Easy-to-pulping die-cutting high-barrier food coating paperboard and preparation method thereof

A high-barrier, cloth card paper technology, applied in the field of coated paper, can solve problems such as environmental pollution, difficulty in paper recycling, and low biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

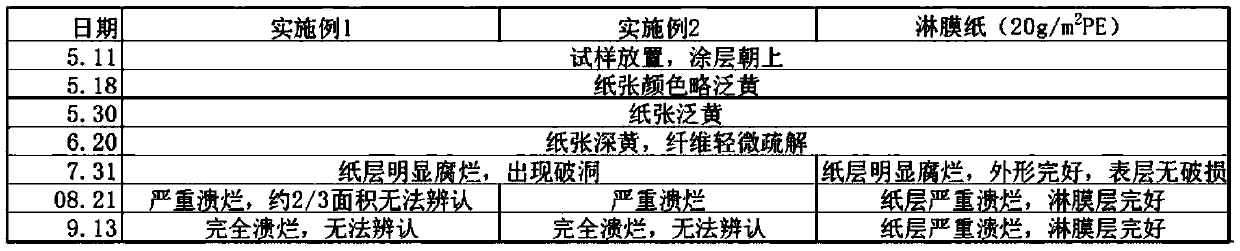

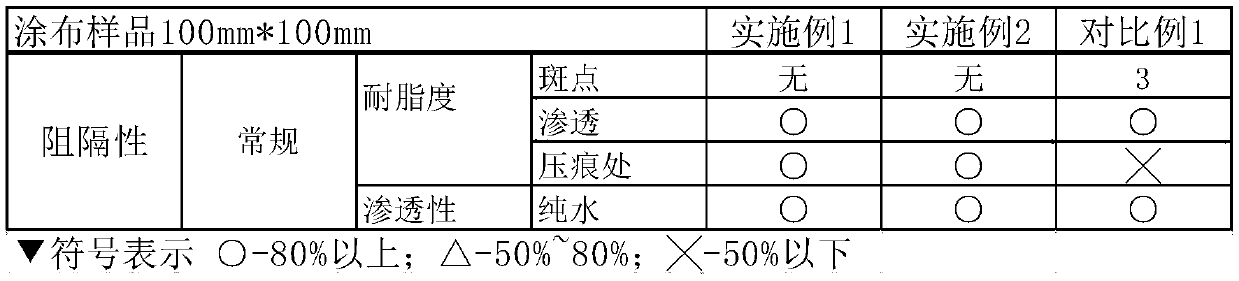

Embodiment 1

[0020] An easy-to-pulp die-cuttable high-barrier food-coated cardboard including 350g / m 2 Cardboard substrate, the surface of the cardboard substrate is coated with two layers of water-based composite coating, and the water-based composite coating is composed of polyvinyl alcohol PVA1788 aqueous solution and isopropyl acrylic acid copolymerized acrylic acid sequentially coated on the paper substrate The film layer composed of methyl ester emulsion and the existing high-barrier emulsion film layer on the market. The high barrier emulsion is BASF Epotal SP-222D.

[0021] The coating film layer of polyvinyl alcohol in this embodiment adopts PVA1788. The coating layer of polyacrylate adopts isopropyl acrylate copolymerized methyl acrylate emulsion with an average molecular weight of 180,000 and a glass transition temperature of -20°C. The dry weight ratio of polyvinyl alcohol and isopropyl acrylate copolymerized methyl acrylate is 1:5, and the coating amount of the first layer i...

Embodiment 2

[0026] An easy-to-pulp die-cuttable high-barrier food-coated cardboard consisting of 260g / m 2 Cardboard substrate, the surface of the cardboard substrate is coated with two layers of water-based composite coating, the water-based composite coating is composed of polyvinyl alcohol PVA1799 aqueous solution and butyl acrylate copolymerized methyl It consists of a coating layer compounded with methyl acrylate emulsion and an existing high-barrier emulsion coating layer on the market. The high barrier emulsion is Henkel YODOSOL GD900.

[0027] The coating film layer of polyvinyl alcohol in this embodiment adopts PVA1799. The coating layer of polyacrylate adopts butyl acrylate copolymerized methyl methacrylate emulsion, the average molecular weight is 210,000, and the glass transition temperature is -7°C. The dry weight ratio of polyvinyl alcohol and isopropyl acrylate copolymerized methyl acrylate is 1:1, and the coating amount of the first layer is dry dry 5g / m 2 (dry weight). ...

Embodiment 3

[0051] This example is basically the same as Example 1, except that in this example, isooctyl acrylate is used as the soft monomer of the polyacrylate emulsion with a low glass transition temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com