Method for testing thermal shrinkage performance of silane crosslinked polyethylene cable material

A silane cross-linking and testing method technology, which is applied in the field of cable production, can solve problems such as cable outlet short circuit, uncoordinated ratio, damage, etc., and achieve the effects of ensuring reliability, fine and rigorous testing process, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

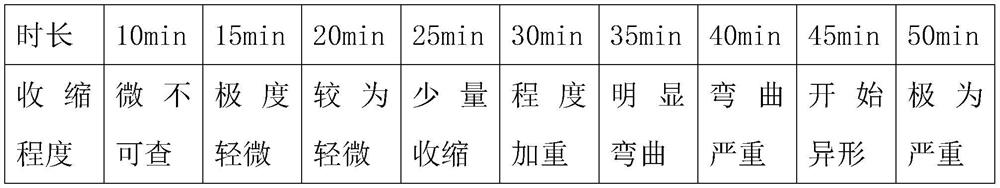

[0020] A thermal shrinkage performance testing method of silane crosslinked polyethylene cable material, comprising the following steps:

[0021] S1. Cut the silane cross-linked cable material to a fixed length, and use an automatic tool to cut it to a fixed length. After the cutting is completed, use a fan to cool the cutting part due to the high temperature generated by the processing, and collect it after the cooling is completed.

[0022] S2. Take out several cut parts of silane cross-linked cable materials as samples, and fix them on the rotating roller with driving components. After the fixation is completed, pour an appropriate amount of clean water into the corresponding processing dish to soak them.

[0023] S3. After soaking for 15 minutes, pour the clear water in the processing dish to the recovery place, then pour an appropriate amount of resin solution into the processing dish, and mix a small amount of higher fatty acid and metal oxide reagents in the resin soluti...

Embodiment 2

[0028] A thermal shrinkage performance testing method of silane crosslinked polyethylene cable material, comprising the following steps:

[0029] S1. Cut the silane cross-linked cable material to a fixed length, and use an automatic tool to cut it to a fixed length. After the cutting is completed, use a fan to cool the cutting part due to the high temperature generated by the processing, and collect it after the cooling is completed.

[0030] S2. Take out several cut parts of silane cross-linked cable materials as samples, and fix them on the rotating roller with driving components. After the fixation is completed, pour an appropriate amount of clean water into the corresponding processing dish to soak them.

[0031] S3. After soaking for 15 minutes, pour the clear water in the processing dish to the recovery place, then pour an appropriate amount of resin solution into the processing dish, and mix a small amount of higher fatty acid and metal oxide reagents in the resin soluti...

Embodiment 3

[0036] A thermal shrinkage performance testing method of silane crosslinked polyethylene cable material, comprising the following steps:

[0037] S1. Cut the silane cross-linked cable material to a fixed length, and use an automatic tool to cut it to a fixed length. After the cutting is completed, use a fan to cool the cutting part due to the high temperature generated by the processing, and collect it after the cooling is completed.

[0038] S2. Take out several cut parts of silane cross-linked cable materials as samples, and fix them on the rotating roller with driving components. After the fixation is completed, pour an appropriate amount of clean water into the corresponding processing dish to soak them.

[0039] S3. After soaking for 15 minutes, pour the clear water in the processing dish to the recovery place, then pour an appropriate amount of resin solution into the processing dish, and mix a small amount of higher fatty acid and metal oxide reagents in the resin soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com