Patents

Literature

82results about How to "Crisp texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soybean tissue albumin dried meat floss

ActiveCN103704463ACrisp textureUnique flavorCheese manufactureVegetable proteins working-upTissue proteinVegetarian diets

The invention discloses soybean tissue albumin dried meat floss. The vegetarian dried meat floss is prepared by performing immersion, cleaning, deodorization, peculiar smell removal, dewatering, chopping into strips, mixing, frying, drying, cooling, packaging and the like on a soybean tissue protein raw material. The soybean tissue protein is used as a full vegetable instead of a filler to be developed and applied; by virtue of rich soybean proteins, the prepared vegetarian dried meat floss is loose, is moderate in sweetness and saltness, tastes mellow and delicious and has a unique flavor; people of all ages can eat the soybean tissue albumin dried meat floss; particularly a new convenient and delicious option is supplied to vegetarians and is a meat-substitute product with rich nutrition.

Owner:ZUMING BEAN PROD

Preparaton method of full debydrated nutritive multiflavoured dried beef

InactiveCN1555730AFull of nutritionCrisp textureFood preservationFood preparationNutrientMedicinal herbs

A fully dewatered multi-taste nutritive beef jerky is prepared from fresh beef throuth cutting to become blocks, washing, preboiling, boiling in the medicinal liquid prepared from 11 Chinese-medicinal materials tearing to become strips or small blocks, immersing in flavouring liquid prepared from 11 flavouring materials, and drying. Its advantages are rich nutrients, multiple taste, and health-care function.

