Patents

Literature

38results about How to "Wide melting temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

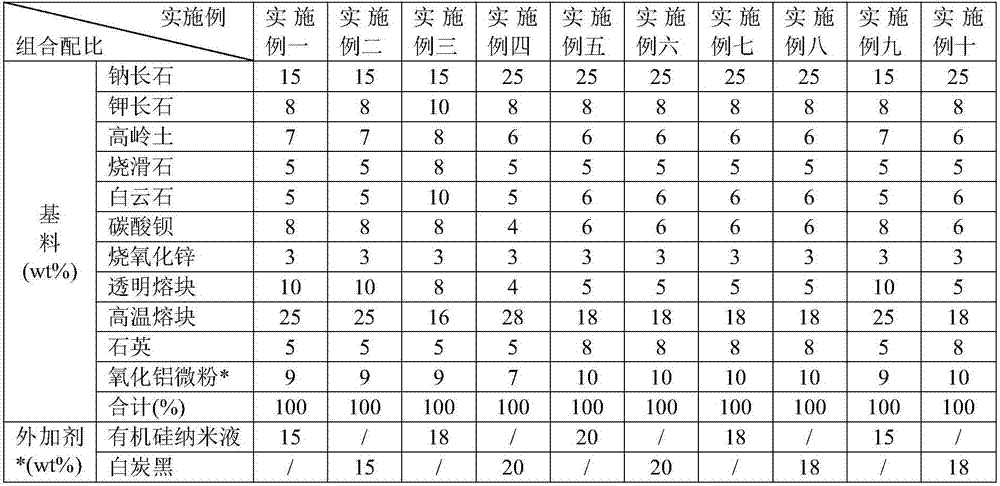

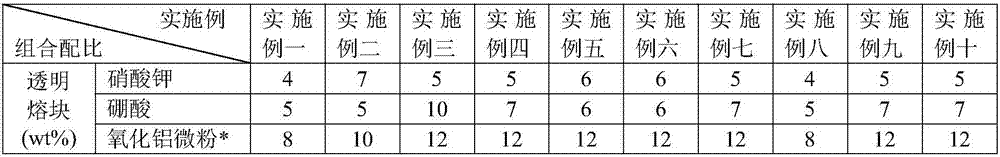

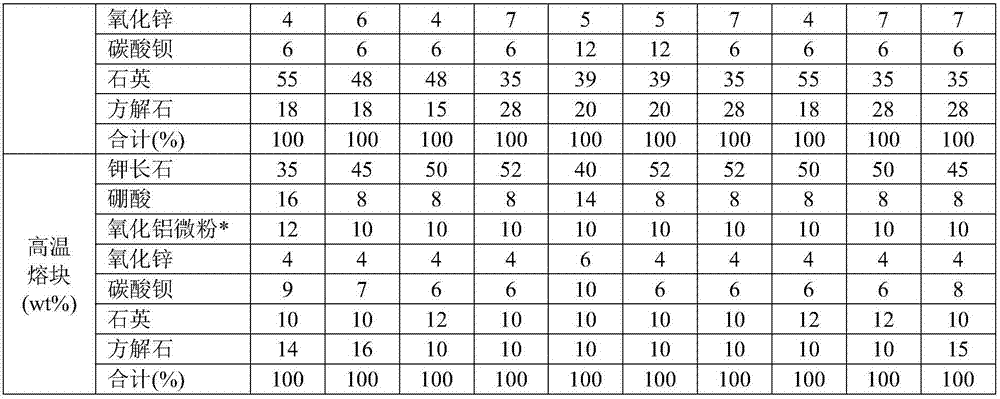

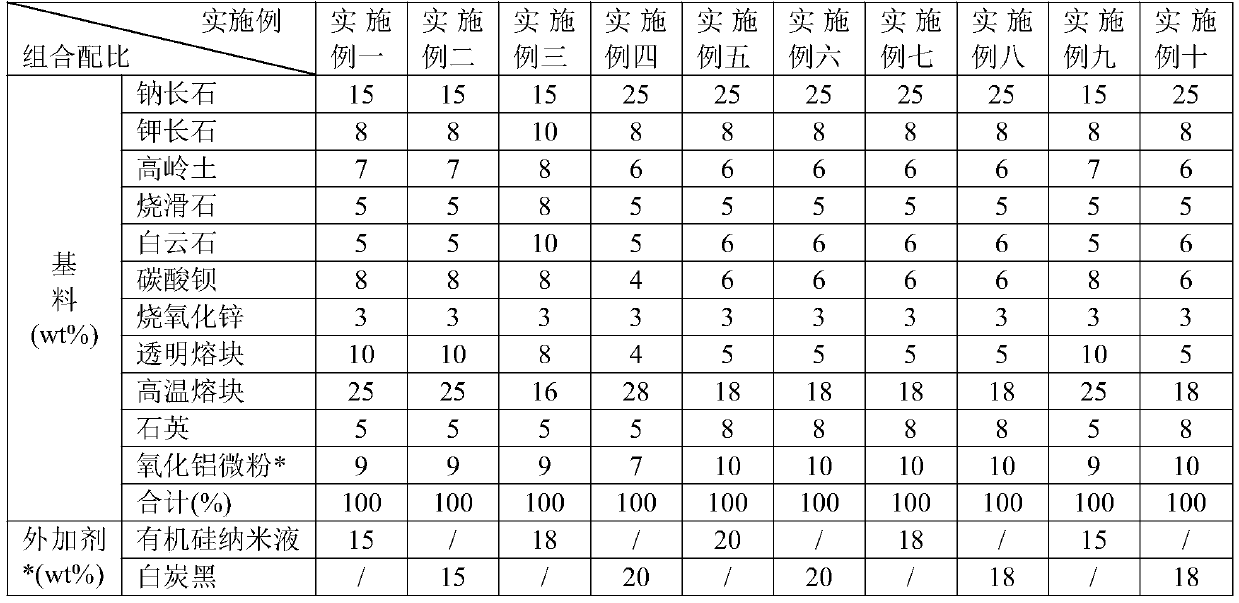

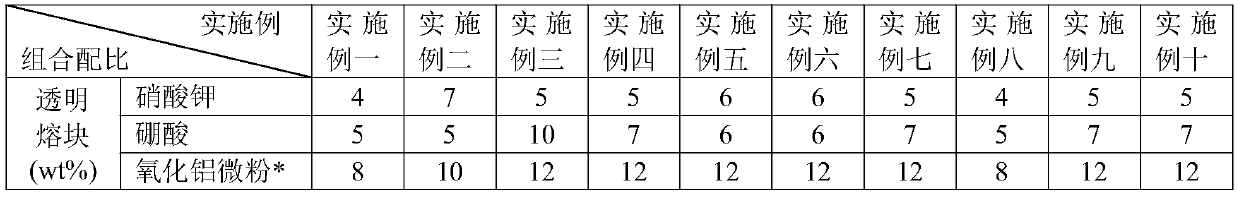

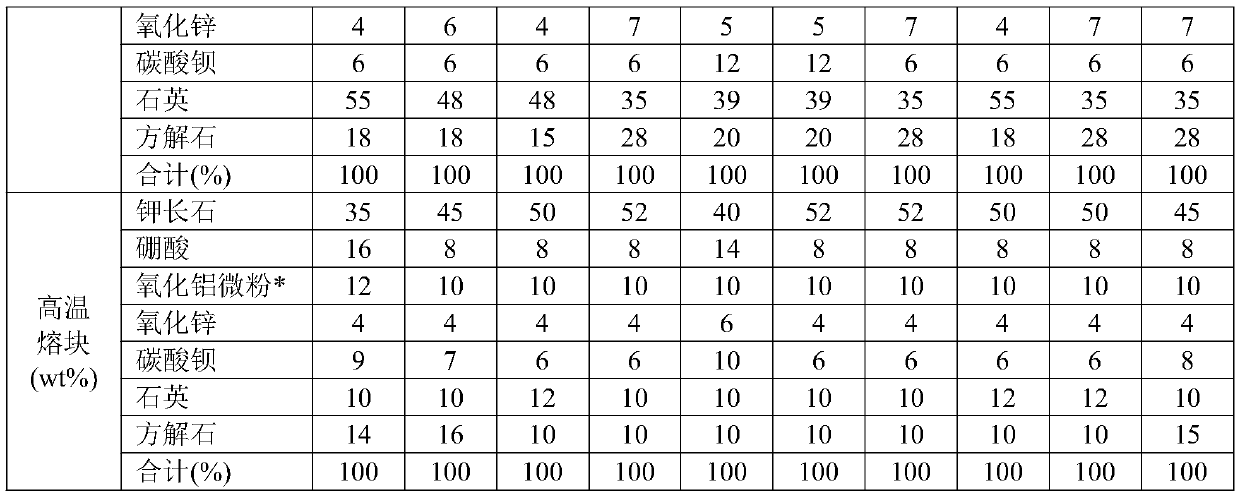

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Raw full-polish glaze with high abrasion resistance and method for preparing raw full-polish glaze

The invention discloses raw full-polish glaze with high abrasion resistance and a method for preparing the raw full-polish glaze. The raw full-polish glaze comprises, by weight, 28-38 parts of potassium feldspar, 4-7 parts of kaolin, 5-10 parts of sintered talc, 5-10 parts of dolomite, 16-22 parts of barium carbonate, 5-8 parts of sintered zinc oxide, 10-18 parts of fused quartz, 3-12 parts of corundum micro-powder, 1-5 parts of lithium-containing mineral and 5-10 parts of additives. The raw full-polish glaze and the method have the advantages that corundum particles and fused quartz particles are led into the raw full-polish glaze, accordingly, the availability of partial original abrasion-resistant particles can be guaranteed, large quantities of anorthite and celsian micro-crystals further can be generated, and the abrasion resistance of glaze surfaces can be improved; the lithium-containing mineral is added into the raw full-polish glaze, and accordingly liquid phases can be generated by the raw full-polish glaze at the low temperatures; lithium element ions have small radiuses, tight glass networks can be formed, and accordingly the abrasion resistance of the glaze surfaces can be improved.

Owner:JIANGSU BAIFU TECH CO LTD

High-performance transparent ceramic whiteware glaze and production method thereof

ActiveCN107162424AImprove thermal shock resistanceHigh melting temperatureMaterials preparationKaolin clay

The invention discloses a high-performance transparent ceramic whiteware glaze and production method thereof, and belongs to the technical field of daily ceramic glazes. The high-performance transparent ceramic whiteware glaze mainly comprises water-milled potassium feldspar, kaolin, calcined talcum, dolomite, barium carbonate, calcined zinc oxide, water-milled quartz, a glaze stabilizer and an expansion coefficient regulator. The production method of the high-performance transparent ceramic whiteware glaze includes the following steps: material preparation, ageing and glaze firing. The high-performance transparent ceramic whiteware glaze produced from the above raw materials has the advantages of high melting temperature, wide melting temperature range of 1290-1330 DEG C, small affection by the fluctuation of the kiln temperature, few pinholes of the glaze surface, bright and smooth glaze surface, adjustable expansion coefficient of the glaze surface, and increase of one stress to the surface of a ceramic body to realize no cracking in the 200-20 DEG C one-shot quick cooling and heating process.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

