Rice seedling machine seedling planting diaphragm and manufacture method of rice seedling machine seedling planting diaphragm

A rice machine and rice seed technology, applied in non-woven fabrics, textiles, papermaking, seed coating/seed dressing, etc., can solve the problems of affecting the efficiency of mechanical transplanting, not easy to control the dosage, and increasing the difficulty of raising seedlings, etc., to achieve Simplify the operation of fertilization and seeding, good tillering, and improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

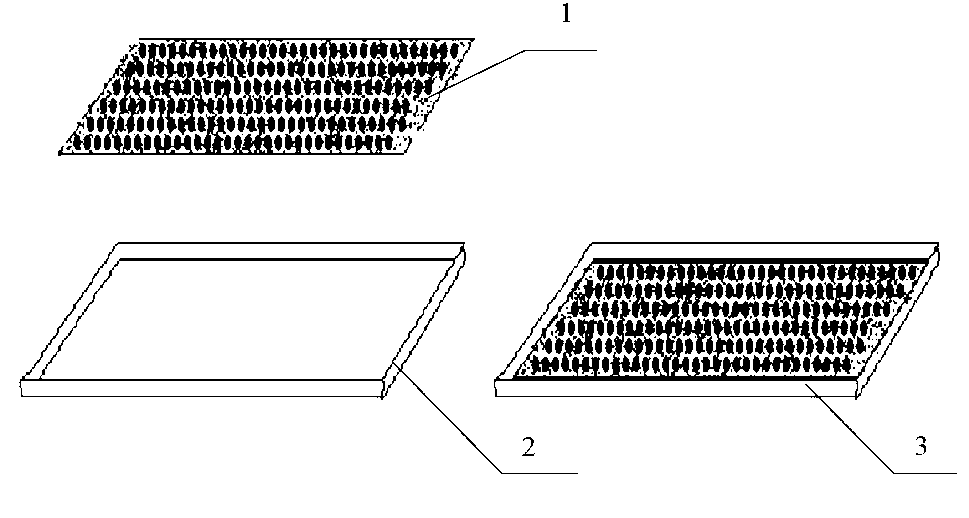

Embodiment 1

[0019] (1) Preparation of hemp fiber membrane substrate: 80% by weight of jute fiber and 20% of cotton fiber are fed into the hemp processing equipment, the fibers are dispersed and mixed by mechanical beating, and then the rollers of the equipment are used to draw The fibers are randomly arranged to form a fiber web. After being impregnated and bonded by starch glue, a hemp fiber membrane substrate is formed by vacuum adsorption and drying. The thickness of the substrate is 3mm. The hemp processing equipment adopts a well-known equipment. The name of the equipment is: environmentally friendly The preparation device of hemp film, the patent number is: ZL200710303484.7;

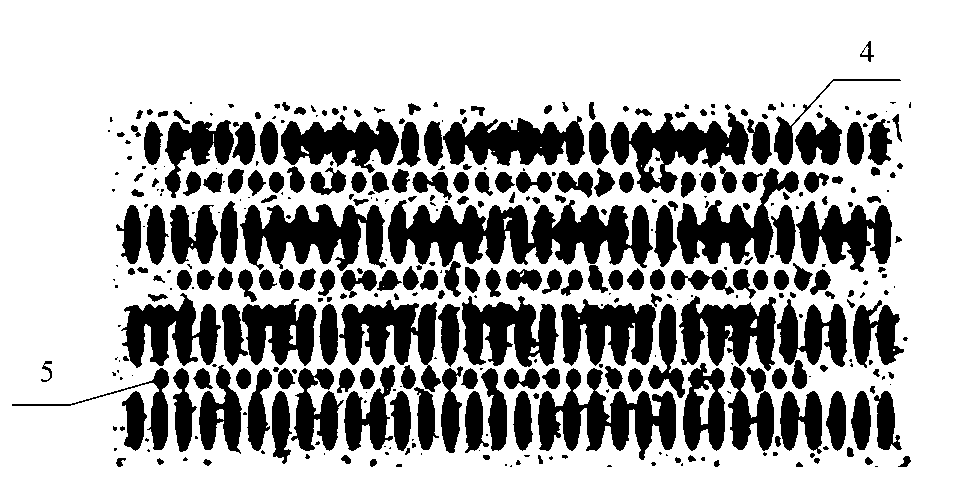

[0020] (2) Preparation of hemp-based seed membrane: uniformly coat a 2%-4% polyvinyl alcohol aqueous solution with a mass concentration of 2%-4% on the hemp fiber membrane substrate, and dry rice seeds according to 500g / m 2 The density (determined according to the seedling demand) is evenly and randomly dispersed ...

Embodiment 2

[0028] The machine-transplanted rice seedling and hemp base seed membrane and seedling were manufactured according to the method of Example 1. The difference is that the raw material composition is 80% kenaf fiber and 20% cotton, the adhesive is starch glue, and the thickness of the hemp fiber membrane base is made 2mm, rice seed density is 300g / m 2 , The seedlings raised are hybrid rice, the seedling age is 20 days, and the root system indicators of the seedlings are shown in Table 2.

Embodiment 3

[0030] The machine-transplanted rice seedling hemp base seed membrane and seedling were manufactured according to the method of Example 2. The difference is that the rice seeds and the slow-release compound fertilizer with the effective ingredient of nitrogen, phosphorus and potassium are uniformly and randomly dispersed and adhered with a 3% polyvinyl alcohol aqueous solution. On the hemp fiber membrane substrate, such as figure 2 As shown, the seedlings raised are hybrid rice, the seedling age is 20 days, and the root system indicators of the seedlings are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com