Purple glaze for insulator processing and processing method of purple glaze

A processing method and technology for insulators, which are applied to the purple glaze for insulator processing and its processing field, can solve the problem that the glazing strength, the porcelain bending strength, the insulator breakdown rate fail to meet the requirements, and the color glaze and the electric porcelain body cannot be combined. In order to achieve the effect of more targeted ball milling, shorten the ball milling time, and improve the performance of porcelain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

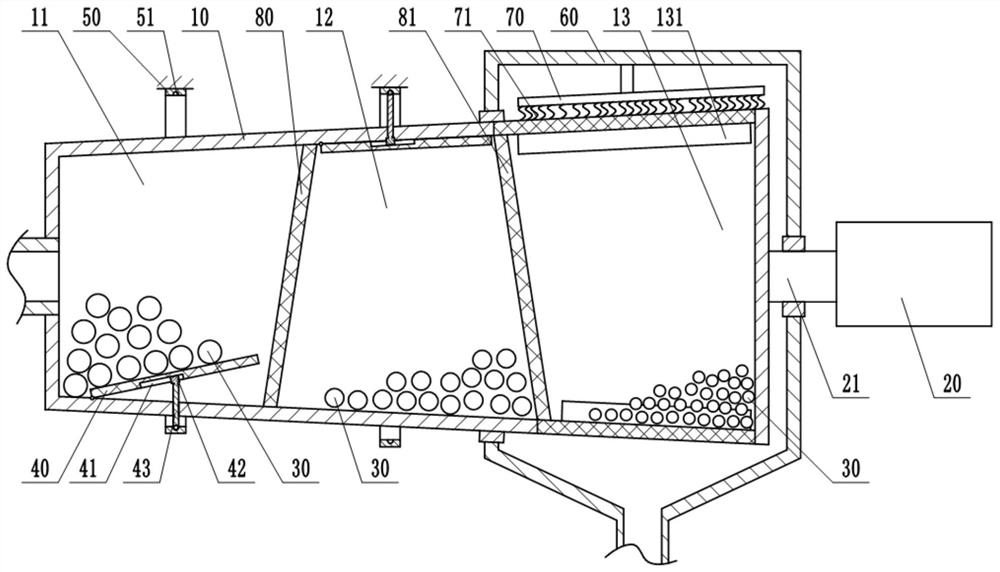

Image

Examples

Embodiment 1

[0118] This embodiment discloses a purple glaze for insulator processing, including the following raw materials in parts by mass: 28 parts of potassium feldspar, 8 parts of albite, 6 parts of ball clay, 21 parts of hard kaolin, 12 parts of calcined talc, and 7 parts of limestone , 24 parts of quartz powder, 2 parts of barium carbonate, 7 parts of purple color base.

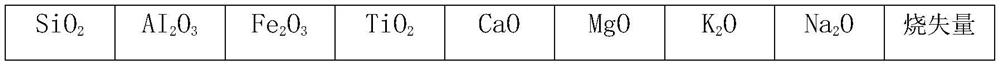

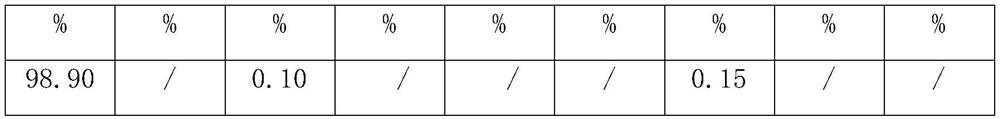

[0119] Purple glaze in the present embodiment comprises following chemical composition:

[0120] SiO 2

AI 2 o 3

Fe 2 o 3

CaO MgO K 2 o

Na 2 o

BaO LL 65.4% 15.1% 0.5% 3.2% 3.5% 2.8% 1.3% 1.8% 6.4%

[0121] The processing method of purple glaze for insulator processing of the present embodiment comprises the following steps:

[0122](1) Prepare the following raw materials in parts by mass: 28 parts of potassium feldspar, 8 parts of albite, 6 parts of ball clay, 21 parts of hard kaolin, 12 parts of calcined talc, 7 parts of limestone, 24 parts of quar...

Embodiment 2

[0139] This embodiment discloses a purple glaze for insulator processing, including the following raw materials in parts by mass: 26 parts of potassium feldspar, 5 parts of albite, 4 parts of ball clay, 20 parts of hard kaolin, 9 parts of calcined talc, and 5 parts of limestone , 22 parts of quartz powder, 1.2 parts of barium carbonate, 7 parts of purple color base.

[0140] Purple glaze in the present embodiment comprises following chemical composition:

[0141] SiO 2

AI 2 o 3

Fe 2 o 3

CaO MgO K 2 o

Na 2 o

BaO LL 65.7% 14.8% 0.4% 3.5% 3.7% 2.8% 1.6% 0.8% 6.7%

[0142] The processing method of purple glaze for insulator processing of the present embodiment comprises the following steps:

[0143] (1) Prepare the following raw materials in parts by mass: 26 parts of potassium feldspar, 5 parts of albite, 4 parts of ball clay, 20 parts of hard kaolin, 9 parts of calcined talc, 5 parts of limestone, 22 parts of qua...

Embodiment 3

[0148] This embodiment discloses a purple glaze for insulator processing, including the following raw materials in parts by mass: 31 parts of potassium feldspar, 9 parts of albite, 7 parts of ball clay, 22 parts of hard kaolin, 13 parts of calcined talc, and 9 parts of limestone , 26 parts of quartz powder, 3 parts of barium carbonate, 8 parts of purple color base.

[0149] Purple glaze in the present embodiment comprises following chemical composition:

[0150] SiO 2

AI 2 o 3

Fe 2 o 3

CaO MgO K 2 o

Na 2 o

BaO LL 65.1% 14.7% 0.6% 3.4% 3.5% 2.6% 1.4% 2.1% 6.6%

[0151] The processing method of purple glaze for insulator processing of the present embodiment comprises the following steps:

[0152] (1) Prepare the following raw materials in parts by mass: 31 parts of potassium feldspar, 9 parts of albite, 7 parts of ball clay, 22 parts of hard kaolin, 13 parts of calcined talc, 9 parts of limestone, 26 parts of qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com