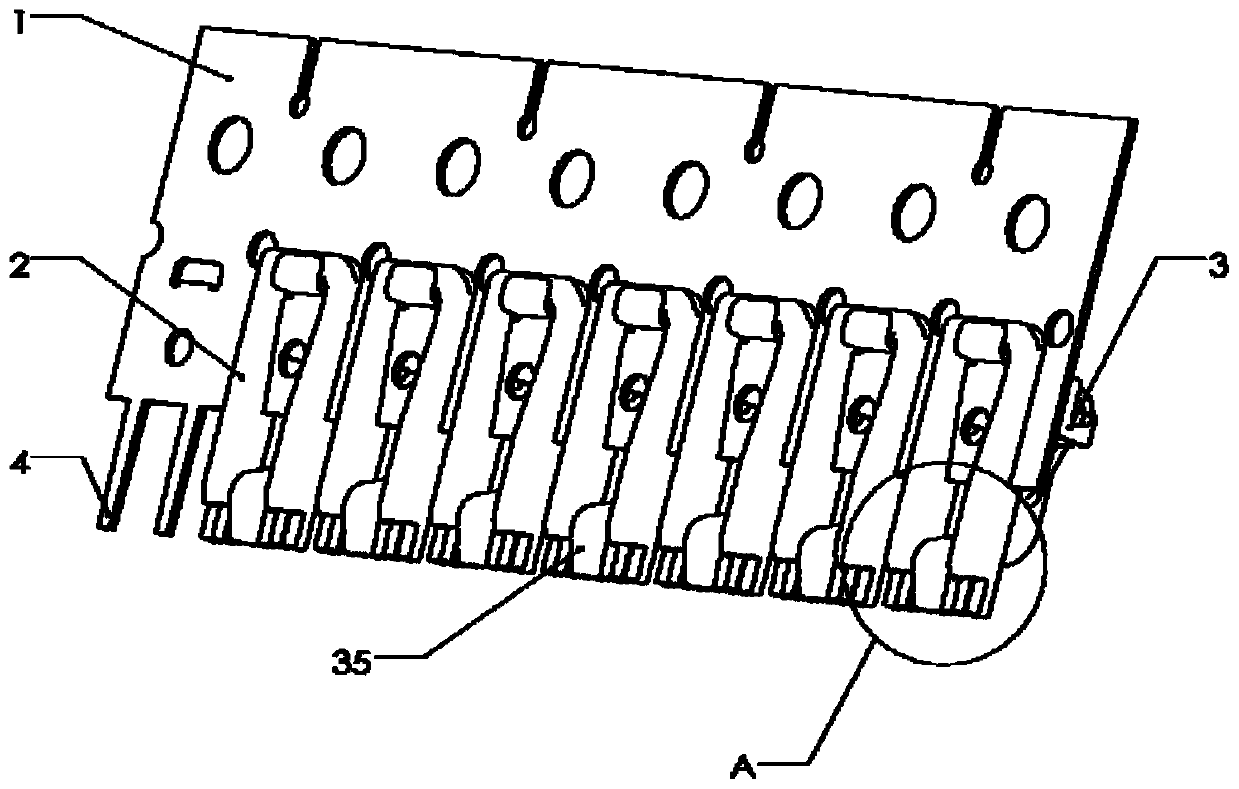

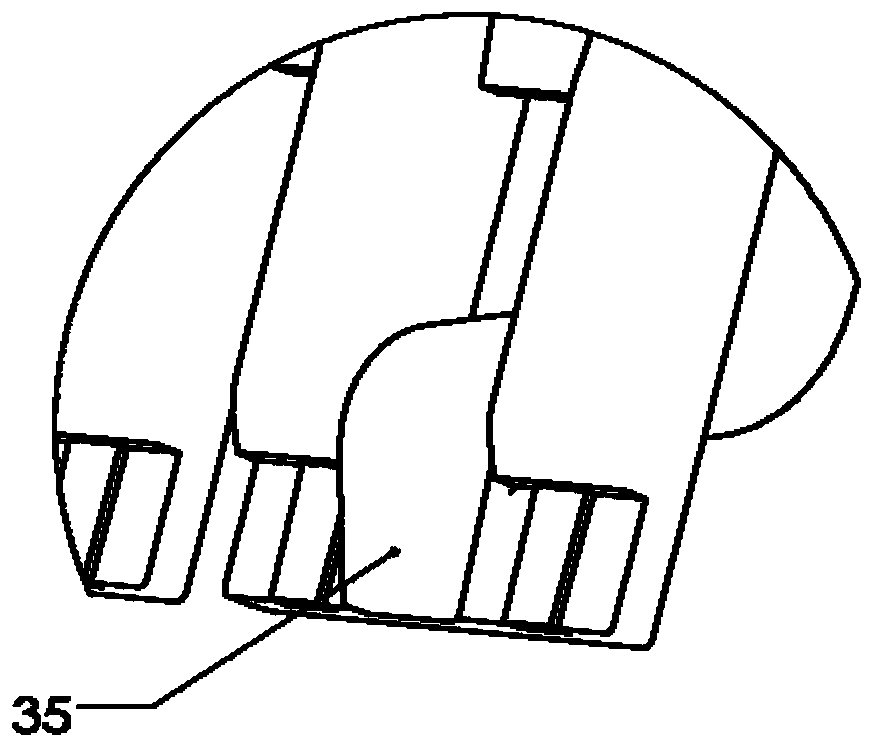

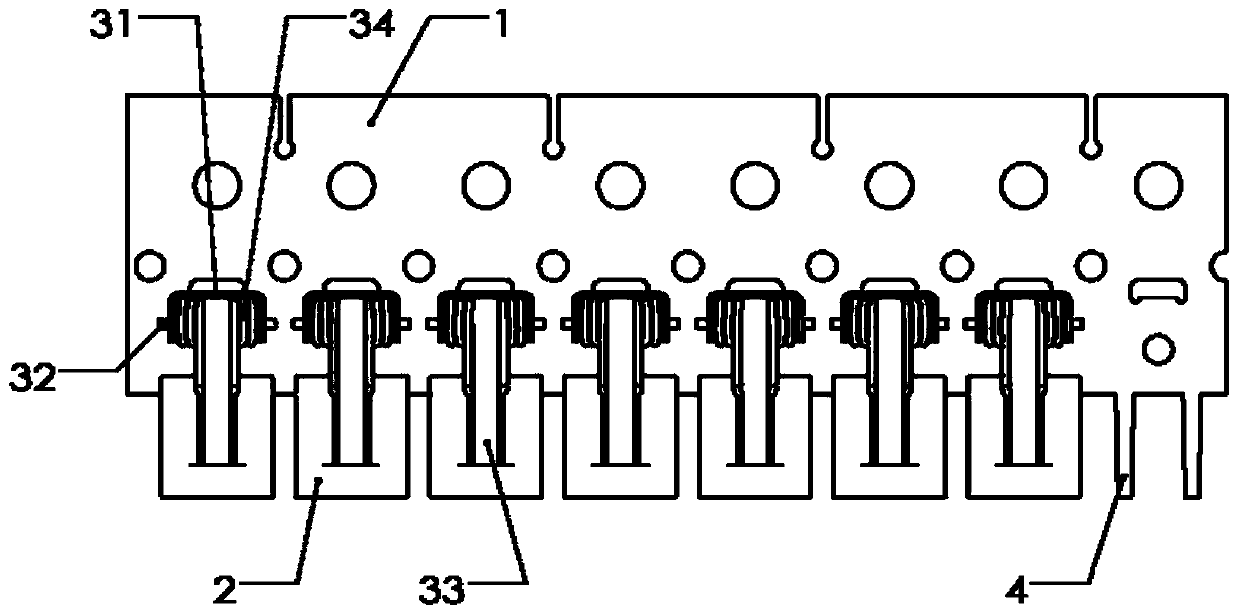

[0049] like Figure 1 to Figure 9 As shown, this embodiment is a basic embodiment of the present invention, which discloses a semiconductor electroplating clamping steel strip, the specific structure is as follows figure 1 , figure 2 and Figure 5 As shown, it includes a steel strip body 1, an insulating bracket 2 and a fixing clip 3, and the insulating bracket 2 is made of an insulating material resistant to electroplating liquid corrosion, such as engineering plastics; the steel strip body 1 is provided with a mounting hole, and the fixing clip The bottom of 3 is inserted into the mounting hole, thereby fixing the clip seat 31 on the steel strip body 1; the clip seat 31 is fixedly provided with a connecting shaft 32, and the middle part of the connecting shaft 32 is connected with a splint 33 through a rotating pair, and the splint The two sides of 33 are respectively connected with the inner side of the corresponding holder 31 by a torsion spring 34;

[0050] The insula...

Embodiment approach 2

[0052] like Figure 10 ~ Figure 18 As shown, this embodiment, as a preferred embodiment of the present invention, discloses a semiconductor electroplating clamping steel strip, its specific structure includes a steel strip body 1, an insulating support 2 and a fixing clip 3, and the fixing clip 3 Transformed by a torsion spring, a connecting rod 36 is provided in the middle of the fixing clip 3, and a mounting hole is provided on the steel belt body 1, and the connecting rod 36 is inserted into the mounting hole to fix the fixing clip; while the insulating bracket 2 One end of the steel belt body 1 is provided with a mounting groove 5 adapted to the steel strip body 1, and the opposite end of the mounting groove 5 is provided with a clamping surface 6; the insulating bracket 2 is also provided with a connecting hole, and the connecting hole can be provided with 2- 4, one end of the connecting hole communicates with the bottom surface of the installation groove 5, and the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com