Patents

Literature

56results about How to "Fast extraction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

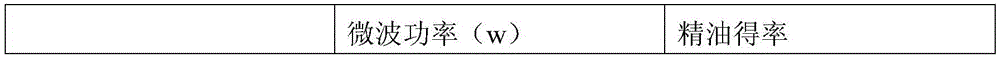

Microwave-assisted subcritical essential oil extracting method

InactiveCN105482897AUndamagedFast extraction rateEssential-oils/perfumesDistillation1,1,1,2-Tetrafluoroethane

The invention discloses a microwave-assisted subcritical essential oil extracting method. The microwave-assisted subcritical essential oil extracting method includes the steps that fresh plant tissues are frozen and then are smashed; 1,1,1,2-tetrafluoroethane is used as an extraction solvent and is led into the smashed plant tissues to perform microwave extraction; during microwave extraction, the extraction temperature is controlled to be 8-12 DEG C, the extraction pressure is controlled to be 0.8-6 Mpa, the microwave frequency is controlled to be 300-2400 MHZ, and the power is controlled to be 200-1200w; after a liquid phase in the system is separated out and microwave extraction is completed, the 1,1,1,2-tetrafluoroethane is recovered from the liquid phase, and the rest of the liquid phase is an essential oil stock solution; the essential oil stock solution is subjected to molecular distillation to obtain essential oil. By the adoption of the microwave-assisted subcritical essential oil extracting method, the essential oil free of any residual solvent can be obtained at lower temperature, the effective ingredients of the essential oil are not destroyed, and the natural quality of the essential oil can be kept to the most degree.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

