Red glaze and preparation method thereof

A red glaze and red technology, applied in the field of red glaze and its preparation, can solve the problems of single color and can not meet the needs of customers, and achieve the effect of increasing the bonding effect, making the porcelain surface smooth and bright, and improving elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

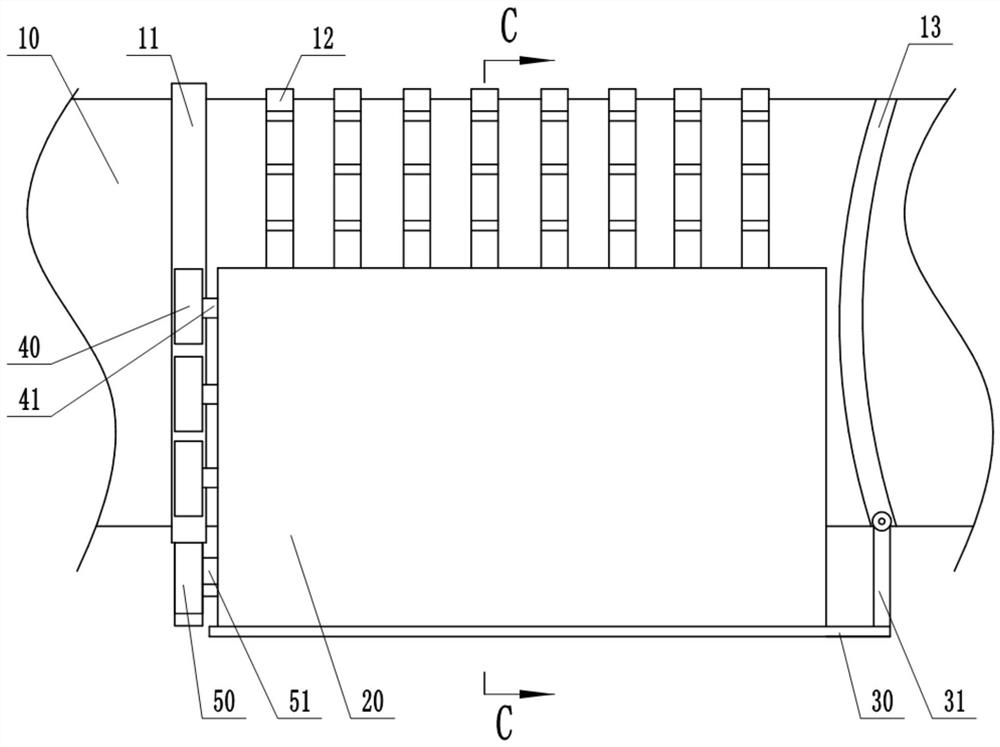

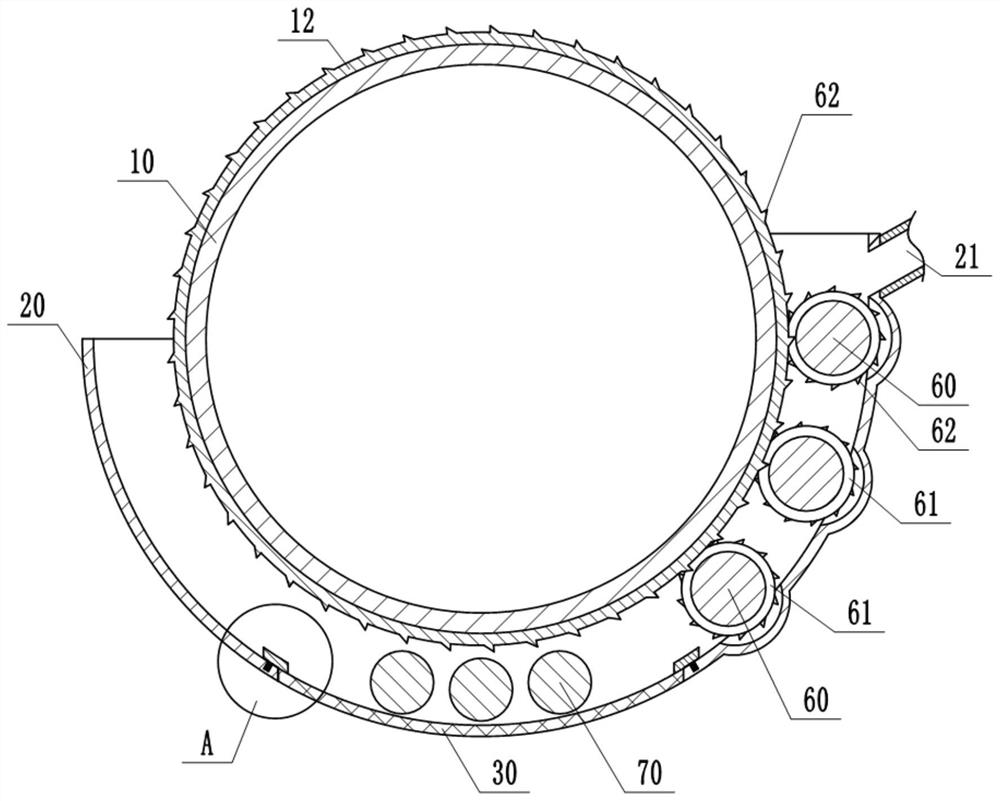

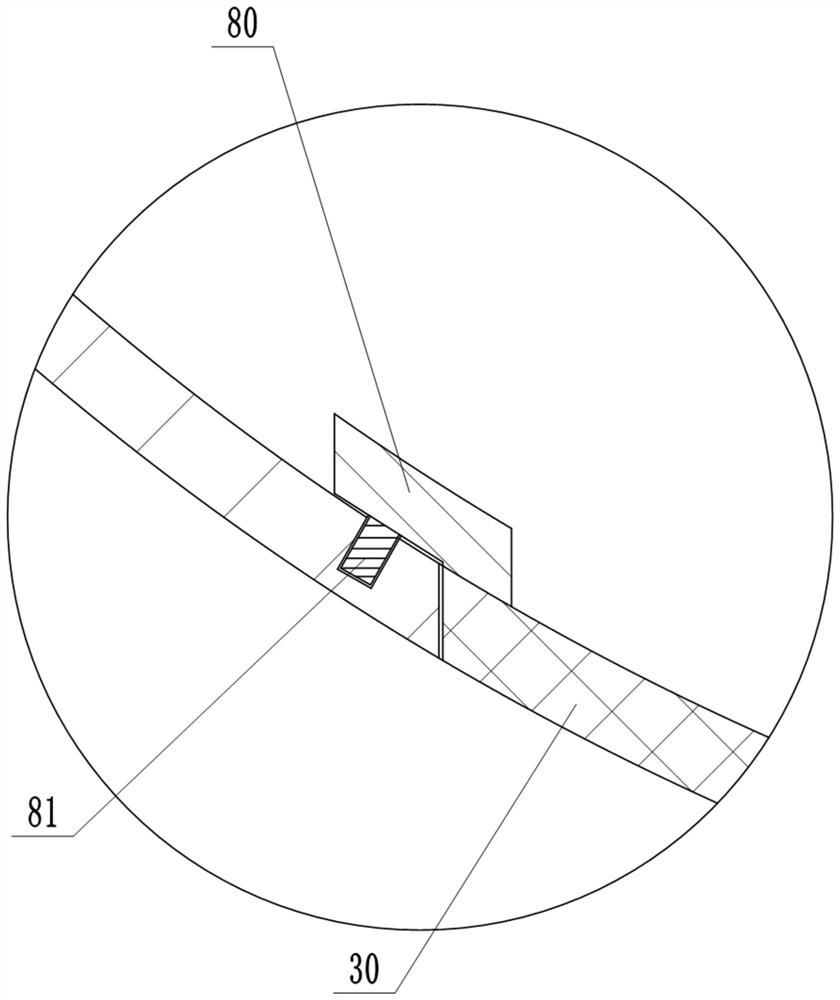

Image

Examples

Embodiment 1

[0113] This embodiment discloses a kind of preparation method of red glaze, comprises the following steps:

[0114] (1) Prepare the following raw materials in parts by mass: 31 parts of potassium feldspar, 6 parts of albite, 6 parts of ball clay, 19 parts of hard kaolin, 12 parts of calcined talc, 7 parts of limestone, 22 parts of quartz powder, barium carbonate 2 parts, 8 parts of red color base.

[0115] (2) Ball milling: use a ball mill to mill the raw materials; the mass ratio of raw materials: ball material: water in the ball mill is 1:2.5:0.8. The pellets include 30% pellets with a specification of 20-35mm, 50% pellets with a specification of 45-65mm, and 20% pellets with a specification of 65-80mm. During the ball milling process, 0.3% sodium carboxymethyl cellulose based on the weight of the raw materials was added. The fineness of the raw material after ball milling is controlled to 0.06-0.3% of the 360-mesh sieve.

[0116] (3) Iron removal treatment: After the bal...

Embodiment 2

[0133] In the present embodiment, a kind of preparation method of red glaze comprises the following steps:

