Reinforced aluminium alloy compressive cable

An aluminum alloy, reinforced technology, used in insulated cables, bendable cables, cable/conductor manufacturing, etc., can solve problems such as poor cable bearing performance, cable core damage, increased laying cost and time, etc., to reduce The effect of cable weight, high mechanical strength, and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings.

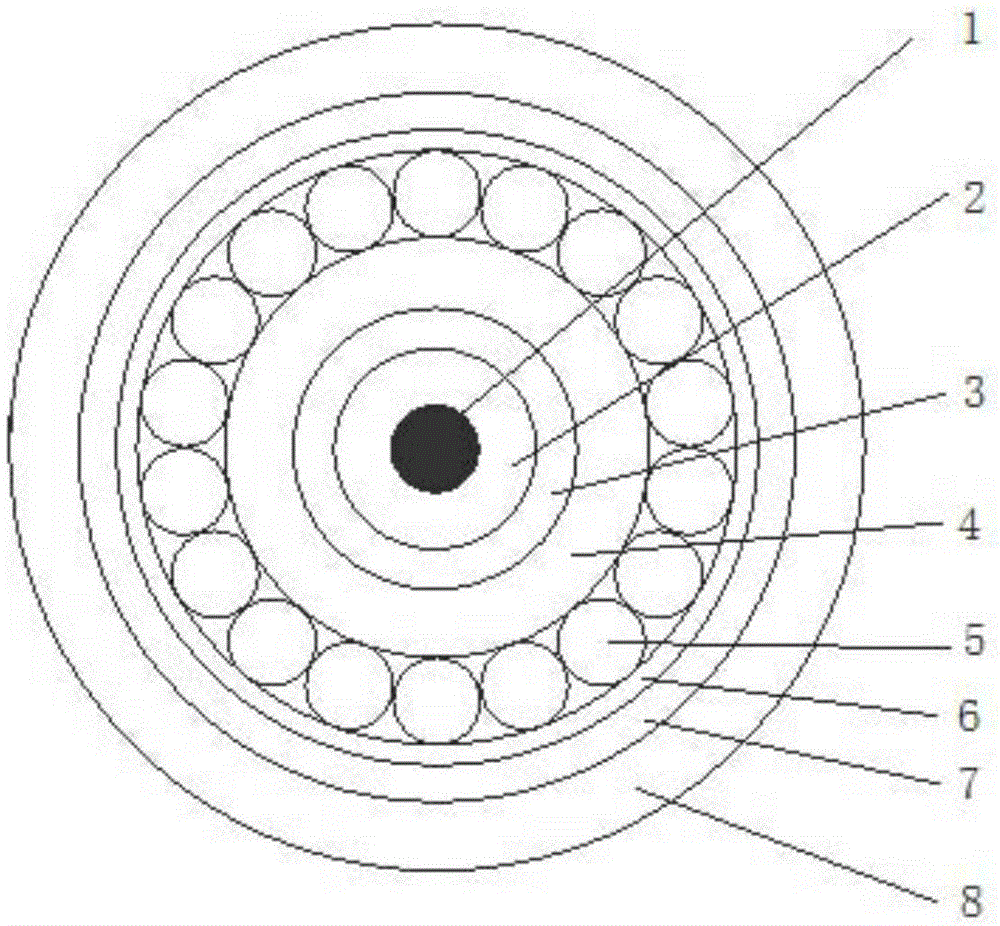

[0017] Such as figure 1 As shown, a reinforced aluminum alloy compression cable of the present invention includes a tubular aluminum alloy conductor 3, and a carbon fiber composite reinforcing core 1 is arranged at the center of the tubular aluminum alloy conductor 3, so that the tensile strength of the aluminum alloy cable itself is increased to The copper conductors of the same cross-section are fairly level, which effectively solves the problem of the cable being broken; a thin copper strip 2 is provided between the carbon fiber composite reinforcing core 1 and the tubular aluminum alloy conductor 3; an insulating layer is extruded outside the tubular aluminum alloy conductor 3 4. A single wire layer formed by winding multiple conductive single wires 5 in parallel is wound outside the insulating layer 4; a buffer layer 6 and an outer sheath 8 are wrapped around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com