A work table cable device

A technology of cable device and workpiece table, which is applied to the exposure device of photo-engraving process, electrical components, photo-engraving process of pattern surface, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

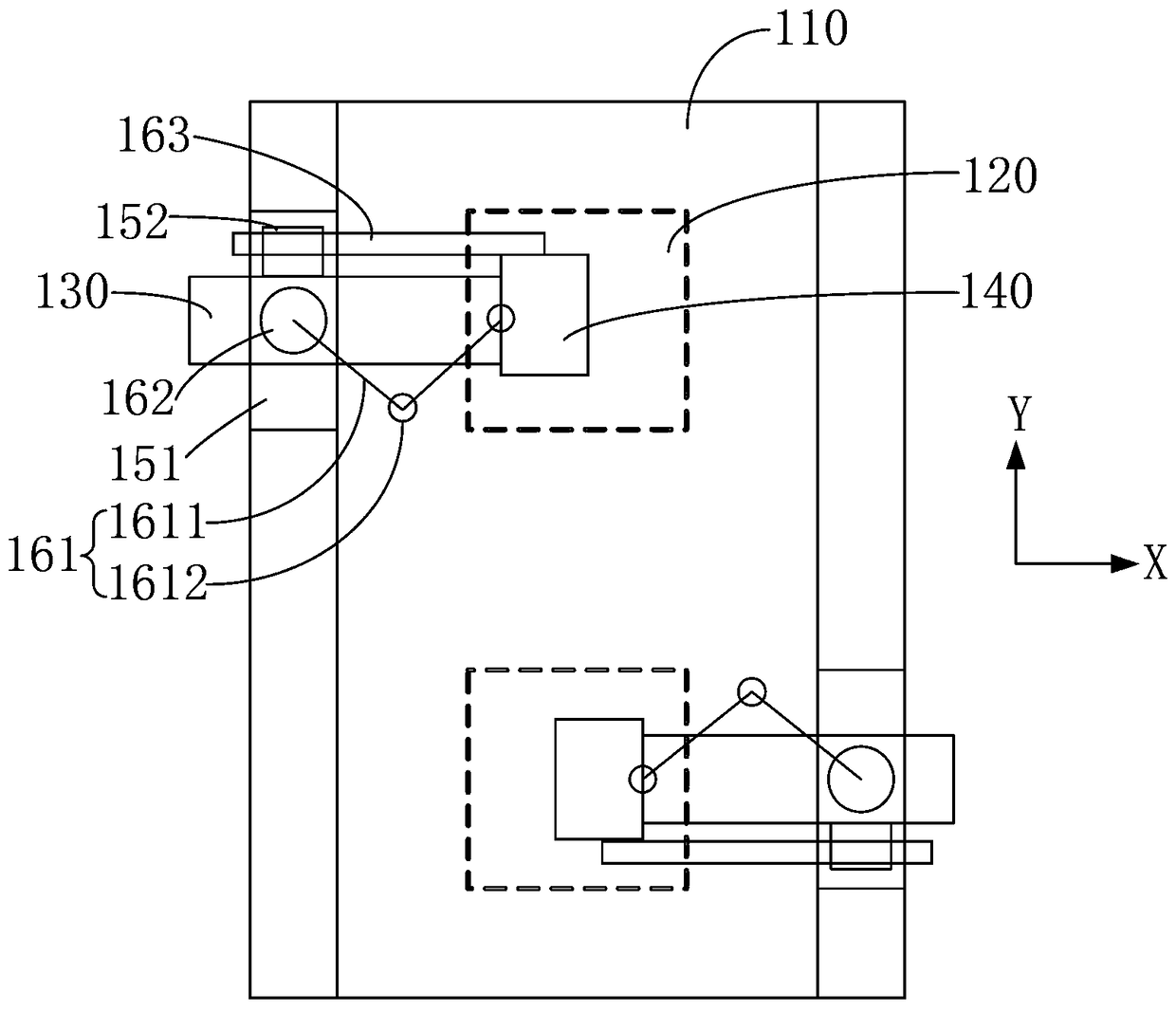

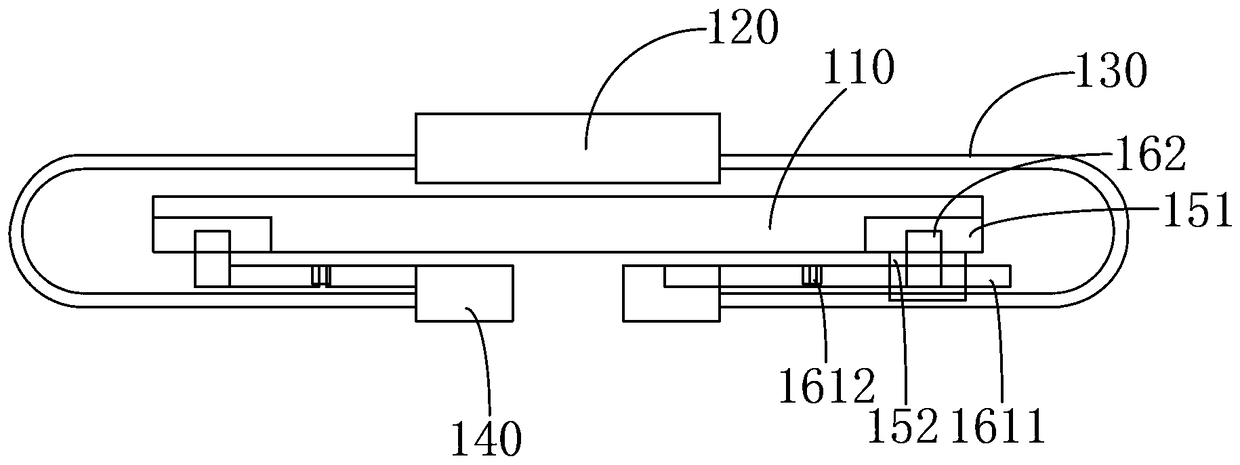

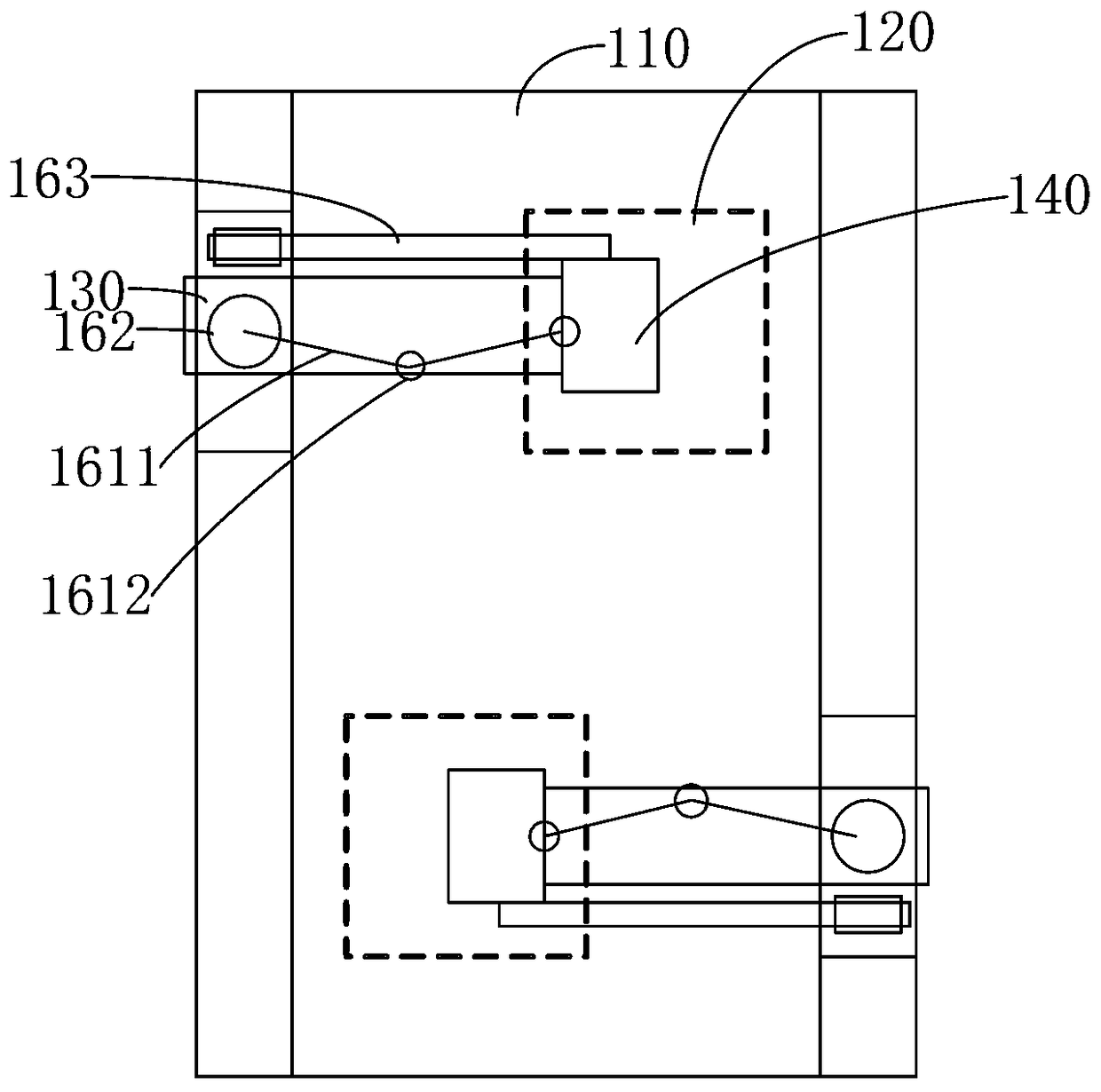

[0041] Please continue to refer Figure 1 to Figure 4, the Y-direction motion equipment includes a slide table 151 fixed on the bottom edge of the workpiece table 110 and a slide block 152 that can slide along the slide table 151, and the X-direction motion equipment includes a telescopic piece, a control motor and a guide device , the guiding device is arranged along the X direction, one end of the telescopic member and the guiding device are respectively installed on the slider 152, and the other ends are respectively installed on the cable connection table 140, and the control motor controls the Telescoping of telescopic parts. Preferably, the guide device is a guide rod 163. Preferably, the guide rod 163 is a linear guide device, and