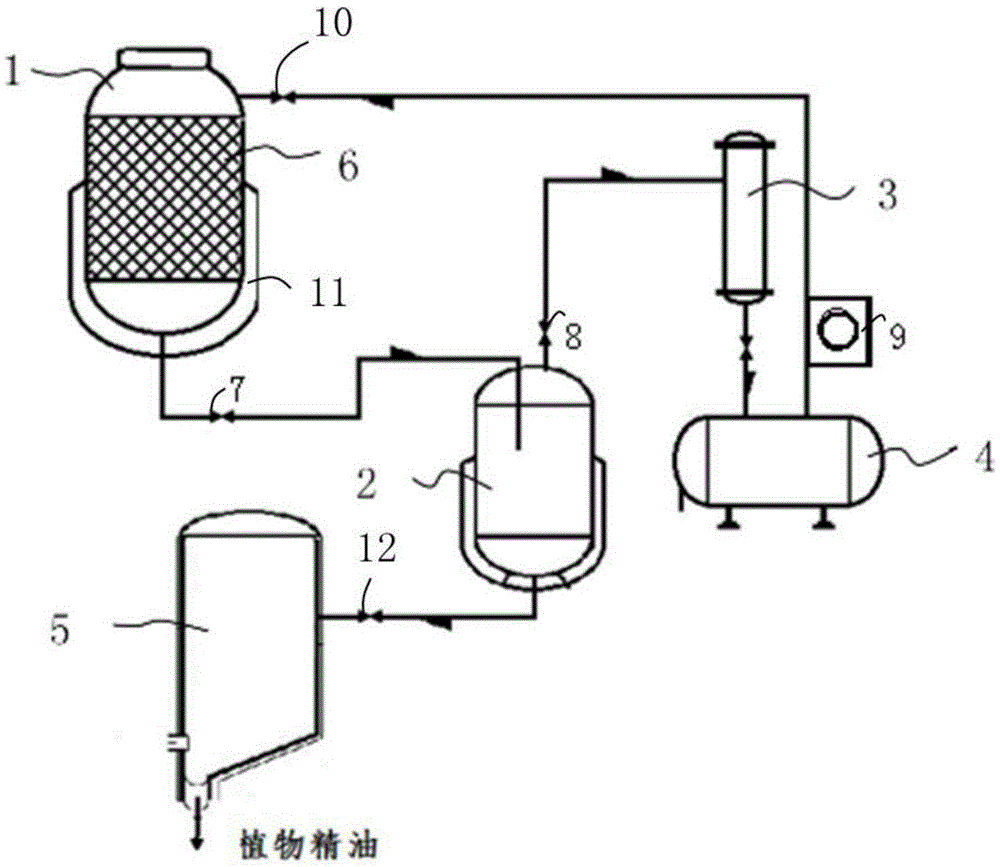

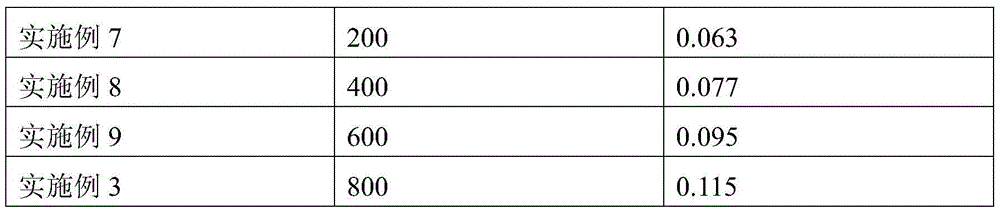

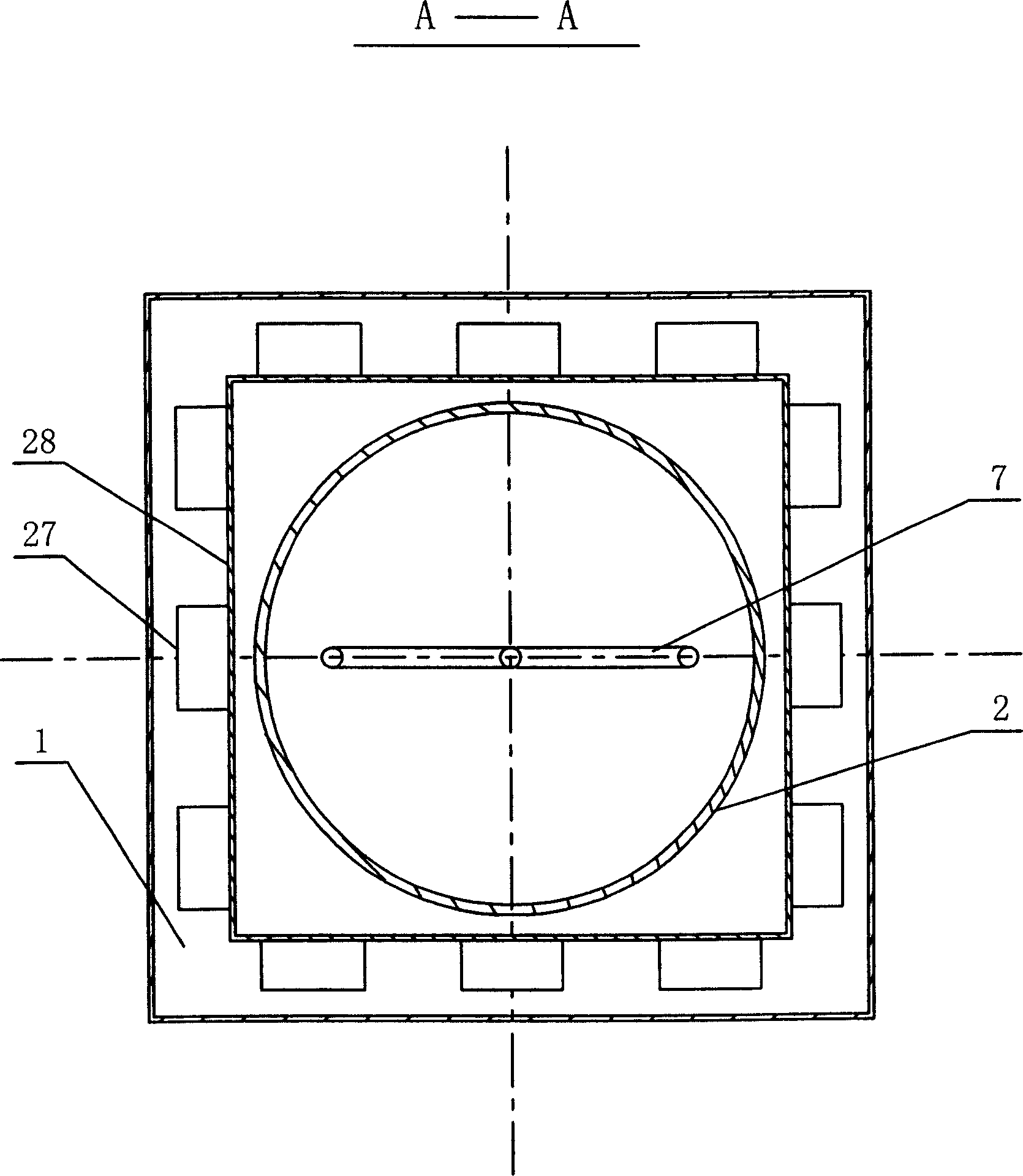

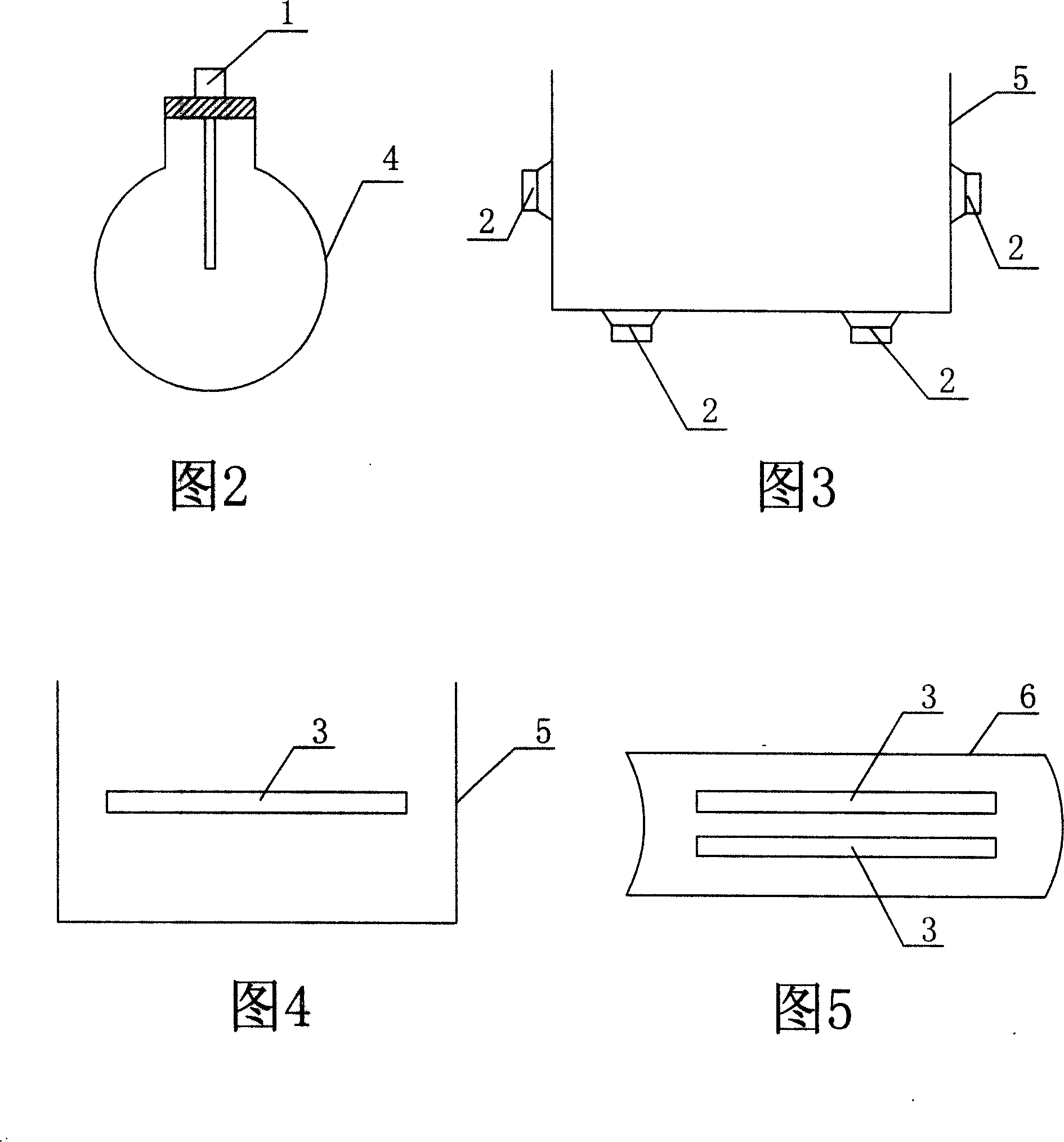

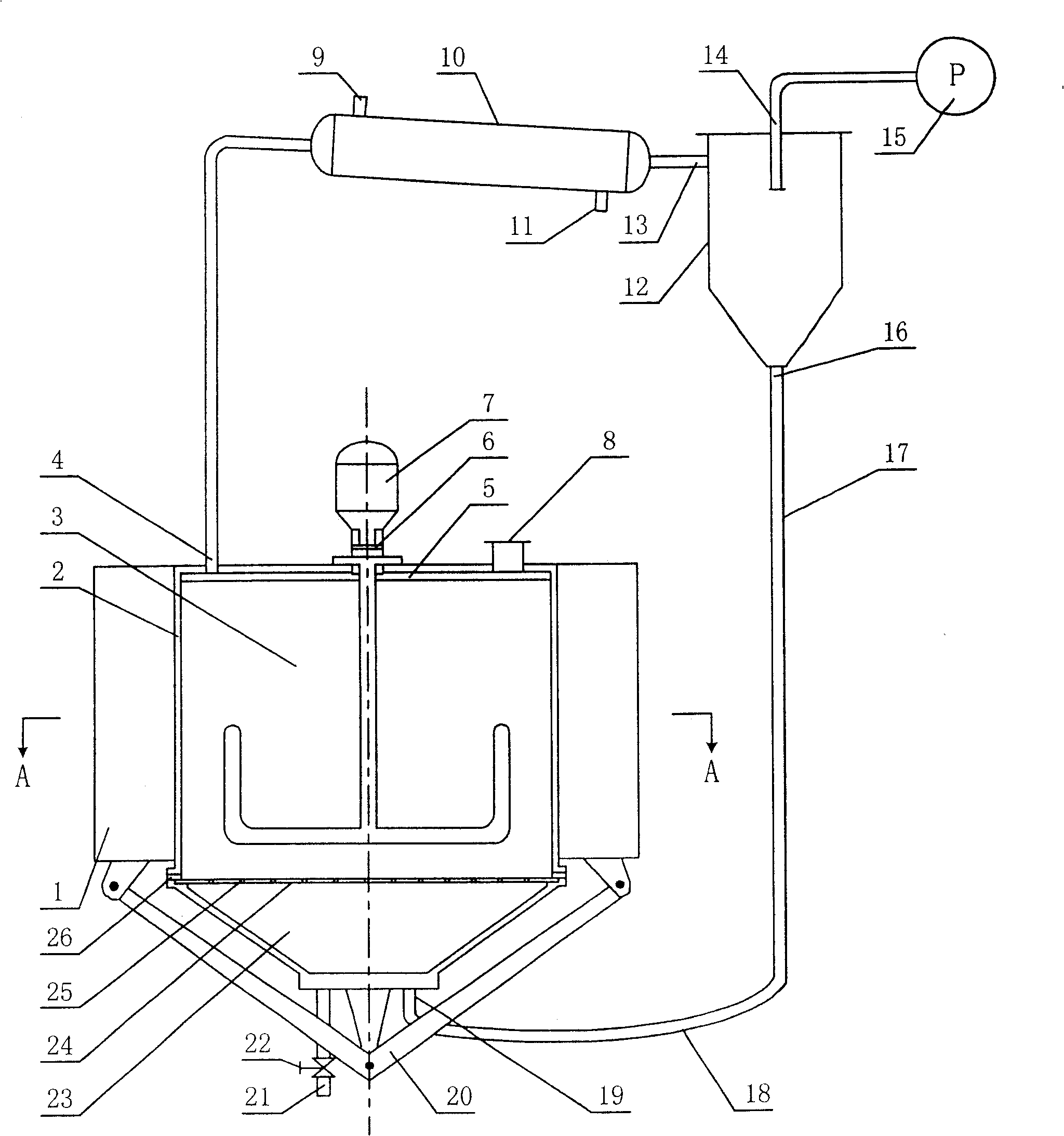

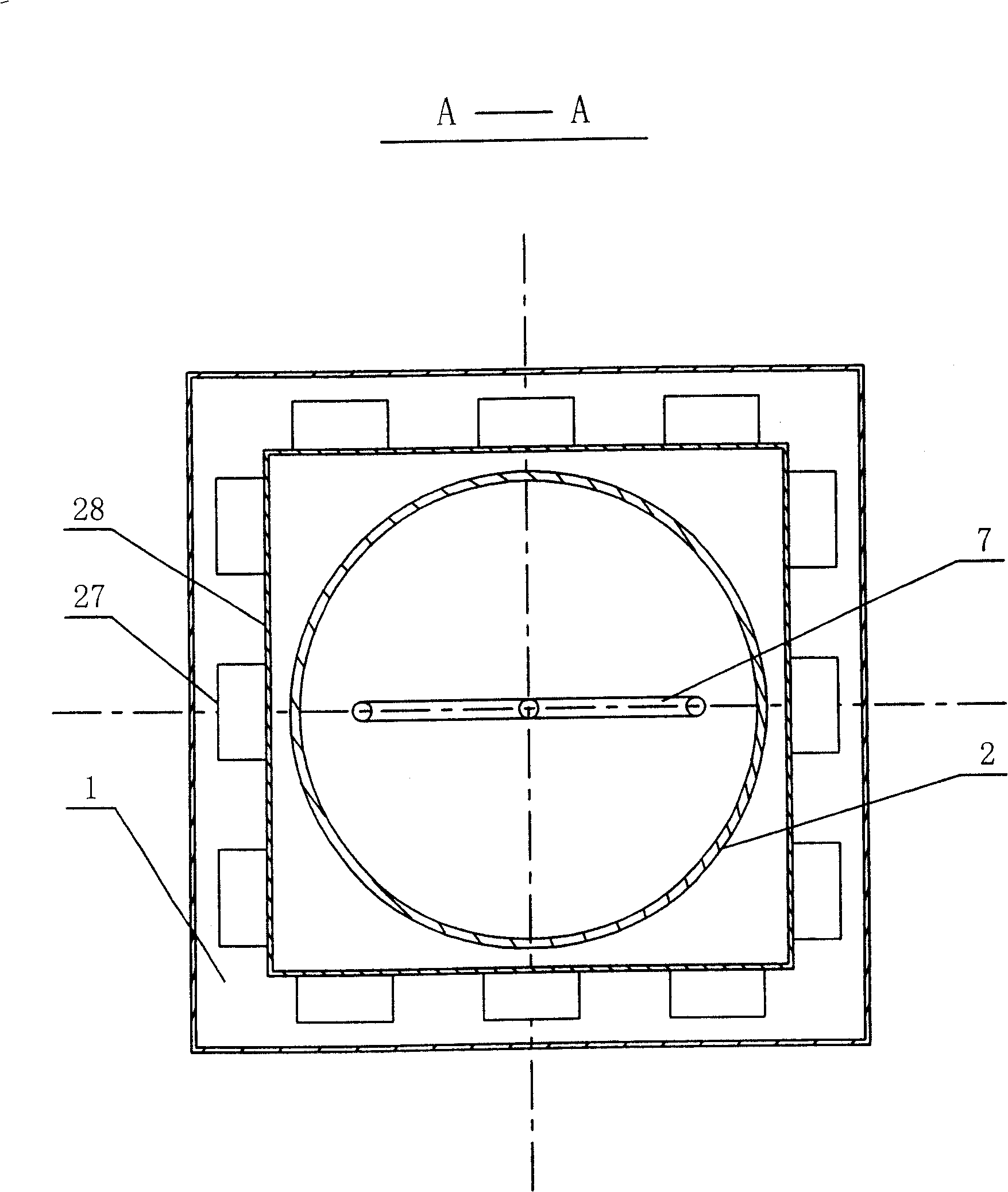

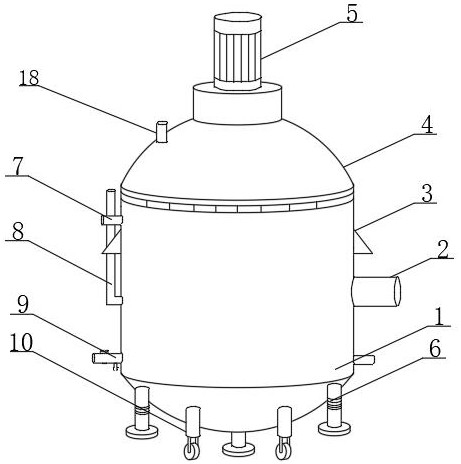

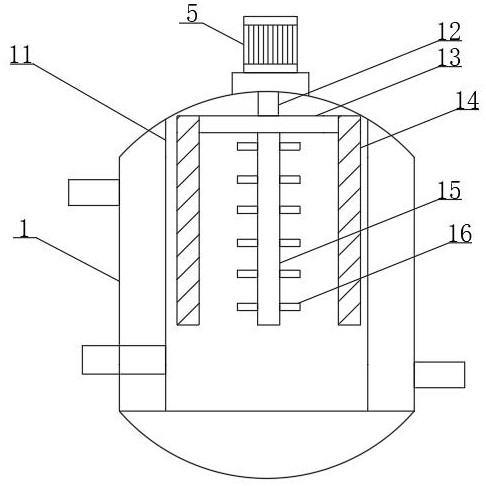

Decompressed microwave extraction device and method for extracting plant effective ingredient

InactiveCN1843552AAccelerated extraction and dissolutionReduce concentrationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveVapor–liquid separator

The invention discloses a decompression micro-wave extraction device and method on the plant effective component, which is formed by a micro-wave oven, an extraction pot, a condenser, a liquid-gas separator, and a decompression device. Wherein, the micro-wave oven is arranged outside the extraction pot, while the micro-wave generators are uniformly arranged inside the micro-wave oven; the extraction pot is mounted with electric mixer, while its top is mounted with magnetic eraser; the upper part of extraction pot is a extraction chamber, the lower part is mounted with a solvent warehouse, and they are separated by a baffle plate with uniform solvent penetrate holes. Via decompression and micro-wave, the gas solvent is condensed into liquid solvent via the condenser and fed back into the solvent warehouse via the cycle tubes; the plant via micro-wave radiation is discharged via the discharge device at the lower part of extraction pot; since said invention uses decompression and solvent cycle devices, the process that extracting plant effective components is accelerated; said components will not thermal deteriorated via high temperature; and the extraction rate and quality are improved to apply the industrial production.