Owner:金龙国

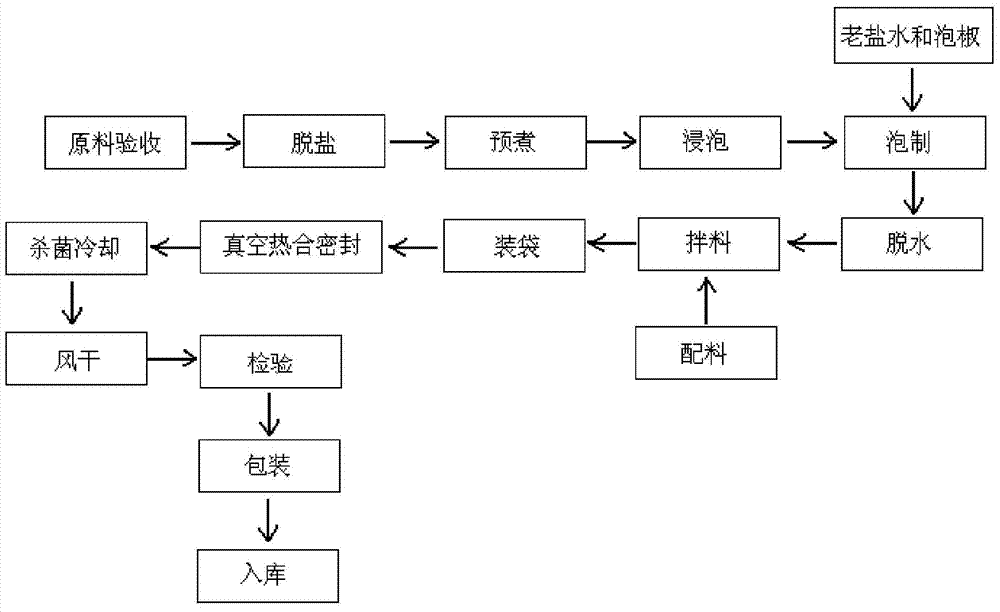

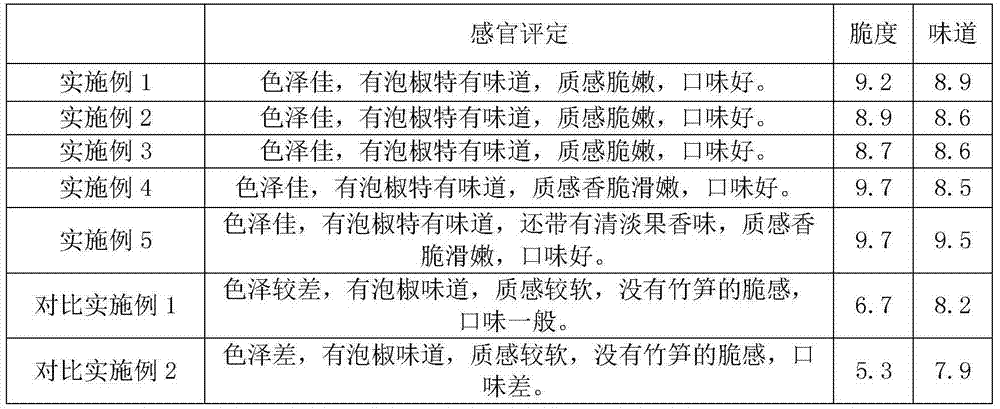

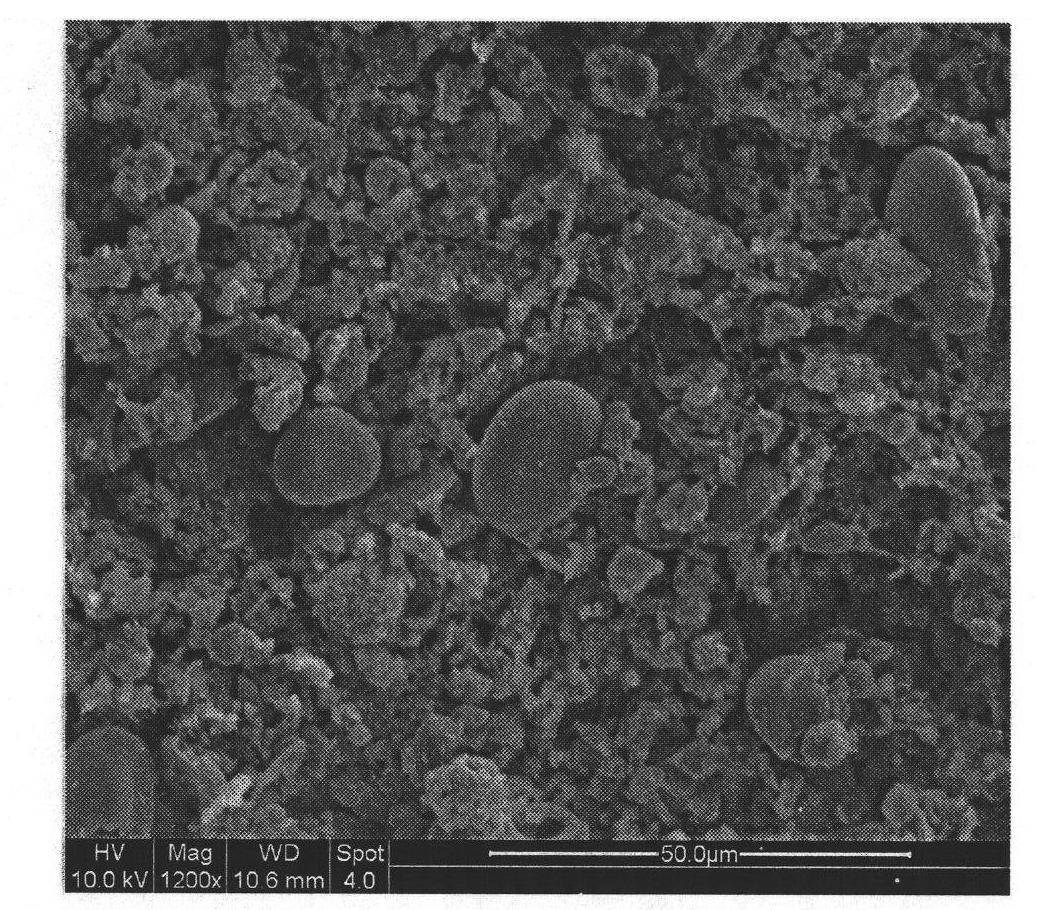

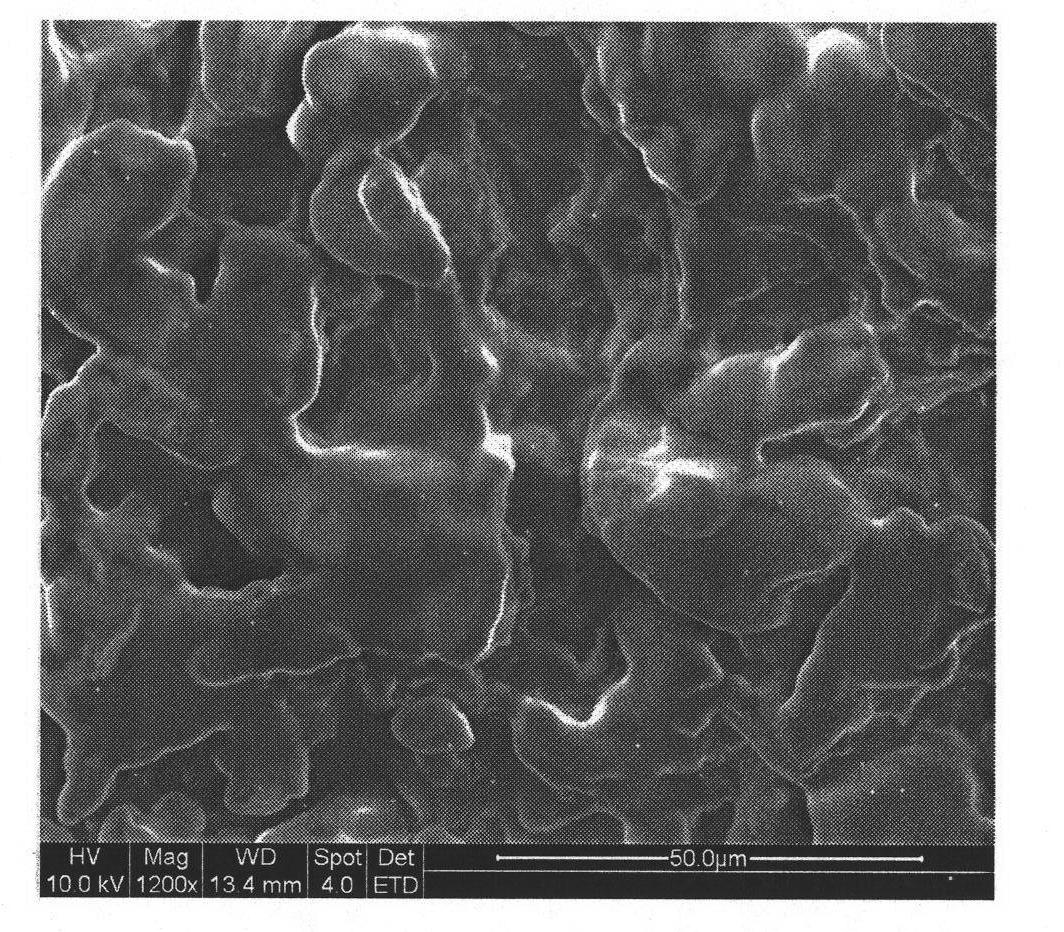

Preparation method of pickled bamboo shoots with pickled peppers

The invention relates to the field of foods and particularly relates to a preparation method of picked bamboo shoots with pickled peppers. The preparation method comprises the following steps: immersing pre-boiled bamboo shoots at a temperature from -5 DEG C to 0 DEG C for 1-3 hours; adjusting the acidity and the salinity of pickled mountain peppers and aged salt water so as to balance the salinity and the acidity; pre-boiling the balanced mountain peppers at 98-100 DEG C for 15-20 minutes to obtain pre-boiled mountain peppers; putting the balanced aged salt water, the pre-boiled mountain peppers and the immersed bamboo shoots into a pickling container according to the weight ratio of 100 to (90-120) to (10-15) and pickling at room temperature for 15-30 hours; and uniformly mixing the pickled bamboo shoots with the auxiliary materials to obtain the pickled bamboo shoots with the pickled peppers. Before pickling, the immersing procedure is added, and thus the obtained bamboo shoots have crispy texture and good mouth feel. Furthermore, a food brittleness increasing agent is added to improve the brittleness of the bamboo shoots. Furthermore, with an auxiliary material prepared from olive oil and / or loquat juice / jam and / or apple juice / jam, the pickled bamboo shoots with the pickled peppers also have a fruit flavor, the improved flavor is unique and novel and the pickled bamboo shoots with the pickled peppers is endowed with innovativeness.

Owner:CHONGQING XINRUN AGRI DEV

Method for cultivating straw mushroom and culture material thereof

InactiveCN102649649ASolve the shortageStable outputRoof improvementClimate change adaptationThermal insulationMushroom mite

The invention relates to a method for cultivating straw mushroom by utilizing waste tea leaf in place of straw and a culture material thereof. The method comprises the following steps of: firstly erecting a mushroom room which is easy for thermal insulation and moisturizing and an anti-leakage plastic net bed; adjusting material ratio, acidity and alkalinity and water content of the culture material before the culture material is fed into the room; laying the culture material which is fed to the bed to be arched and then directly sealing the window and the door to perform pasteurization; subsequently opening the window to cool to 40 DEG C; spraying water to moisturize and then sowing after one hour; adjusting and controlling the material temperature to be 35 DEG C and air humidity to be 90 percent after sowing; and stably maintaining for five to seven years to spray out mushroom water. The method has the advantages of relieving the contradiction between supply and demand of the straw by using the cheap waste tea leaf resource, reducing the production cost, simplifying the production process, cultivating annularly, preventing mushroom pickup from being affected by mushroom mites, achieving an input-output ratio of 1:2.5 and being superior to the cultivation method with the straw as a main material.

Owner:XIAMEN NONGJIA SUNSHINE BIOTECH

Formula capable of effectively improving quality of cocoa butter substitute chocolate

The invention provides a formula capable of effectively improving the quality of lauric acid cocoa butter substitute (CBS) chocolate. According to the formula, the chocolate comprises the following components in percentage by weight: 30 to 45 percent of fat, 10 to 15 percent of cocoa powder, 15 to 30 percent of white granulated sugar, 5 to 25 percent of cane sugar substitute, 10 to 20 percent of defatted milk powder and 0.3 to 0.5 percent of emulsifying agent. The invention also provides a method for preparing the chocolate by using the formula. The chocolate has the advantages of effectively solving the problem that the traditional chocolate is easy to frost, endowing the chocolate with a constant smooth surface, comprising rich probiotic factors and having nutritional and health-care functions, and having pleasant odour, refreshing mouthfeel and crisp character by a proper process.

Owner:JIANGNAN UNIV

Method for producing chondroitin sulfate by reverse precipitation

The invention discloses a method for producing chondroitin sulfate by reverse precipitation, comprising the following steps of: adjusting pH of the chondroitin sulfate solution obtained by oxidation to 5-6, controlling the temperature at 15-20 DEG C and slowly adding the solution in 95% alcohol which is being stirred, wherein the weight concentration of alcohol in the whole process is always maintained in 75% or above. The precipitated chondroitin sulfate is loose in texture, easy to dehydrate and dry and not necessary to be smashed and has the advantages of saving energy and production cost.The product is coloury and stable in quality. The content of chondroitin sulfate is above 98%. The product has extremely low content of organic solvent which is lower than 0.2%.

Owner:江苏麦德森制药有限公司

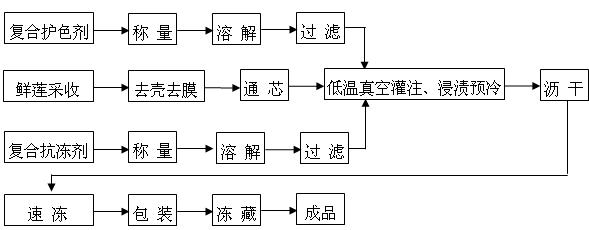

Method for processing quick-frozen fresh lotus

ActiveCN101965860AReduce damage and softenReduce the temperature difference between inside and outsideFruit and vegetables preservationBiotechnologyBrowning

The invention provides quick-frozen fresh lotus processing technology. In the technology, a quick-frozen fresh lotus finished product is obtained by the harvesting of fresh lotus, shelling, stripping, core hollowing, low-temperature vacuum filling, impregnation for pre-cooling, draining, quick-freezing, packaging and cold storage. Due to the adoption of the low-temperature vacuum filling technology to combine pre-cooling, color conservation and anti-freezing processes, the technology inhibits the activity of PPO and POD, prevents the browning of the quick-frozen fresh lotus in the processing and storage, reduces the damage and softening of tissue cells, endows the product with crisp texture and faint scent, improves the ion concentration and osmotic pressure of the cells of the fresh lotus, effectively rises the vitrification transition temperature, promotes the exhaust of air from tissues, reduces the swelling pressure of ice crystals, prevents low-temperature breakage, shortens the processing time, is easy to control, high in operability, less in energy consumption and suitable for the large-scale production of the quick-frozen fresh lotus, and develops a new way for the deep processing of the lotus industry. The product completely keeps the original taste and smell of the fresh lotus, has the faint scent and is convenient to take.

Owner:福建闽江源绿田实业投资发展有限公司

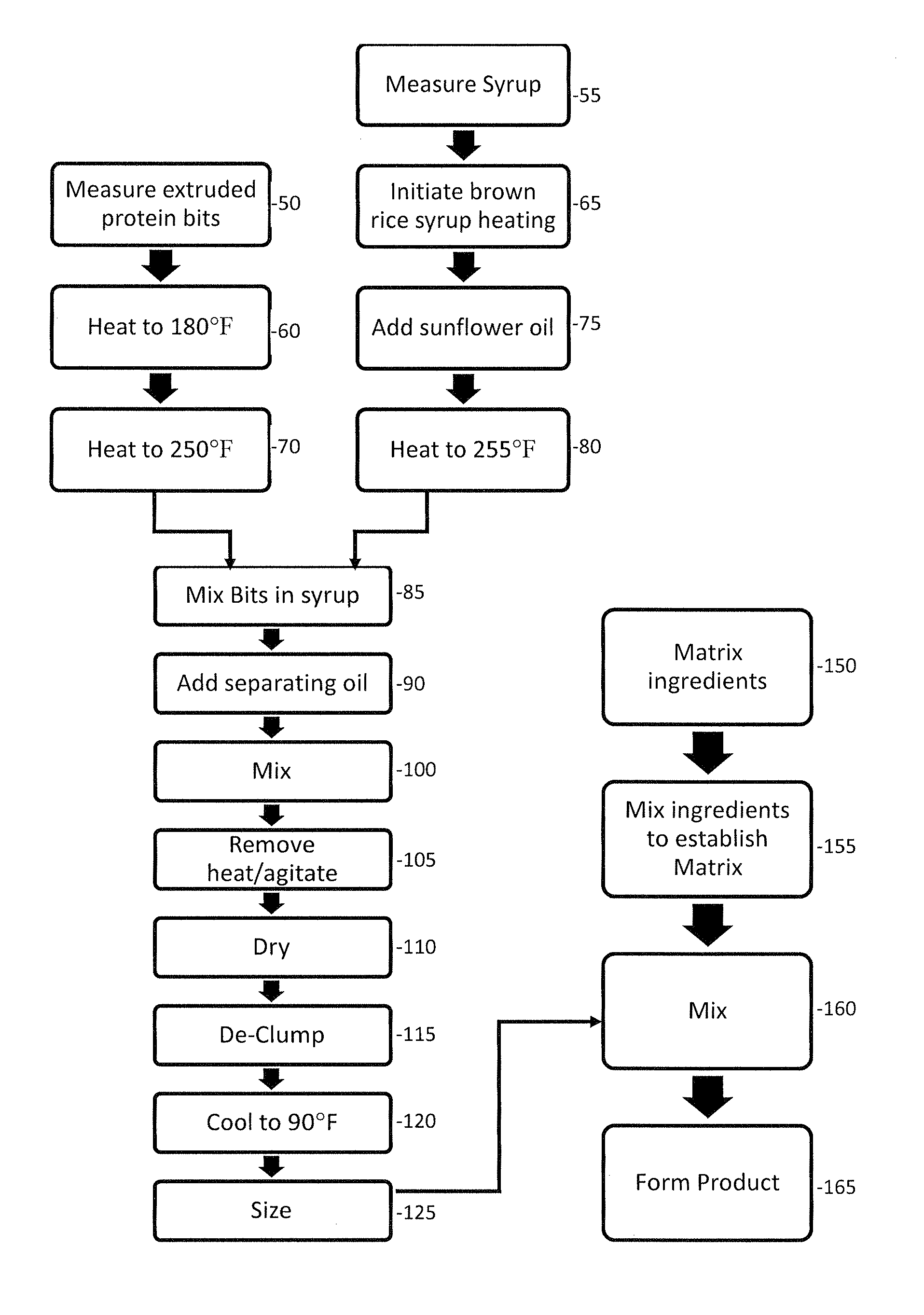

Fruit Paste-Based Food Product Incorporating High Protein Particulates

A food product is defined by a moist, fruit-paste matrix, having a water activity level in a range of 0.55 to 0.70, within which protein particulates are intermixed. The protein particulates include protein bits having a bulk density of about 0.4 g / cc and provided with a natural syrup coating. With the added protein bits, the protein level of the food product is at least 10 grams per serving or 10 grams / 50-55 grams of the food product. The food product can be provided in the form of a snack product, such as a bite-sized snack product or a snack bar. The invention also sets forth a method of making the food product wherein provisions are taken to assure that the protein bits are properly coated, separated, sized and added to the fruit-paste matrix under time and other condition constraints to assure the integrity of the protein bits.

