A rake-tooth brick without texture defects and its preparation process

A preparation process and technology of rake-toothed bricks, which are applied in the field of architectural ceramics, can solve the problems of reducing the decorative effect of rake-toothed bricks, uneven texture distribution, and reduced to defective products, and achieve good density, good sintering degree and anti-corrosion The effect of folding strength and simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

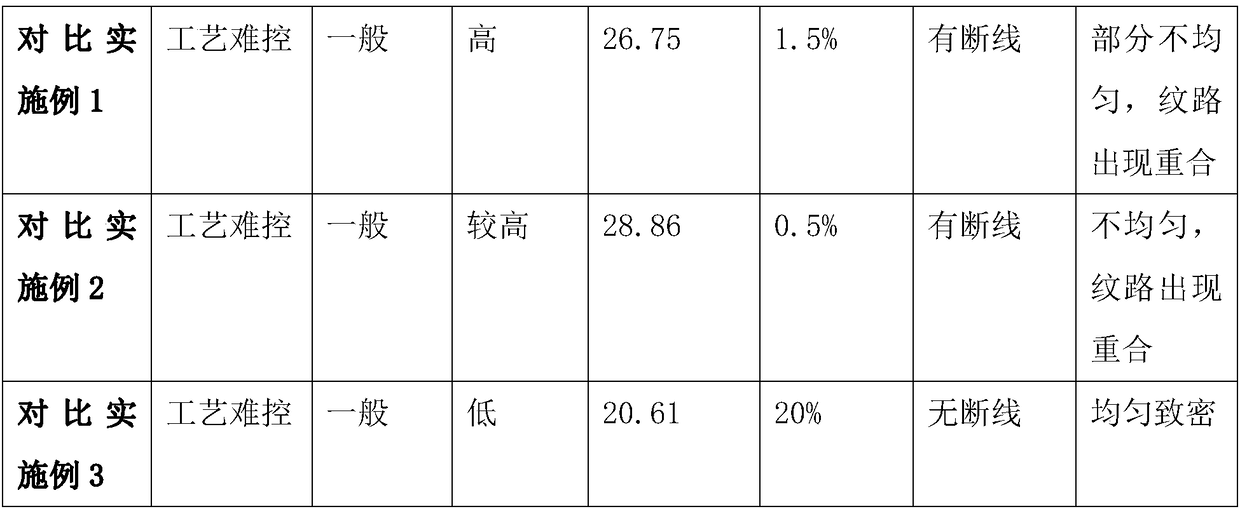

Examples

Embodiment 1

[0021] Embodiment 1-a kind of preparation technology of the rake-tooth brick without grain defect, comprises the following steps:

[0022] 1. Preparation of ceramic brick plain mud:

[0023] Carry out weighing according to the proportioning of mud billet raw material as follows:

[0024] raw material

plastic clay

vitrified clinker particles

High alumina clay

Flux

Pigment for billet

Proportion

50%

15%

6%

20%

9%

[0025] Among them, vitrified clinker particles are vitrified clinker particles formed by mixing 30% of 20-40 mesh particles, 50% of 50-70 mesh particles and 20% of 80-100 mesh particles;

[0026] Mix the above raw materials with water and knead evenly to make mud, the amount of water added is 17-20% of the weight of the mud, and after aging the mud for 24-48 hours, use a screen granulator to make mud granules;

[0027] 2. Preparation of finished rake tooth bricks:

[0028] (1) Extrude the mud particles into a v...

Embodiment 2

[0030] Embodiment 2-a kind of preparation technology of the rake-tooth brick without grain defect, comprises the following steps:

[0031] 1. Preparation of ceramic brick plain mud:

[0032] Carry out weighing according to the proportioning of mud billet raw material as follows:

[0033] raw material

plastic clay

vitrified clinker particles

High alumina clay

Flux

Pigment for billet

Proportion

60%

10%

4%

18%

6%

2%

[0034] Among them, vitrified clinker particles are vitrified clinker particles mixed with 15% of 20-40 mesh particles, 65% of 50-70 mesh particles and 20% of 80-100 mesh particles; The diameter is 200 mesh;

[0035] Mix the above raw materials with water and knead evenly to make mud, the amount of water added is 17-20% of the weight of the mud, and after aging the mud for 24-48 hours, use a screen granulator to make mud granules;

[0036] 2. Preparation of finished rake tooth bricks: ...

Embodiment 3

[0039] Embodiment 3-a kind of preparation technology of the rake tooth brick without grain defect, comprises the following steps:

[0040] 1. Preparation of ceramic brick plain mud:

[0041] Carry out weighing according to the proportioning of mud billet raw material as follows:

[0042] raw material

plastic clay

vitrified clinker particles

High alumina clay

Flux

Pigment for billet

Attapulgite

Proportion

55%

12.5%

5%

15%

6%

1.5%

5%

[0043]Among them, vitrified clinker particles are vitrified clinker particles mixed with 15% of 20-40 mesh particles, 50% of 50-70 mesh particles and 35% of 80-100 mesh particles; The diameter is 300 mesh;

[0044] Mix the above raw materials with water and knead evenly to make mud, the amount of water added is 17-20% of the weight of the mud, and after aging the mud for 24-48 hours, use a screen granulator to make mud granules;

[0045] 2. Preparation of fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com