Non-contact silicon chip deformation compensation apparatus and method based on electrostatic effect

A deformation compensation device and non-contact technology, applied in the field of integrated circuit equipment manufacturing, can solve the problems of inability to solve the deformation of the silicon wafer itself and clamping deformation, unfavorable overlay and focal plane error, uncontrollable local deformation amount, etc. Eliminate thermal deformation effects, avoid contact contamination, improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

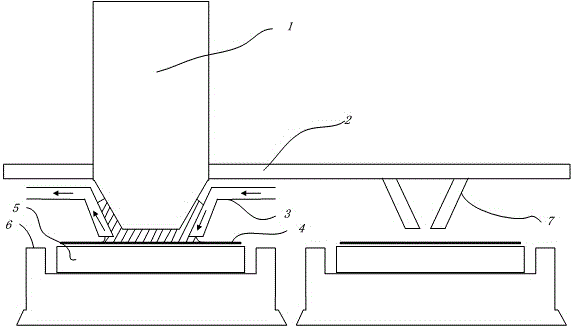

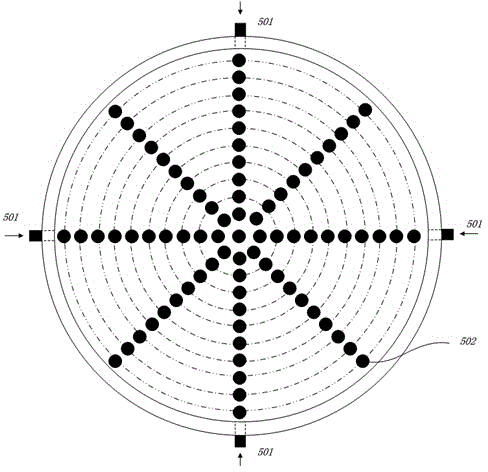

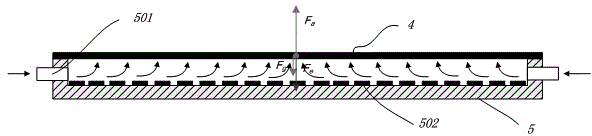

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The present invention discloses a non-E-PIN type silicon chip clamping and surface compensation device coupled with positive air flotation and non-contact electrostatic adsorption, so as to eliminate contact pollution, and can monitor and adjust the local surface shape of silicon chips in real time , to eliminate the deformation of the silicon wafer itself and the clamping deformation. The technical solution provided by the present invention can further couple the local temperature measurement of the silicon wafer and the compensation electrode array together, and can further eliminate the influence of the thermal deformation of the silicon wafer, thereby optimizing the effect of the deformation of the silicon wafer introduced by the immersion flow field on overlaying and focusing. Deep impact, and can avoid the continuous leveling and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com