Light ceramsite prepared from oil shale semi-coke and preparation method thereof

An oil shale semi-coke, light ceramsite technology, applied in the application, household appliances, clay products and other directions, can solve the problems of endangering the health of surrounding residents, seriously polluting land and water sources, destroying soil productivity, etc. Use value, expand the melting temperature range, solve the effect of low capacity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

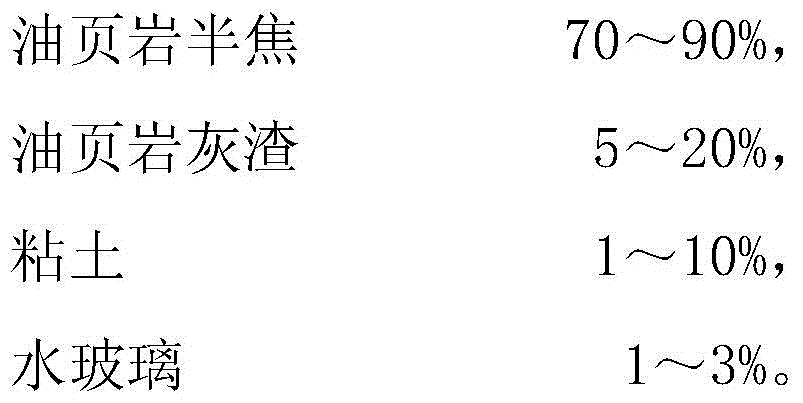

[0018] A lightweight ceramsite prepared from oil shale semi-coke, consisting of the following raw materials in mass percentage:

[0019]

[0020] The preparation method of this lightweight ceramsite comprises the steps:

[0021] 1) Crushing the oil shale semi-coke, weighing the broken oil shale semi-coke, oil shale ash and clay according to the above ratio, mixing and grinding, and grinding for 3 hours to obtain a mixture;

[0022] 2) Put the mixture into the ball forming disc of the disc granulator, prepare water glass into 0.01% aqueous solution in advance, spray it on the mixture in the disc with a spraying device, roll into balls in the ball forming disc, and get wet material ball;

[0023] 3) The maximum particle size of the obtained wet pellets is 10mm, first let it dry naturally for 12 hours, and then place it in an oven at a temperature of 100°C to dry;

[0024] 4) Place the sieved pellets in a sintering kiln for sintering at a temperature of 1130°C and keep the t...

Embodiment 2

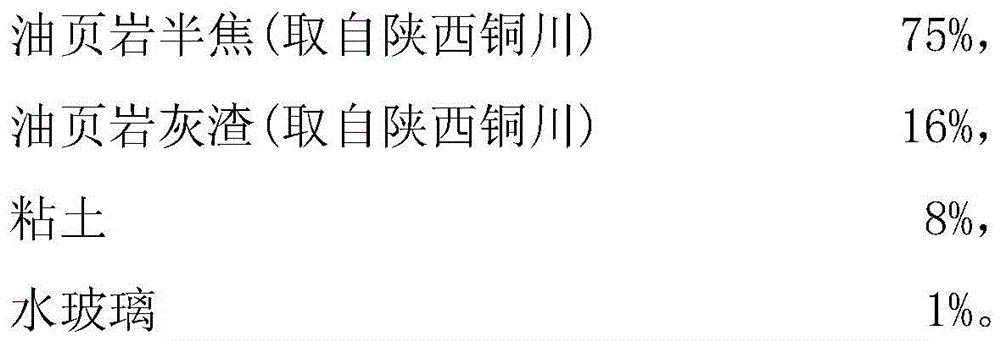

[0028] A lightweight ceramsite prepared from oil shale semi-coke, consisting of the following raw materials in mass percentage:

[0029]

[0030] The preparation method of this lightweight ceramsite comprises the steps:

[0031] 1) Crushing the oil shale semi-coke, weighing the broken oil shale semi-coke, oil shale ash and clay according to the above ratio, mixing and grinding, and grinding for 3 hours to obtain a mixture;

[0032] 2) Put the mixture into the ball forming disc of the disc granulator, prepare water glass into 0.02% aqueous solution in advance, spray it on the mixture in the disc with a spray device, roll it into balls in the ball forming disc, and get wet material ball;

[0033] 3) The maximum particle size of the obtained wet pellets is 10mm, first let it dry naturally for 12 hours, and then place it in an oven at a temperature of 100°C to dry;

[0034] 4) Place the sieved pellets in a sintering kiln for sintering at a temperature of 1140°C and keep the t...

Embodiment 3

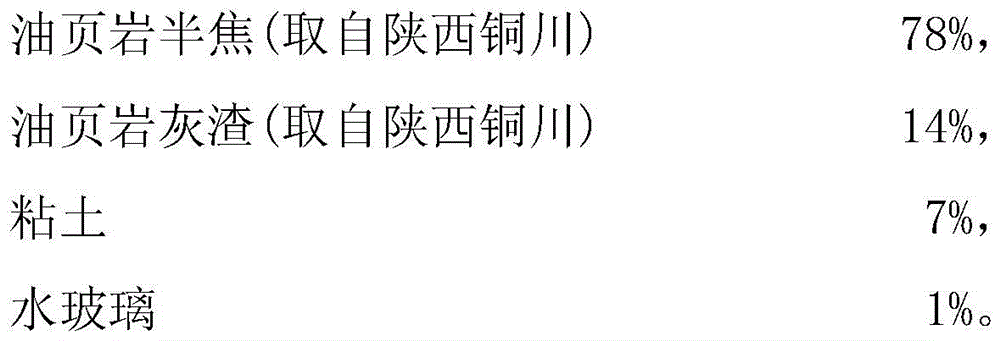

[0038] A lightweight ceramsite prepared from oil shale semi-coke, consisting of the following raw materials in mass percentage:

[0039]

[0040] The preparation method of this lightweight ceramsite comprises the steps:

[0041]1) Crushing the oil shale semi-coke, weighing the broken oil shale semi-coke, oil shale ash and clay according to the above ratio, mixing and grinding, and grinding for 3 hours to obtain a mixture;

[0042] 2) Put the mixture into the ball forming disc of the disc granulator, prepare water glass into 0.02% aqueous solution in advance, spray it on the mixture in the disc with a spray device, roll it into balls in the ball forming disc, and get wet material ball;

[0043] 3) The maximum particle size of the obtained wet pellets is 10mm, first let it dry naturally for 12 hours, and then place it in an oven at a temperature of 100°C to dry;

[0044] 4) Place the sieved pellets in a sintering kiln for sintering at a temperature of 1150°C and keep the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com