White ceramic high-performance transparent glaze and preparation method thereof

一种高性能、透明釉的技术,应用在日用陶瓷釉料领域,能够解决限制德化白瓷使用的范围、熔融温度范围窄、不能稳定保证等问题,达到釉面膨胀系数可调、熔融温度范围广、经济效益和社会效益显著的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

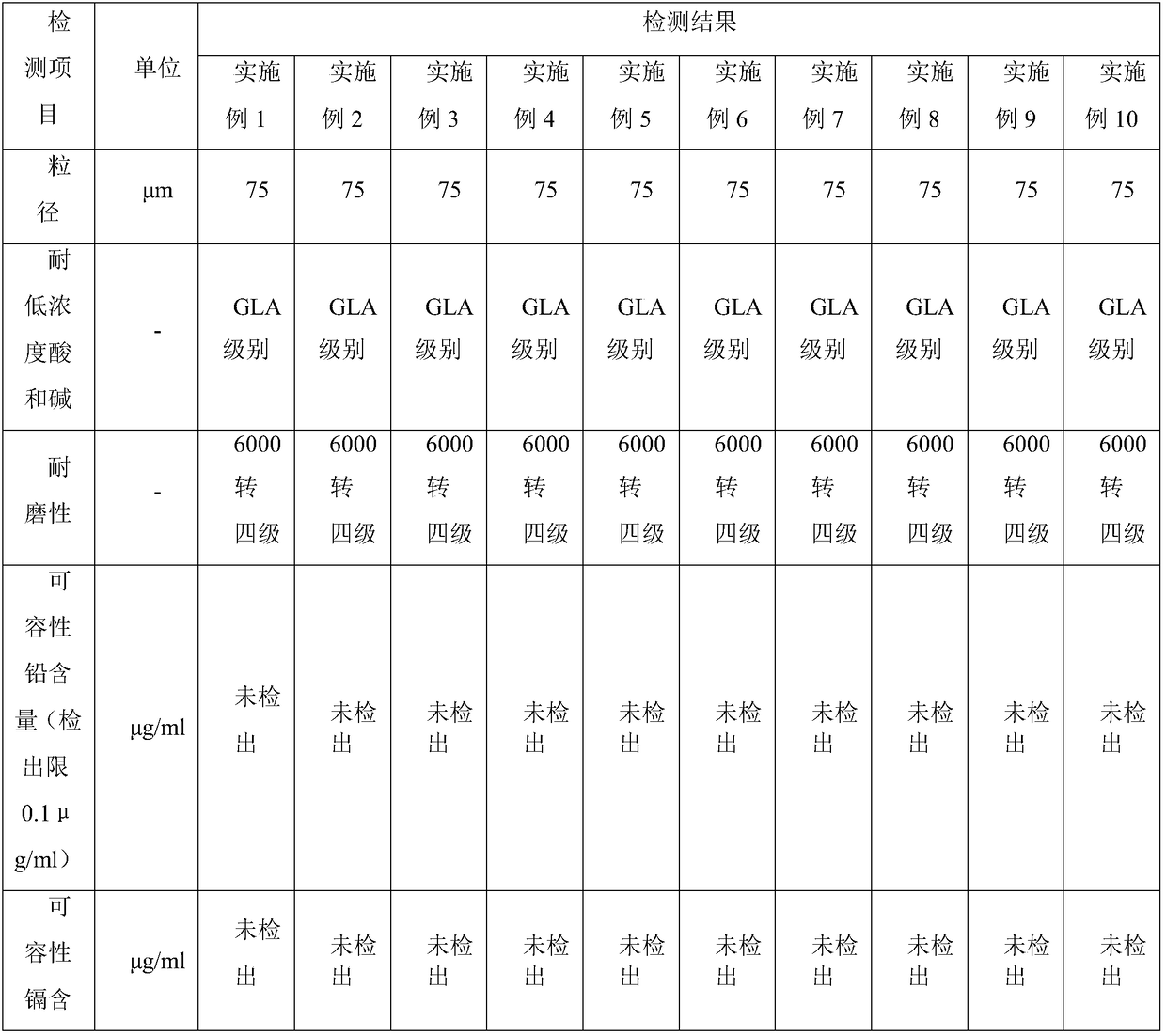

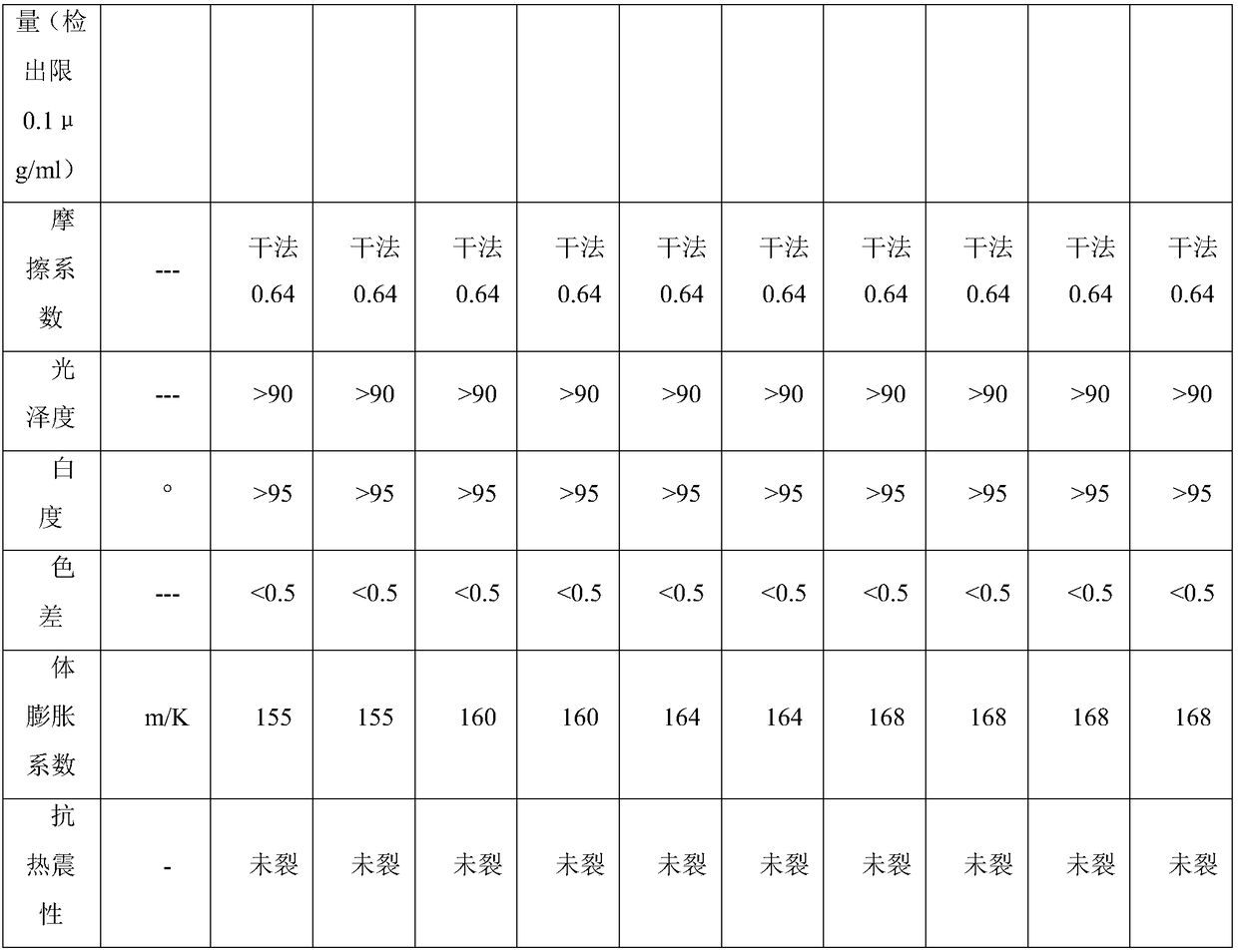

Examples

Embodiment 1

[0024] The high-performance transparent glaze of white porcelain is mainly composed of the following components according to weight percentage: terrazzo potassium feldspar 20%, kaolin 6wt%, burnt talc 15wt%, barium carbonate 2%, calcined zinc oxide 9wt%, terrazzo 30wt%, glaze surface Stabilizer 3wt%, expansion coefficient regulator 15wt%, the total of the above components is 100wt%.

[0025] Wherein, the glaze stabilizer is zirconium silicate micropowder, and the expansion coefficient regulator is spodumene.

[0026] Wherein, the particle size of the glaze stabilizer is 1 μm.

[0027] The preparation method of white porcelain high-performance transparent glaze comprises the following steps:

[0028] Step 1. Prepare materials:

[0029] The terrazzo feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide and terrazzo are proportioned according to a total of 100wt% to obtain a primary proportioning material, and then the resulting primary proportioning ...

Embodiment 2

[0036] The high-performance transparent glaze of white porcelain is mainly composed of the following components according to weight percentage: terrazzo feldspar 25%, kaolin 6wt%, burnt talc 12wt%, barium carbonate 2%, calcined zinc oxide 7wt%, terrazzo 32wt%, glaze surface The stability is 3wt%, the expansion coefficient regulator is 13wt%, and the total of the above components is 100wt%.