Owner:QILU UNIV OF TECH

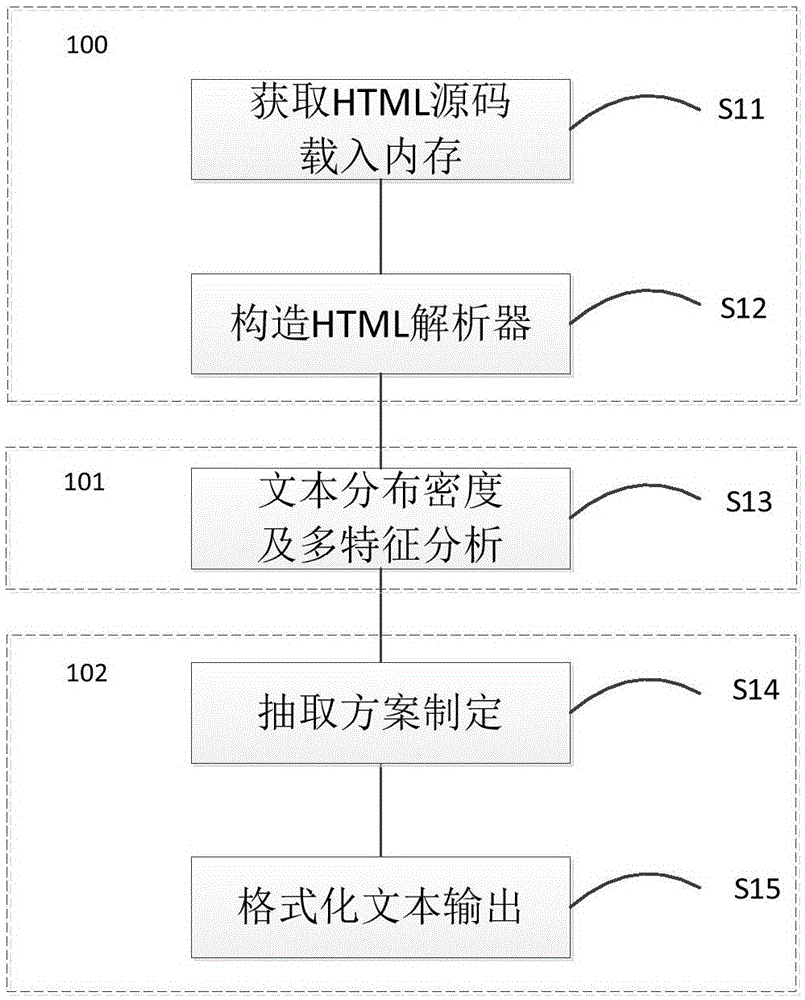

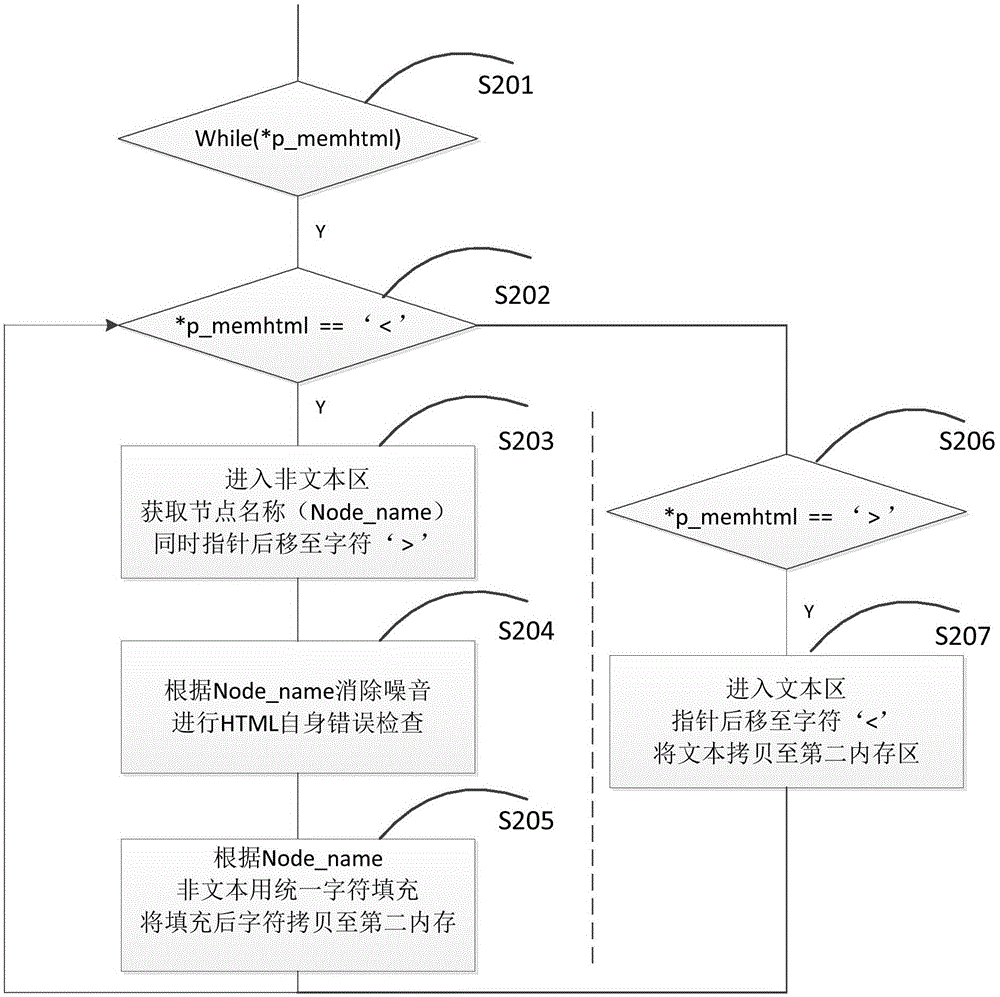

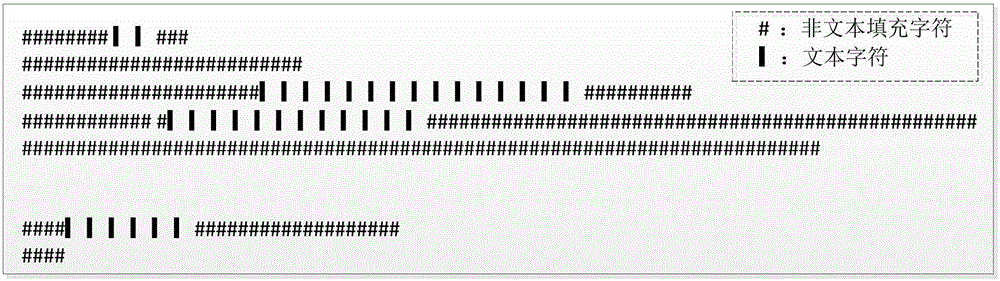

Web text information extraction method

InactiveCN105095466AAccurate extractionSmall footprintWeb data indexingWebsite content managementComputer moduleVolumetric Mass Density

The invention provides a web information extraction method aiming to solve the problems of high complexity and low accurate rate of an existing information extraction method. The method includes the steps that an HTML source code is obtained and loaded to a first memory zone; an HTML parser is built, the HTML source code is parsed in combination with page label distribution, and parsed data are stored to a second memory zone; unit windows are defined, the unit windows are moved to conduct primary feature statistics on data in the windows, voice variance and text similarity are sequentially adopted to serve as secondary features to further remove noise, and the density quantitative value of all the windows is obtained; the relation between the density threshold and the text density of all the windows is concluded according to sample data, and a reasonable extraction scheme is formulated; finally, a text integration module is entered, and a text with a normative format is output. Above all, a loading-parsing-quantizing-selecting-outputting processing scheme is adopted for the HTML source code, different web pages are adapted automatically according to the text density relative value, a great number of web pages can be processed, and webpage information is extracted automatically.

