High-temperature fire-resistant watertight insulating rubber for cable applied to safe return of ship to port, and manufacturing method of high-temperature fire-resistant watertight insulating rubber

A high-temperature refractory, manufacturing method technology, applied in the direction of rubber insulators, organic insulators, etc., can solve problems such as no cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

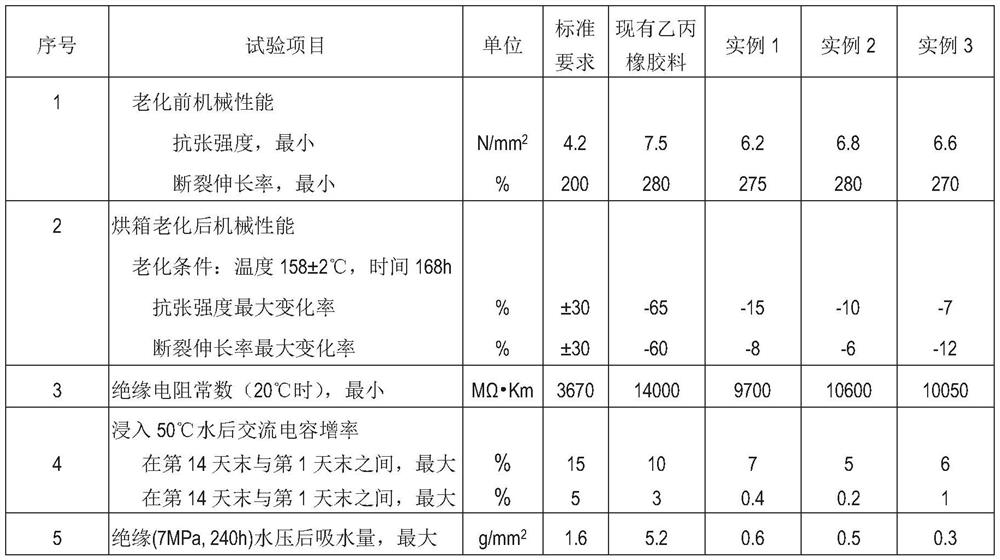

Examples

Embodiment 1

[0037] A high-temperature fire-resistant watertight insulating rubber used for a ship's safe return to port cable. The raw material components and weight content are: methyl vinyl silicone rubber 110-3-B: 20 parts; EPDM Mitsui EPT 4045M: 20 parts; Bis-tert-butylperoxycumene BIPB: 0.6 parts; trimethylolpropane trimethacrylate LS-3-80: 0.3 parts; amine-aldehyde compound antioxidant XH-3: 0.6 parts; 2-mercapto Benzimidazole MBI: 0.3 parts; Vapor phase method surface treatment silica: 5 parts; Softening temperature 400℃~700℃ Low temperature low melting point glass powder: 8 parts; Softening temperature 600℃~1100℃ High temperature low melting point glass powder: 4 parts ; Ferric oxide: 0.5 parts; Diphenylsilanediol: 1 part; SI69-50: 0.1 parts.

[0038] Described rubber adopts following preparation method:

[0039] (1) Prepare raw materials according to the following components and weight content: raw rubber: methyl vinyl silicone rubber 110-3-B: 20 parts; EPDM Mitsui EPT 4045M...

Embodiment 2

[0050] A high-temperature fire-resistant watertight insulating rubber used for a ship's safe return to port cable. The raw material components and weight content are: methyl vinyl silicone rubber 110-3-B: 20 parts; EPDM Mitsui EPT 4045M: 20 parts; Bis-tert-butylperoxycumene BIPB: 1 part; trimethylolpropane trimethacrylate LS-3-80: 0.2 part; amine-aldehyde compound antioxidant XH-3: 0.5 part; 2-mercapto Benzimidazole MBI: 0.2 parts; Vapor phase method surface treatment silica: 7 parts; Softening temperature 400℃~700℃ Low temperature low melting point glass powder: 4 parts; Softening temperature 600℃~1100℃ High temperature low melting point glass powder: 8 parts ; Ferric oxide: 1.5 parts; Diphenylsilanediol: 0.4 parts; SI69-50: 0.1 parts.

[0051] Described rubber adopts following preparation method:

[0052] (1) Prepare raw materials by following components and weight content:

[0053] Raw rubber: methyl vinyl silicone rubber 110-3-B: 20 parts; EPDM Mitsui EPT 4045M: 20 p...

Embodiment 3

[0064] A high-temperature fire-resistant watertight insulating rubber used for a ship's safe return to port cable. The raw material components and weight content are: methyl vinyl silicone rubber 110-3-B: 20 parts; EPDM Mitsui EPT 4045M: 20 parts; Bis-tert-butylperoxycumene BIPB: 0.8 parts; trimethylolpropane trimethacrylate LS-3-80: 0.2 parts; amine-aldehyde compound antioxidant XH-3: 0.4 parts; 2-mercapto Benzimidazole MBI: 0.4 parts; Vapor phase method surface treatment silica: 9 parts; Softening temperature 400℃~700℃ Low temperature low melting point glass powder: 6 parts; Softening temperature 600℃~1100℃ High temperature low melting point glass powder: 6 parts ; Ferric oxide: 1.1 parts; Diphenylsilanediol: 0.9 parts; SI69-50: 0.2 parts.

[0065] Described rubber adopts following preparation method:

[0066] (1) Prepare raw materials according to the following components and weight content: raw rubber: methyl vinyl silicone rubber 110-3-B: 20 parts; EPDM Mitsui EPT 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com