[0134] (1) Prepare the following raw materials in parts by mass: 28 parts of potassium feldspar, 5 parts of albite, 5 parts of ball clay, 19 parts of hard kaolin, 10 parts of calcined talc, 6 parts of limestone, 22 parts of quartz powder, barium carbonate 1.2 parts, 7 parts of red color base.

[0135] (2) Ball milling: use a ball mill to mill the raw materials; the mass ratio of raw materials: ball material: water in the ball mill is 1: 2.4-2.6: 0.7-0.9. The pellets include 25% pellets with a specification of 20-35mm, 52% pellets with a specification of 45-65mm, and 23% pellets with a specification of 65-80mm. During the ball milling process, 0.3% sodium carboxymethyl cellulose based on the weight of the raw materials was added. The fineness of the raw material after ball milling is controlled to be 0.06-0.3% on a 360-mesh sieve.

[0136] (3) Iron removal treatment: ...

Embodiment 3

[0142] A kind of preparation method of present embodiment red glaze comprises the following steps:

[0143] (1) Prepare the following raw materials in parts by mass: 28 parts of potassium feldspar, 5 parts of albite, 5 parts of ball clay, 19 parts of hard kaolin, 10 parts of calcined talc, 6 parts of limestone, 22 parts of quartz powder, barium carbonate 1.2 parts, 7 parts of red color base.

[0144] (2) Ball milling: use a ball mill to mill the raw materials; the mass ratio of raw materials: ball material: water in the ball mill is 1: 2.4-2.6: 0.7-0.9. The pellets include 32% pellets with a specification of 20-35mm, 46% pellets with a specification of 45-65mm, and 22% pellets with a specification of 65-80mm. Add 0.32% sodium carboxymethyl cellulose in the ball milling process based on the weight of the raw material. The fineness of the raw material after ball milling is controlled to be 0.06-0.3% on a 360-mesh sieve.

[0145] (3) Iron removal treatment: After the ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com