[0037] Wherein, the glaze stabilizer is zirconia micropowder, and the expansion coefficient regulator is petalite.

[0038] Wherein, the particle size of the glaze stabilizer is 2 μm.

[0039] The preparation method of white porcelain high-performance transparent glaze comprises the following steps:

[0040] Step 1. Prepare materials:

[0041] The terrazzo feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide and terrazzo are proportioned according to a total of 100wt% to obtain a primary proportioning material, and then the resulting primary proportioning mate...

Embodiment 3

[0048] The high-performance transparent glaze of white porcelain is mainly composed of the following components according to weight percentage: terrazzo potassium feldspar 30%, kaolin 8wt%, burnt talc 8wt%, barium carbonate 4%, calcined zinc oxide 9wt%, terrazzo 25wt%, glaze surface Stabilizer 3wt%, expansion coefficient regulator 13wt%, the total of the above components is 100wt%.

[0049]Wherein, the glaze stabilizer is zirconium silicate micropowder, and the expansion coefficient regulator is mainly composed of the following components according to weight percentage: 40 wt% of spodumene and 60 wt% of petalite.

[0050] Wherein, the particle size of the glaze stabilizer is 3 μm.

[0051] The preparation method of white porcelain high-performance transparent glaze comprises the following steps:

[0052] Step 1. Prepare materials:

[0053] The terrazzo feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide and terrazzo are proportioned according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com