Quick analysis method of fuel gas component and gas chromatography system thereof

A technology for rapid analysis of gas components, applied in the field of analysis and testing, which can solve problems such as shortened equipment life, long separation time, and molecular sieve column damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

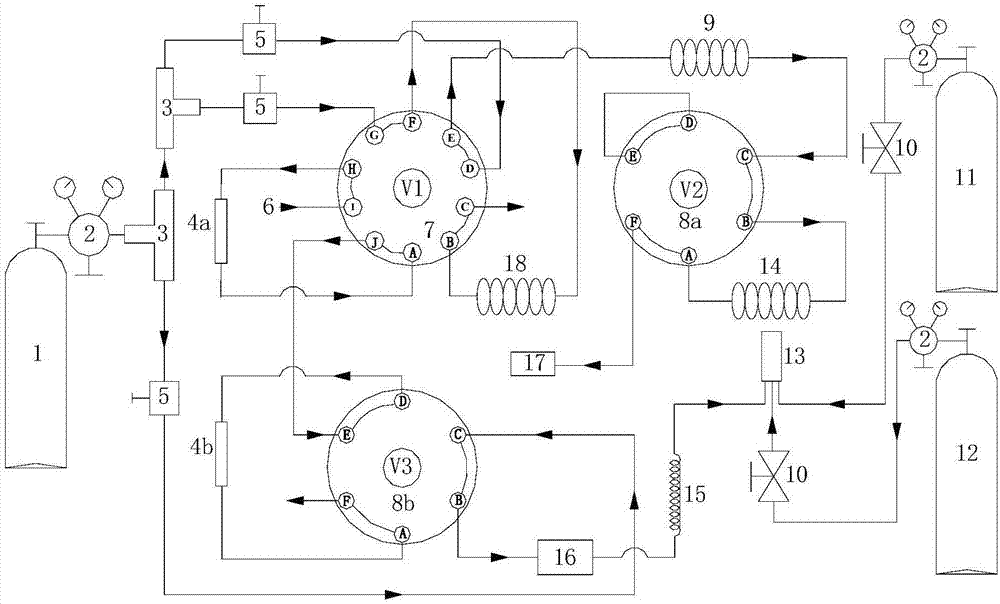

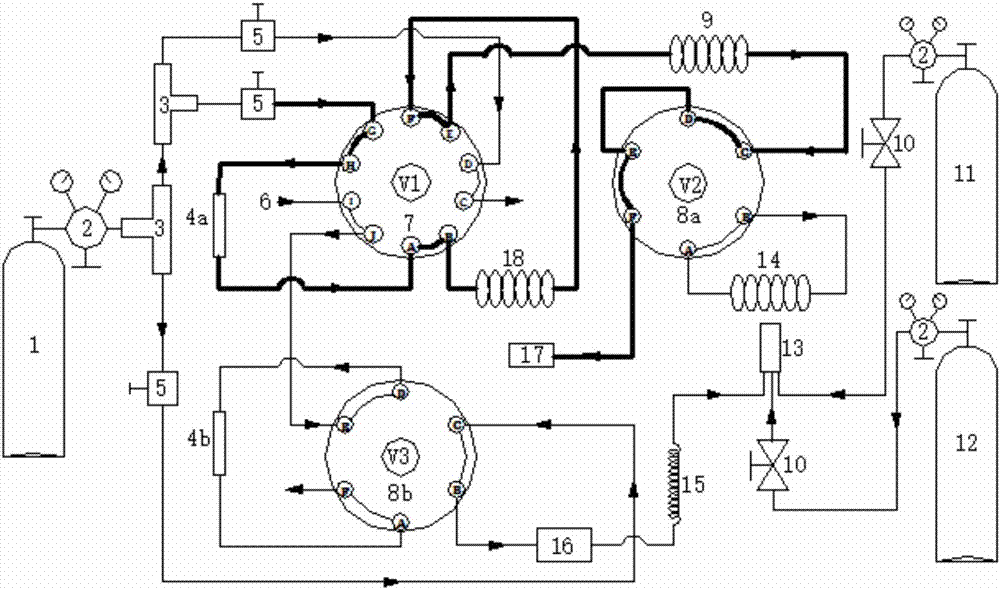

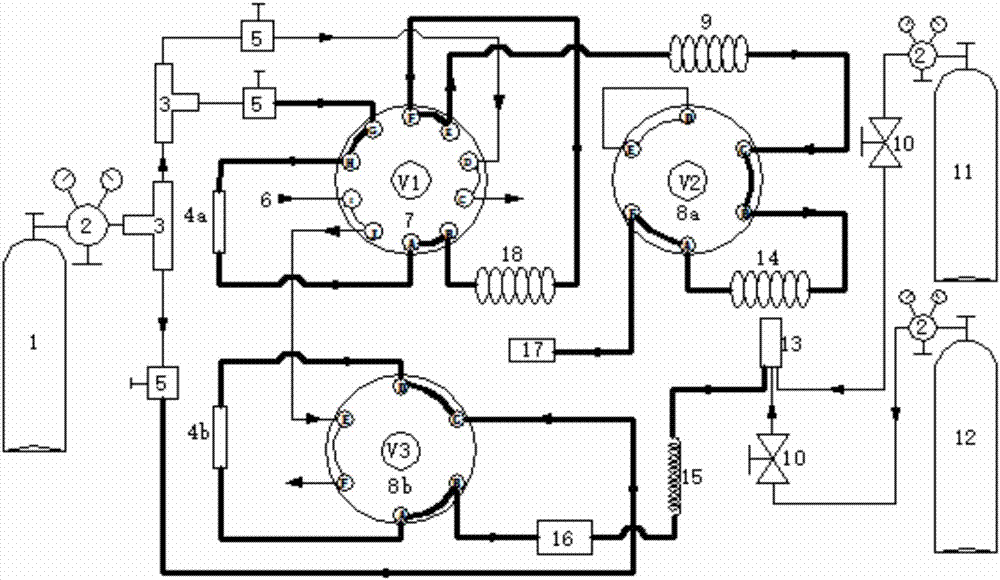

Method used

Image

Examples

Embodiment 1

[0066] Sample: conventional natural gas from a certain place in Sichuan;

[0067] Method and chromatographic analysis system: see above.

[0068] Analysis results: See Table 1.

[0069] Analytical chromatogram: see Figure 4 .

[0070] The time to detect all components is within 30 minutes, and the separation effect of each component is good.

[0071] Table 1 Composition of conventional natural gas in a place in Sichuan

[0072]

[0073]

[0074] Note: C 7 +, C 8 +, C 9 +Respectively refer to the sum of the hydrocarbon components with 7, or 8, or 9 carbons or more.

Embodiment 2

[0076] Sample: coke oven gas from an enterprise in Shanxi;

[0077] Method and chromatographic analysis system: see above.

[0078] Analysis results: see Table 2.

[0079] Analytical chromatogram: see Figure 5 .

[0080] The time for all detection of all components is within 30 minutes, and the separation effect is still good for the detection of components that are not completely the same as in Example 1.

[0081] Table 2 Composition of coke oven gas in an enterprise in Shanxi

[0082]

[0083]

Embodiment 3

[0085] Sample: Biomass gas from a place in Sichuan;

[0086] Method and chromatographic analysis system: see above.

[0087] Analysis results: see Table 3.

[0088] Analytical chromatogram: see Figure 6 .

[0089] The detection time of all components is within 30 minutes, and the separation effect of biomass gas components is still good.

[0090] Table 3 Composition of biomass gas in a place in Sichuan

[0091]

[0092]

[0093] It can be seen that the chromatographic analysis system of the present invention and the method for rapid analysis of different gas components using the system have a wide range of applications, good separation effect, fast analysis speed, no interference between components, and accurate and reliable results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com