Production process of sesamol-rich fragrant sesame oil

A technology of sesame sesame oil and production process, applied in the directions of fat oil/fat production, production of fat, edible oil/fat, etc., can solve the problems of poor transparency, deepening color of sesame oil, and increased risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

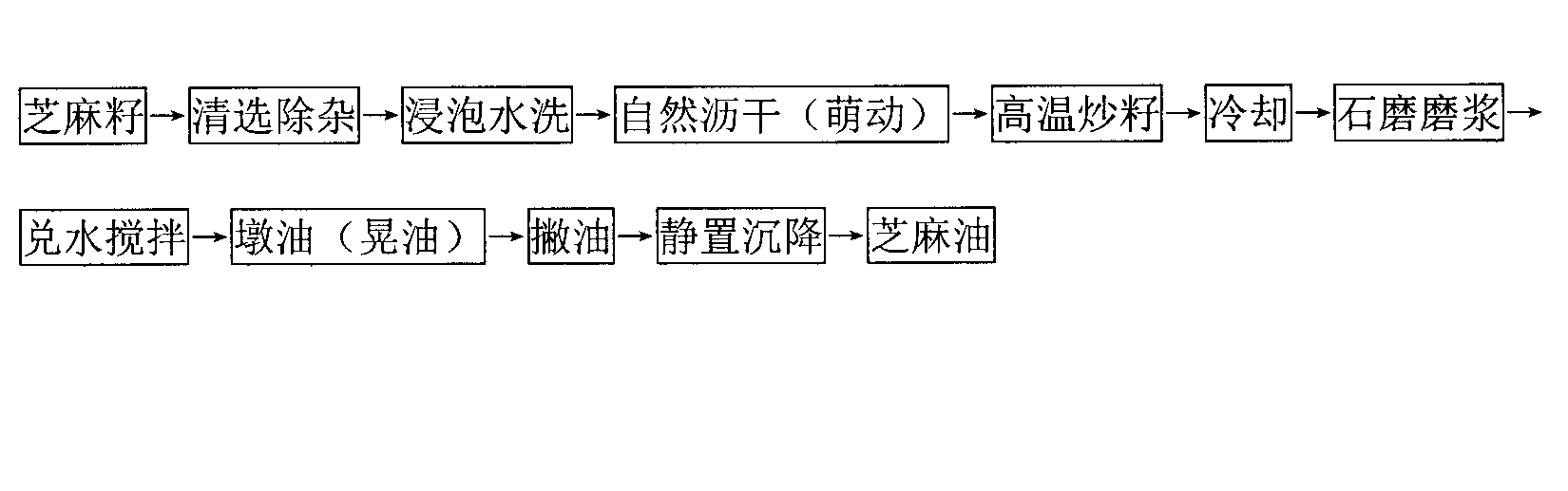

Method used

Image

Examples

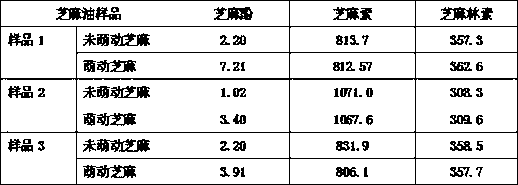

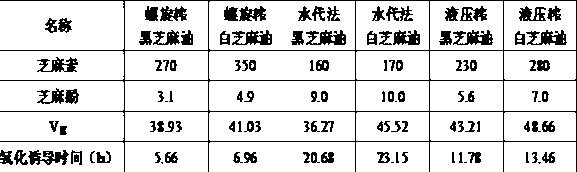

Embodiment 1

[0053] Sesame seeds (white sesame, black sesame, etc.) that meet the quality index of "Sesame GB 11761-2006" are cleaned and removed after screening, winnowing, specific gravity stone removal, magnetic separation, etc.; The sesame is soaked and washed in clean water at about 25°C, and the soaked and washed sesame is sent to a container with a gap at the bottom to drain the water naturally. Drain and germinate for 3 hours, and the water content of the sesame after draining is 25%; After soaking, washing and draining, the volume of the seeds expands, and 5%-20% of the sesame seeds have inconspicuous germination at the radicle, and the sesame seeds are in a germination state; the germinated sesame seeds after soaking, washing and draining are sent to high temperature Stir-fry the seeds in a frying pan (or frying machine), the temperature of the frying seeds is 140 ° C, the roasting time is 25 minutes, the water content of the sesame seeds after frying is 0.2%, and then cool with c...

Embodiment 2

[0056] The difference between this example and Example 1 is that the origin of the sesame samples is different, the germination time of draining is 4 hours, the moisture content of the sesame after draining is about 20%, the temperature of roasting seeds is 160°C, and the roasting time is 20 minutes. same.

[0057] After testing, the sesamol and vitamin E contents (mg / 100g) of the sesame oil produced in this example are as follows: the content of sesamol is 5.56, and the content of vitamin E is 30.98.

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com