Lightweight and high-strength ceramsite prepared by taking slate as raw material, and preparation method thereof

A high-strength ceramsite and slate technology, which is applied to clay products, ceramic products, and other household appliances, can solve the problems of ceramsite products such as high bulk density, high water absorption rate, and low cylinder compressive strength, so as to improve the use value, The effect of lowering the firing temperature and improving the quality of ceramsite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

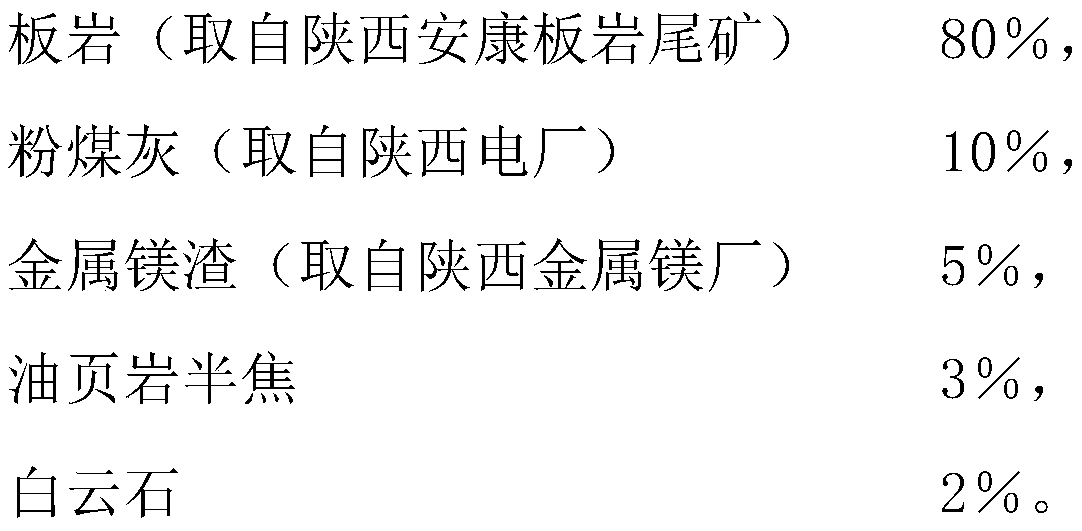

[0031] Embodiment 1 of the present invention provides a kind of lightweight high-strength ceramsite with slate as raw material, and its raw material ratio according to mass percentage is:

[0032]