Owner:GENERAL MILLS INC

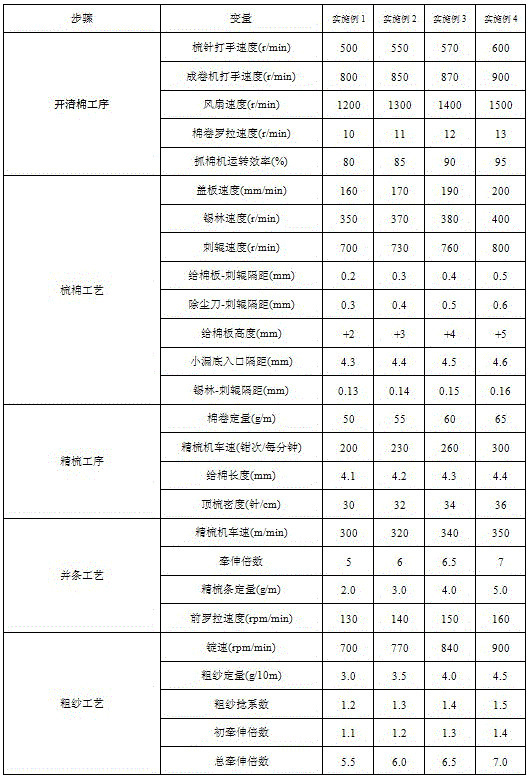

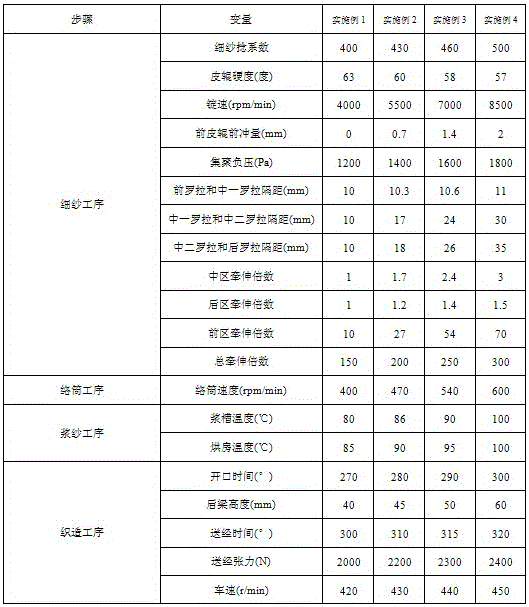

Method for weaving high-count and high-density home textile fabric and method for aftertreatment thereof

InactiveCN105780257AGood drapabilityImprove breathabilityBed linenHeating/cooling textile fabricsYarnHigh density

The invention provides a method for weaving a high-count and high-density home textile fabric and a method for aftertreatment thereof and relates to the field of spinning. The high-count and high-density home textile fabric is made of pima cotton, warp and weft each are 100 pieces of double strand yarn, the warp direction density is 200 pieces / inch, the weft direction density is 100 pieces / inch, and the fabric weave is satin weave. The best pima cotton among the cotton is utilized to weave 100 pieces of yarn, the all spinning double strand yarn is utilized to weave the fabric unique in style, and the fabric has more excellent elasticity, wrinkle resistance, draping, breathability, anti-pilling performance and dimensional stability and the like than a conventional product. The finished product produced by the process for production and aftertreatment of the high-count and high-density home textile fabric has smooth surface and is gentle in color, soft in touch, good in moisture absorption and breathability, unique in appearance, good in skin friendliness, drapability and abrasion resistance, comfortable to use, bright in color and stiff and smooth in texture.

Owner:ZHENGZHOU DEHUI TEXTILE CO LTD

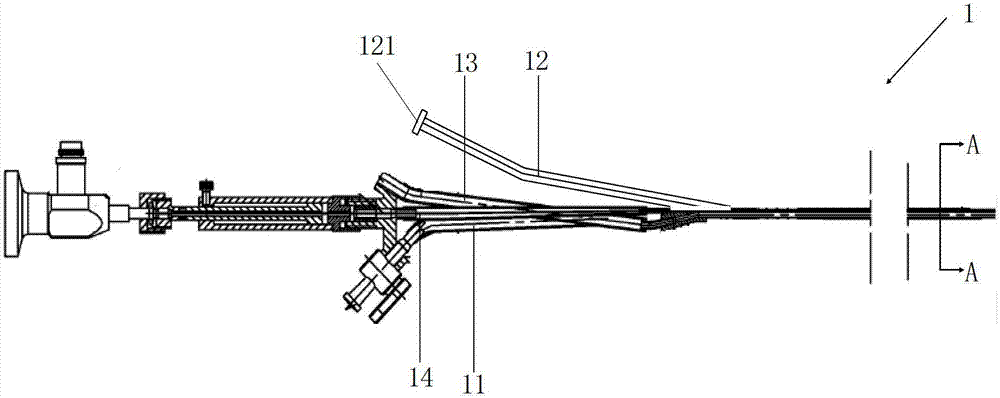

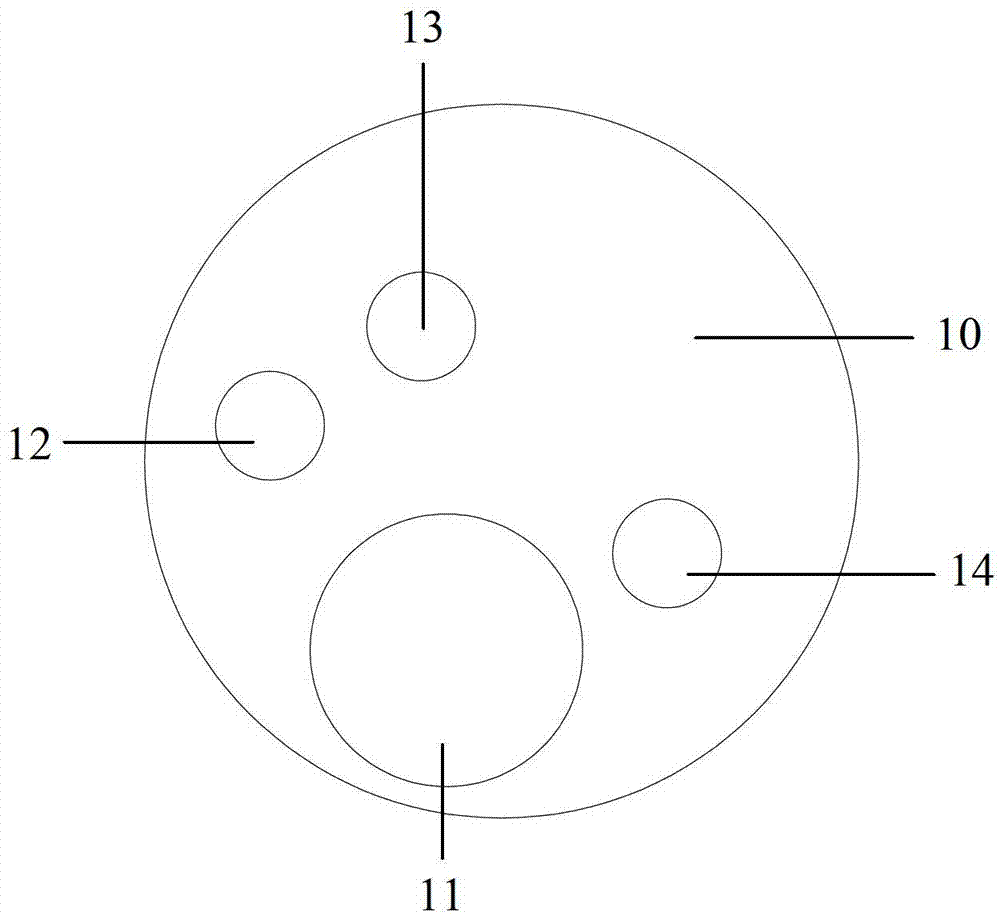

Detachable endoscope

ActiveCN103040431AEasy to carry outLower surgery costsSuture equipmentsInternal osteosythesisFiberGynecology

The invention provides a detachable endoscope. The detachable endoscope comprises a tube body which at least comprises an instrument passage tube, a water inlet passage tube and an illumination passage tube, wherein the illumination passage tube is suitable for accommodating an illuminating optic fiber which is in detachable connection with the tube body. By detachably connecting the illuminating optic fiber with the tube body, after other low-cost parts of the endoscope are damaged, the optic fiber can be taken out to match with other parts in a new endoscope, so that operation cost is reduced, and many operations are facilitated.

