Plugging effect evaluation method for low-aperture low-permeability formation

An evaluation method and technology of holes and slits, applied in earthwork drilling, wellbore/well parts, etc., can solve the problems of inaccurate evaluation results, poor repeatability, complicated operation, etc., and achieve low cost, short time consumption and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] This example is used to illustrate the plugging effect evaluation method for low porosity, fracture and low permeability formations of the present invention.

[0155] (1) Preparation of "simulated core" of low porosity, fracture and low permeability formation

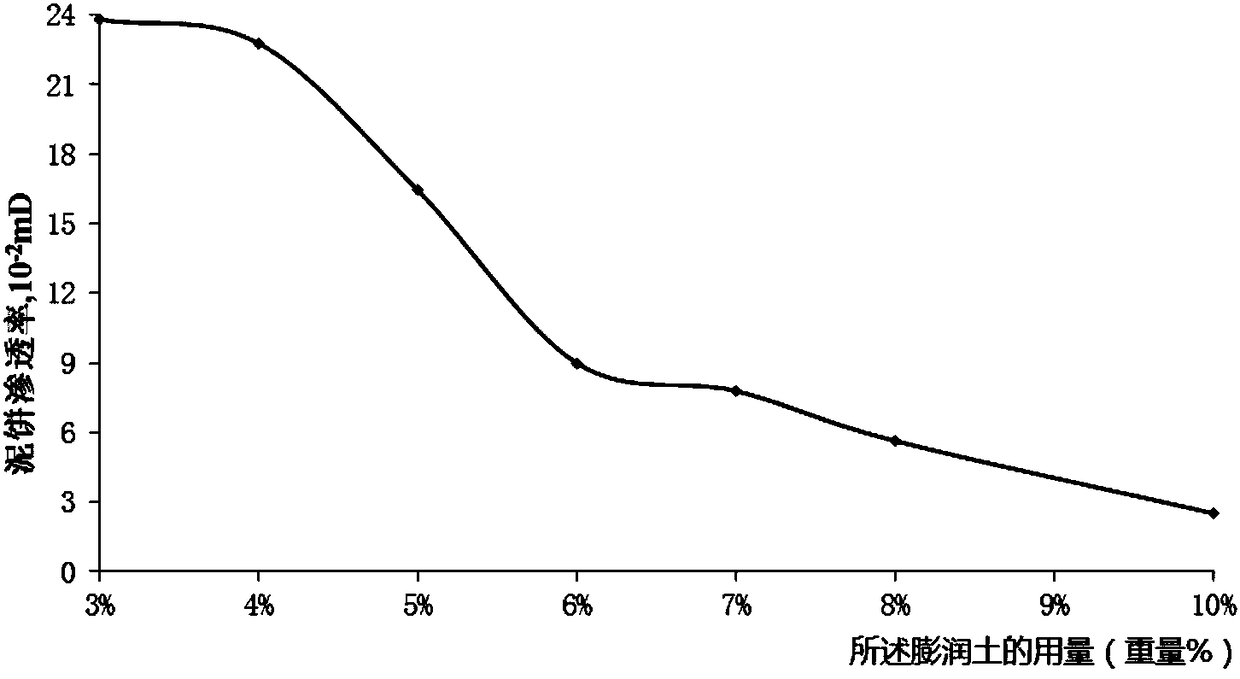

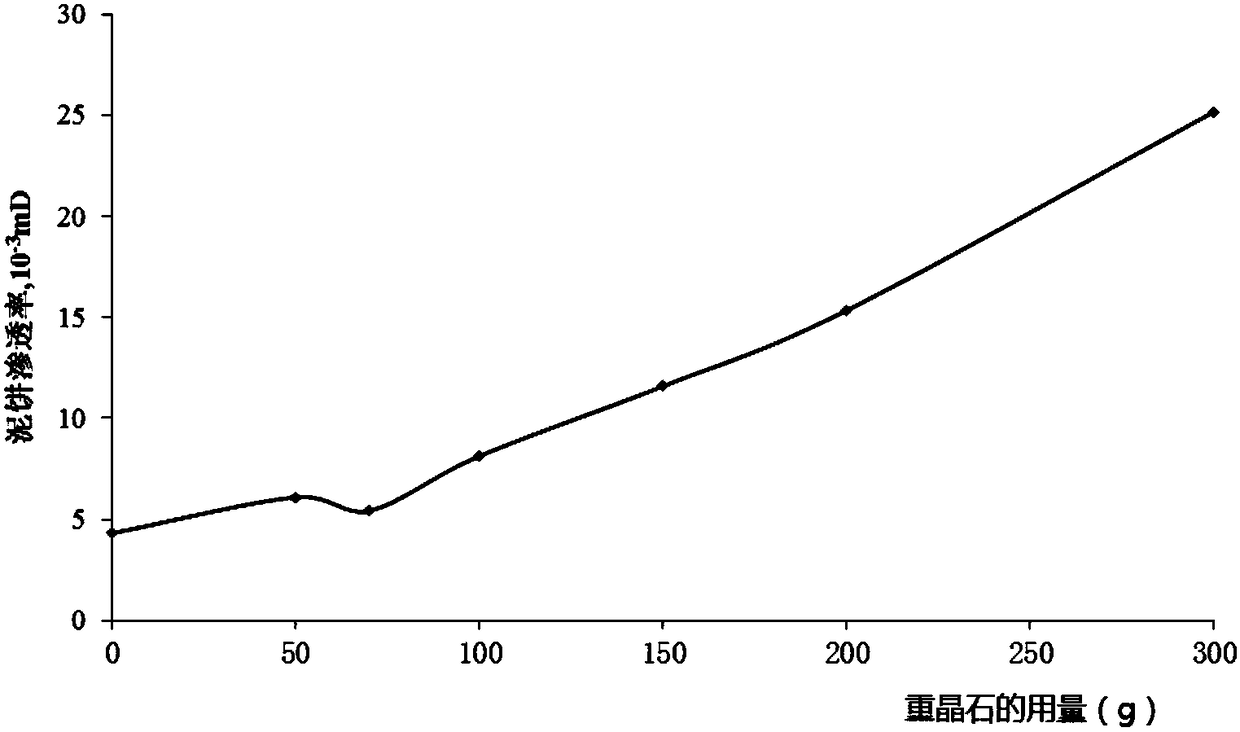

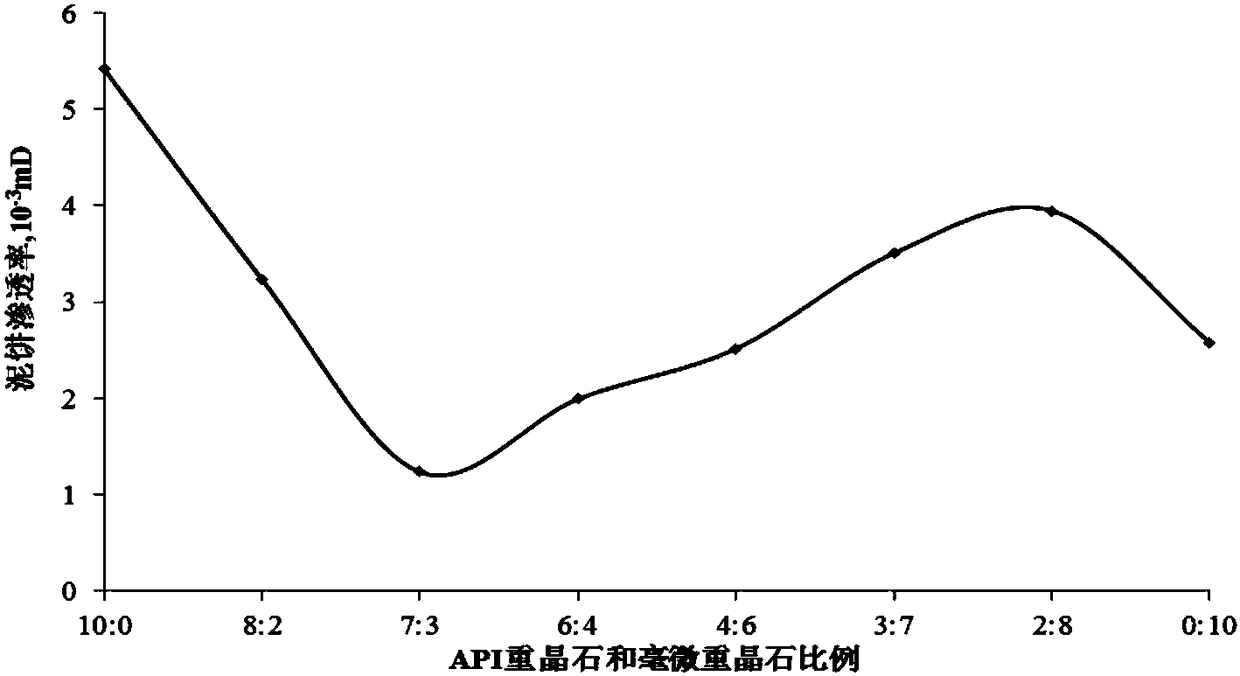

[0156] Measure a certain volume of 10% prehydrated bentonite slurry (10% bentonite + 5% Na 2 CO 3 ) into an enamel cup, add 1.5% SXY while stirring with a D96 electric mixer, and after stirring for 40 minutes, pour it into a high-temperature aging tank, seal and hydrate at 60°C for 24 hours, take it out and cool it to room temperature, and pour it into an enamel cup while stirring While adding 0.5% FV-2, continue to stir until there is no "fish eye" (about 40min), then add 70g of barite (API barite: nanobarite = 7:3), and stir for 40min , put it into the aging tank, and roll it under the condition of 105°C / 16h to prepare the standard slurry for plugging evaluation.

[0157] Cool the standard slurry to room tem...

Embodiment 2

[0174] This example is used to illustrate the plugging effect evaluation method for low porosity, fracture and low permeability formations of the present invention.

[0175] Evaluate according to the same method as in Example 1, the difference is that the formulation of the drilling fluid containing the plugging agent is: zwitterionic polymer system b: zwitterionic polymer system a+plugging agent YFD-1 ( blocking agent).

[0176] Permeability reduction rate K of drilling fluid containing plugging agent r and K 0 and K 1 As shown in Table 1.

Embodiment 3

[0178] This example is used to illustrate the plugging effect evaluation method for low porosity, fracture and low permeability formations of the present invention.

[0179] Evaluate according to the same method as in Example 1, except that the formula of the drilling fluid containing the plugging agent is: amphoteric potassium-based polyalcohol system a: 4% soil slurry+0.2%FV-2+0.3 %FA 367 +1.6%JT 888 +33%KCOOH+0.1%XY 27 +0.05%CaO+5.0%CaCO 3 +2.0% RH-220.

[0180] Permeability reduction rate K of drilling fluid containing plugging agent r and K 0 and K 1As shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com