Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

A high-hardness, high-wear-resistant technology, applied in the field of architectural ceramic glazes, can solve problems such as Vickers hardness not meeting high use requirements, unfavorable sustainable development of production, and failure to meet energy conservation and emission reduction, etc., to achieve glazed surface dimensionality Improvement of hardness, promotion of technological progress and application development, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

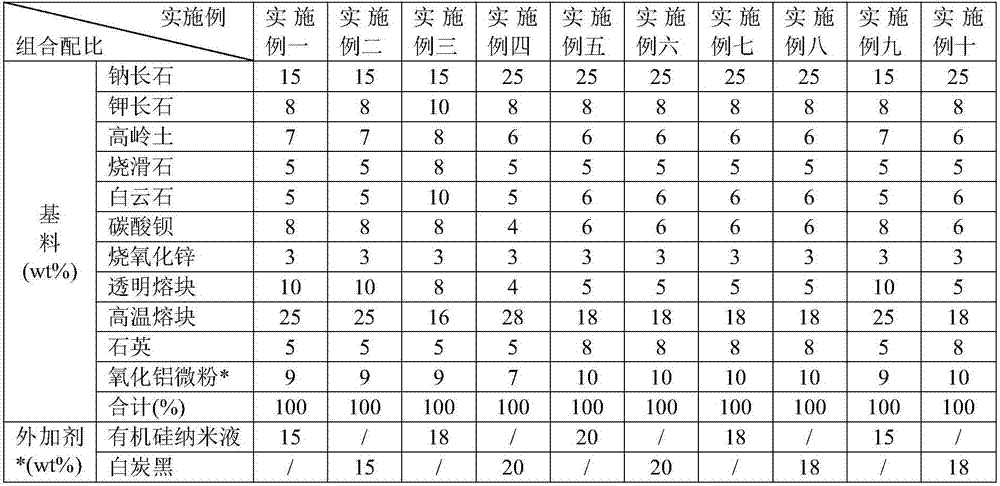

[0021] An embodiment of the present invention is a low-temperature, high-hardness, high-wear-resistance full-polish glaze, including a base material and an admixture, and its composition ratio is shown in Table 1, and the composition ratio of transparent frit and high-temperature frit is shown in Table 2.

[0022] Table 1 The composition ratio of low-temperature, high-hardness, high-wear-resisting full-polished glazes of various embodiments of the present invention

[0023]

[0024] *The particle size of alumina fine powder is 25~40μm.

[0025] *The amount of admixture is the weight percentage relative to the base material.

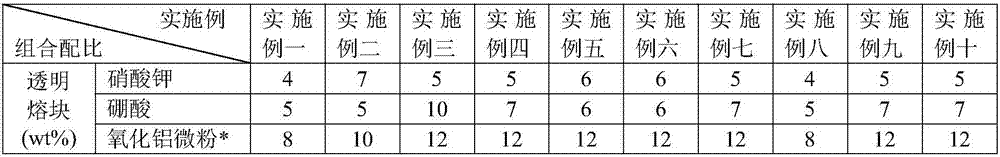

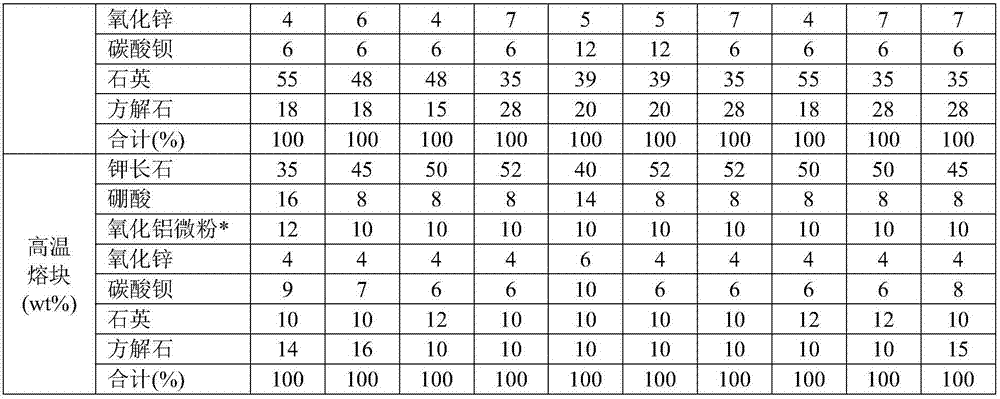

[0026] Table 2 The composition ratio of transparent frit and high-temperature frit in each embodiment of the present invention

[0027]

[0028]

[0029] *The particle size of alumina fine powder is 25~40μm.

[0030] An embodiment of the present invention is a method for preparing a low-temperature, high-hardness, high-wear-resistant full-polis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com