Owner:SHANGHAI RAYKEEN LASER TECH CO LTD

Nuisance-free cultivation technology of grapes

Owner:HEFEI FENGSHENGYUAN AGRI SCI & TECH CO LTD

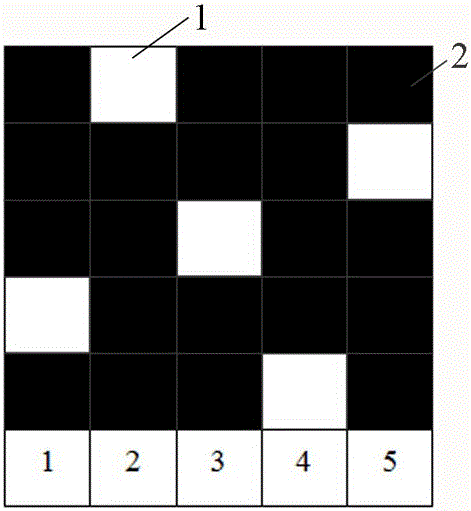

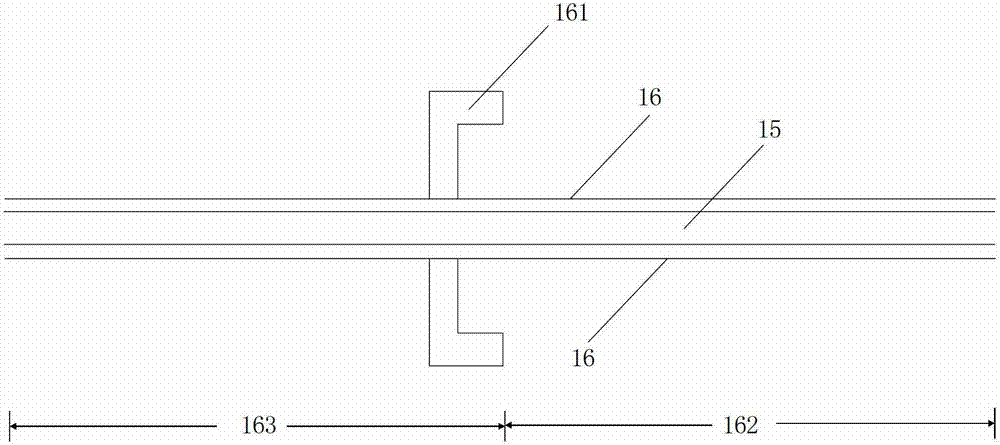

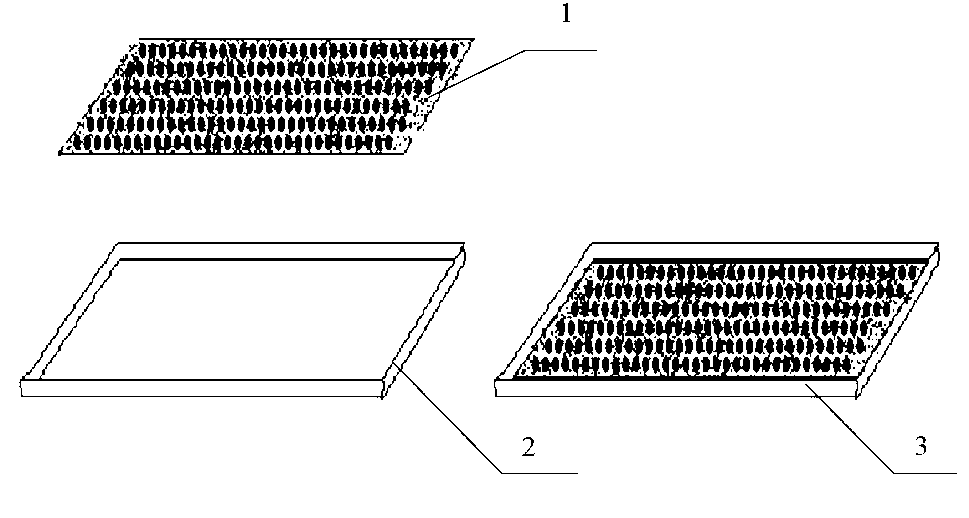

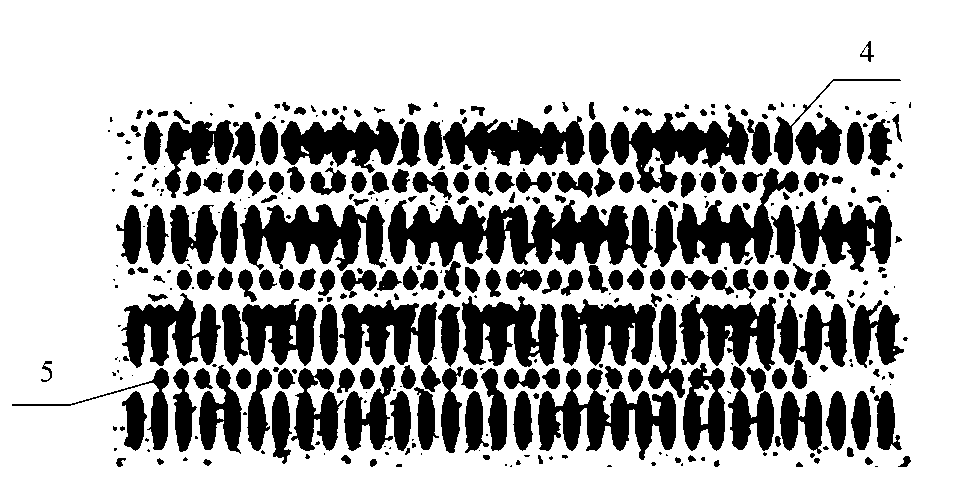

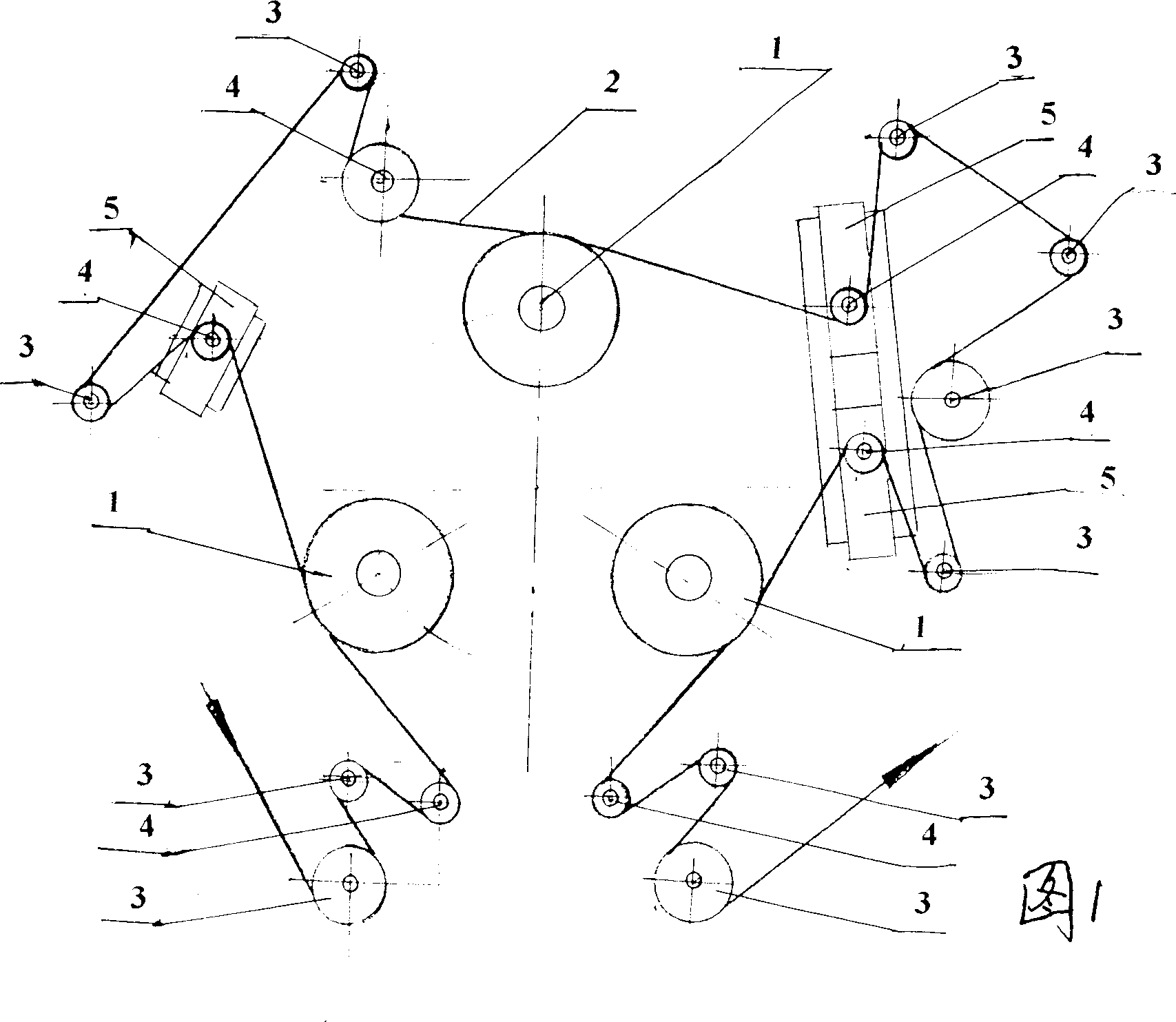

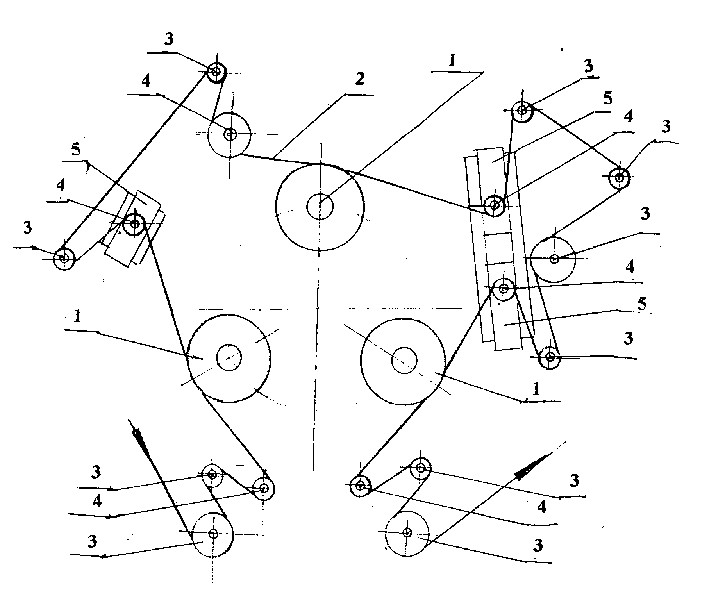

Rice seedling machine seedling planting diaphragm and manufacture method of rice seedling machine seedling planting diaphragm