Owner:SHANDONG UNIV

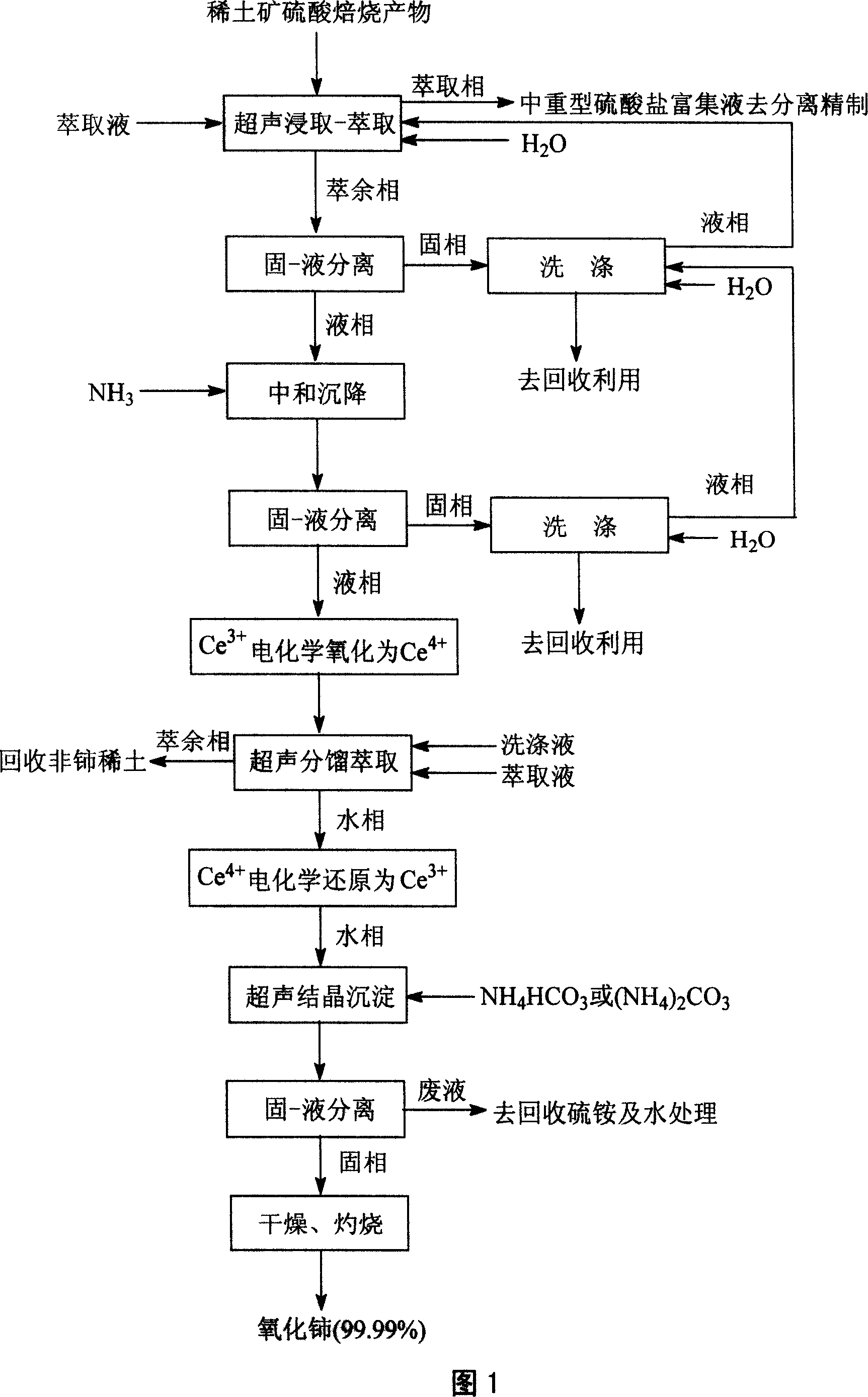

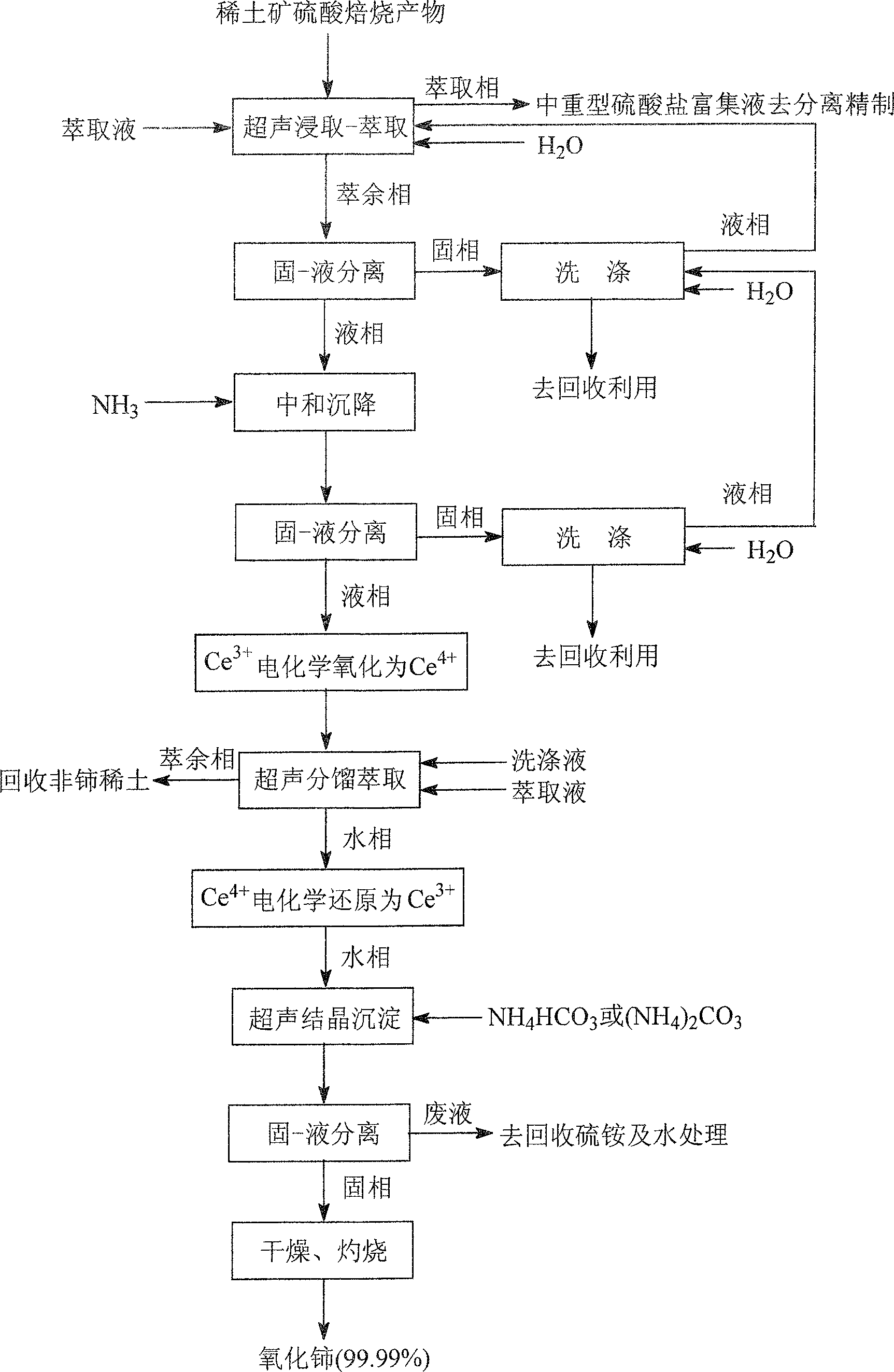

Method for preparing superfine high-purity cerium oxide by using rear earth ore sulfuric acid calcination products

InactiveCN101024504AIncrease speedImprove efficiencyRare earth metal compoundsProcess efficiency improvementSulfateRare earth

The invention relates to a method to make high purity cerium oxide that includes the following steps: taking ultrasonic leaching and extraction to gain rare earth sulfate enriched liquid; taking solid-liquid separation; taking neutralization deposition, taking solid-liquid separation, taking electrochemistry oxide to gain quadravalence cerous sulfate material liquid, taking ultrasonic fractional extraction, taking electrochemistry reducing to gain trivalence cerous sulfate, taking ultrasonic crystallization deposition to gain cerous sulfate crystal deposition, taking solid-liquid separation, drying and burning to gain the superfine high purity cerium oxide product of content over 99.99%, and the particle diameter is 0.01-10.0um. The advantages of the invention are that it improves leaching and extracting speed, improves yield, and purity, lowers cost and is environment protection.

Owner:常州市西南化工研究所 +2

Method for extracting and separating molybdenum (VI) in aqueous solution

ActiveCN106591604AWide concentration rangeFast extraction rateProcess efficiency improvementPhase ratioSaline solutions

The invention discloses a method for extracting and separating molybdenum (VI) in an aqueous solution. The method is mainly characterized in that a non-ionic surface active agent, the molybdenum-containing aqueous solution, a saline solution and deionized water are mixed and stirred evenly, the concentration of the non-ionic surface active agent is 50-300 g / L, the concentration of molybdenum is 1-40 g / L, and the salt concentration is 50-300 g / L; the pH value is adjusted to 1-4, the mixture is subjected to still standing and phase separation after being stirred for 10-60 min at 25-80 DEG C, phase separation is conducted for 10-60 min, an aqueous two-phase system with the upper phase being a non-ionic surface active agent phase loading the molybdenum and the lower phase being an aqueous phase, and the concentration of the molybdenum in the non-ionic surface active agent phase loading the molybdenum is 2-80 g / L; the reextraction temperature is 25-80 DEG C, the time is 10-60 min, phase separation is conducted for 10-60 min, the phase ratio of the non-ionic surface active agent phase loading the molybdenum to an ammonium sulfate aqueous solution is 1 to 5, and the reextraction product is ammonium molybdate. According to the method, the extraction rate is high, good phase separation is achieved, the molybdenum extraction rate reaches 95% or above, and the molybdenum reextraction rate reaches 95% or above.