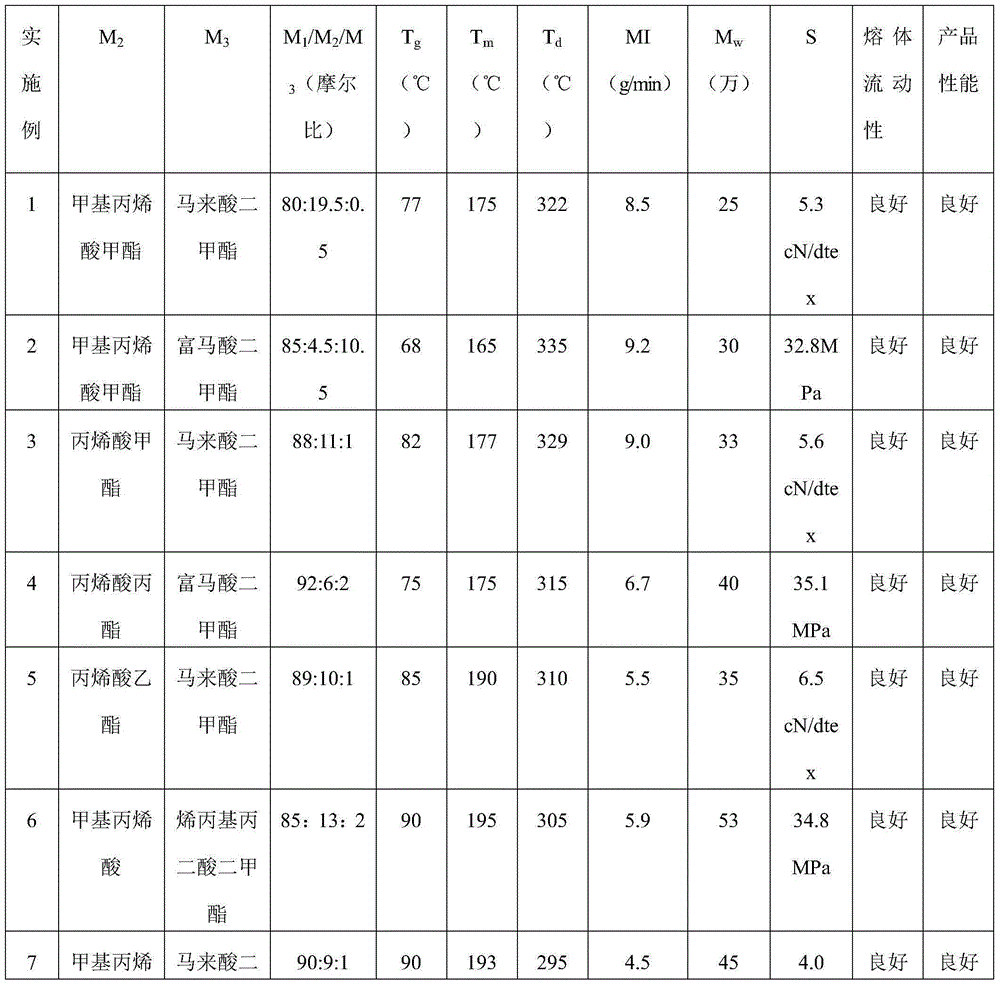

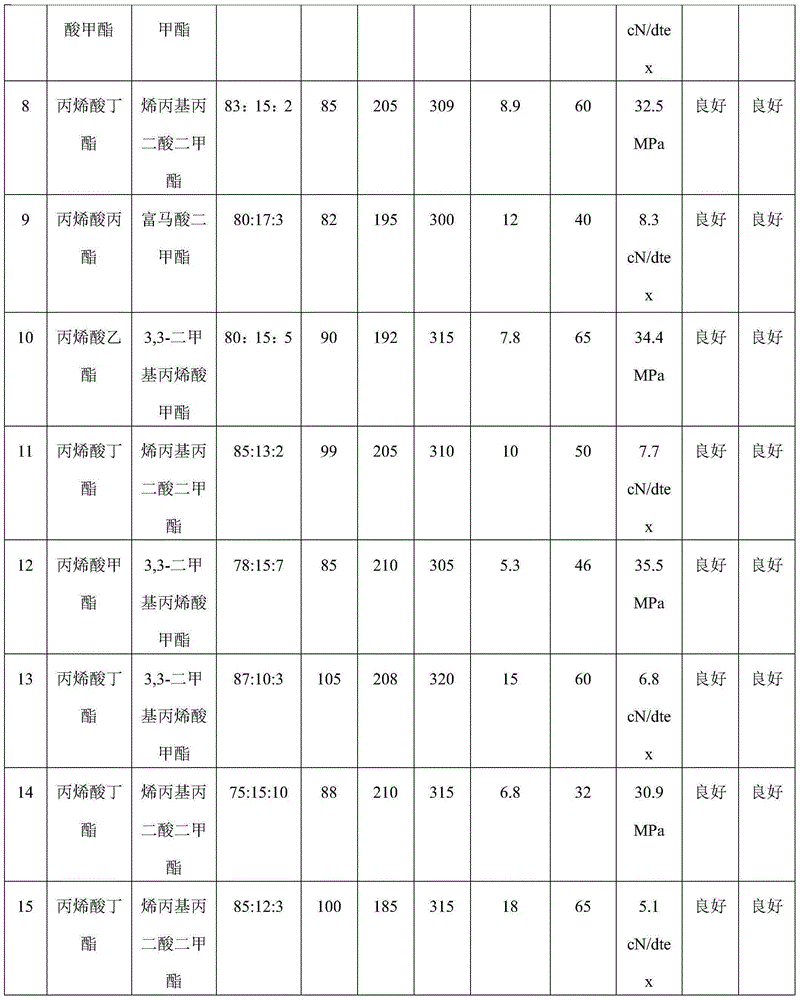

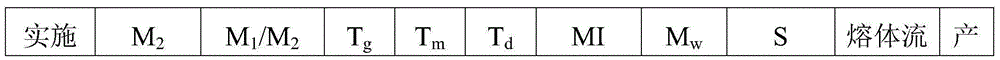

Preparation method and application of thermoplastic acrylonitrile-based terpolymer

ActiveCN105199042AImprove melt fluidityThe polymerization process is simple and easy to controlMonocomponent synthetic polymer artificial filamentThermoplasticPolymer science

The invention discloses a preparation method and an application of a thermoplastic acrylonitrile-based terpolymer. In the preparation method, a selected reactive monomer consists of an acrylonitrile monomer, a second monomer and a third monomer. A method for preparing the thermoplastic acrylonitrile-based terpolymer with the reactive monomer comprises the following steps: adding an emulsifying agent into a reaction container filled with deionized water under an oxygen-free condition; adding a chain transfer agent, an initiator and the reactive monomer; reacting at a temperature being 20 to 90 DEG C for 3 to 16 hours to obtain an emulsion; demulsifying the emulsion and standing; performing suction filtration in vacuum to collect a solid; washing the solid with acetone; washing with the deionized water; finally drying in vacuum to obtain powder, namely, the thermoplastic acrylonitrile-based terpolymer. An obtained product can be directly processed into polyacrylonitrile fibers or a polyacrylonitrile film with a melt spinning method, has high performance, and is low in cost.

Owner:TIANJIN POLYTECHNIC UNIV

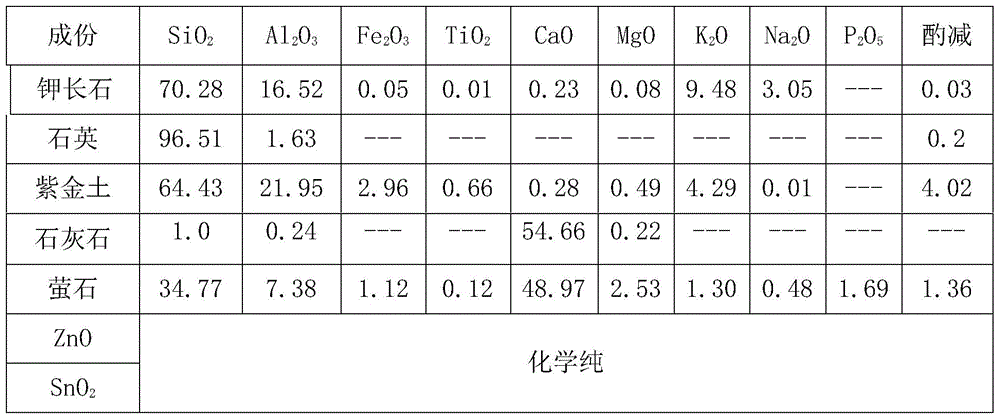

Longquan celadon jasper green glaze, jasper green Longquan celadon and preparation method thereof

ActiveCN105776866AHigh in Calcium OxideEnhance glaze effectClaywaresAlkali feldsparPotassium feldspar

The invention relates to Longquan celadon jasper green glaze, a jasper green Longquan celadon product and a preparation method of the product.The Longquan celadon jasper green glaze is prepared from, by weight, 30-50% of potassium feldspar, 10-20% of quartz, 15-25% of violet gold, 7-13% of limestone, 6-10% of fluorite, 3-5% of ZnO and 2-4% of SnO2, wherein the total percentage of all the ingredients is 100%.On the basis of ensuring the traditional aesthetic effect of Longquan celadon, the violet gold with the high iron content is introduced as a coloring agent, meanwhile, the ZnO and the SnO2 are introduced as emulsion, the Longquan celadon glaze similar to jasper in appearance, color and texture is obtained by adjusting the formula of the glaze, and the purpose of enriching colors and enamels of Longquan celadon is achieved.

Owner:LISHUI UNIV

A low-temperature, high-hardness, high-wear-resistant full-polish glaze and its preparation method

