High-performance transparent ceramic whiteware glaze and production method thereof

A high-performance, transparent glaze technology, which is applied in the field of daily-use ceramic glazes, can solve the problems of limiting the range of use of Dehua white porcelain, narrow melting temperature range, and inability to guarantee stability, and achieves adjustable glaze expansion coefficient and melting Wide temperature range, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

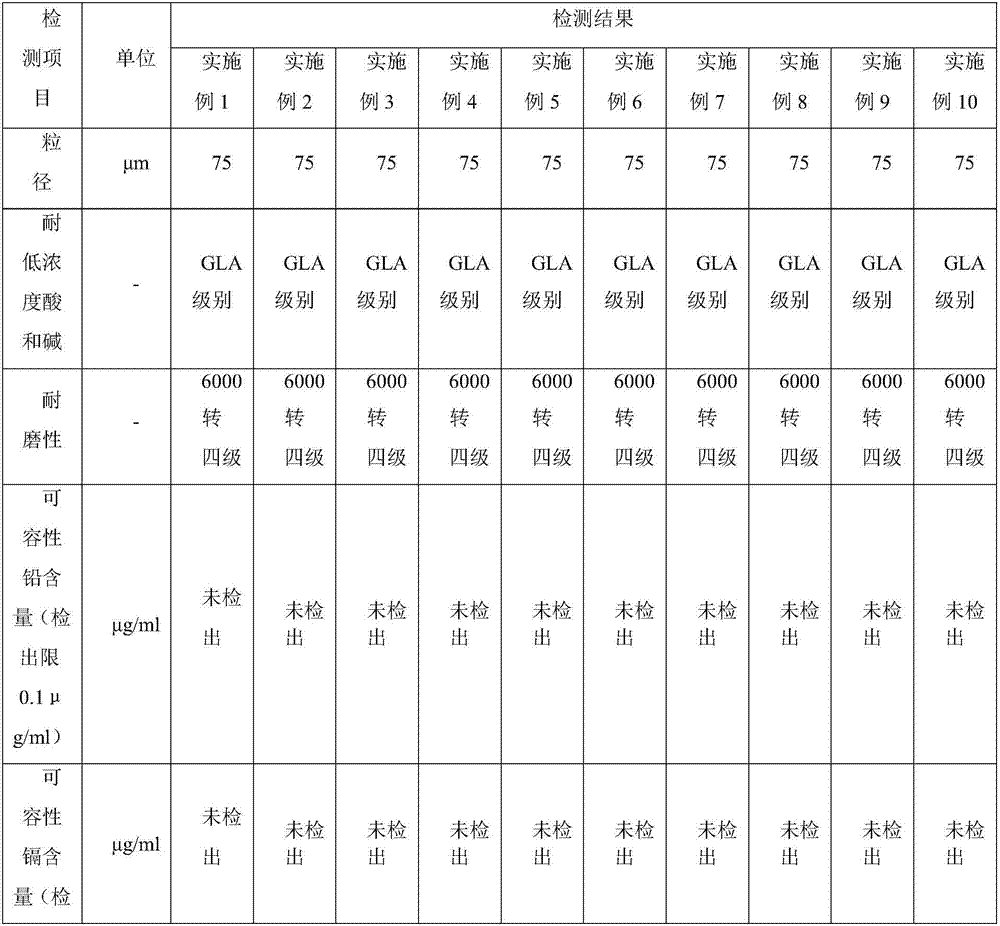

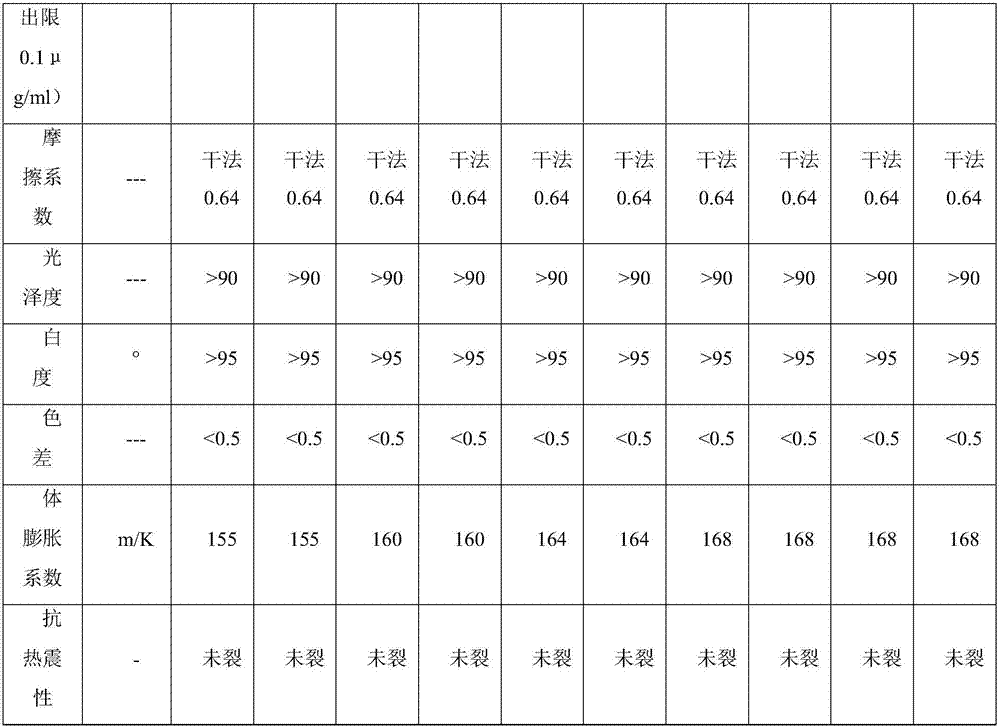

Examples

Embodiment 1

[0023] White porcelain high-performance transparent glaze is mainly composed of the following components according to weight percentage: terrazzo feldspar 20%, kaolin 6wt%, burnt talc 15wt%, barium carbonate 2%, calcined zinc oxide 9wt%, terrazzo 30wt%, glaze surface Stabilizer 3wt%, expansion coefficient regulator 15wt%, the total of the above components is 100wt%.

[0024] Wherein, the glaze stabilizer is zirconium silicate micropowder, and the expansion coefficient regulator is spodumene.

[0025] Wherein, the particle size of the glaze stabilizer is 1 μm.

[0026] The preparation method of white porcelain high-performance transparent glaze comprises the following steps:

[0027] Step 1. Prepare materials:

[0028] Proportioning the terrazzo feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide and ink quartz according to a total of 100wt% to obtain a primary proportioning material, and then performing a primary proportioning process on the obta...

Embodiment 2

[0035] White porcelain high-performance transparent glaze is mainly composed of the following components according to weight percentage: terrazzo feldspar 25%, kaolin 6wt%, burnt talc 12wt%, barium carbonate 2%, calcined zinc oxide 7wt%, terrazzo 32wt%, glaze surface The stability is 3wt%, the expansion coefficient regulator is 13wt%, and the total of the above components is 100wt%.