a mechanical bearing or an air bearing or a magnetic bearing is provided between the guide rod 163 and the slider 152. bearings. One end of the guide rod 163 is fixedly connected to the cable connection platform 140, and the other end of the...

Embodiment 2

[0050] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the telescopic member is a linear slide rail, and the linear slide rail includes a track 261 in the X direction and a fixed block 262 sliding along the track 261, and the track 261 One end of one end is fixedly connected to the slider 252, and the cable connection table 240 is fixed on the fixed block 262; the control motor is a linear motor (not shown in the figure), and the linear motor controls the fixed The block 262 moves linearly along the track 261. Preferably, the linear motor is also provided with a linear encoder (not shown in the figure). That is to say, the Y-direction motion equipment is the same as Embodiment 1, including a slide table 251 fixed on the bottom edge of the workpiece table 210 and a slide block 252 capable of sliding along the slide table 251; and in the X-direction motion equipment The telescopic part is a linear slide rail, such as a linear motor, a...

Embodiment 3

[0052] The difference between this embodiment and Embodiments 1 and 2 is that both the X-direction motion device and the Y-direction motion device are provided by a magnetic steel array or a coil array.

[0053] Preferably, please refer to Figure 8 and Figure 9 , the bottom of the workpiece table 310 is provided with a first magnetic steel array (or first coil array) 350, and the cable connection table 340 is provided with a Corresponding second magnetic steel array (or second coil array). The first magnetic steel array (or first coil array) 350 and the second magnetic steel array (or second coil array) form a planar motor, thereby controlling the movement of the cable connection table 340 in the X and Y directions. relative movement.

[0054] Preferably, please continue to refer to Figure 8 and Figure 9 , the wafer stage 320 is provided with a Hall sensor array (not shown in the figure), and a follower sensor (not shown in the figure) is provided between the cable de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com