Refining equipment based on waste mineral oil solvent extraction

A waste mineral oil, extraction technology, applied in the refining of hydrocarbon oil, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of inability to extract the agent, reduce the service life of the device, easy to paste and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

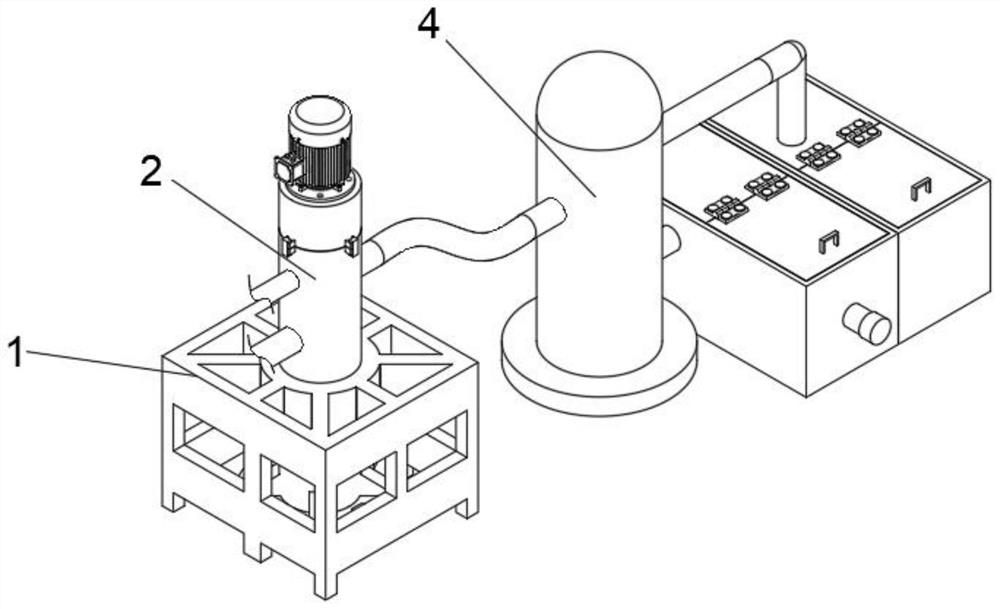

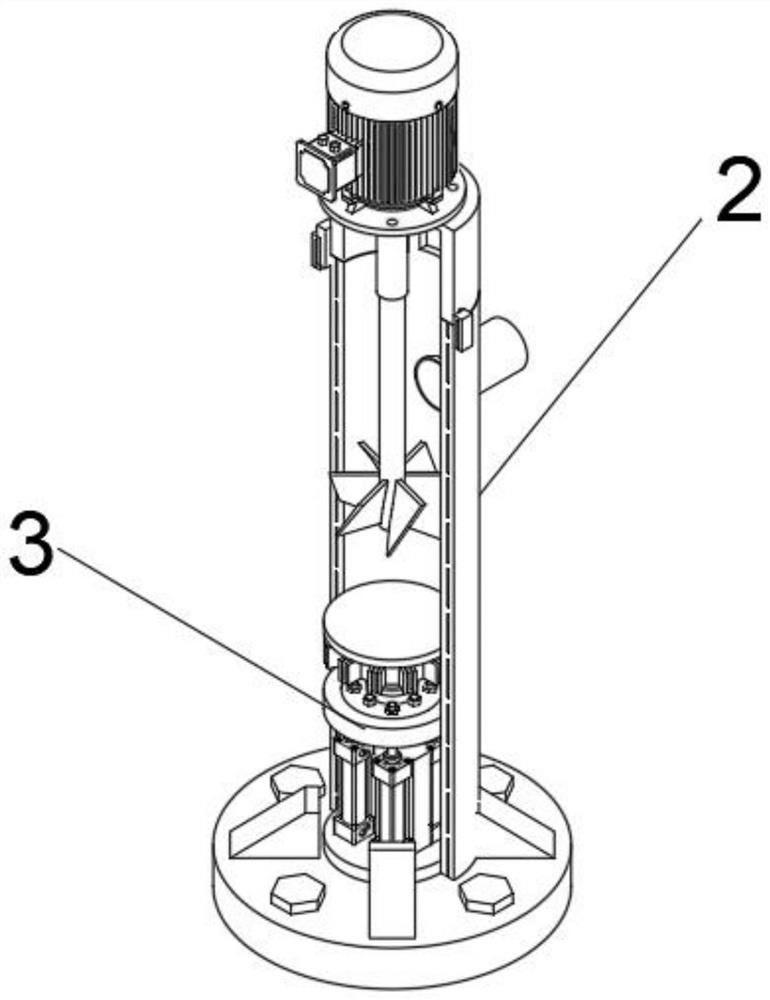

[0062] see Figure 1-Figure 11 As shown, a refining equipment based on waste mineral oil solvent extraction is provided, a reinforcement device 1, an extraction device 2 is provided on the top of the reinforcement device 1, a cleaning device 3 is provided at the center of the inner bottom of the extraction device 2, and a side of the extraction device 2 is provided with Discharging device 4;