Owner:YANSHAN UNIV

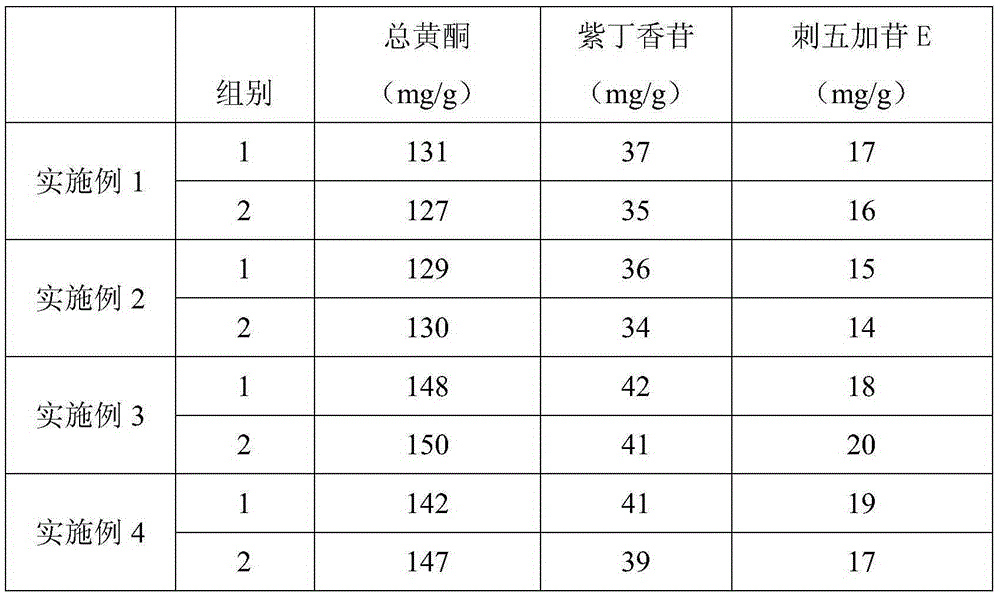

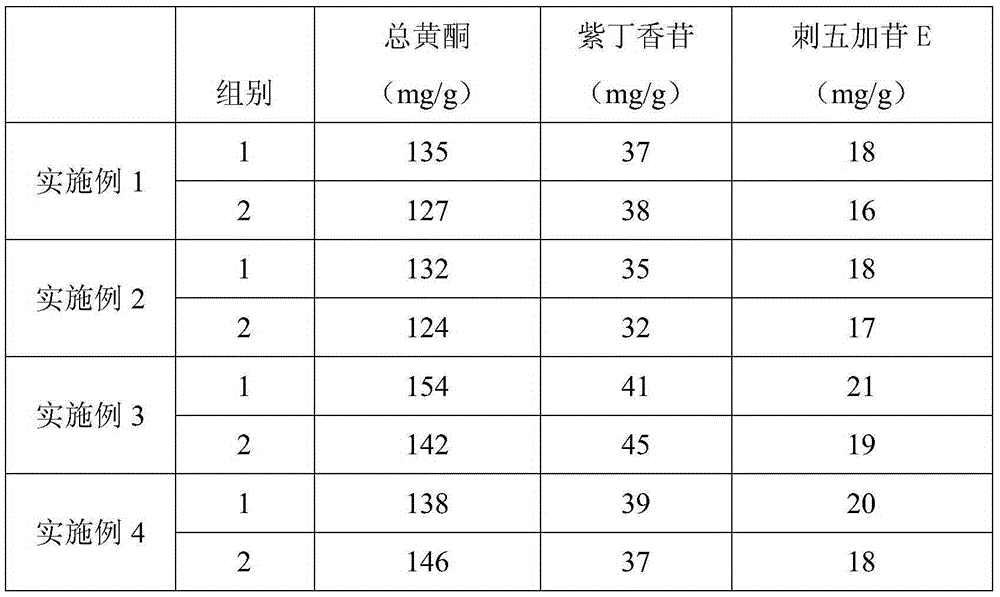

Preparation method of manyprickle acanthopanax root extract

ActiveCN105311075AReduce usageReduce energy consumptionPlant ingredientsEleutherococcus senticosusAlcohol

The invention relates to a preparation method of traditional Chinese medicine extract, in particular to a preparation method of extract of medicine material manyprickle acanthopanax root. The manyprickle acanthopanax root extract is prepared through the procedures of conducting countercurrent extracting through ethyl alcohol with concentration of 40-70%, alcohol precipitating, resin purifying, sterilizing, concentrating and the like on medicine material manyprickle acanthopanax root. By means of the method, impurities in the manyprickle acanthopanax root extract can be remarkably reduced, the purity of effective components in the manyprickle acanthopanax root extract and the safety and stability of the manyprickle acanthopanax root extract are improved, the extract cycle can be shortened, energy conservation and high efficiency are achieved, and the method is particularly suitable for industrial production.

Owner:HARBIN ZHENBAO PHARMA

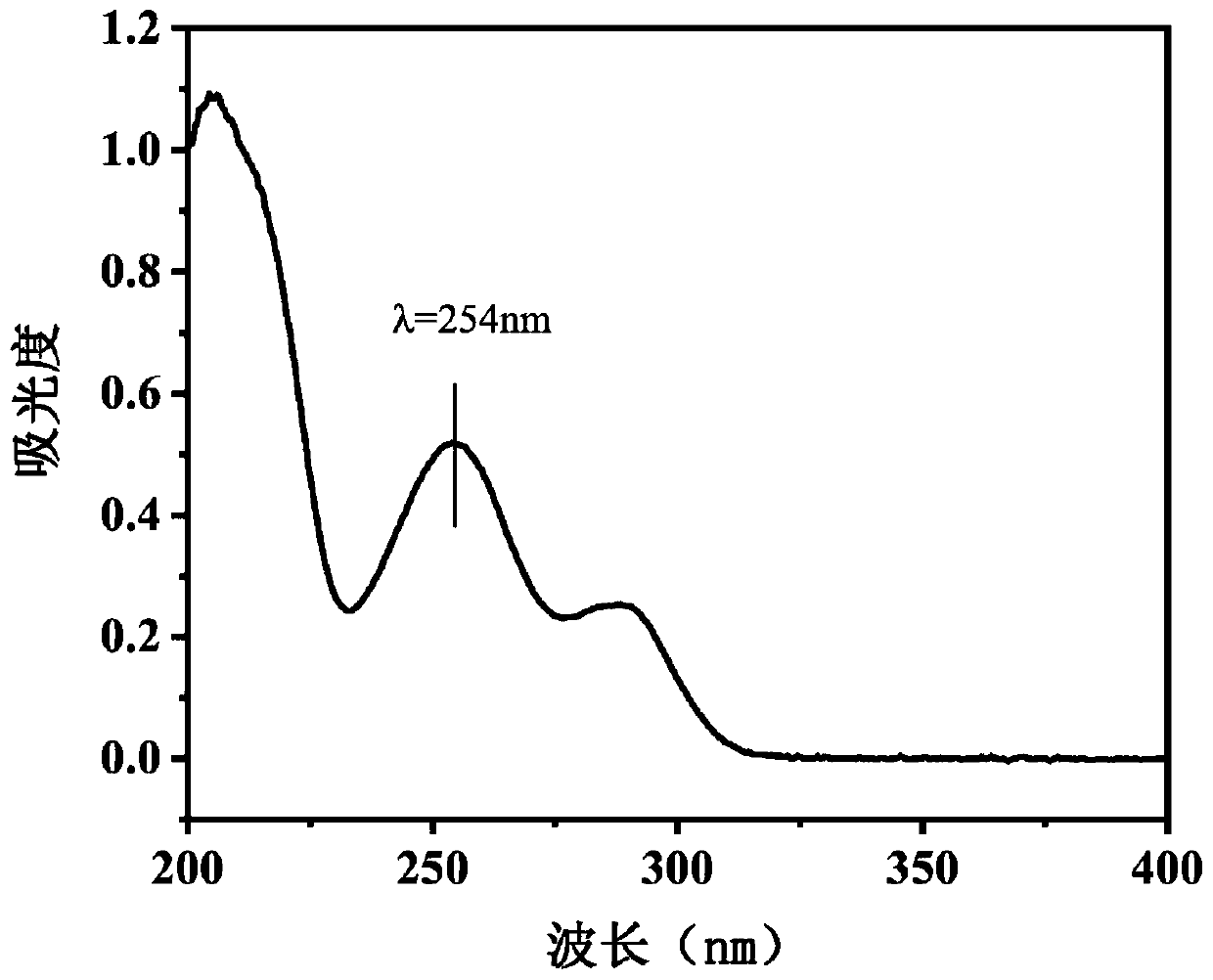

Method for extracting vanillic acid by using deep-eutectic solvent/normal propyl alcohol aqueous two-phase system

