A kind of easy-to-clean milky white glaze suitable for low-expansion ceramics and its preparation method and application

A low-expansion, ceramic technology, applied in the field of ceramic glaze, to achieve the effect of improving cleanability, less pores, technological progress and application development promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

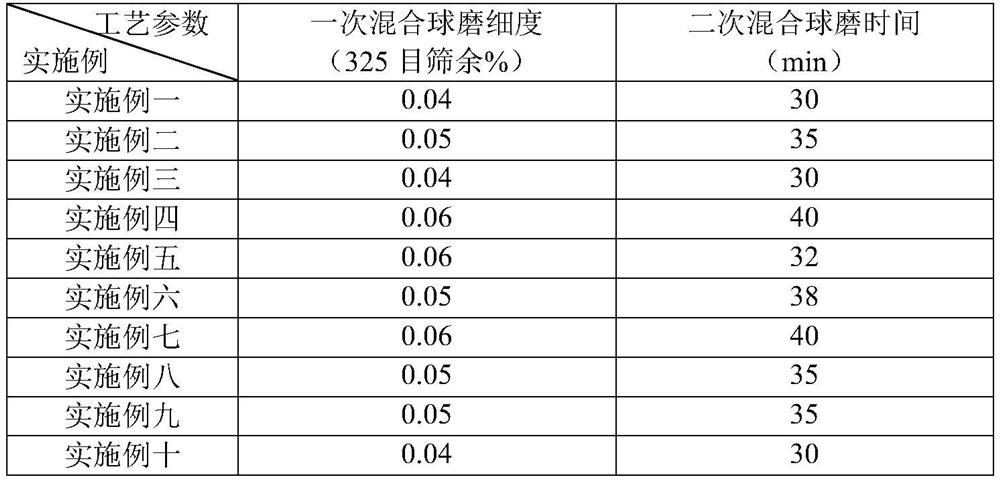

Examples

Embodiment Construction

[0016] An embodiment of the present invention is an easy-to-clean milky white glaze suitable for low-expansion ceramics. The raw materials are composed of: petalite feldspar 45-55wt%, kaolin 4-7wt%, high-temperature low-expansion frit 25-35wt%, high-temperature transparent frit Block 5-15wt%, silicon micropowder 0-10wt%, glaze stabilizer 3-6wt%.

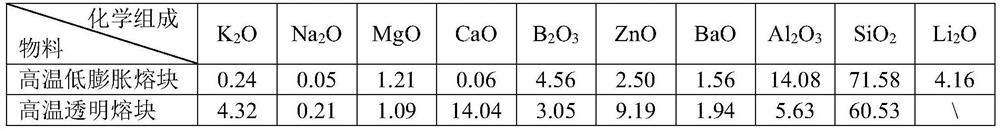

[0017] Among them, the chemical compositions of the high-temperature low-expansion frit and the high-temperature transparent frit are shown in Table 1.

[0018] Table 1 Chemical composition of high temperature low expansion frit and high temperature transparent frit of the present invention

[0019]

[0020] The particle size of silicon micropowder is 2000 mesh; the glaze stabilizer is zirconium silicate micropowder, and its fineness is ≤0.5μm.

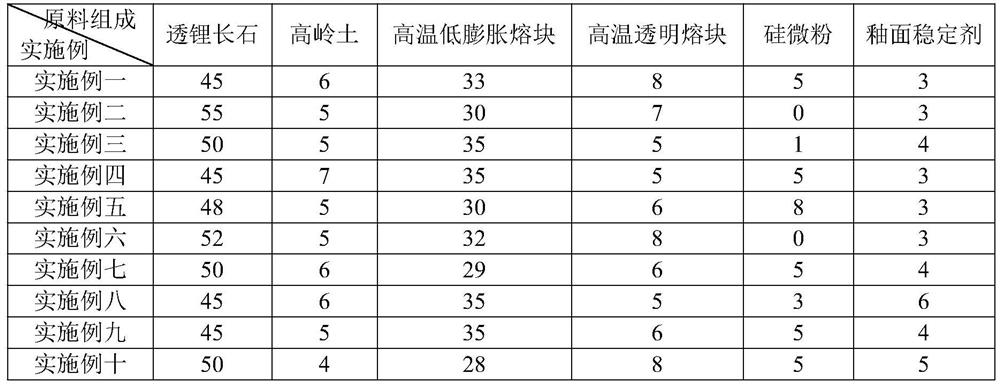

[0021] The raw material composition of each embodiment is as shown in table 2.

[0022] Table 2 The raw material composition (wt%) of the easy-clean milky white glaze of each embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com