ActiveCN103070045AGood consolidationPromote growth and developmentCultivating equipmentsNon-woven fabricsMechanical stretchingEconomic benefits

The invention discloses a rice seedling machine seedling planting diaphragm and a manufacture method of the rice seedling machine seedling planting diaphragm. By aiming at the problems that the seedling root winding effect in the rice seedling machine seedling planting is poor, the seedlings can easily get scattered, and the operation is complicated, the invention provides the rice seedling machine seedling planting hemp-base diaphragm, which consists of a hemp fiber diaphragm substrate and rice seeds fixedly carried on the substrate. The hemp fiber raw materials are subjected to loosening, scattering and mechanical stretching to form a net, then, biodegradable bonding agents are adopted for bonding, baking is carried out, the hemp fiber diaphragm substrate is formed, and next, the rice seeds are uniformly scattered and pasted on the hemp fiber diaphragm substrate through the biodegradable bonding agents. When the rice seedling machine seedling planting hemp-base diaphragm provided by the invention is adopted, the seedling culture operation can be greatly simplified, farmers can realize the seedling culture without seeding, in addition, the seedling root system winding effect can be obviously promoted, the winding force is improved, seedlings conforming to the machine seeding requirements are formed, meanwhile, because the seedling quality is improved, the green returning speed of the seedlings after the machine seedling planting is high, the tillering effect is good, the rice yield is obviously improved, and good economic benefits are realized.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Application of eggshell in preparing friction agent

The invention discloses an application by adopting an eggshell to prepare a friction agent and a frication agent prepared by the eggshell thereof. By adopting the eggshell to prepare the friction agent, the invention not only effectively utilizes the eggshell, but also protects the health of gingival and oral mucosa when being used for cleaning teeth, for the friction agent produced by eggshell containing a large amount of trace elements and nutrition compositions that are beneficial to human health. At the same time, the invention is used for cleaning skin as cosmetics, so as to have excellent performances of moistening, enhancing skin elastic and luster, etc. Compared with the industrial material such as mineral deposit containing calcium, the eggshell is a pure natural biological material, which has the advantages of no heavy metal impurities containing such as mercury, lead and manganese, no stimulation, toxicity and side effect in human body, having high security and environment friendly. The invention has wide application prospect in the friction agent field.

Owner:上海宇盛科技有限公司

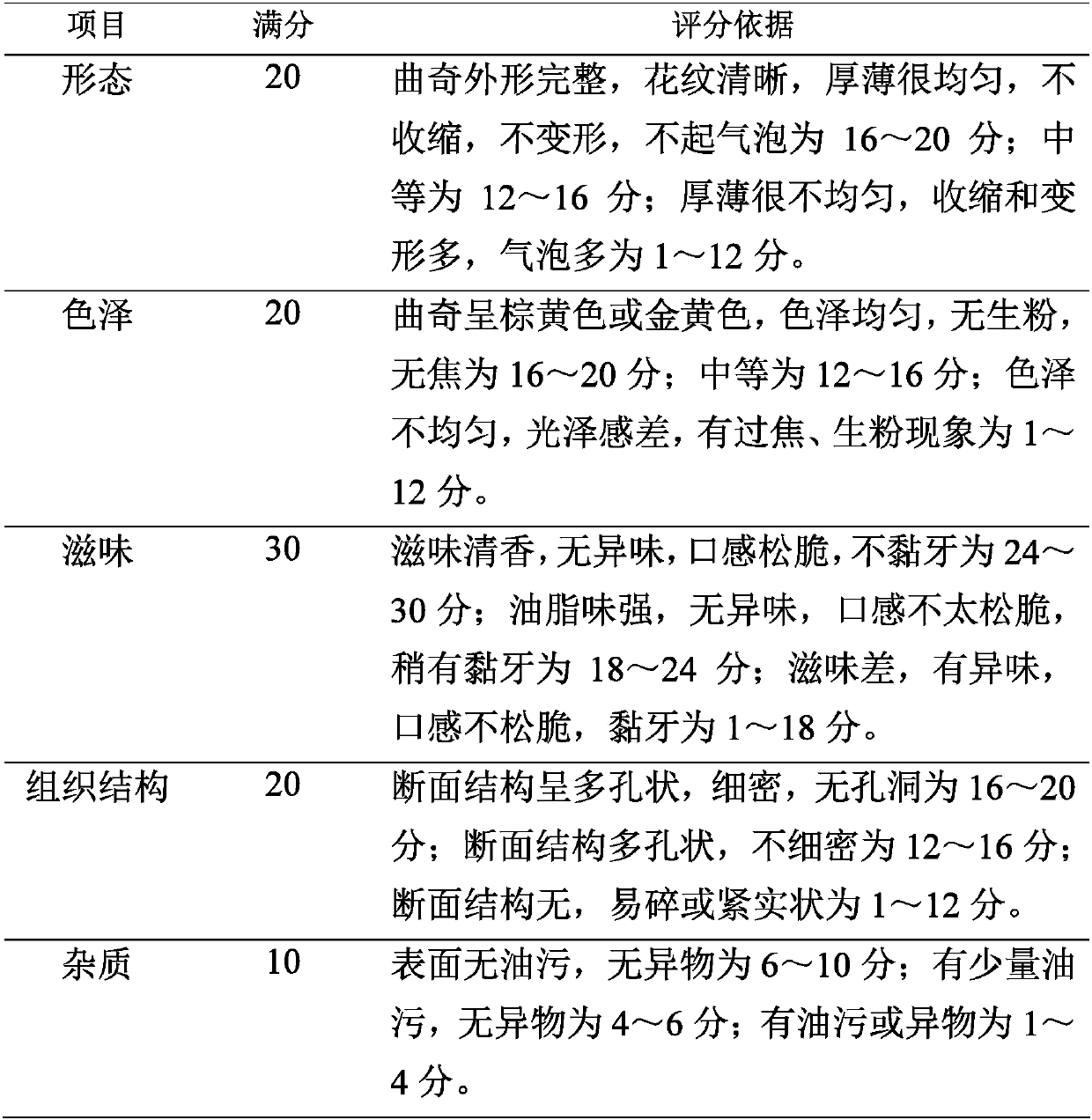

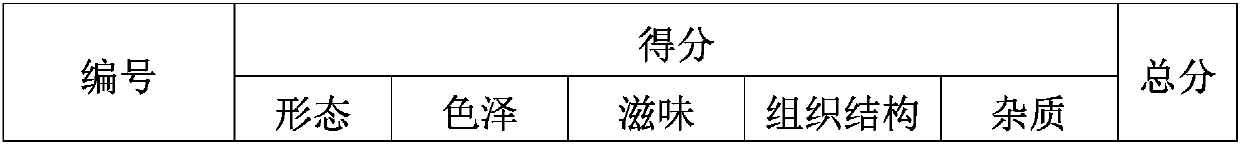

Coarse cereal cookie and preparation method thereof

The invention provides a coarse cereal cookie. The coarse cereal cookie is prepared from the following raw materials including, by weight, 30-50 parts of buckwheat flour, 30-50 parts of naked oat flour, 10-30 parts of corn flour, 50-70 parts of fat, 30-50 parts of powdered sugar, 40-60 parts of eggs and 0.1-1 part of baking soda. The fat is a combination of cream and milk or butter. The preparation method comprises the first step of mixing and sieving the buckwheat flour, the naked oat flour and the corn flour and sieving the powdered sugar, the second step of whisking the eggs and the powdered sugar into a creamy egg paste, the third step and the fourth step of mixing the fat and the creamy egg paste into a flocculent shape, the fifth step of pouring the buckwheat flour, the corn flour, the naked oat flour mixture into the paste and stirring the mixture to be uniform, the sixth step of extruding a semi-finished cookie, and the seventh step of baking. The coarse cereal cookie is rich in dietary fiber, protein and minerals, has golden color, oatmeal flavor, crisp texture and a simple formula, and is suitable for a cake shop, a snack food processing enterprise and home making.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

Preparing method of gentian capsule for purging liver fire

The preparation process of gentian capsule for purging liver fire with ten kinds of Chinese medicinal materials, including gentian, bupleurum root, skullcap root, cape jasmine, oriental water plantain, etc. includes the following steps: twice decoction for 1.5 hr each, filtering, merging the filtrate, concentrating to density of 1.25-1.28, adding alcohol to alcohol content of 70 %, standing for over 24 hr, filtering and recovering alcohol from the filtrate, adding dextrin to density of 1.18, spray drying to obtain extractum powder, mixing with dextrin, pelletizing, low temperature drying and encapsulating. The gentian capsule has less moisture absorption and high stability.