ActiveCN111087299ALow costWide range of synthetic raw materialsCarboxylic compound separation/purificationVanillic acidN-Propyl alcohol

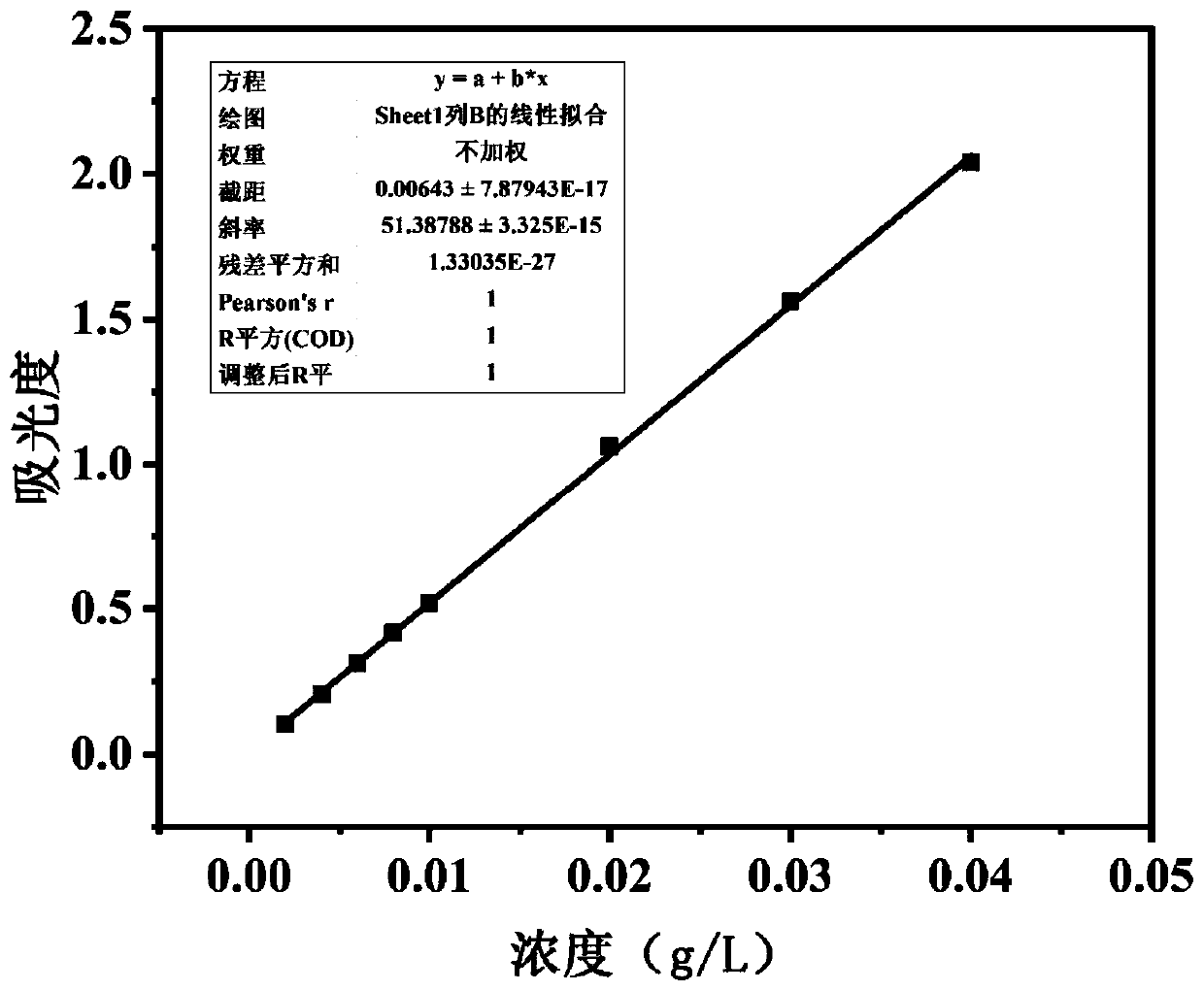

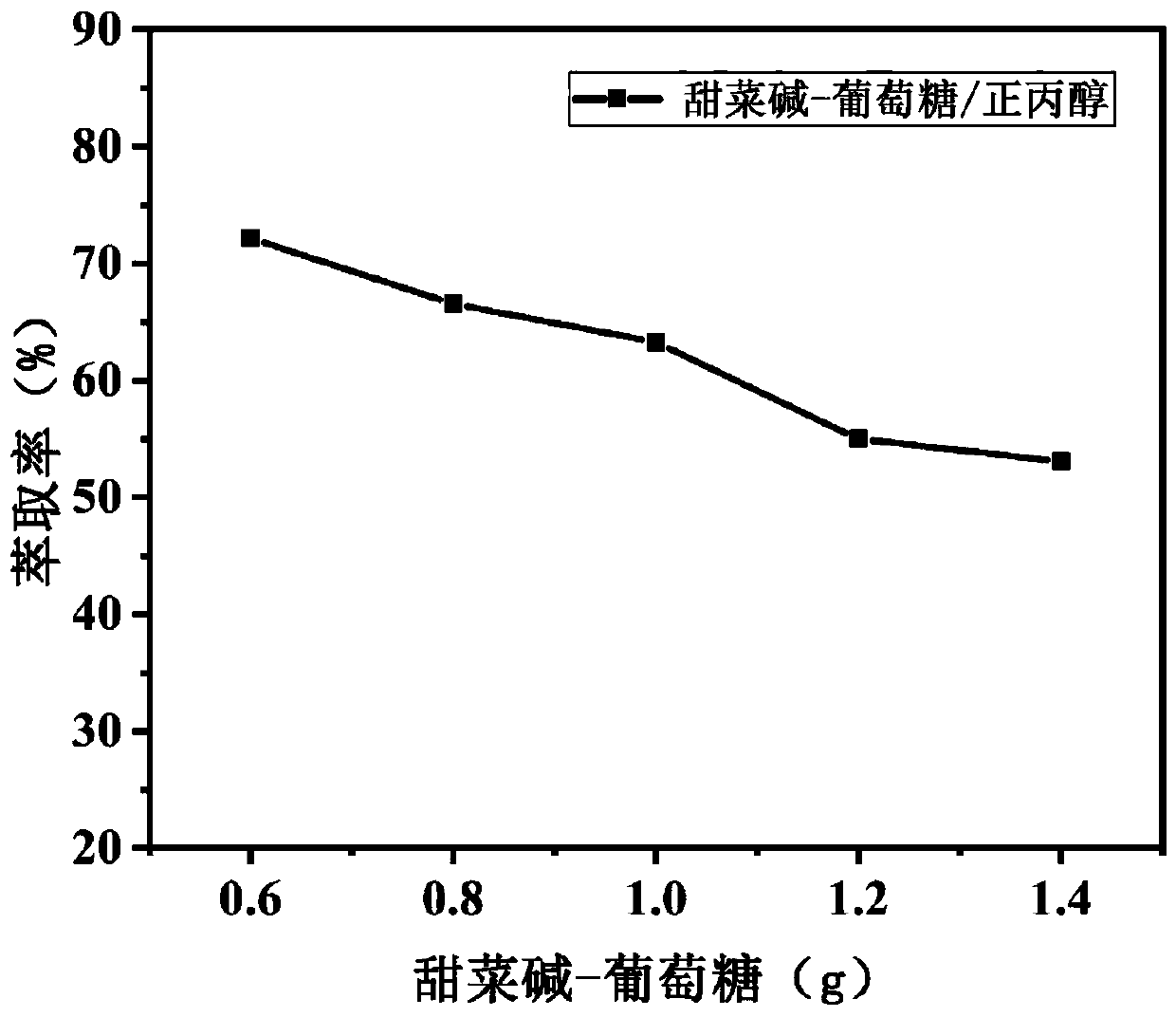

The invention discloses a method for extracting vanillic acid by using a deep-eutectic solvent / normal propyl alcohol aqueous two-phase system. According to the method, extraction solvents including adeep-eutectic solvent and normal propyl alcohol are mixed to jointly construct the aqueous two-phase system, salts in a conventional aqueous two-phase system are replaced, and the salting-out problemof a salt-containing system is avoided. According to the method, the deep-eutectic solvent and normal propyl alcohol are added into an aqueous solution of vanillic acid to form the aqueous two-phase extraction system with a lower phase rich in the deep-eutectic solvent and an upper phase rich in the normal propyl alcohol, and vanillic acid is extracted into the upper phase. The purpose of enriching and recovering the vanillic acid from the aqueous solution is achieved by utilizing the deep-eutectic solvent / normal propyl alcohol aqueous two-phase system, the deep-eutectic solvent can be recycled, the process is simple, and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of compound liquid enzymes