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC UNIV

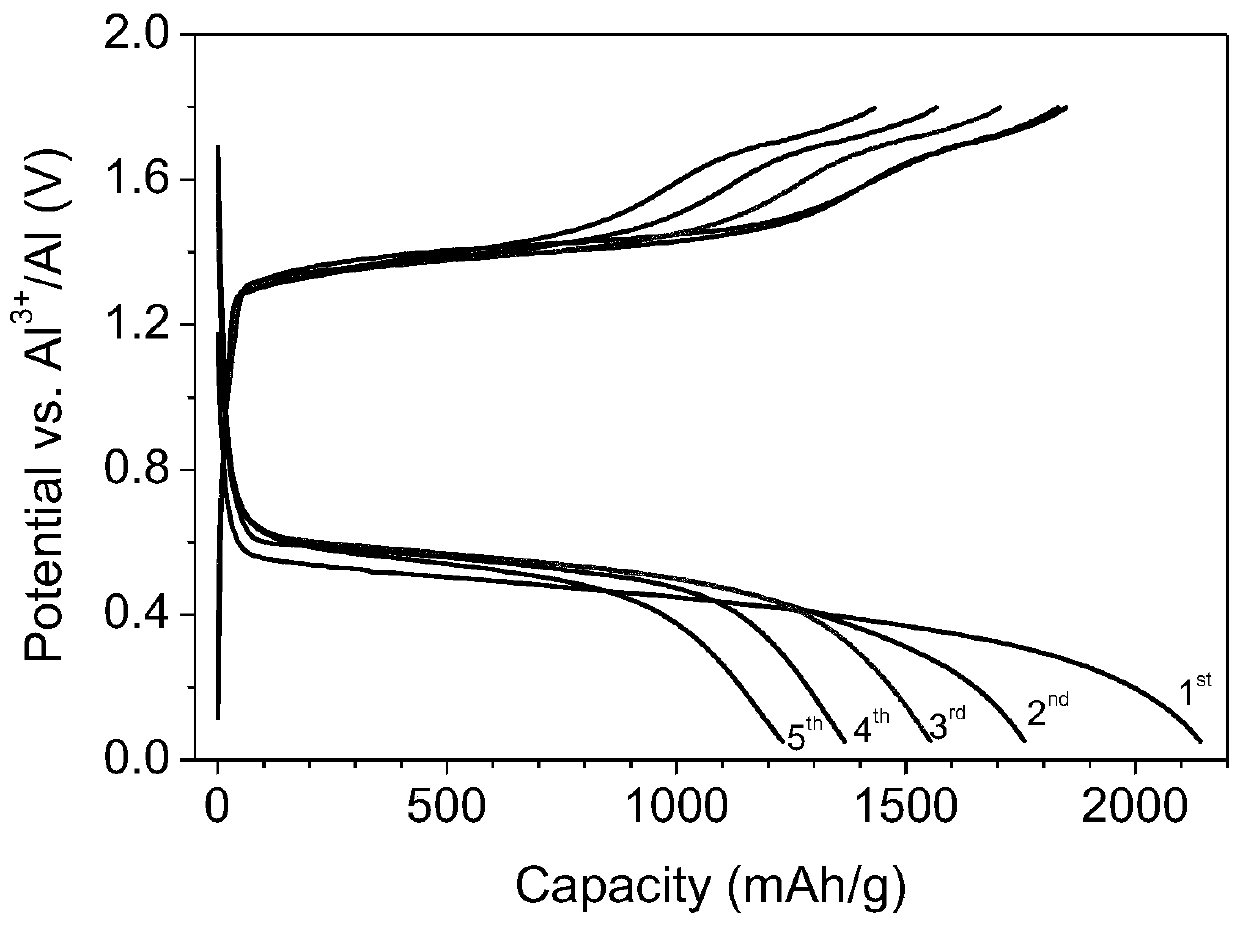

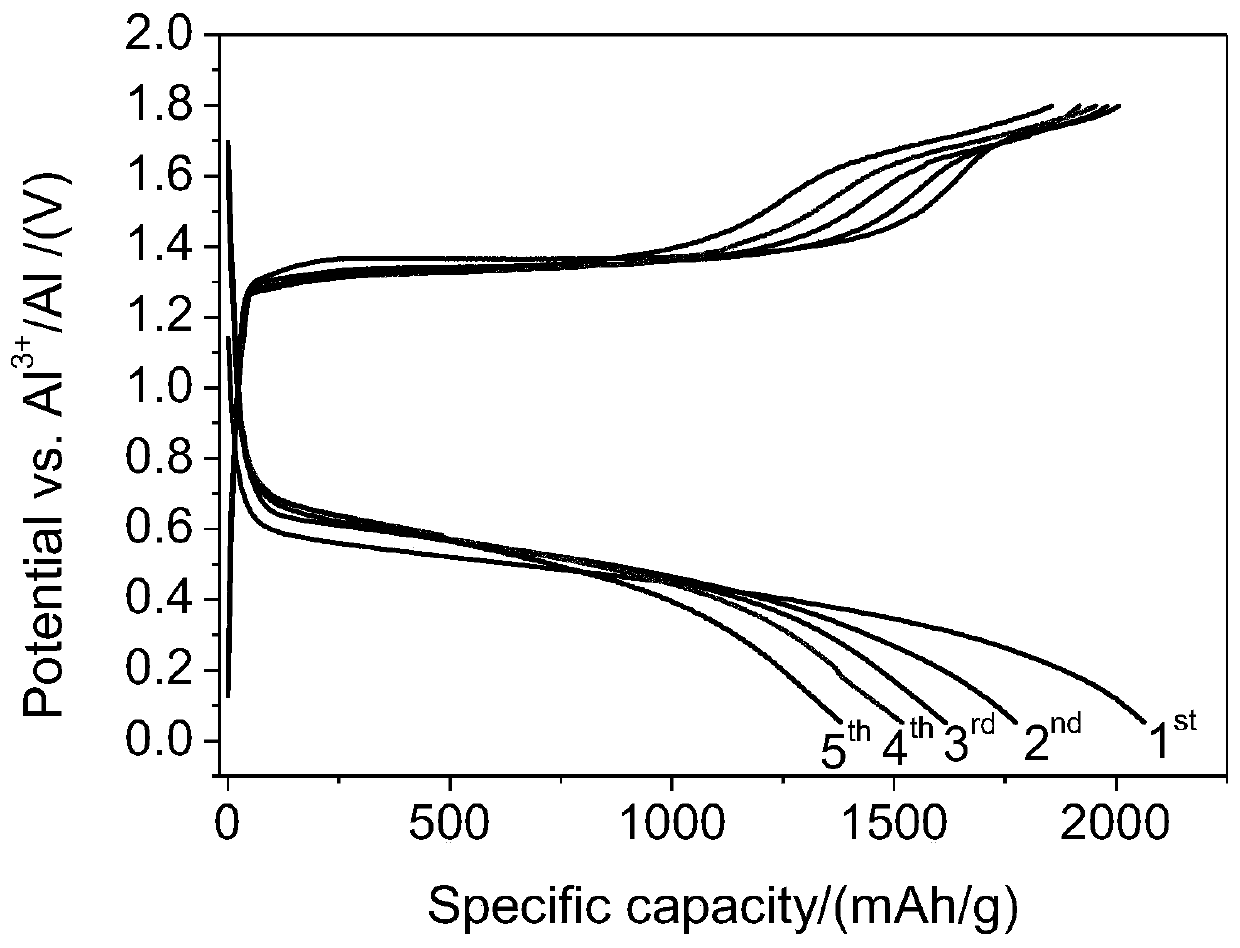

Low-cost aluminum-based electrolyte and aluminum battery application thereof

The invention discloses a low-cost aluminum-containing electrolyte and an application of an aluminum battery thereof, and belongs to the technical field of electrochemical energy storage. Electrolyteis ionic-like liquid of aluminum halide-A and amide compound and an amount of an additive, wherein the aluminum halide-A is preferably aluminum chloride, the amide compound is preferably acetamide, and the additive contains one of aluminum halide-B (when the additive is aluminum halide-B, the extracts of the aluminum halide-B and aluminum halide A are different), Bis(trifluoromethane)sulfonimide aluminum (Al(TFSI)3), Bis(trifluoromethane)sulfonimide sodium (Na(TFSI)), Bis(trifluoromethane)sulfonimide magnesium (Mg(TFSI)2), Bis(trifluoromethane)sulfonimide zinc (Zn(TFSI)2), aluminum perchlorate(Al(ClO4)3), chloroaluminate, bromine aluminate, urea, aluminum trifluoromethanesulfonate (Al(OTF)3), benzene, toluene, chlorobenzene, and 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropylether (HFE) or more. The electrolyte can be used in the fields of aluminum ion batteries, aluminum-sulfur batteries and the like. An aluminum-sulfur battery assembled by using the electrolyte provided by the invention is high in capacity, good in cycling stability and excellent in rate capability. Meanwhile, the aluminum-sulfur battery is low in cost, does not contain high-pollution substances such as heavymetals, is easy to assemble and high in safety, and has a good industrial application prospect.

Owner:BEIJING UNIV OF TECH

Light ceramsite prepared from oil shale semi-coke and preparation method thereof

InactiveCN105731998AImprove use valueLower firing temperatureCeramic materials productionClaywaresCapacity valueOil shale gas

The invention relates to light ceramsite prepared from oil shale semi-coke and a preparation method thereof. The light ceramsite consists of the raw materials such as oil shale semi-coke, oil shale ash, clay and water glass. The preparation method comprises the process steps such as pulverization, pelletizing, sintering and cooling. The light ceramsite provided by the invention has the advantages of widely available raw materials, easiness in preparation, low production cost, environmental friendliness and the like; by implementing the technical scheme, much land occupation caused by stacking oil shale semi-coke and ash can be reduced, consequent severe threat to the ecology, environment and human health is relieved, the problems such as low capacity value, low water absorption and low cylinder compressive strength of the commercially available ceramsite products are solved, and the use value of the oil shale semi-coke is increased so that the oil shale semi-coke is turned into wealth; and the light ceramsite is suitable for industrial production.

Owner:陕西省能源化工研究院

Composite rare earth RE cast aluminum alloy material and preparation method thereof

The invention provides a composite rare earth RE cast aluminum alloy material and a preparation method thereof. The alloy is mainly prepared from the following components in percentage by mass: 0.12%-0.85% of Er, 0.18%-0.68% of Sc, 5.8%-7.5% of Si, 0.15%-0.48% of Mg, 0.08%-0.20% of Ti, less than 0.25% of Fe, less than 0.10% of Cu, less than 0.05% of Mn, less than 0.08% of Zn and the balance of Al.Eutectic silicon is refined into 1[mu]m granules, and the structure of the cast aluminum alloy is improved, a Al3.21Si0.47 phase, a Al3Sc phase, a Sc Phase, a ScSi2 phase, an ErSi2 phase and other hard phases are formed, the performance is greatly improved, especially the erbium and scandium elements are dispersed and distributed in the aluminum alloy, so that the aluminum alloy has higher strength, plastic deformation, elastic modulus and wider melting temperature range and has stronger practicability.

