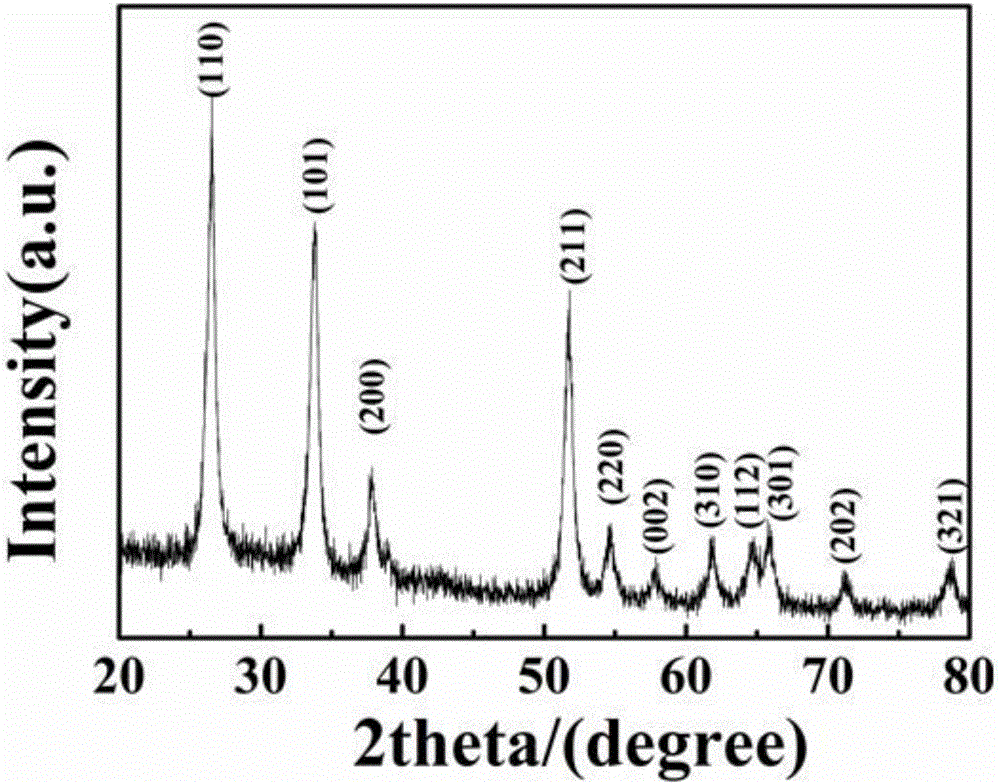

Gas-sensitive material for detecting formaldehyde gas and preparation method

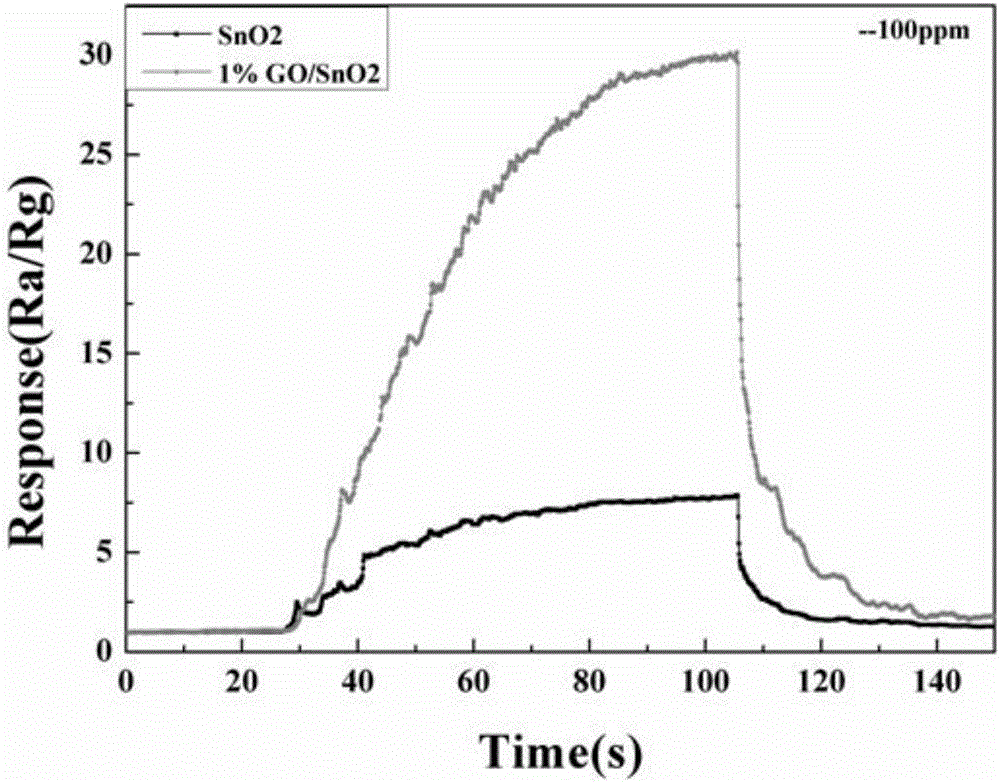

A gas-sensitive material and formaldehyde gas technology, applied in analytical materials, measuring devices, instruments, etc., can solve the problems of gas-sensitive material sensitivity, poor selectivity and stability, and achieve low cost, good stability, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

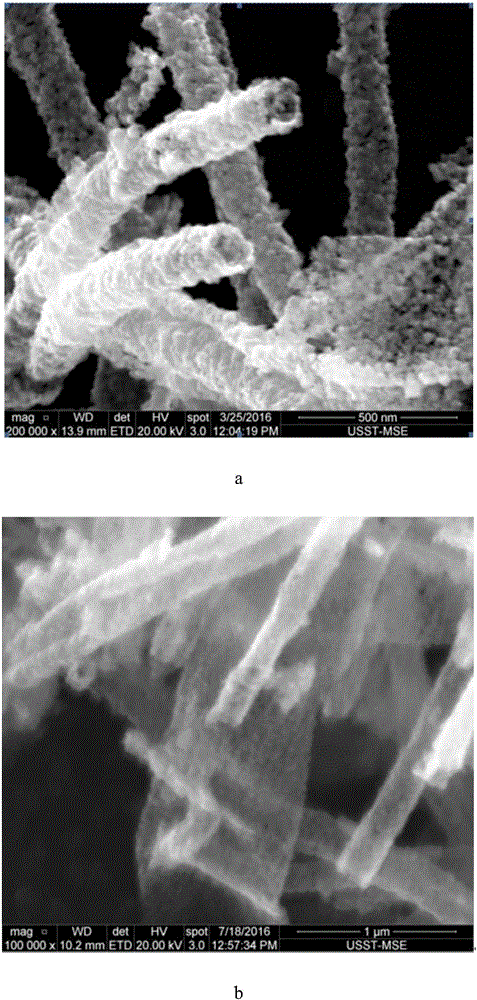

Embodiment 1

[0049] Manufacturing steps of formaldehyde gas sensor:

[0050] a. with SnCl 2 2H 2 O as raw material, take 1.4 g SnCl 2 2H 2 O was dissolved in a beaker containing 5 mL of DMF, added a magnet, placed on a magnetic stirrer, and stirred for 2 h to make the solution transparent. Dissolve 0.6 g of PVP in another beaker containing 4 ml of ethanol, add a magnet, place it on a magnetic stirrer, and stir for 2 h to make it transparent. After the two beakers have been stirred, mix and stir for another 12 h . When complete, collect into a 10 mL syringe for use.

[0051] b. The prepared syringe was put into the electrospinning machine, and the relevant parameters were set as follows: the temperature inside the spinning machine was 40 °C, the relative humidity was 20%, the voltage between the polar plate and the needle tip was 20 kV, and the distance between the polar plate and the needle tip was 20 cm. After spinning, the collected samples were calcined at a heating rate of 2 °C / ...

Embodiment 2

[0057] Embodiment 2: the present embodiment is substantially the same as embodiment 1, and difference is: the massfraction of graphene oxide is 0.5% in the d step.

Embodiment 3

[0058] Embodiment 3: the present embodiment is substantially the same as example 1, and difference is: the massfraction of graphene oxide is 2% in d step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com