Owner:文永盛 +2

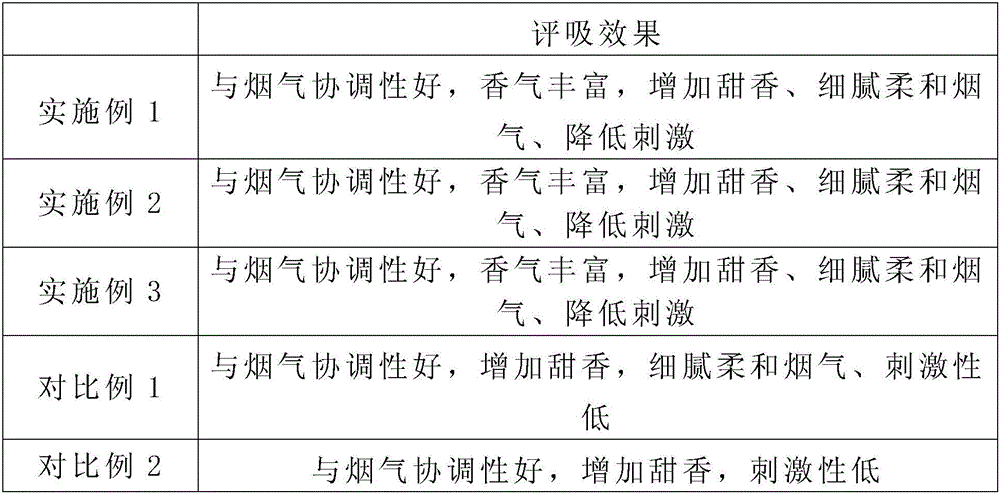

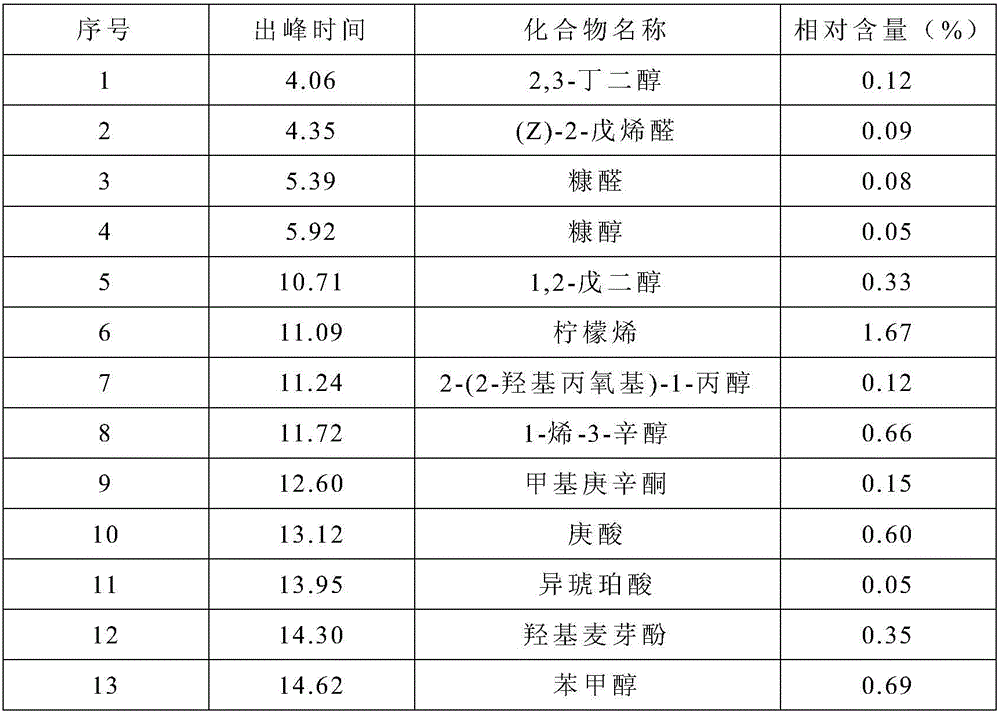

Preparation method of wolfberry reactant for cigarette

InactiveCN106520367APreserve the flavor profileCrisp textureTobacco preparationEssential-oils/perfumesFlavorMaillard reaction

The invention provides a preparation method of a wolfberry reactant for cigarette. The wolfberry reactant for cigarette is prepared by the following steps: freeze-drying wolfberry and then crushing, carrying out low-temperature extraction by adding 40-70% ethanol, filtering an extracting solution and carrying out low-temperature vacuum concentration, and finally carrying out a Maillard reaction. According to the invention, wolfberry can be extracted and concentrated at low temperature so as to maintain the original flavor of the extract to the maximum, and through the maillard reaction, aroma and fragrance of the extract are further enriched and smoke panel test effect of the extract in the cigarette is improved. In comparison with a common wolfberry extract, the prepared reactant has good compatibility with smoke, has rich fragrance, increases sweet taste, and can be applied to cigarette so as to increase sweet aroma, refine and soften smoke and reduce stimulation.

Owner:HUBEI CHINA TOBACCO IND

Tomato biscuits and its prodn. method

A tomato cracker for improving immunity is prepared from wheat flour, solid oil, granular sugar and tomato sauce proportionally through mixing, shaping, roasting and cooling.

Owner:李光博

Artificial silk hollow check pattern plus material

The invention relates to an artificial silk hollow check pattern plus material, which is in a double-layer hollow structure and comprises surface warps, surface wefts, inner warps and inner wefts, wherein the surface formed by the surface warps and the surface wefts is selectively crossed with the inner surface formed by the inner warps and the inner wefts, and the multi-layer and multi-point connection is formed, wherein the surface warps and the inner warps adopt 70D light nylon, the surface wefts adopt 75D artificial silk, and the inner wefts adopt 75D dacron twisted yarns. The artificial silk hollow check pattern plus material has good moisture absorption performance of the artificial silk and the stiff and light tissue of the nylon and the dacron, the color is bright, and in addition, the air content in the plus material is improved through the double-layer hollow structure, so the moisture absorption, sweat discharge, ventilation and moisture penetrability performances of the plus material are further improved, and the plus material belongs to the good plus material for clothes for women.

Owner:WUJIANG XINFENG WEAVING

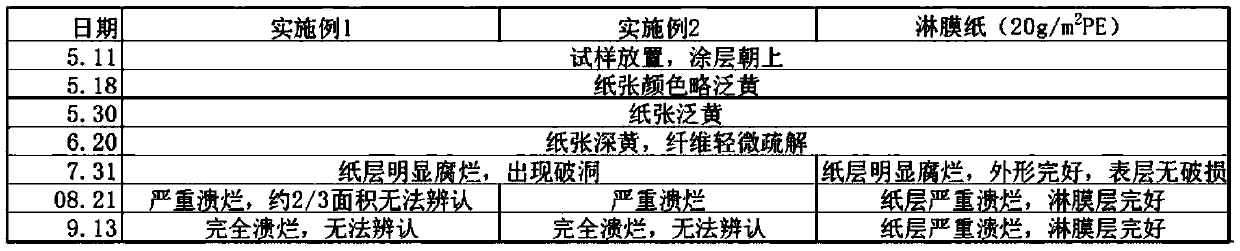

Easy-to-pulping die-cutting high-barrier food coating paperboard and preparation method thereof

ActiveCN111379189AReduce intensityImprove mechanical propertiesNon-fibrous pulp additionClimate change adaptationPolyvinyl alcoholPaperboard

The invention relates to an easy-to-pulping die-cutting high-barrier food coating paperboard and a preparation method thereof. The coated paper comprises a paperboard base material, wherein the surface of the paperboard base material is coated with two layers of water-based composite coatings, and each water-based composite coating is composed of a film coating layer compounded by a polyvinyl alcohol aqueous solution and polyacrylate emulsion with low glass-transition temperature and a film coating layer of emulsion with high barrier property, which are sequentially coated on the paperboard base material; during preparation, a polyvinyl alcohol aqueous solution and polyacrylate emulsion compound solution with low glass-transition temperature coat one surface of a paperboard base material for one time, then the paperboard base material is dried and is coated with a high-barrier emulsion for the second time, and the paper is dried and cooled to obtain the coated paper. Compared with theprior art, the coating disclosed by the invention is small in molecular elongation, relatively crisp in texture, low in strength, easy to naturally crush, convenient for waste paper recycling, pulpingand reusing, and beneficial to ecological balance and environmental protection.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD +1

Production process of non-woven fabric collar interlining with high moisture absorption performance and breathability

ActiveCN105124811AGood hygroscopicityImprove breathabilityFibre treatmentGarmentsInterliningCooking & baking

The invention relates to the field of non-woven fabric adhesive-bonded interlining and discloses a production process of non-woven fabric collar interlining with high moisture absorption performance and breathability. The production process includes the steps of firstly, preprocessing grey fabric, to be more specific, stirring non-woven fabric in water bath of the liquid tank of a desizing machine, adding desizing auxiliaries during stirring, heating for desizing after even stirring, taking out, cleaning and drying for standby; secondly, pressing coatings, to be more specific, dipping the preprocessed non-woven fabric into dipping liquid, taking out for compressing and rolling, and drying; thirdly, dispersing adhesives, to be more specific, performing double-point coating treatment on the non-woven fabric processed by the steps above, coating size points on the non-woven fabric, spreading powder, and removing and recycling powder points which do not adhere to the size points; fourthly, baking, performing infrared heating and baking room baking on the non-woven fabric after adhesive dispersing to obtain the non-woven fabric collar interlining with high moisture absorption performance and breathability. The production process has the advantages that the production process is simple, the non-woven fabric collar interlining produced by the production process is high in moisture absorption performance and breathability, high in adhesive force, low in cost and stiff and smooth in texture.

Owner:广东赛洁无纺布科技有限公司

Fish skin ham sausage preparation method using ictalurus punctatus skin

The present invention discloses a fish skin ham sausage preparation method using ictalurus punctatus skin and the preparation method which uses ictalurus punctatus skin and frozen hypophthalmichthys molitrix surimi as raw materials to prepare the fish skin ham. The preparation method is as follows: firstly thawing fish skin, dicing, marinating for the next step, and secondly thawing the frozen hypophthalmichthys molitrix surimi, adding accessory ingredients, chopping, and finally adding fish skin grains at a certain percentage, mixing evenly, vacuum pumping, and filling ham sausage, sterilizing, cooling and preparing finished products. The method maintains the original flavor of the fish meat sausage, at the same time improves taste and nutritional value enriches the variety of the ham sausage, and provides a new way for the use of ictalurus punctatus.