Owner:KUNMING METALLURGY INST

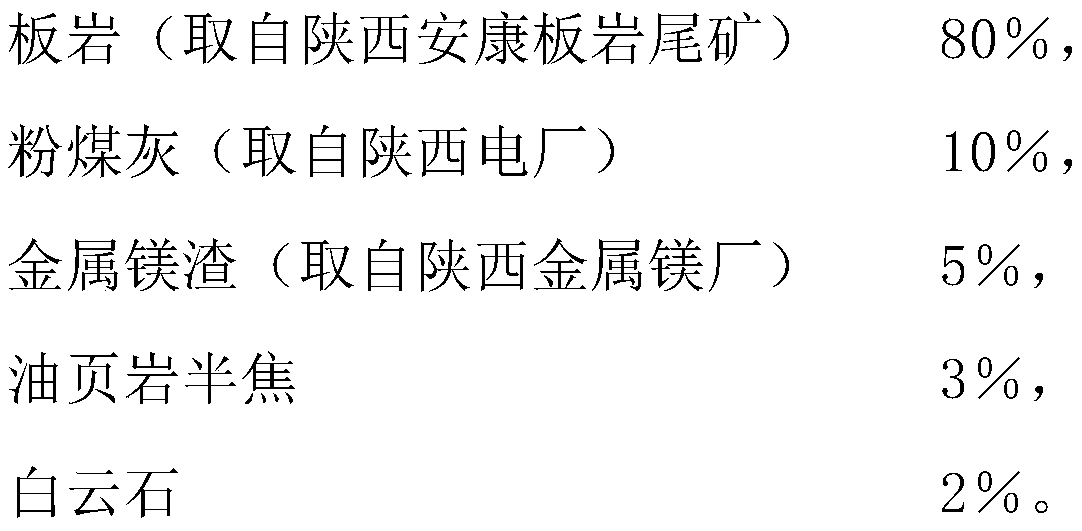

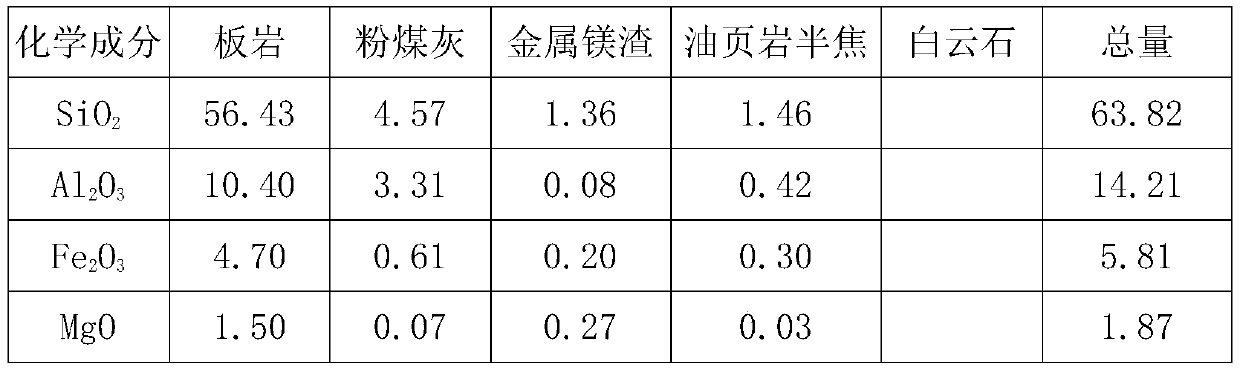

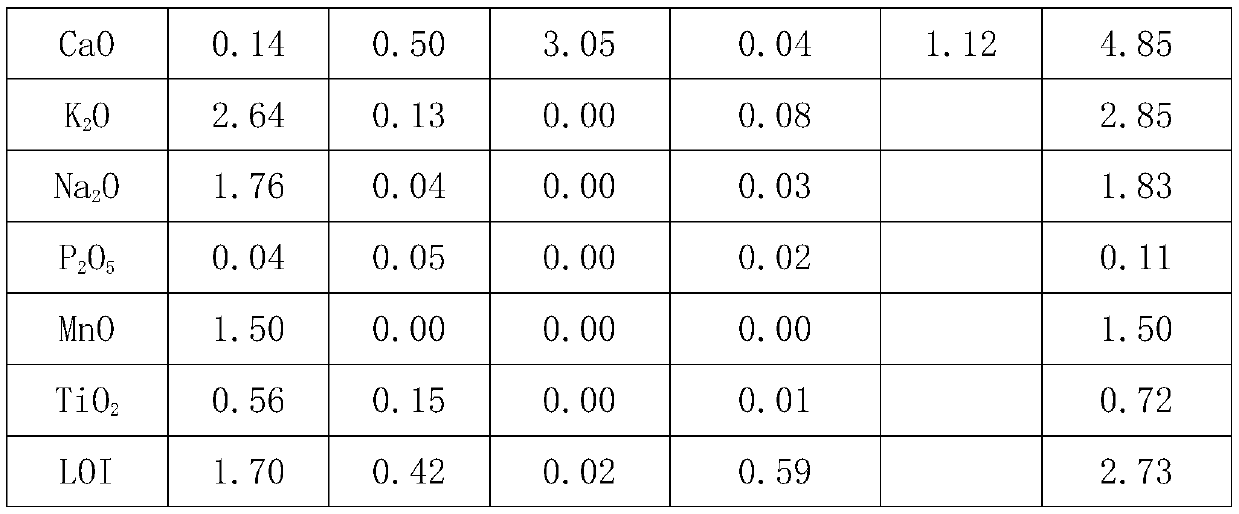

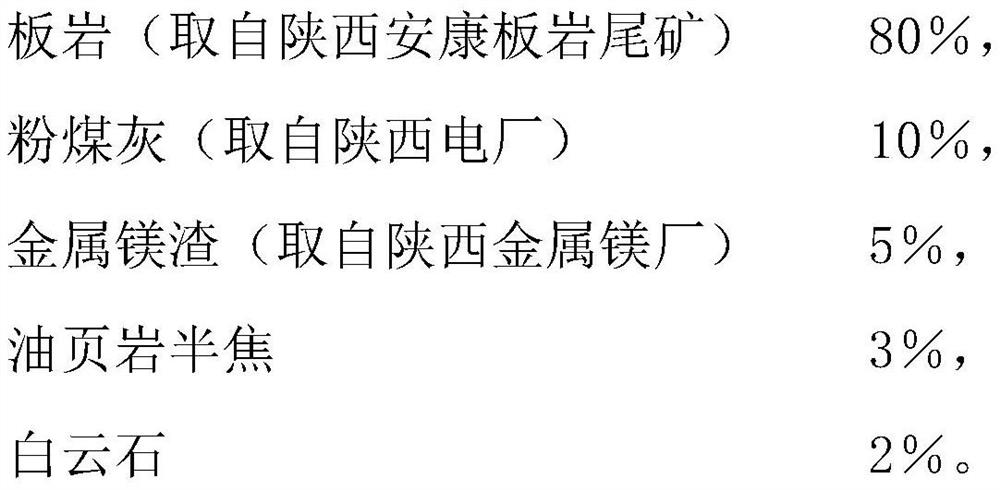

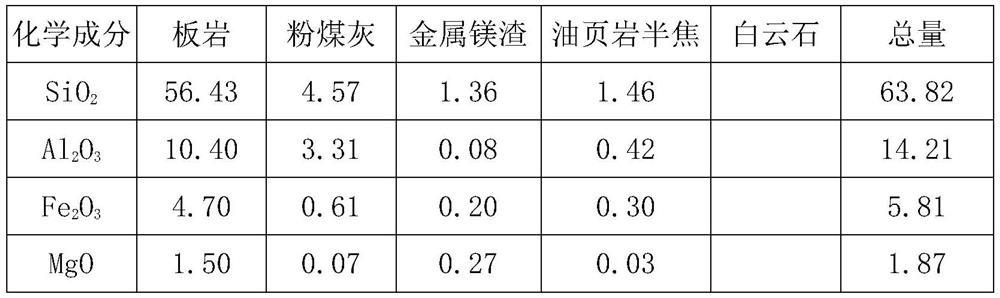

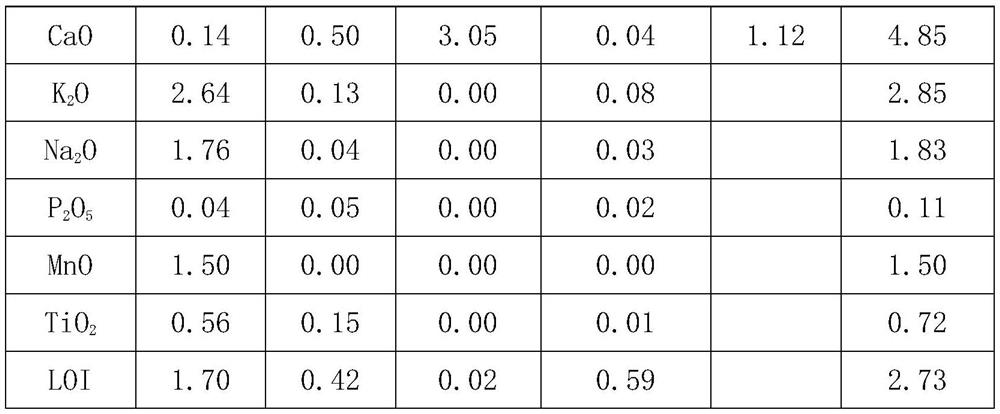

Lightweight and high-strength ceramsite prepared by taking slate as raw material, and preparation method thereof

ActiveCN110627521AHigh strengthLower firing temperatureCeramic materials productionCeramicwareSlagExpanded clay aggregate

The invention discloses a lightweight and high-strength ceramsite prepared by taking slate as a raw material, and a preparation method thereof, and relates to the technical field of preparation of building materials. The lightweight and high-strength ceramsite is prepared from the raw materials by mass percent: 50% -90% of slate, 5% -30% of fly ash, 2% -6% of metal magnesium slag, 1% -10% of oil shale semicoke and 1% -4% of dolomite. The fly ash added into the lightweight and high-strength ceramsite taking slate as the raw material can reduce SiOs as well as increase the Al2O3 content; the occupation on a large amount of land by the slate tailings piling can be reduced, thereby relieving the serious threat on the ecology, the environment and the human health, and further solving the problem that the ceramsite product on the former market is high in piling density, high in water absorption and low in cylinder pressure strength; a value in use of the slate taiings, the metal magnesium slag, the oil shale semicoke and flyash are improved, the solid wastes are changed into valuables, and the lightweight and high-strength ceramsite is suitable for the industrial production.

Owner:NORTHWEST UNIV(CN)

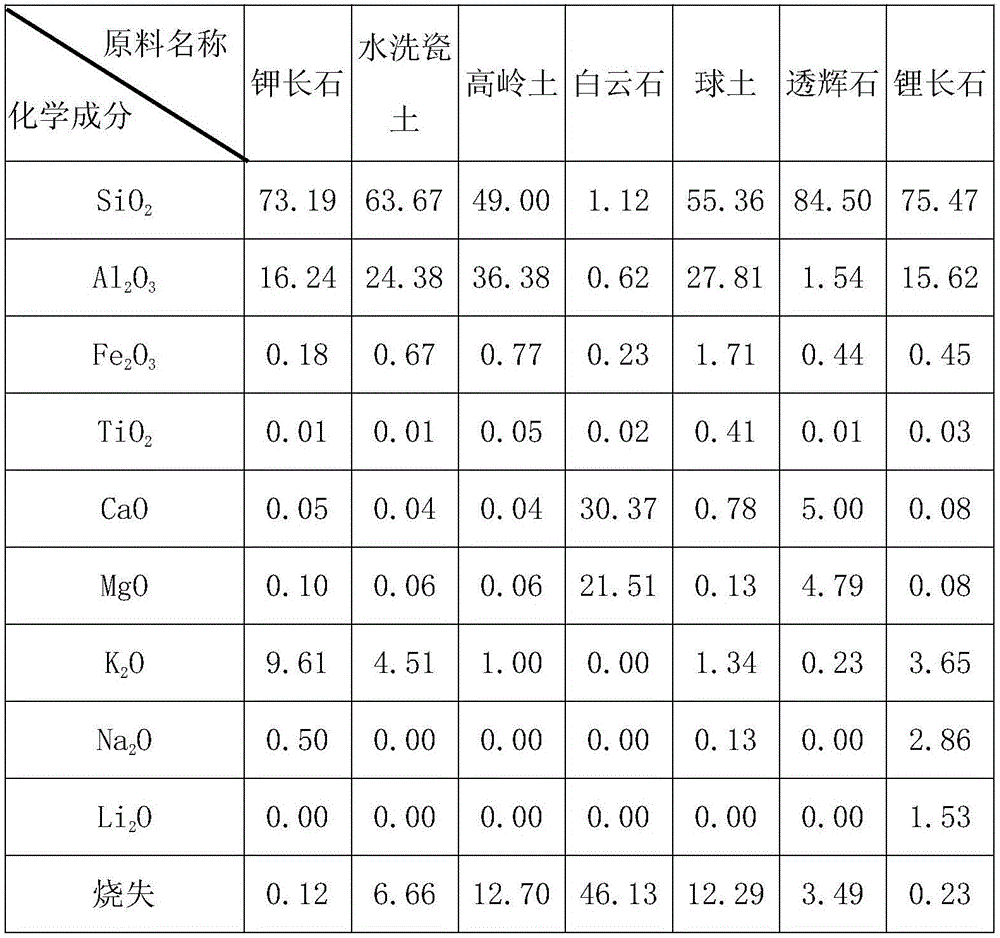

Slurry for craft ceramic and composition for preparation of slurry

The invention discloses a slurry for craft ceramic and a composition for preparation of the slurry. The composition comprises the following matters in parts by weight: 40 to 60 parts of washed clay, 5 to 10 parts of kaolin, 3 to 8 parts of ball clay, 3 to 5 parts of potassium feldspar, 3 to 5 parts of lithium feldspar, 10 to 15 parts of dolomite, 8 to 15 parts of diopside and 0.01 to 0.03 part of cobalt blue. The slurry prepared from the composition provided by the invention has the advantages of low sintering temperature, short sintering time, low energy consumption, and high product strength and whiteness.