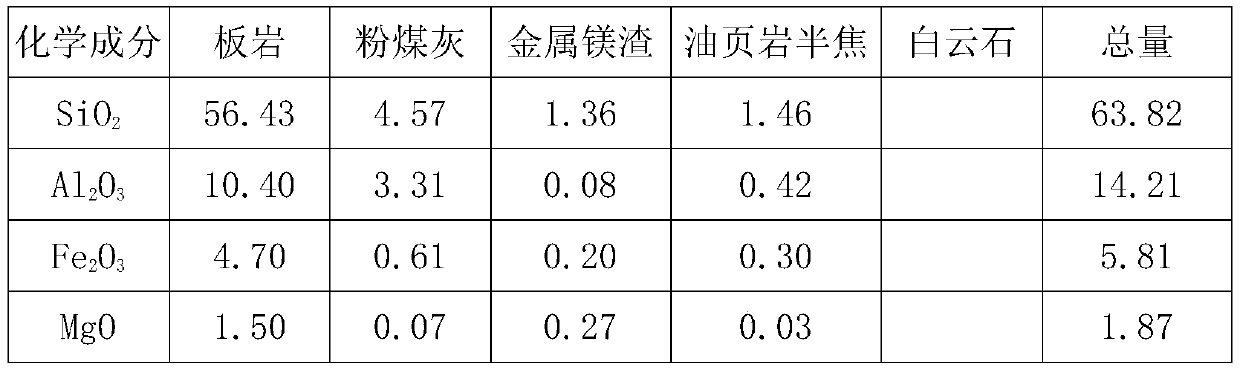

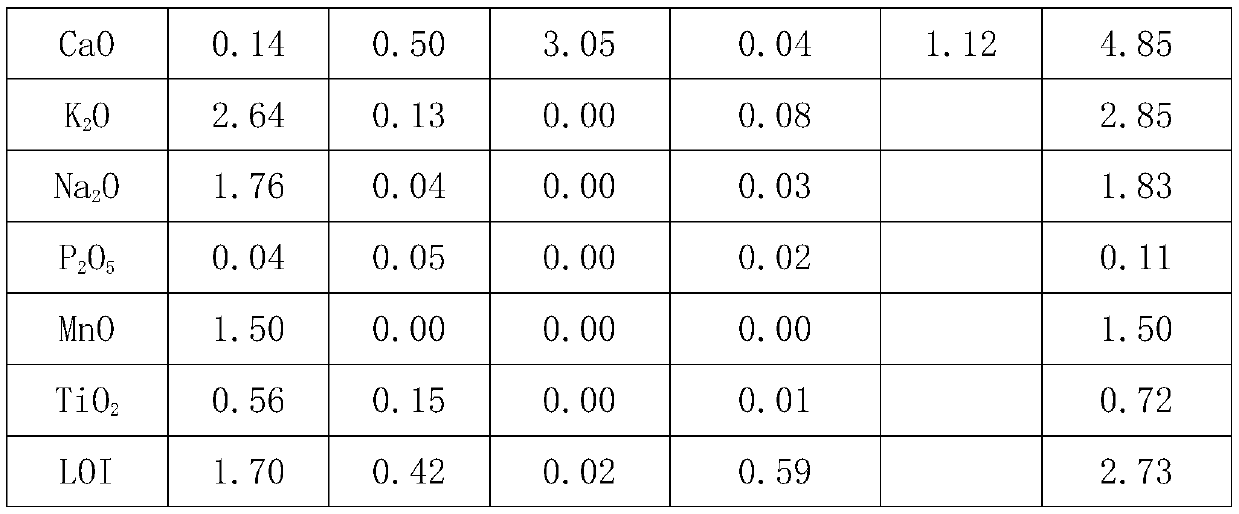

[0033] In this embodiment 1, the light high-strength ceramsite with slate as raw material, the chemical composition and content of the raw material are shown in Table 5 below:

[0034] The raw material chemical composition and content (%) involved in table 5 embodiment 1

[0035]

[0036]

[0037] Its manufacturing method is implemented according to the following steps:

[0038] (1) Weigh 80% of slate, 10% of fly ash, 5% of magnesium metal slag, 3% of oil shale semi-coke, and 2% of dolomite according to mass percentage, and crush and grind the slate to 200 mesh, the metal magnesium slag, oil shale semi-coke and dolomite are ground to 200 mesh, and the above raw materials are mixed to obtain a mixture;

[0039] (2) Put the mixture into the intensive mixer, spray water on ...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a kind of lightweight high-strength ceramsite with slate as raw material, and its raw material ratio according to mass percentage is:

[0046]

[0047]

[0048] In this embodiment 2, the light high-strength ceramsite with slate as raw material, the chemical composition and content of the raw material are shown in Table 6 below:

[0049] The raw material chemical composition and content (%) involved in table 6 embodiment 2

[0050] chemical composition slate fly ash Magnesium slag Oil Shale Semi-coke dolomite Total SiO 2

49.35 8.22 1.36 2.44 61.37 Al 2 o 3

9.10 5.96 0.08 0.70 15.84 Fe 2 o 3

4.12 1.10 0.20 0.50 5.92 MgO 1.32 0.13 0.27 0.05 1.77 CaO 0.13 0.92 3.05 0.07 1.12 5.29 K 2 o

2.31 0.23 0.00 0.14 2.68 Na 2 o

1.54 0.07 0.00 0.05 1.66 P 2 o 5

0.04 0.09 0.00 0.03 0.16 Mn...

Embodiment 3

[0059] Embodiment 3 of the present invention provides a kind of lightweight high-strength ceramsite with slate as raw material, and its raw material ratio according to mass percentage is:

[0060]

[0061] In this embodiment 3, the light high-strength ceramsite with slate as raw material, the chemical composition and content of the raw material are shown in Table 7 below:

[0062] The raw material chemical composition and content (%) involved in table 7 embodiment 3

[0063] chemical composition slate fly ash Magnesium slag Oil Shale Semi-coke dolomite Total SiO 2

42.32 12.79 1.36 2.44 58.91 Al 2 o 3

7.80 9.27 0.08 0.70 17.85 Fe 2 o 3

3.53 1.71 0.20 0.50 5.94 MgO 1.13 0.20 0.27 0.05 1.64 CaO 0.11 1.41 3.05 0.07 1.12 5.76 K 2 o

1.98 0.36 0.00 0.14 2.48 Na 2 o

1.32 0.11 0.00 0.05 1.47 P 2 o 5

0.03 0.14 0.00 0.03 0.21 MnO 1.13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com