Owner:YIYANG YIHUA AQUATIC PRODS +1

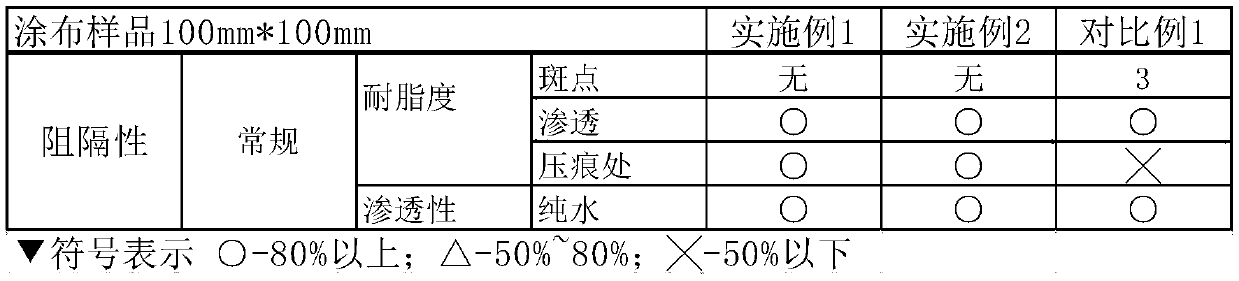

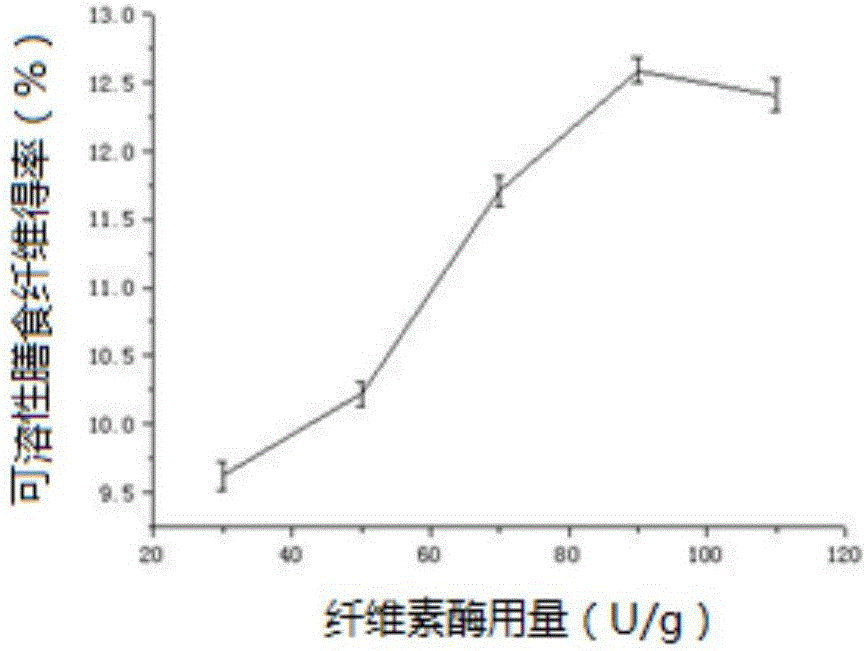

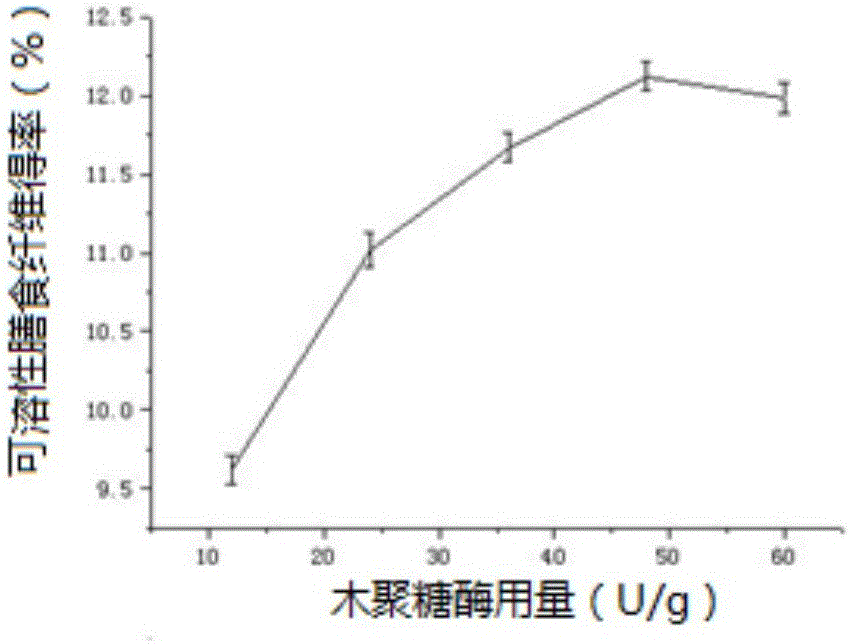

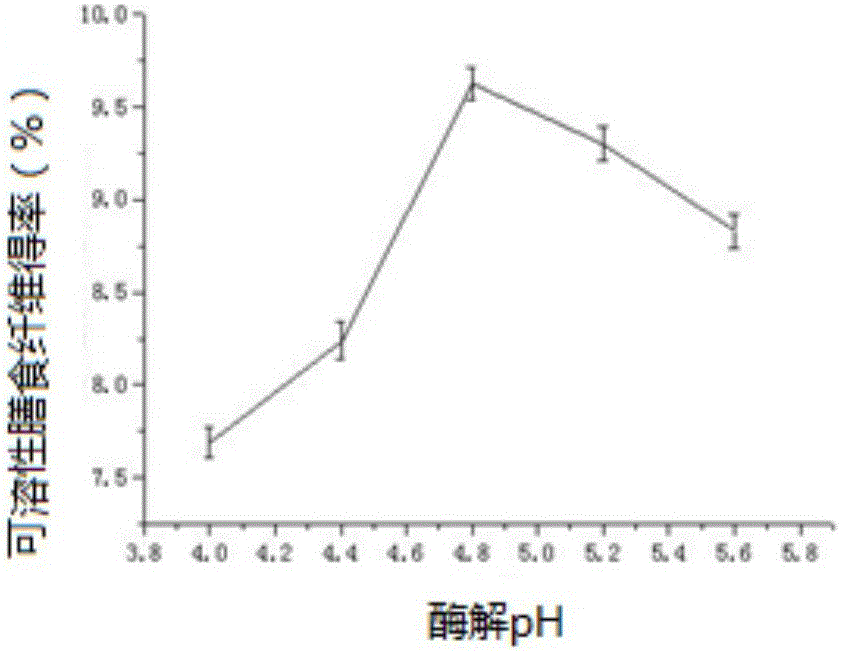

Biscuits containing modified dietary fibers sourced from carrot peel pomace and preparation method of biscuits

ActiveCN106561777AReduce manufacturing costSimple processDough treatmentBakery productsCation-exchange capacityAdditive ingredient

The invention discloses biscuits containing modified dietary fibers sourced from carrot peel pomace and a preparation method of the biscuits. The biscuits are prepared from, by weight, 15-20 parts of the modified dietary fibers sourced from the carrot peel pomace, 100 parts of flour, 20-60 parts of butter, 1-11 parts of milk powder, 40-50 parts of eggs, 10-24 parts of sugar and 0-0.5 part of baking powder. A preparation method of the modified dietary fibers sourced from the carrot peel pomace comprises the following steps of adding cellulose and xylanase to extract of the modified dietary fibers sourced from the carrot peel pomace for enzymolysis and modification; and then conducting sedimentation, so that the modified dietary fibers sourced from the carrot peel pomace are obtained, and conducting drying after dehydration is completed. The biscuits contain the modified dietary fibers sourced from the carrot peel pomace; the modified dietary fibers are high in content of soluble dietary fibers, and expansibility, water-holding capacity, oil-holding capacity, cation exchange capacity, glucose adsorption capacity and cholesterol adsorption amount of the modified dietary fibers are all improved remarkably.

Owner:CHINA AGRI UNIV

Method for producing yellow pickled capsicums

InactiveCN101940286AGolden colorAdd flavorFruits/vegetable preservation using acidsFood preparationFlavorAcetic acid

The invention provides a method for producing yellow pickled capsicums. The yellow pickled capsicums are mainly prepared from the following raw materials by weight: 100kg of fresh capsicum fruits from white trees, 100kg of spring water, 15kg of salt, 3-5kg of acetic acid, 1.5-3 of sodium benzoate, 2-4kg of sorbic acid, 2-3kg of fresh yellow gardenia fruits, 3-10kg of fructus tsaoko and 1kg of anise. The yellow pickled capsicums are golden yellow, have better flavors, moderate acid and alkali and good taste and are crisp, up to the national standard of quality and sanitation indexes and favored by the consumers.

Owner:贵州遵义贵山红食品厂

Elastic suede knitted fabric containing spandex and brushing process thereof

InactiveCN1530483ACrisp textureGood two-way elasticityWeft knittingRougheningSurface elasticityCombing

A polyurethane fibre contained elastic knitted fabric with pile surfaces is made up of the (20-40)-count combed cotton yarn and the 3.3tex (30-70)-D elastic polyurethane fibres (3-15%) through knitting, dyeing, finishing and brushing pile on both surfaces. Its pile brushing technology features that said fabric is driven by several drive rollers and supporting rollers to pass through the surface of brushing rollers for generating pile on its both surfaces. Its advantages are comfortable handle, good surface elasticity and high thermal insulating effect.

Owner:SHANGHAI THREE GUN GROUP

Flavored sauce radish and pickling method thereof

InactiveCN104799231ACompatibility is reasonableCrisp textureFood ingredient as flavour affecting agentNatural extract food ingredientsNutrientSophora japonica

The invention discloses a flavored sauce radish and a pickling method thereof. The flavored sauce radish consists of the following raw materials in parts by weight: 5o to 55 parts of sliced radish, 12 to 15 parts of oat, 2 to 4 parts of sesame, 2 to 5 parts of pepper, 3 to 5 parts of fennel, 1 to 3 parts of medlar, 1 to 2 parts of kalimeris indica, 3 to 5 parts of fructus cannabis, 2 to 4 parts of mint, 10 to 12 parts of fermented glutinous rice, 2 to 3 parts of fructus mume, 4 to 5 parts of lemon leaves, 3 to 5 parts of pine pollen, 3 to 5 parts of semen euryales, 2 to 4 parts of sophora japonica, 1 to 3 parts of cichorium intybus, 4 to 6 parts of santalum album, 3 to 5 parts of dried orange peel, 30 to 40 parts of edible salts, a proper amount of water and 10 to 15 parts of homemade sauce. By adopting traditional Chinese medicinal nourished ingredients and coarse grain nutrition powder, the flavored sauce radish disclosed by the invention is crisp in texture, sweet in taste and proper in aroma; nutrient extracts are reasonably matched, so that the flavored sauce radish has the effects of compound nutrition, heath care and heath preservation; lotus leaves are used for pickling in a layered and separated manner, so that the flavored sauce radish emits a faint scent of the lotus leaves.

Owner:HEFEI YUEJIE ECOLOGICAL AGRI TECH

Japanese pepper pickling process

The invention discloses a Japanese pepper pickling process relating to the field of Japanese pepper pickled bamboo shoots. The Japanese pepper pickling process comprises the following steps: pretreating a bamboo shoot raw material, performing screening grading, performing bleaching desalting desulfuration treatment, performing pre-boiling deactivation, cooling, pickling, bagging, vacuuming, performing sterilization, drying in air, packaging with bags, and storing in warehouses. The Japanese pepper pickling process disclosed by the invention has the advantages that the production process is standardized, the pickling time is fixed, and the taste of Japanese pepper pickled bamboo shoots is consistent and authentic.