Owner:福建科福材料有限公司

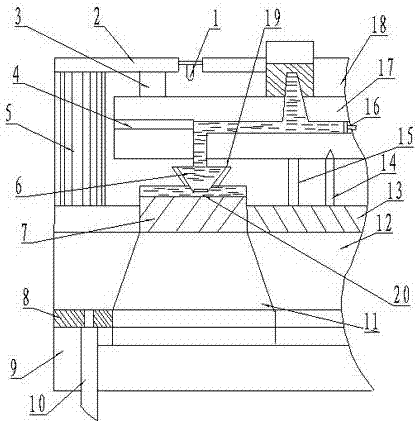

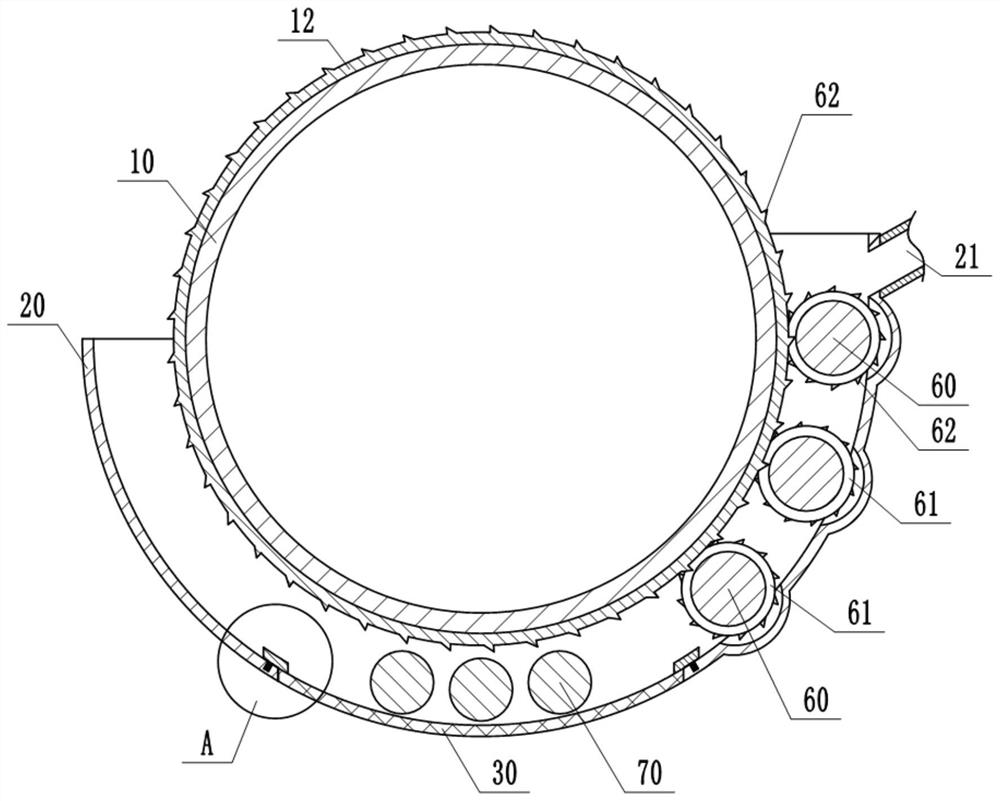

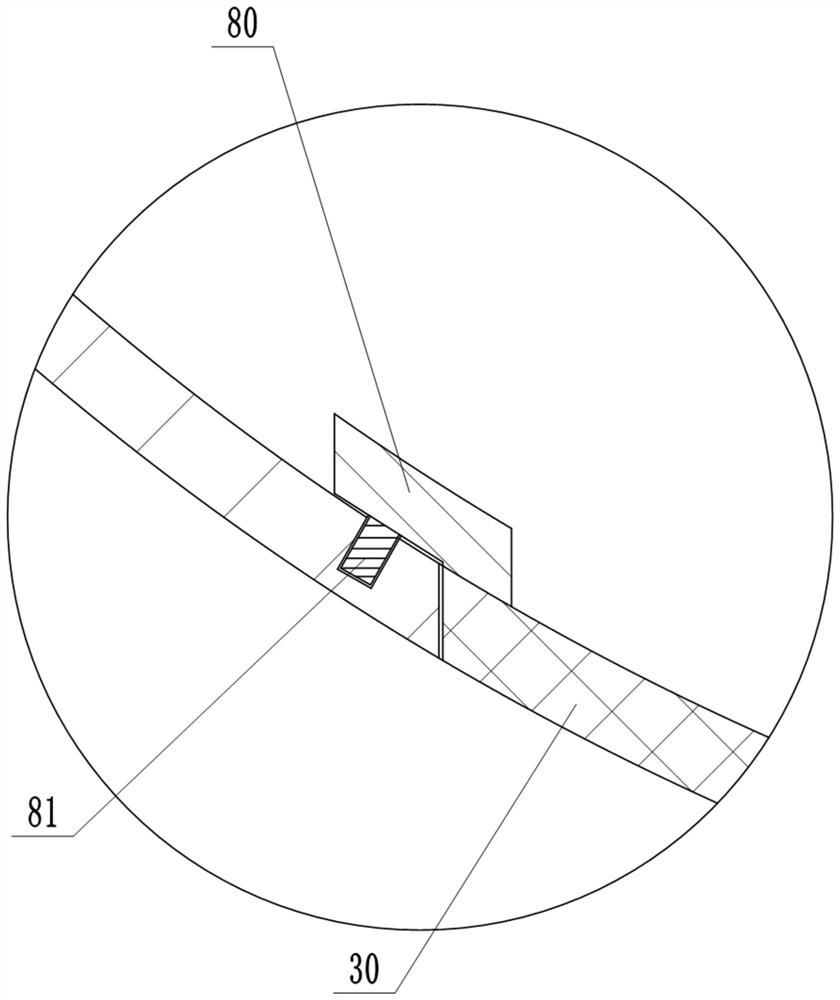

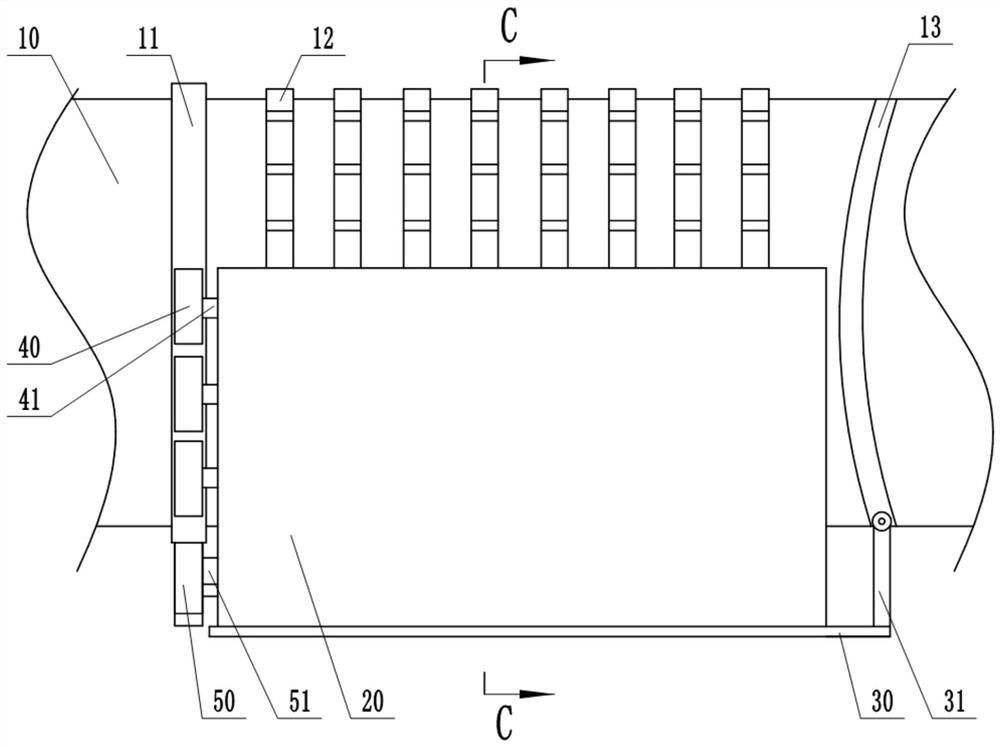

Heat insulation hot runner system of automobile injection mold

The invention discloses a heat insulation hot runner system of an automobile injection mold. The heat insulation hot runner system comprises a fixed die, a movable die and a hot runner, wherein the fixed die comprises a fixed seat plate; a positioning screw is arranged on the fixed seat plate; the movable die comprises a movable plate; a pouring gate sleeve is arranged on a fixed plate; one end of the pouring gate sleeve is connected with an injection molding machine, and the other end of the pouring gate sleeve is connected with a nozzle through the hot runner; a needle valve is arranged in the nozzle, so that the phenomenon of tape casting of melted plastic is avoided; the hot runner and a surrounding hot runner plate are made of a heat insulation material, and the hot runner and the hot runner plate are fixed through a sealing plug; the hot runner is also provided with a spring pressing ring; an electrothermal ring for keeping the temperature of the nozzle is arranged round the nozzle; the nozzle is connected with a molded core through a pouring gate lining; a push rod is arranged on a movable plate panel; the head of the push rod leans against a piece pushing plate. The heat insulation hot runner system is used for die opening, has a heat insulation function and keeps the constant temperature; plastic in a pouring system is always in a melted state, and a multi-point pouring gate can be realized; the forming period is short, and the production efficiency is high.

Owner:SUZHOU YIQUN MOLD

Zirconite tailing and coal gangue ceramic grinding ball and preparation method thereof

ActiveCN112374865ARealize resource utilizationReduce manufacturing costCeramic materials productionClaywaresCalciteDolomite

A disclosed zirconite tailing and coal gangue ceramic grinding ball is prepared from the following components in percentage by mass: 40-80 percent of zirconite tailings, 5-30 percent of coal gangue, 5-20 percent of aluminum oxide, 2-10 percent of feldspar, 1-5 percent of dolomite, 1-5 percent of talc, 1-5 percent of calcite, 1-5 percent of barium carbonate and 1-10 percent of quartz. The inventionfurther discloses a preparation method of the zirconite tailing and coal gangue ceramic grinding ball. The ceramic grinding ball prepared by taking the zirconite tailings and the coal gangue as mainraw materials is suitable for the related fields of mine metal mineral grinding, white mineral grinding, petroleum fracturing propping agents and the like, solid waste resource utilization is realized, and the production cost is greatly reduced.

Owner:江苏金石研磨有限公司

White ceramic high-performance transparent glaze and preparation method thereof

ActiveCN109336394AImprove thermal shock resistanceHigh melting temperatureAlkali feldsparPotassium feldspar

The invention discloses a white ceramic high-performance transparent glaze and a preparation method thereof, which belong to the technical field of domestic ceramic glazes. The white ceramic high-performance transparent glaze mainly comprises the following ingredients: water grinded potassium feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide, water grinded quartz, aglaze stabilizer and an expansion coefficient regulator. The preparation method of the white ceramic high-performance transparent glaze comprises the following steps: preparation for materials, agingand glaze firing. The white ceramic high-performance transparent glaze prepared from the raw materials has the advantages that the melting temperature of a glaze material is high, the melting temperature range of the glaze material is wide and reaches 1,290-1,330 DEG C, the affection of kiln temperature fluctuation on a glaze surface is small, the pinholes of the glaze surface are less, the glazesurface is bright and smooth, an expansion coefficient of the glaze surface is adjustable, so that one stress is added for the surface of a ceramic blank, and an effect of non-cracking under a condition of quick heating and cooling at the temperature of 200 DEG C-20 DEG C is achieved.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

Red glaze and preparation method thereof

ActiveCN111995252AIncrease brightnessLow chemical stabilityGrain treatmentsCeramic materials productionGlazeIron removal

The invention belongs to the technical field of electric porcelain glazes, and particularly relates to a red glaze and a preparation method thereof, and the preparation method of the red glaze comprises the following steps: (1) preparing the following raw materials: potassium feldspar, albite, ball clay, hard kaolin, calcined talc, limestone, quartz powder, barium carbonate and a red color base; (2) performing ball milling: carrying out ball milling on the raw materials by using a ball mill; wherein the mass ratio of the raw materials to the ball materials to the water in the ball mill is 1: (2.4-2.6): (0.7-0.9); (3) performing iron removal treatment; and (4) aging. After the prepared red glaze and a green body form porcelain, the surface of the porcelain body is bright red, smooth, bright, fine, mild and moist, and the requirements of customers on red electric porcelain can be well met. Moreover, the red glaze in the scheme can be well combined with a green body, an excellent middle layer can be generated between the glaze and the green body after the red glaze is formed into the porcelain, the performance of the porcelain can be greatly improved (the strength of the porcelain isimproved by 22% or above), and the development of the red glaze achieves the design purpose and meets the process and industry standards of companies.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Method of preparing downward-blowing water-cooling blow-molding polyethylene membrane

InactiveCN101209581AReduce the temperatureIncrease melt viscosityFlat articlesBlow moldingPolymer science

The invention relates to a manufacturing method of a downward blowing water-cooling blow polyethylene film. The invention is characterized in that downward blowing wind-cooling is first carried out to polyethylene bulb which is extruded out of a finish mold and water-cooling is carried out thereof so as to implement the sudden reduction of the temperature of a fused mass film. The temperature of the fused mass film is reduced rapidly to ensure that the viscosity of the fused mass is increased rapidly, the active capability of molecular chain is weakened, the crystallisation process is not perfect, the formed crystal is small, the film with low degree of crystallisation has wider melting temperature range, good transparency and flexible performance; meanwhile, after being cooled by water, the film adsorbs part of the low molecules which are separated out of the surface and reduces the peculiar smell of the film.

