Composite rare earth RE cast aluminum alloy material and preparation method thereof

A technology for casting aluminum alloy and compound rare earth, which is applied in the field of compound rare earth RE casting aluminum alloy material and its preparation, and can solve the problem that the shape and size of eutectic silicon cannot be effectively improved, the content of Sc and Er are low, and the eutectic silicon cannot be formed effectively. and other problems, to achieve the effect of high performance and quality, simplified process, high plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

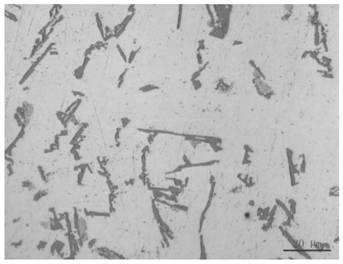

Examples

Embodiment 1

[0053] A preparation method of composite rare earth RE casting aluminum alloy material, comprising the following steps:

[0054] (1) Heat the Er and Sc alloys to melt, keep them at 741°C for 15 minutes, and remove the slag;

[0055] (2) Add high-silicon cast aluminum alloy, stir for 2 minutes to melt, keep warm at 741°C for 15 minutes, and stir for 2 minutes;

[0056] (3) Add Al-2.01% Sc master alloy, keep warm for 15min, stir for 1min, keep warm for 15min at 741°C, stir for 1min, keep warm for 15min, stir for 1min, remove slag, and heat up to 760°C;

[0057] (4) Add Al-5.82% Er intermediate alloy, stir for 5 minutes, keep warm at 760°C for 20 minutes, stir for 5 minutes, remove slag, continue to keep warm for 20 minutes, cool down to 741°C, keep warm for 10 minutes, cool down to 710°C, nitrogen refining and degassing for 15 minutes, Remove slag, cool down to 705°C, and let stand for 30 minutes;

[0058] (5) Cool down to 600°C with the furnace, keep it warm for 10min, pour i...

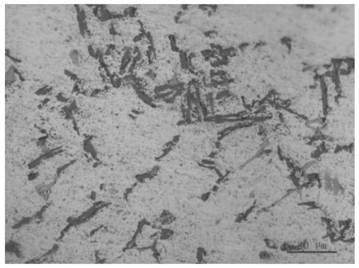

Embodiment 2

[0062] A preparation method of composite rare earth RE casting aluminum alloy material, comprising the following steps:

[0063] (1) Heating the Er and Sc alloys to melt, keeping them at 721°C for 30 minutes, and removing the slag;

[0064] (2) Add high-silicon cast aluminum alloy, stir and melt, keep warm at 731°C for 29 minutes, and stir for 2 minutes;

[0065] (3) Add Al-2.01% Sc master alloy, keep warm for 10min, stir for 1min to melt, keep warm for 20min at 731°C, stir for 1min, keep warm for 20min, stir for 1min, remove slag, and heat up to 750°C;

[0066] (4) Add Al-5.82% Er intermediate alloy, stir for 5 minutes, keep warm at 760°C for 20 minutes, stir for 5 minutes, remove slag, continue to keep warm for 15 minutes, cool down to 721°C, keep warm for 10 minutes, nitrogen refining and degassing for 10 minutes, remove slag, and cool down to 705°C, stand still for 35 minutes;

[0067] (5) Cool down to 580°C with the furnace, keep it warm for 5 minutes, pour it into a ca...

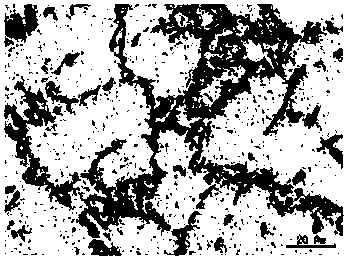

Embodiment 3

[0072] A preparation method of composite rare earth RE casting aluminum alloy material, comprising the following steps:

[0073] (1) Heating the Er and Sc alloys to melt, keeping the temperature at 759°C for 10 minutes, and removing the slag;

[0074] (2) Add Si element, stir for 2 minutes to melt, keep warm at 759°C for 10 minutes, and stir for 2 minutes;

[0075] (3) Add Al-2.01% Sc master alloy, heat for 20 minutes, stir for 1 minute to melt, heat at 750°C for 10 minutes, stir for 3 minutes, heat for 20 minutes, stir for 3 minutes, remove slag, and heat up to 790°C;

[0076] (4) Add Al-5.82% Er intermediate alloy, stir for 10 minutes, keep warm at 790°C for 15 minutes, stir for 10 minutes, remove slag, continue to keep warm for 25 minutes, cool down to 745°C, keep warm for 15 minutes, nitrogen refining and degassing for 20 minutes, remove slag, and cool down to 715°C, let stand for 35 minutes;

[0077](5) Cool down to 580°C with the furnace, keep it warm for 15min, pour i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com