[0036] Wherein, the glaze stabilizer is zirconia micropowder, and the expansion coefficient regulator is petalite.

[0037] Wherein, the particle size of the glaze stabilizer is 2 μm.

[0038] The preparation method of white porcelain high-performance transparent glaze comprises the following steps:

[0039] Step 1. Prepare materials:

[0040] Proportioning the terrazzo feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide and ink quartz according to a total of 100wt% to obtain a primary proportioning material, and then performing a primary proportioning process on th...

Embodiment 3

[0047] The high-performance transparent glaze of white porcelain is mainly composed of the following components according to weight percentage: terrazzo potassium feldspar 30%, kaolin 8wt%, burnt talc 8wt%, barium carbonate 4%, calcined zinc oxide 9wt%, terrazzo 25wt%, glaze Stabilizer 3wt%, expansion coefficient regulator 13wt%, the total of the above components is 100wt%.

[0048] Wherein, the glaze stabilizer is zirconium silicate micropowder, and the expansion coefficient regulator is mainly composed of the following components according to weight percentage: 40wt% of spodumene and 60wt% of petalite.

[0049] Wherein, the particle size of the glaze stabilizer is 3 μm.

[0050] The preparation method of white porcelain high-performance transparent glaze comprises the following steps:

[0051] Step 1. Prepare materials:

[0052] Proportioning the terrazzo feldspar, kaolin, calcined talc, dolomite, barium carbonate, calcined zinc oxide and ink quartz according to a total of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com