A preparation process of kiln-transformed brick with uniform kiln-transformation effect

A preparation process and technology of kiln transformation, which is applied in the field of preparation technology of kiln transformation bricks, can solve the problems of high yield and unstable kiln transformation effect on the surface of the green body, achieve good sintering degree and flexural strength, avoid unstable kiln transformation effect, and broaden the Effect of Melting Temperature Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

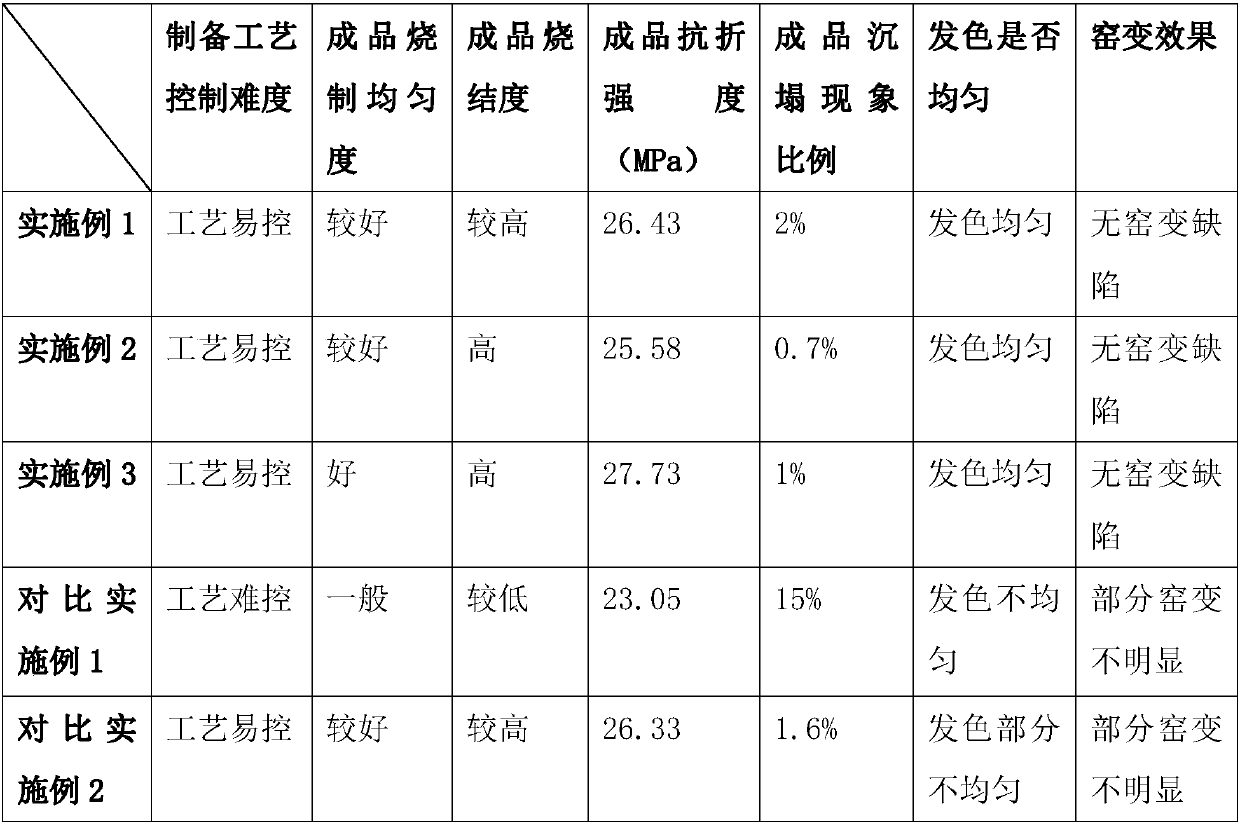

Examples

Embodiment 1

[0020] Embodiment 1-a kind of preparation technology of kiln-changing brick with uniform kiln-changing effect, comprises the following steps:

[0021] 1. Preparation of ceramic brick plain mud and color glaze slurry:

[0022] A. Prepare ceramic tile plain mud adobe according to the following raw materials:

[0023] raw material

plastic clay

clinker pellets

sandy raw material

Flux

Proportion

60%

10%

10%

8%

2%

[0024] Weigh the above raw materials according to the ratio, add water and knead evenly to make mud, the amount of water added is 17-20% of the weight of the mud, and age the mud for 24-48 hours, and then use a screen granulator to make mud Granules, mud granules are extruded by a vacuum extruder and cut to form ceramic brick plain mud.

[0025] B. Prepare the chromogenic slurry according to the following raw materials:

[0026] raw material

Raw ore slime

stone powder

fine sa...

Embodiment 2

[0031] Embodiment 2-a kind of preparation technology of kiln-changing brick with uniform kiln-changing effect, comprises the following steps:

[0032] 1. Preparation of ceramic brick plain mud and color glaze slurry:

[0033] A. Prepare ceramic tile plain mud adobe according to the following raw materials:

[0034] raw material

plastic clay

clinker pellets

sandy raw material

Flux

Attapulgite

Proportion

50%

20%

15%

5%

0.5%

9.5%

[0035] Weigh the above raw materials according to the ratio, add water and knead evenly to make mud, the amount of water added is 17-20% of the weight of the mud, and age the mud for 24-48 hours, and then use a screen granulator to make mud Granules, mud granules are extruded by a vacuum extruder and cut to form ceramic brick plain mud.

[0036] B. Prepare the chromogenic slurry according to the following raw materials:

[0037] raw material

Raw ore slime

...

Embodiment 3

[0042] Embodiment 3-a kind of preparation technology of kiln-changing brick with uniform kiln-changing effect, comprises the following steps:

[0043] 1. Preparation of ceramic brick plain mud and color glaze slurry:

[0044] A. Prepare ceramic tile plain mud adobe according to the following raw materials:

[0045] raw material

plastic clay

clinker pellets

sandy raw material

Flux

Lithium feldspar

Attapulgite

Proportion

52%

15%

12%

15%

1%

5%

[0046] Weigh the above raw materials according to the ratio, add water and knead evenly to make mud, the amount of water added is 17-20% of the weight of the mud, and age the mud for 24-48 hours, and then use a screen granulator to make mud Granules, mud granules are extruded by a vacuum extruder and cut to form ceramic brick plain mud.

[0047] B. Prepare the chromogenic slurry according to the following raw materials:

[0048] raw material

Raw ore slime

s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com