Owner:DALIAN DAFU PLASTIC COLOR PRINTING

Velvet glaze ceramic product and preparation method thereof

The invention relates to a ceramic product and a preparation method thereof, in particular to a velvet glaze ceramic product and a preparation method thereof. A blank after bisque firing adopts a glazed velvet glaze for glaze firing to obtain the velvet glaze ceramic product. The velvet glaze with modern ceramic feature is developed through the technology innovation of the production technique; the surface of the glaze presents the texture touch enjoyment with jade-like crystal clearness and the visual effect; unique style is achieved without belonging to the traditional glaze; the velvet glaze is one development and breakthrough of the ceramic decoration technology. Furthermore, compared with the low-temperature color glaze, the velvet glaze has the advantages of good stability of surface high temperature resistance and capability of reburning for many times, so that the products can execute a plurality of subsequent techniques such as pattern color drawing and stained paper decoration, and the modern ceramic style is shown more perfectly.

Owner:江苏省宜兴彩陶工艺厂

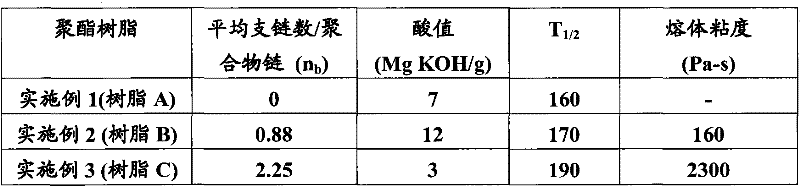

Toner composition with broad fusing temperature range and process for preparing the same

InactiveCN102334071AWide melting temperature rangeAvoid diversionDevelopersPolyester resinHot Temperature

The present invention relates to a toner composition with a broad fusing temperature range and a process for preparing the same. The toner composition according to the present invention creates entanglement between adjacent polymer chains using a non-linear polyester resin having a branch structure, provides elasticity to molten materials by the branch structure when the resin is molten, prevents the molten materials from being transferred to the surface of a roller at a high temperature, and thereby increases the maximum fusing temperature. Therefore, as the average branch number per polyester resin increases, the maximum fusing temperature rises and the fusing temperature range of the toner composition can be widened.

Owner:EXAX TONER

Black glaze for insulator and preparation method of black glaze

The invention belongs to the technical field of electric porcelain glaze, and particularly relates to black glaze for an insulator and a preparation method of the black glaze. The black glaze comprises the following raw materials in parts by mass: Hunan high-potassium low-sodium feldspar 27-31 parts, Hunan high-sodium low-potassium feldspar 4-8 parts, ball clay 3-7 parts, hard kaolin 18-22 parts,calcined talc 9-13 parts, limestone 5-9 parts, quartz powder 21-25 parts, barium carbonate 1-3 parts and black color base 6-10 parts. After the black glaze for the insulator and a green body form porcelain, the surface of the porcelain body is bright black, smooth, bright, fine, mild and moist, and the requirements of customers on black electric porcelain can be well met. Moreover, the black glazein the scheme can be well combined with the blank body, an excellent middle layer can be generated between the glaze and the blank body after the black glaze is formed into the porcelain, the performance of the porcelain can be greatly improved (the strength of the porcelain is improved by 22% or above), and the black glaze for the insulator is developed to achieve the design purpose and meet theprocess and industry standards of companies.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

A kind of black glaze for insulator and preparation method thereof

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

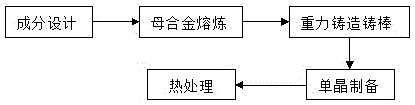

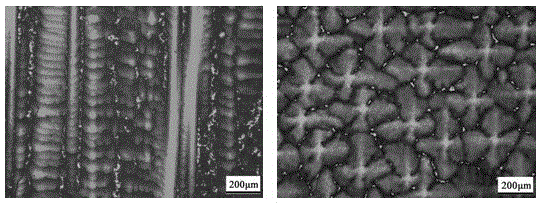

A kind of rhenium-free nickel-based single crystal superalloy and preparation method thereof

ActiveCN103436740BImprove antioxidant capacityAccelerated corrosionPolycrystalline material growthFrom frozen solutionsRheniumSolution treatment

Owner:NANJING UNIV OF SCI & TECH

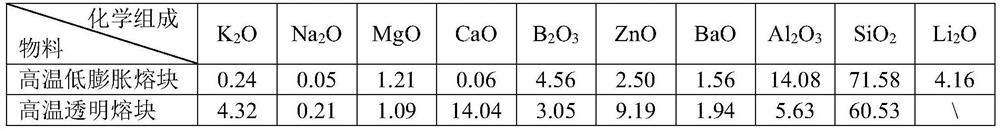

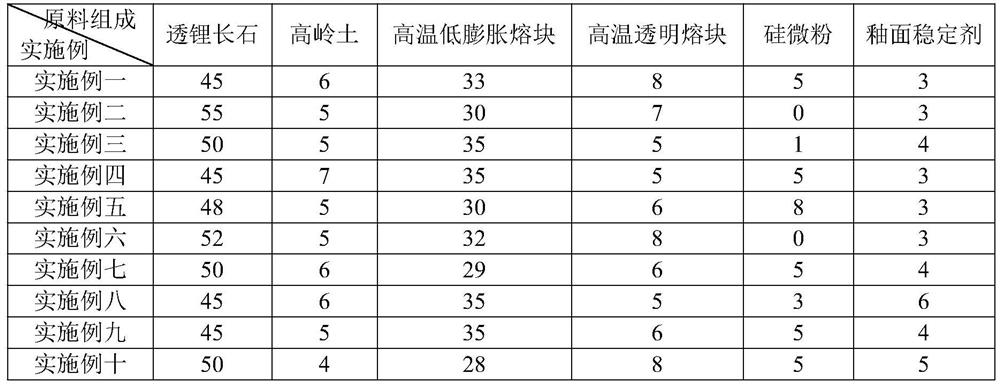

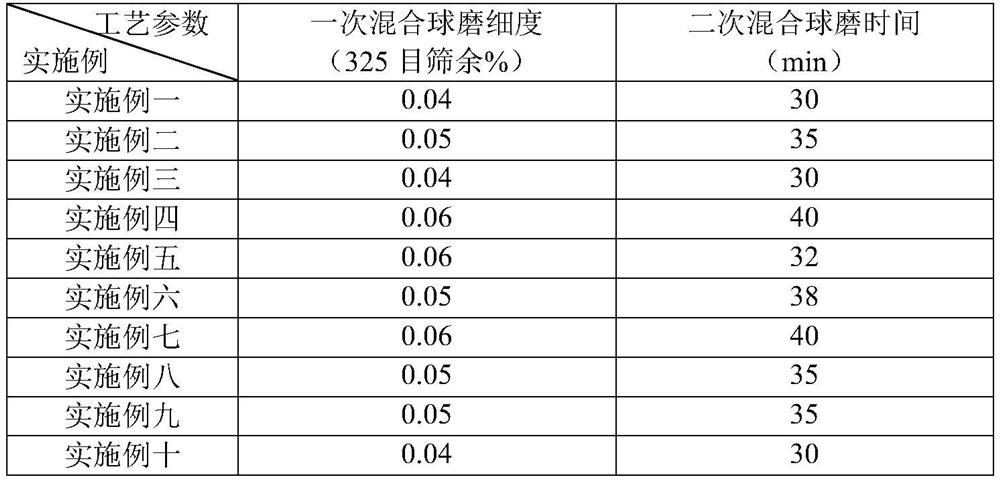

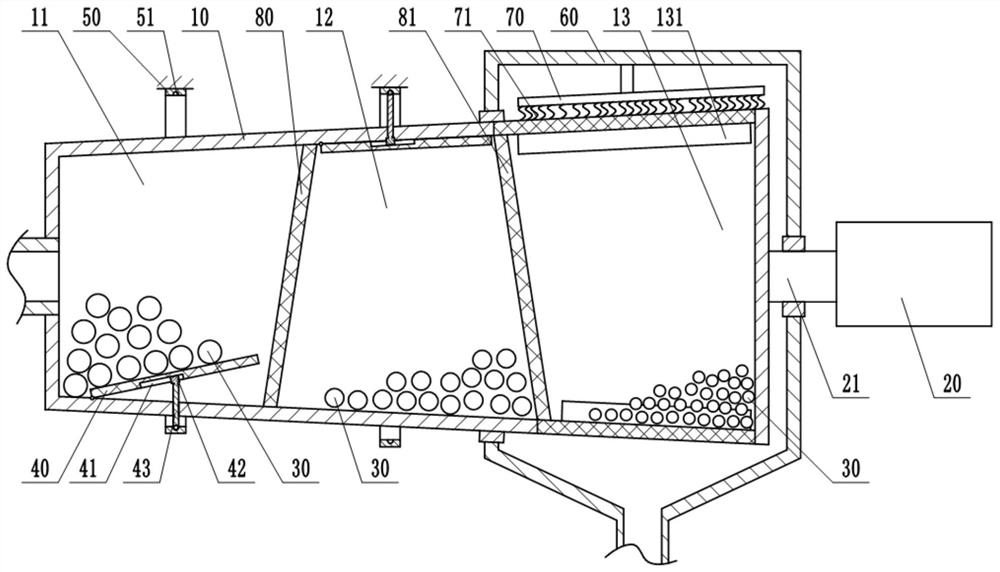

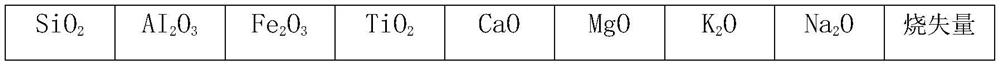

A kind of easy-to-clean milky white glaze suitable for low-expansion ceramics and its preparation method and application

The invention discloses an easy-to-clean milky white glaze suitable for low-expansion ceramics. The raw materials are composed of: petalite feldspar 45-55wt%, kaolin 4-7wt%, high-temperature low-expansion frit 25-35wt%, high-temperature transparent frit Block 5-15wt%, silicon micropowder 0-10wt%, glaze stabilizer 3-6wt%. In addition, the preparation method and application of the above-mentioned easy-to-clean milky white glaze suitable for low-expansion ceramics are also disclosed. The formula system of the invention has a relatively large melting temperature range under the condition of an oxidizing atmosphere, effectively solves defects such as holes in the glaze surface, and achieves the purpose of easy cleaning while having good stability. The preparation method of the present invention is based on the general daily-use ceramic glaze and the production process of daily-use ceramics. It is suitable for various low-expansion ceramic bodies, and especially provides prerequisites for low-expansion ceramic pots used in conjunction with electrical appliances. It can promote the technological progress and application development of the low expansion ceramic industry.

