Toner composition with broad fusing temperature range and process for preparing the same

A toner, composition technology, applied in the direction of developer, electrography, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

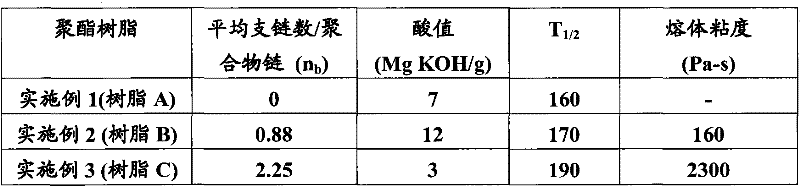

[0050] Preparation Example 1: Preparation of Linear Polyester Resin

[0051] Polyester resins have a linear molecular structure (currently used as the standard for chemical milling) and allow for cationic dyeing. The polyester resin is polymerized by a melt condensation process.

[0052] 955.6g (4.925mol) dimethyl terephthalate, 955.6g (4.925mol) dimethyl isophthalate, 44.5g (0.15mol) sodium salt of dimethyl 5-sulfoisophthalate and 1520 g (20 mol) of 1,2-propanediol was added to a 10 L glass reactor equipped with a paddle stirrer and a 20 cm fractionating column. 1.4 g of titanium tetraisopropoxide and 5.0 g of IGANOX 1010 (commercially available from Clariant Corporation, East Hanover, N.J.) were used as transesterification catalysts. The reactants were introduced at room temperature and purged with argon for about 1 hour. The mixed reactants were then heated to 150°C and the stirrer was run at 50 rpm to form a homogeneous molten state. In addition, the mixed reactants we...

preparation Embodiment 2

[0054] Preparation Example 2: Preparation of Non-linear Polyester Resin

[0055] In order to manufacture a toner having better melting properties than a toner composition made with a linear resin, a polyester resin composed of a non-linear molecule having a branched chain structure and allowing cationic dyeing is synthesized through a melt condensation process.

[0056] 955.6g (4.925mol) dimethyl terephthalate, 955.6g (4.925mol) dimethyl isophthalate, 44.5g (0.15mol) sodium salt of dimethyl 5-sulfoisophthalate, 42.1 g (0.2 mol) of anhydrous trimellitic chloride and 1520 g (20 mol) of 1,2-propanediol were added to a 10 L glass reactor equipped with a paddle type stirrer and a 20 cm fractionation column. Subsequent steps were carried out in the same manner as in Preparation Example 1 above, to obtain about 2082 g of polyester resin B.

[0057] The polyester resin has a glass transition temperature (Tg) of 71°C. As a result of gel permeation chromatography calibrated by polysty...

preparation Embodiment 3

[0058] Preparation Example 3: Preparation of Non-linear Polyester Resin

[0059] A polyester resin composed of a nonlinear molecule having more branched chain structures than the nonlinear polyester resin in Preparation Example 2 above and allowing cationic dyeing was synthesized by a melt condensation process.

[0060] 955.6g (4.925mol) dimethyl terephthalate, 955.6g (4.925mol) dimethyl isophthalate, 44.5g (0.15mol) sodium salt of dimethyl 5-sulfoisophthalate, 105.3 g (0.5 mol) of anhydrous chlorinated trimellitic anhydride and 1520 g (20 mol) of 1,2-propanediol were added to a 10 L glass reactor equipped with a paddle type stirrer and a 20 cm fractionating column. Subsequent steps were performed in the same manner as in Preparation Example 1 above, to obtain about 2082 g of polyester resin C.

[0061] The polyester resin has a glass transition temperature (Tg) of 68°C. As measured by gel permeation chromatography calibrated by polystyrene standards, the polyester resin had...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com