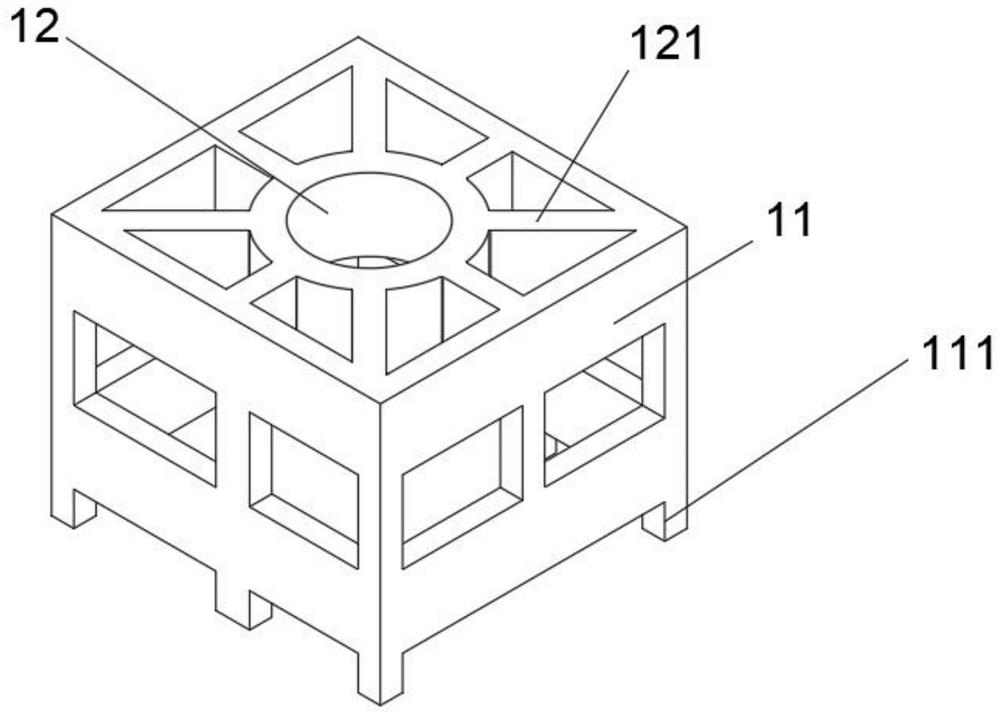

[0063] The reinforcement device 1 includes a reinforcement chassis 11 welded by several rectangular plates, reinforcement sleeves 12 are provided at the bottom and top circle centers of the reinforcement chassis 11, and side support plates 212 are provided around the reinforcement sleeve 12;

[0064] When the reinforcing device 1 of the mobile device transportation device of this embodiment is in use, the reinforcing sleeve 12 is clamped to catch the mixing extraction tower 21, the reinforcing chassis 11 is fixed on the ground through the support column 111, and the reinforcing rod 121 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com