Owner:JINGDEZHEN CERAMIC UNIV

Purple glaze for insulator processing and processing method of purple glaze

The invention belongs to the technical field of electric porcelain glaze, and particularly relates to purple glaze for insulator processing and a processing method of the purple glaze, and the purpleglaze for insulator processing comprises the following components in parts by weight: 26-31 parts of potassium feldspar, 5-10 parts of albite, 3-7 parts of ball clay, 19-23 parts of hard kaolin, 9-13parts of calcined talc, 5-9 parts of limestone, 22-26 parts of quartz powder, 1-3 parts of barium carbonate and 6-10 parts of purple color base. After the purple glaze for an insulator and a green body form porcelain, the surface of the porcelain body is bright purple, smooth, bright, fine, mild and moist, and the requirements of customers on purple electric porcelain can be well met. Moreover, the purple glaze of the scheme can be well combined with the green body, an excellent middle layer can be generated between the glaze and the green body after the porcelain is formed, the performance ofthe porcelain can be greatly improved (the strength of the porcelain is improved by 22% or above), and the development of the purple glaze for the insulator achieves the design purpose and meets theprocess and industry standards of companies.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Lightweight high-strength ceramsite prepared from slate as raw material and preparation method thereof

ActiveCN110627521BHigh strengthLower firing temperatureCeramic materials productionCeramicwareSlagMining engineering

The invention discloses a light-weight high-strength ceramsite prepared from slate as a raw material and a preparation method thereof, and relates to the technical field of preparation of building materials. According to mass percentages, the ratio of raw materials is 50%-90% of slate, pulverized coal Ash 5%‑30%, metal magnesium slag 2%‑6%, oil shale semi-coke 1%‑10%, dolomite 1%‑4%. In the present invention, the fly ash added in the light high-strength ceramsite with slate as raw material can reduce the SiO 2 content can increase Al 2 o 3 content, not only can reduce the occupation of a large amount of land by the accumulation of slate tailings, reduce their serious threats to ecology, the environment and human health, but also solve the problems of high bulk density, high water absorption and low Problems such as cylinder compressive strength have improved the utilization value of slate tailings, metal magnesium slag, oil shale semi-coke and fly ash, and turned solid waste into treasure, which is suitable for industrial production.

Owner:NORTHWEST UNIV

Purple glaze for insulator processing and its processing method

ActiveCN112028485BImprove performanceImprove performance (improve porcelain strengthGlazeKaolin clay

The invention belongs to the technical field of electric porcelain glazes, in particular to purple glaze for insulator processing and a processing method thereof, purple glaze for insulator processing, 26-31 parts of potassium feldspar, 5-10 parts of albite, 3-7 parts of ball clay, 19-23 parts of hard kaolin, 9-13 parts of calcined talc, 5-9 parts of limestone, 22-26 parts of quartz powder, 1-3 parts of barium carbonate, 6-10 parts of purple color base. After the insulator is made into porcelain with the purple glaze and the green body, the surface of the porcelain body is bright purple, smooth and bright, delicate and moist, which can well meet the customer's demand for purple electric porcelain. Moreover, the purple glaze of this program can be well combined with the green body. After the porcelain is formed, an excellent intermediate layer can be produced between the glaze and the green body, which can greatly improve the performance of the porcelain (improving the strength of the porcelain by more than 22%). The development of the glaze achieves the design purpose and meets the company's technology and industry standards.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

