Preparation method and application of thermoplastic acrylonitrile-based terpolymer

A technology of acrylonitrile-based terpolymers and acrylonitrile terpolymers, applied in the direction of single-component synthetic polymer rayon, textiles and papermaking, fiber chemical characteristics, etc., can solve the problem of very high precision and performance Poor repeatability and other problems, to achieve the effect of simple and easy to control polymerization process, wide range of melting processing temperature and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

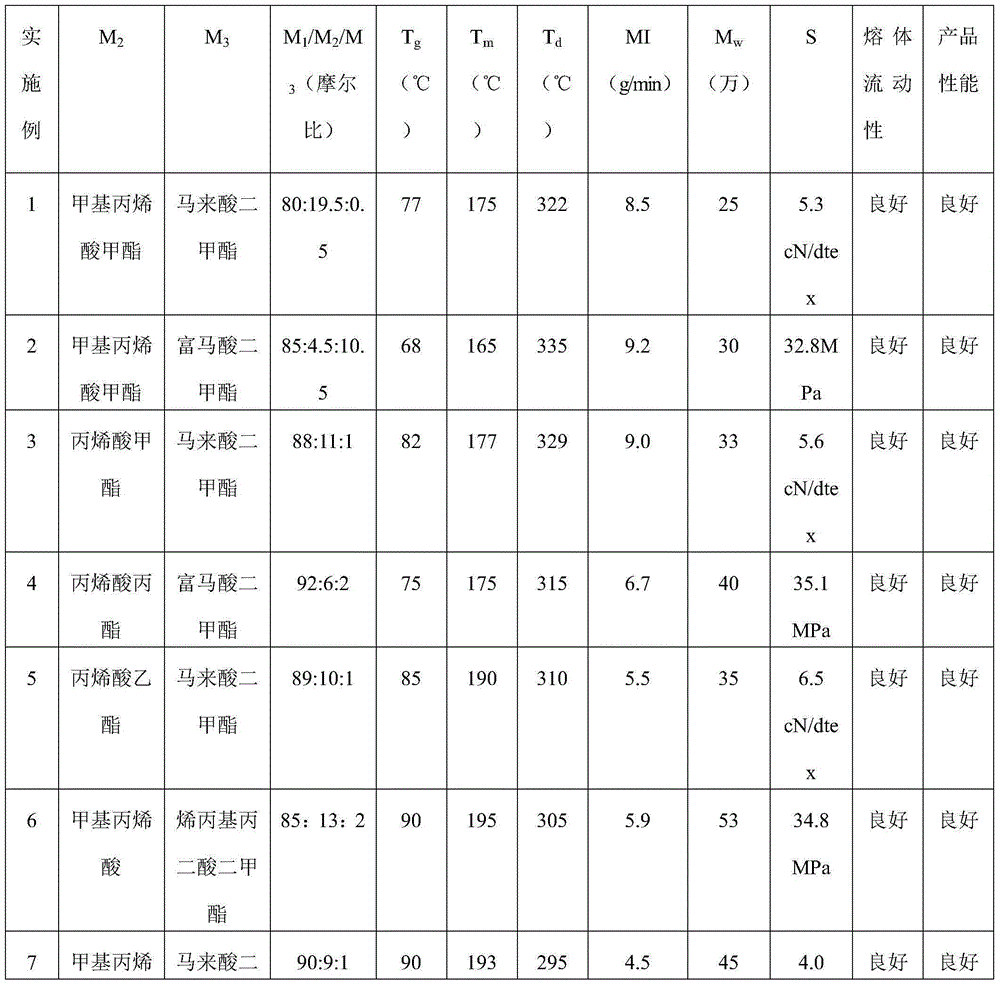

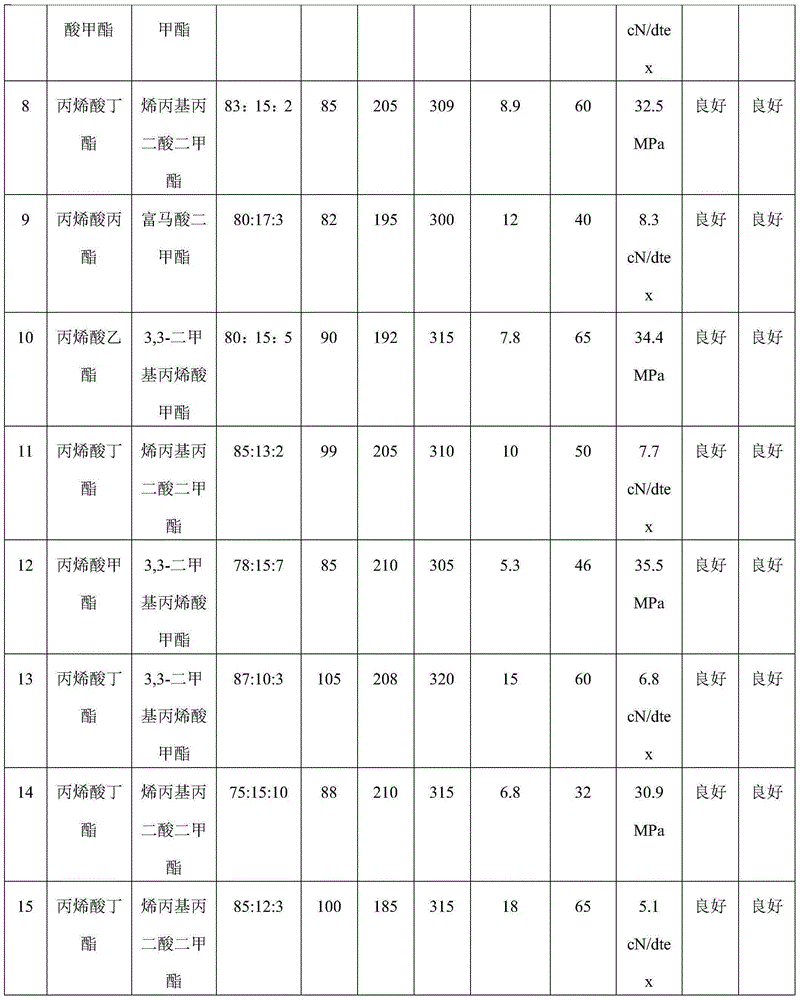

Examples

Embodiment 1

[0033] A reactive monomer for preparing thermoplastic acrylonitrile-based terpolymer, which consists of acrylonitrile, methyl methacrylate and dimethyl maleate in a molar ratio of 80.0:19.5:0.5.

[0034] A preparation method of thermoplastic acrylonitrile-based terpolymer, the steps are as follows:

[0035] Add 0.6L deionized water to the 2L reaction kettle, pass through N 2 The air in the reaction kettle was discharged, the temperature of the reaction system was raised to 70°C, and a compound emulsifier (the mass ratio of OP-10 and sodium lauryl sulfate was 1:9) was added with a total monomer amount of 1.5wt.%. , add the monomer premix that accounts for 1 / 2 of the monomer premix mass, the chain transfer agent dodecyl mercaptan that accounts for 5wt.% of the total amount of reaction monomers and the initiator that accounts for 1wt.% of the total amount of reaction monomers Ammonium persulfate (ammonium persulfate is added in the form of an aqueous solution with a concentration ...

Embodiment 2

[0040] A reactive monomer for preparing thermoplastic acrylonitrile-based terpolymers, consisting of acrylonitrile, methyl methacrylate and dimethyl fumarate in a molar ratio of 85.0:4.5:10.5.