Owner:唐石勇

Textile yarn easy to clean

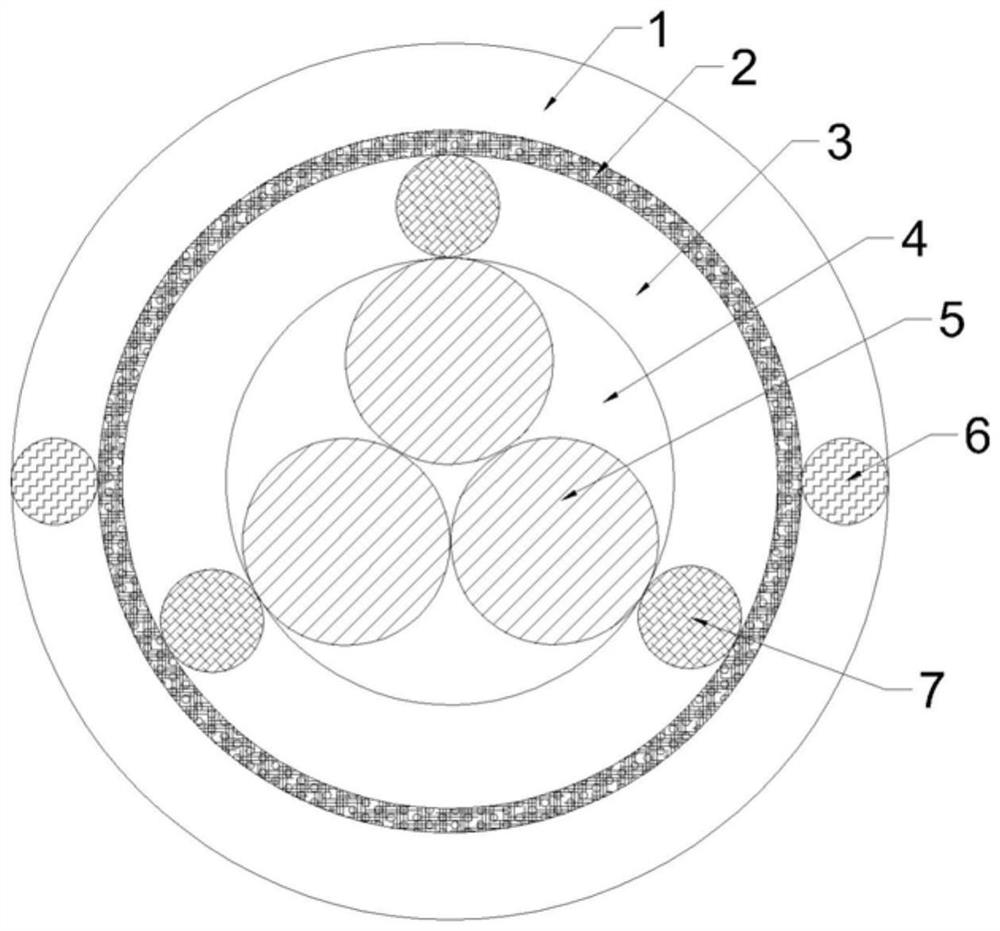

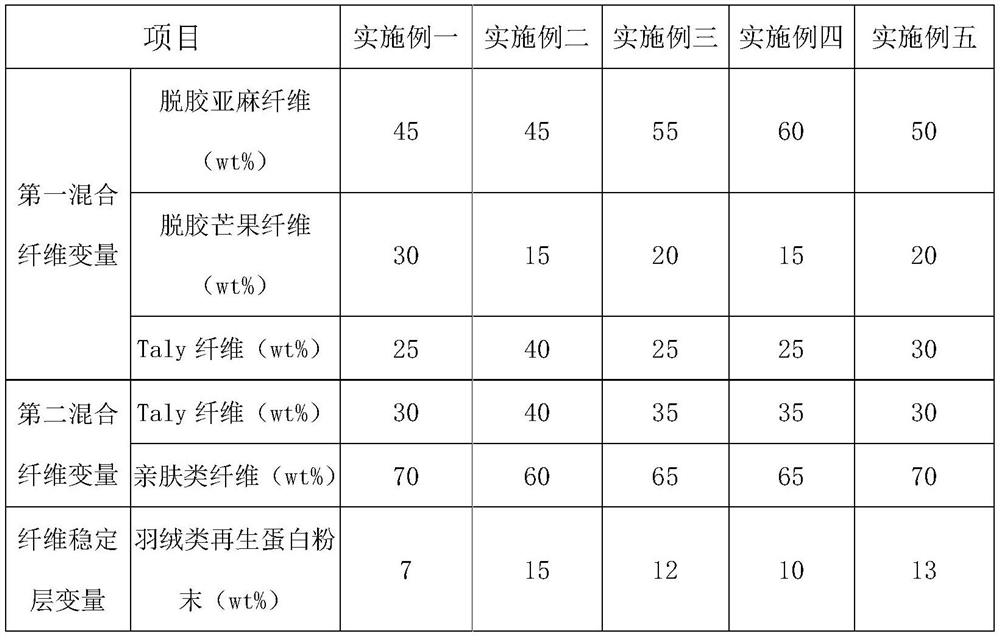

PendingCN114059208ADemonstrates easy-to-clean performanceGood physical propertiesArtificial filaments from viscoseGrip property fibresPolymer scienceTextile yarn

ATextile yarn easy to clean of the invention comprises a core yarn, a first coating layer and a second coating layer, the first coating layer and the second coating layer sequentially wrap the outer layer of the core yarn, and a modified viscose fiber layer is formed between the first coating layer and the second coating layer to serve as a fiber stabilizing layer; the core wire is formed by spirally twisting high-elasticity fibers, and the first wrapping layer is formed by twisting 45-60 wt% of degummed linen fibers, 15-30 wt% of degummed mango fibers and the balance Taly fibers; the second coating layer is formed by spirally twisting 30%-40% of Taly fibers and the balance of skin-friendly fibers; and down regenerated protein powder is added into the modified viscose fiber layer of the fiber stabilizing layer to serve as a modified material. According to the prepared yarn, it can be guaranteed that the yarn shows the high easy-to-clean performance, meanwhile, the using amount of the Taly fibers is reduced, and the compatibility of other fiber mixtures and the Taly fibers is improved, so that the high-performance yarn with toughness, strength, hand feeling and easy-to-clean performance is obtained.

Owner:湖南科力嘉纺织股份有限公司

Processing method of health-care candied bananas

InactiveCN105265715AHas a sweet flavorClearing away heat and nourishing the lungsConfectionerySweetmeatsBiotechnologyNutritive values

The invention discloses a processing method of health-care candied bananas, and belongs to the field of food processing. The processing method is characterized by adopting the processing technological processes of selecting raw materials, treating the selected raw materials namely bananas, rinsing the treated bananas, dyeing the rinsed bananas, candying the dyed bananas for the first time, candying the candied bananas for the second time, candying the candied bananas for the third time, baking the bananas which are candied for the third time, and packaging the baked bananas. The processing method disclosed by the invention has the beneficial effects that the products which are processed by the processing method disclosed by the invention are sweet rather than greasy and crisp in texture, and have special clean and sweet flavor of the bananas. The products are very high in nutrient value, are rich in varied nutrient substances, are beneficial to cleaning intestines and stomach and promoting the metabolism of human bodies, have the efficacies of clearing heat, nourishing the lungs, quenching the thirst, removing toxicity, invigorating the spleen, stimulating the appetite and reducing the blood pressure, and are economic, practical, green, healthy and delicious foods.

Owner:张建新

Dried bamboo shoot processing technology

InactiveCN106262129AHigh nutritional valueFast ripeFood ingredient as flavour affecting agentFood dryingAdditive ingredientContact time

The invention discloses a dried bamboo shoot processing technology of a food pickling method. The dried bamboo shoot processing technology comprises steps as follows: materials are selected and peeled; bamboo shoots subjected to bamboo shoot shell removing are put in a rice steamer and heated with steam for 30-40 min; the bamboo shoots are taken out and subjected to air cooling to the room temperature, and then the bamboo shoots are subjected to vacuum drying until the water content is 20%-30%; the bamboo shoots after vacuum drying are heated with steam for 50-60 min again; the bamboo shoots obtained in the step four are dehydrated and then are put into a preservation box, the preservation box is placed in a refrigeration dryer, the bamboo shoots are subjected to freeze drying until the water content of the bamboo shoots is 10%-15%, and then the bamboo shoots are taken out. The bamboo shoots are heated with the steam, so that the bamboo shoots can be cooked more quickly and are crisper, and the dried bamboo shoots are tasty, refreshing and easy to chew up after cooking. The rice steamer and a vacuum drier used during vacuum drying are relatively closed, the direct contact time of the bamboo shoots and air is shortened, and the color of the bamboo shoots is prevented from being changed greatly due to oxidation; besides, with the adoption of the refrigeration drying method, rapid growth of bacteria in air due to acquisition of nutritional ingredients of the bamboo shoots is avoided, and the probability of change of color, fragrance and taste of the bamboo shoots is reduced.

Owner:贵州省桐梓县康利绿色食品有限公司

Processing method for crisp sweet potato chips

The invention discloses a processing method for crisp sweet potato chips and belongs to the field of food processing. The processing method is characterized in that the processing technological process of raw material selecting, sorting, peeling, cutting, starch removing, sugar steeping, freezing, vacuum frying, centrifugal oil removing, cooling, weighing and packaging is adopted. The processing method has the advantages that the crisp sweet potato chips are golden in color, crisp in texture, not soft, fragrant, crisp and tender in taste, have the special fragrance and sweetness of sweet potatoes and the faint scent of roses and are crisp and delicious; the crisp sweet potato chips are beneficial to improving the immunity of the human body and maintaining and conditioning functions of the human body, further have the effects of preventing osteoporosis, resisting senescence and preventing atherosclerosis, and is rare food which is low in calorie, sugar and fat.

Owner:NANLING ZINGIBER MIOGA ROSE IND ASSOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com