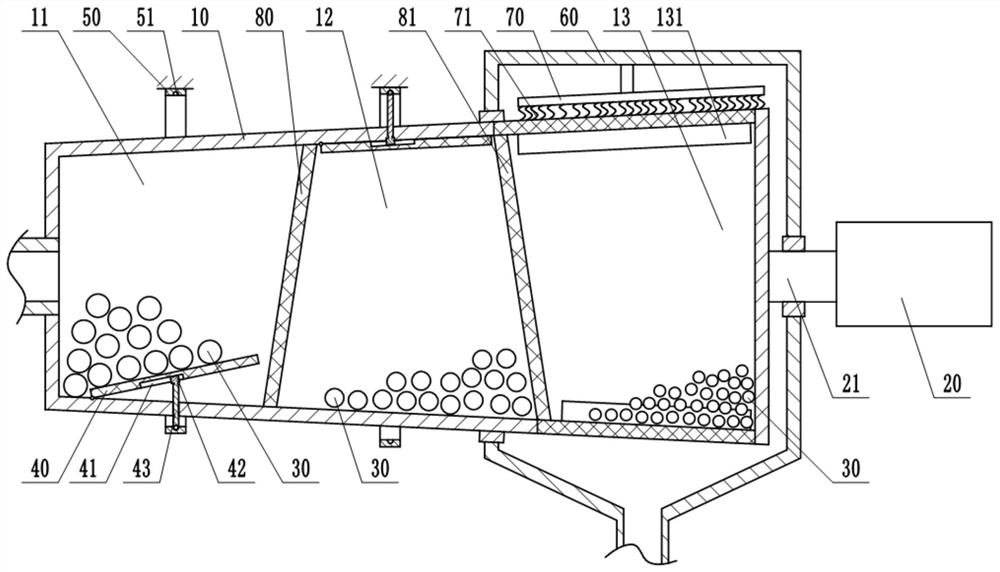

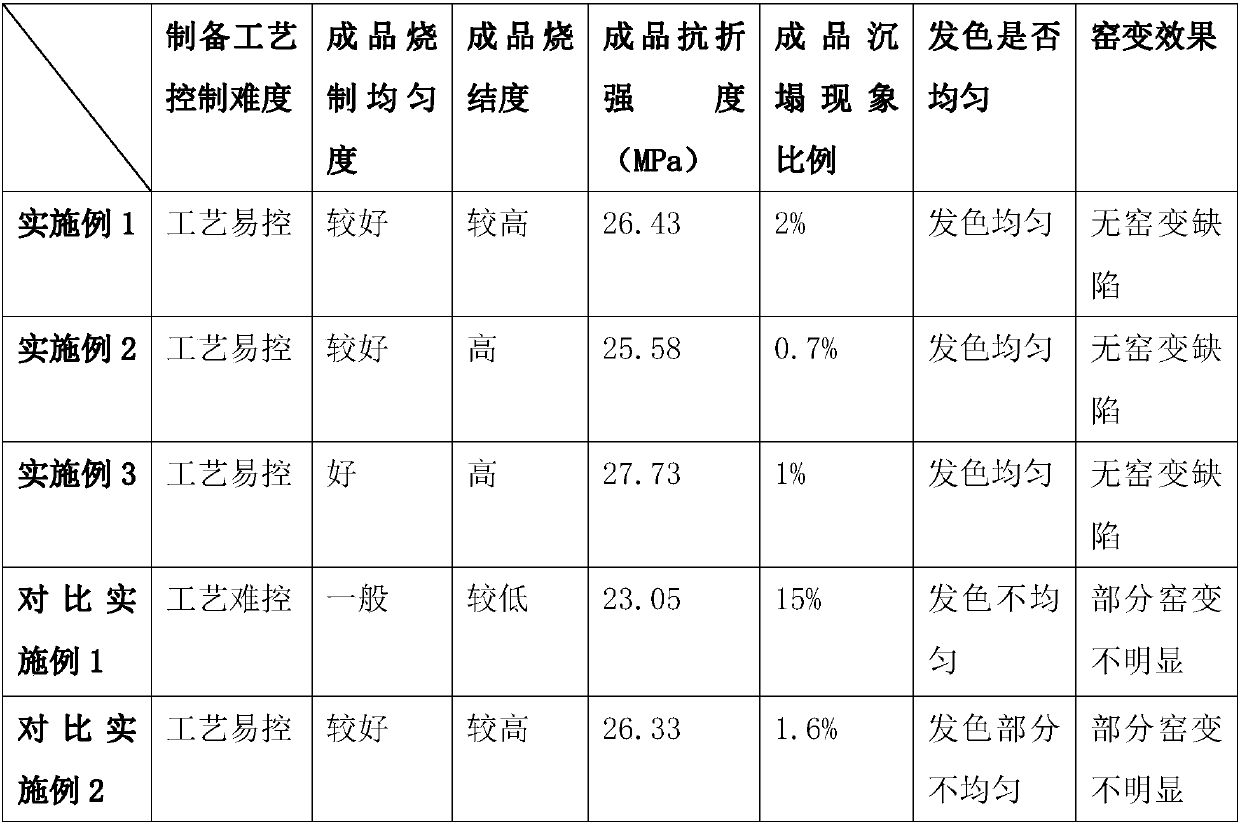

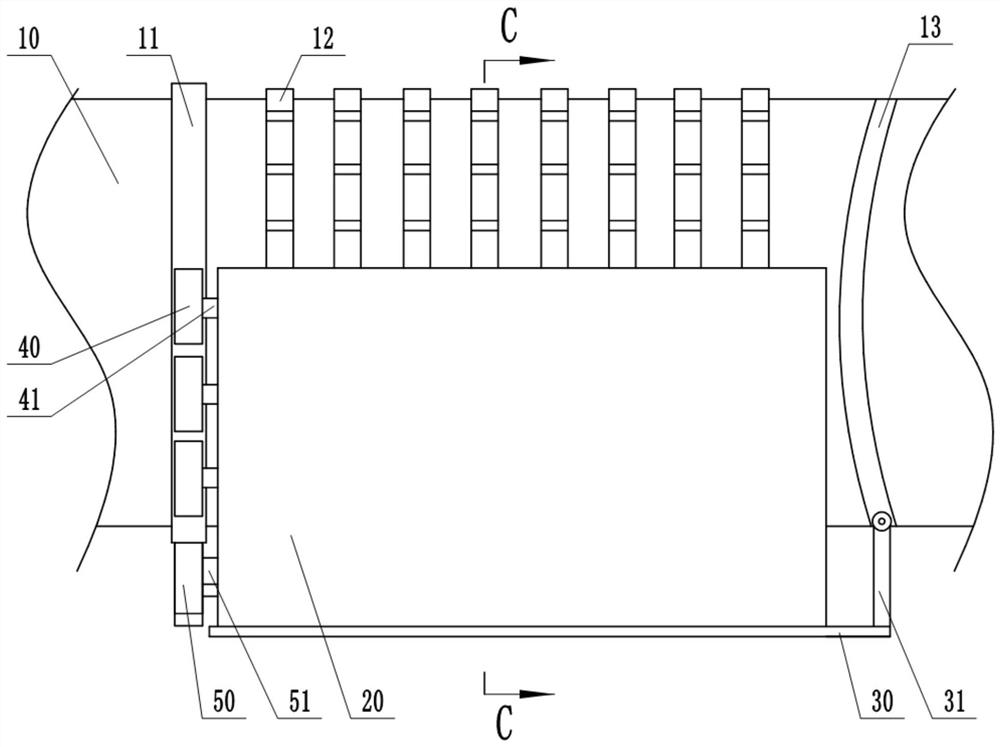

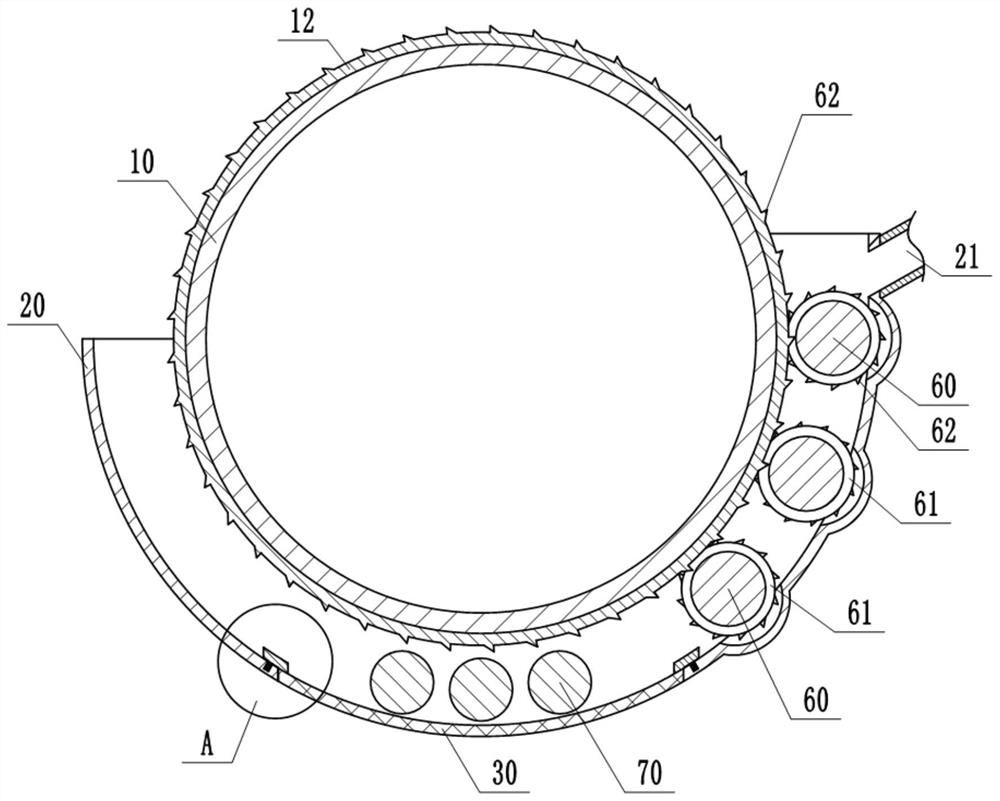

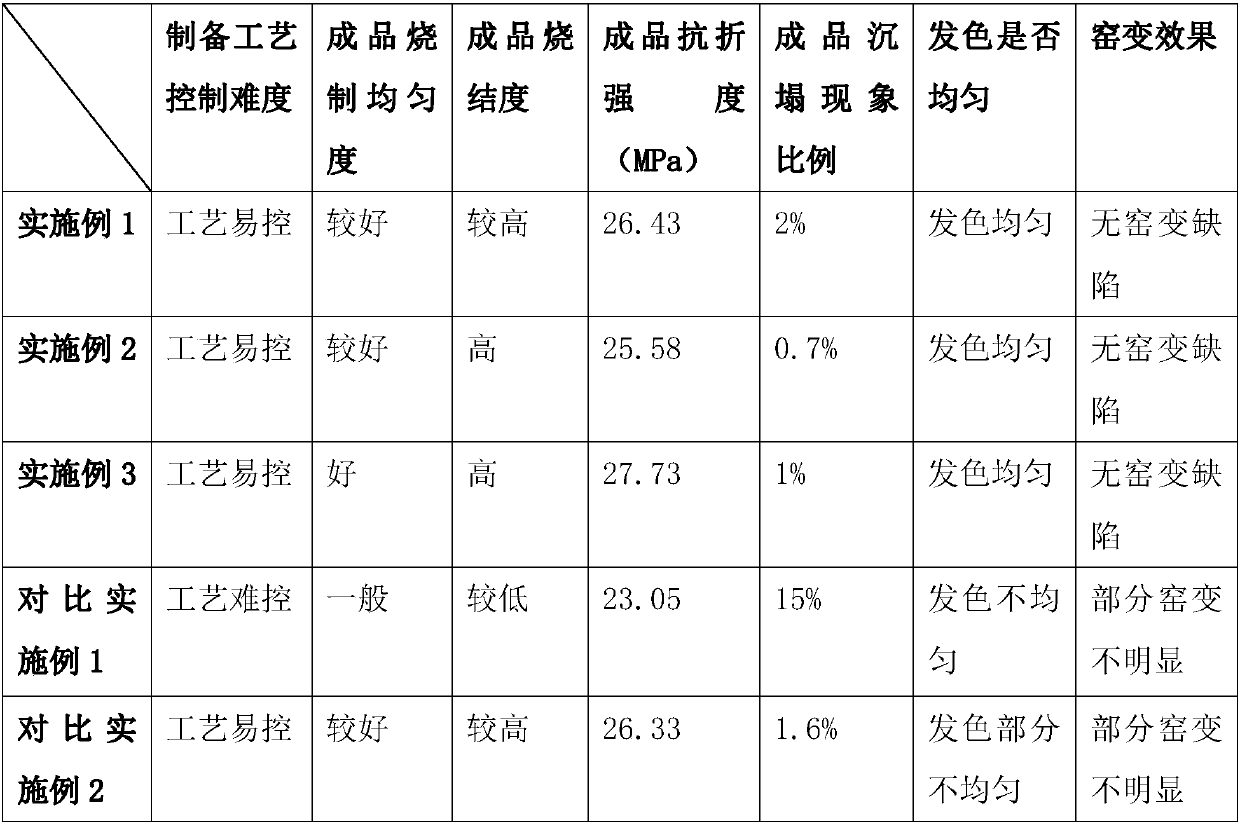

Preparation process of transmuted tile with uniform transmutation effect

The invention discloses a preparation process of a transmuted tile with a uniform transmutation effect. Chromogenic glaze slip is applied to the surface of a ceramic tile bisque, the surface of a bisque body with a glaze slip layer is dried, and a transmuted tile finished product is obtained by firing. The ceramic tile bisque is prepared from the following raw components in percentage by mass: 50to 60 percent of plastic pug, 10 to 20 percent of clinker particles, 10 to 15 percent of a sandy raw material, 5 to 15 percent of a flux and 0.5 to 2 percent of lithium feldspar. The chromogenic glazeslip is prepared from the following raw components in percentage by mass: 50 to 65 percent of crude ore pug, 4 to 8 percent of rock flour, 6 to 8 percent of fine sand, 6 to 10 percent of a soluble metal salt, 10 to 15 percent of a chromogenic auxiliary and the balance of water. According to the preparation process of the transmuted tile with the uniform transmutation effect, a chromogenic glaze slip application manner is adopted, so that the problem of high occurrence of unstable transmutation effect on the surface of the bisque body is solved, and the yield is high.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

A kind of red glaze and preparation method thereof

ActiveCN111995252BIncrease brightnessLow chemical stabilityGrain treatmentsCeramic materials productionGlazeIron removal

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

A preparation process of kiln-transformed brick with uniform kiln-transformation effect

The invention discloses a preparation process of a transmuted tile with a uniform transmutation effect. Chromogenic glaze slip is applied to the surface of a ceramic tile bisque, the surface of a bisque body with a glaze slip layer is dried, and a transmuted tile finished product is obtained by firing. The ceramic tile bisque is prepared from the following raw components in percentage by mass: 50to 60 percent of plastic pug, 10 to 20 percent of clinker particles, 10 to 15 percent of a sandy raw material, 5 to 15 percent of a flux and 0.5 to 2 percent of lithium feldspar. The chromogenic glazeslip is prepared from the following raw components in percentage by mass: 50 to 65 percent of crude ore pug, 4 to 8 percent of rock flour, 6 to 8 percent of fine sand, 6 to 10 percent of a soluble metal salt, 10 to 15 percent of a chromogenic auxiliary and the balance of water. According to the preparation process of the transmuted tile with the uniform transmutation effect, a chromogenic glaze slip application manner is adopted, so that the problem of high occurrence of unstable transmutation effect on the surface of the bisque body is solved, and the yield is high.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

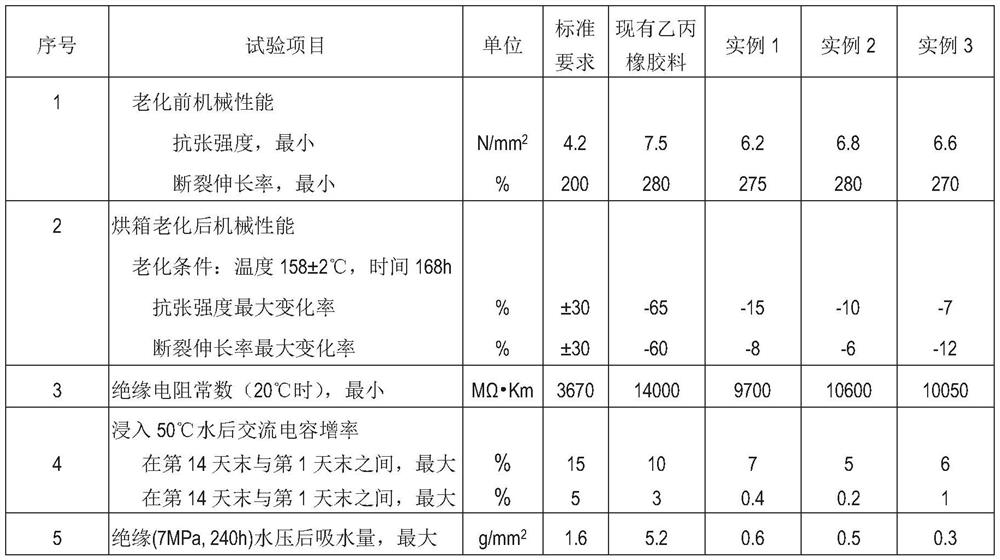

High-temperature fire-resistant watertight insulating rubber for cable applied to safe return of ship to port, and manufacturing method of high-temperature fire-resistant watertight insulating rubber

The invention belongs to the technical field of cables, and discloses a high-temperature fire-resistant watertight insulating rubber for a cable applied to safe return of a ship to a port, and a manufacturing method of the high-temperature fire-resistant watertight insulating rubber. The rubber comprises the following raw material components in parts by weight: 20 parts of methyl vinyl silicone rubber 110-3-B, 20 parts of EPDM (ethylene propylene diene monomer) Mitsui EPT 4045M, 0.6 to 1 part of bis(tert-butylperoxyisopropyl)benzene (BIPB), 0.2 to 0.3 part of trimethylolpropane trimethacrylate (LS-3-80); 0.4 to 0.6 part of an amine aldehyde compound anti-aging agent XH-3, 0.2 to 0.4 part of 2-mercapto benzimidazole (MBI), 5 to 9 parts of white carbon black having undergone gas-phase-method surface treatment, 4 to 8 parts of low-temperature low-melting-point glass powder with a softening temperature of 400-700 DEG C, 4 to 8 parts of high-temperature low-melting-point glass powder with a softening temperature of 600-1100 DEG C, 0.5 to 1.5 parts of iron sesquioxide, 0.4 to 1 part of diphenylsilanediol and and 0.1 to 0.2 part of SI69-50. The manufacturing method comprises the following steps: firstly, carrying out two-side mixing operation in an open mill, then adding the methyl vinyl silicone rubber 110-3-B and the raw rubber of EPDM Mitsui EPT 4045M, conducting mixing for 2-3 minutes, then sequentially adding other components, carrying out mixing for 7-8 minutes, performing discharging, conducting extruding and granulating on a double-screw granulator, and preforming cooling for separate use.

Owner:NANJING QUANXIN CABLE TECH

Rare earth formula salt for deep qpq technology and preparation method thereof

ActiveCN105543773BImprove wear resistanceImprove corrosion resistanceSolid state diffusion coatingIron nitrideRare earth

The invention discloses a rare earth formula salt for a deep QPQ technology and a preparation method thereof. The rare earth formula salt is prepared from 35-45 parts by weight of CO(NH2)2, 15-25 parts by weight of Na2CO3, 15-25 parts by weight of K2CO3, 3-7 parts by weight of NaCl, 3-7 parts by weight of KCl, 1-5 parts by weight of Na2SO3, 1-5 parts by weight of La2(CO3)3 and 1-5 parts by weight of Ce2(CO3)3. The nitrided salt contains lanthanum carbonate, cerous carbonate and reasonable other components. In a work state, cyanate ions are decomposed to form active nitrogen atoms and the active nitrogen atoms permeate into the surface of an iron base material and form a hard and compact iron nitride on the material surface so that material wear resistance and corrosion resistance are improved. The salt has a low melting point, can keep a certain nitrogen potential at a low temperature, is stable at a high temperature, has a wide melting point temperature range and can form a deep compound layer through nitridation treatment.

Owner:ZAOZHUANG HAIDI ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com