[0041] A preparation method of thermoplastic acrylonitrile-based terpolymer, the steps are as follows:

[0042] Add 0.8L deionized water to the 2L reaction kettle, pass through N 2 The air in the system was discharged, the temperature of the reaction system was raised to 50°C, and a compound emulsifier (a mixture of Tween-60 and sodium lauryl sulfate with a mass ratio of 9:1), Add monomer premix accounting for 1 / 5 of the total monomer premix (the molar ratio of acrylonitrile, methyl methacrylate and dimethyl fumarate is 85.0:4.5:10.5), and then add 0.4wt.% initiator sodium persulfate (sodium persulfate is added in the form of an aqueous solution of 0.1wt.% with a concentration of 0.1wt.%); Mercaptan, after reacting for 1h, adjust the reaction temperature of the system to be 60°C, add...

Embodiment 3

[0046] A reactive monomer for preparing thermoplastic acrylonitrile-based terpolymer, which consists of acrylonitrile, methyl acrylate and dimethyl maleate in a molar ratio of 88:11:1.

[0047] A preparation method of thermoplastic acrylonitrile-based terpolymer, the steps are as follows:

[0048] Replace sodium lauryl sulfate in Example 1 with SP-80, and the mass ratio of the two single components of the compound emulsifier is 8:2; replace methyl methacrylate with methyl acrylate, and the feeding mole of three monomers The ratio is 88:11:1, and the others are the same as in Example 1 to obtain an acrylonitrile-based terpolymer.

[0049] The experimental results of differential scanning calorimeter and thermogravimetric analysis show that the obtained thermoplastic acrylonitrile-based terpolymer has a glass transition temperature of 82°C, a melting point of 177°C and a thermal decomposition temperature of 329°C. Adopt gel permeation chromatography to characterize the molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com