InactiveCN105124579ATreats restlessness and shortness of breathIncrease viscosityNatural extract food ingredientsFood ingredient functionsAqueous ethanolSlurry

The invention discloses a preparation method of compound liquid enzymes. The preparation method comprises the following steps: taking papaya cores, longan cores, litchi cores, peach core and mango cores in parts by weight, then mixing, crushing, soaking in aqueous ethanol, taking soak solution, diluting by water and filtering to obtain the first separated liquid; taking grapes, apples, oranges, pitayas, sugar orange peels, tomatoes, papaya, Hami melon, pomelo flesh, peach flesh, hawthorn fruits, mulberries and brown sugar solution in parts by weight, then mixing aeating to pulp and fermenting the pulp to obtain the first fermentation broth. According to the preparation method, the raw materials not only comprises the fruits with rich nutrients, such as the Hami melon, the pomelo flesh, the peach flesh, the hawthorn fruits, the mulberries and the like, but also comprises three Chinese herbal medicines with very good medical values, including rhizoma polygonati, root of Japanese stemona and asparagus root; the rhizoma polygonati has very good treatment effects to stomach weakness, spleen weakness, body weakness and tiredness and functions of strengthening bone and musculature and invigorating spirit and marrow; the root of Japanese stemona and the asparagus root have very good effects in moistening the lung, relieving cough and eliminating sputum; thus, the compound liquid enzymes have very good health-care effects.

Owner:南宁荣港生物科技有限公司

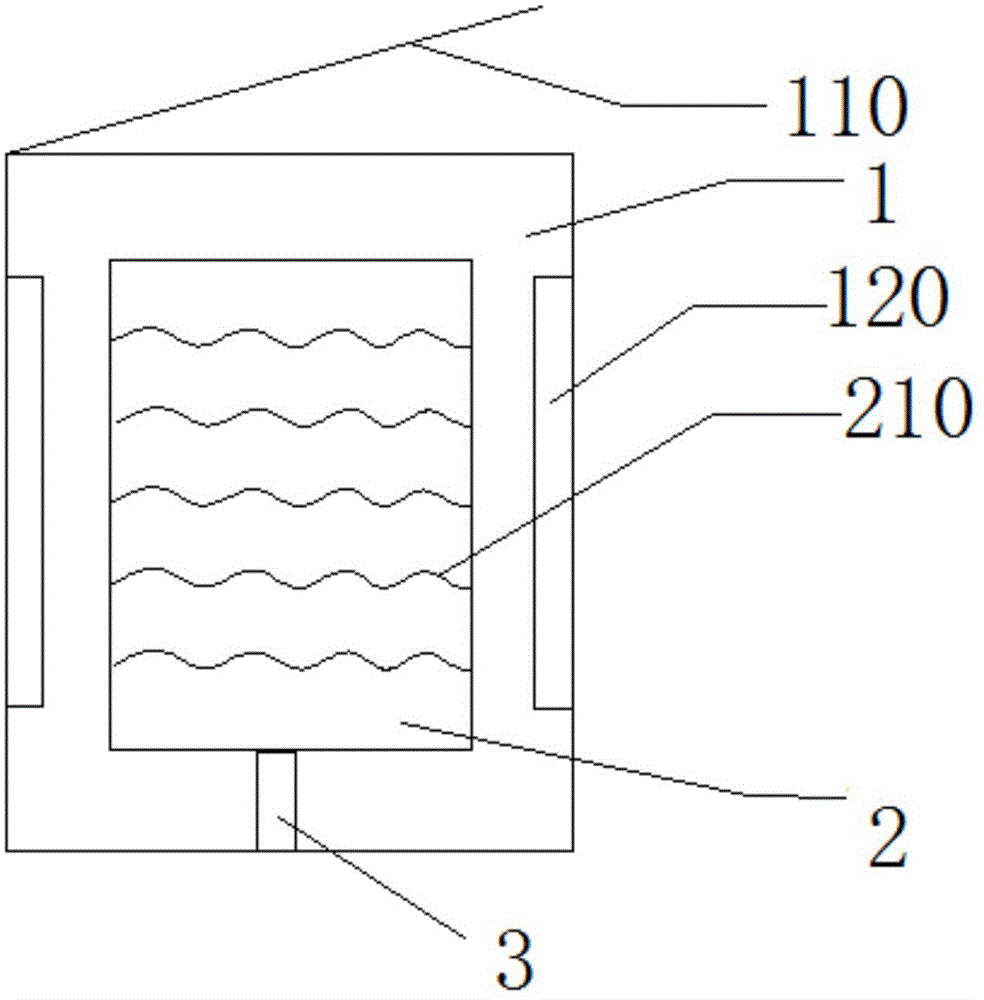

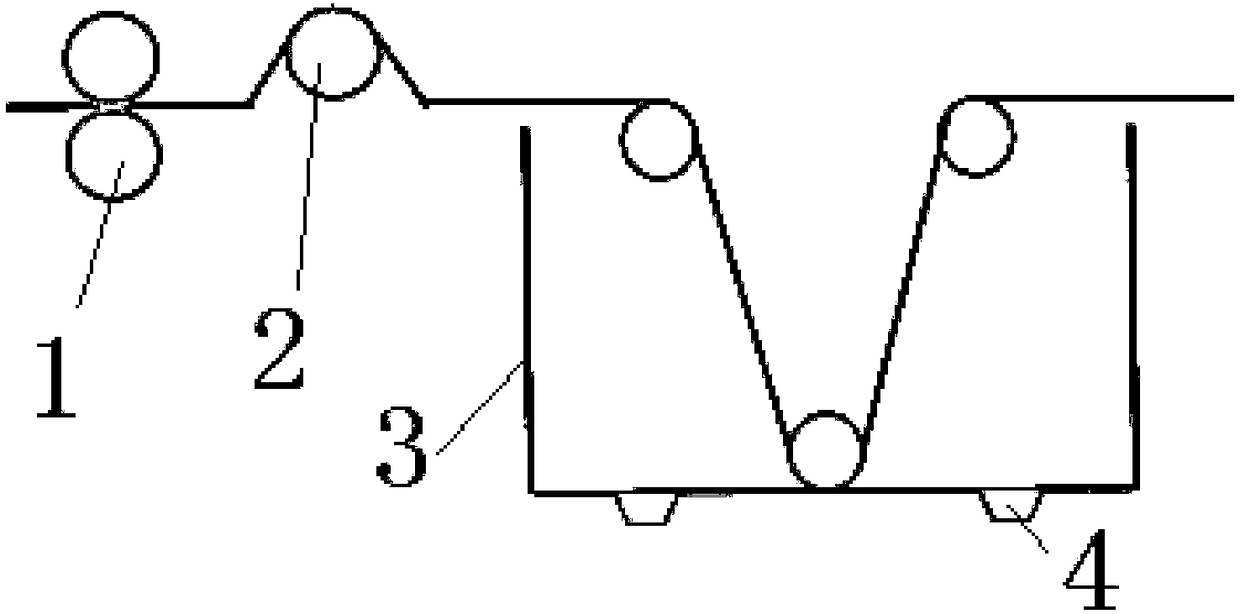

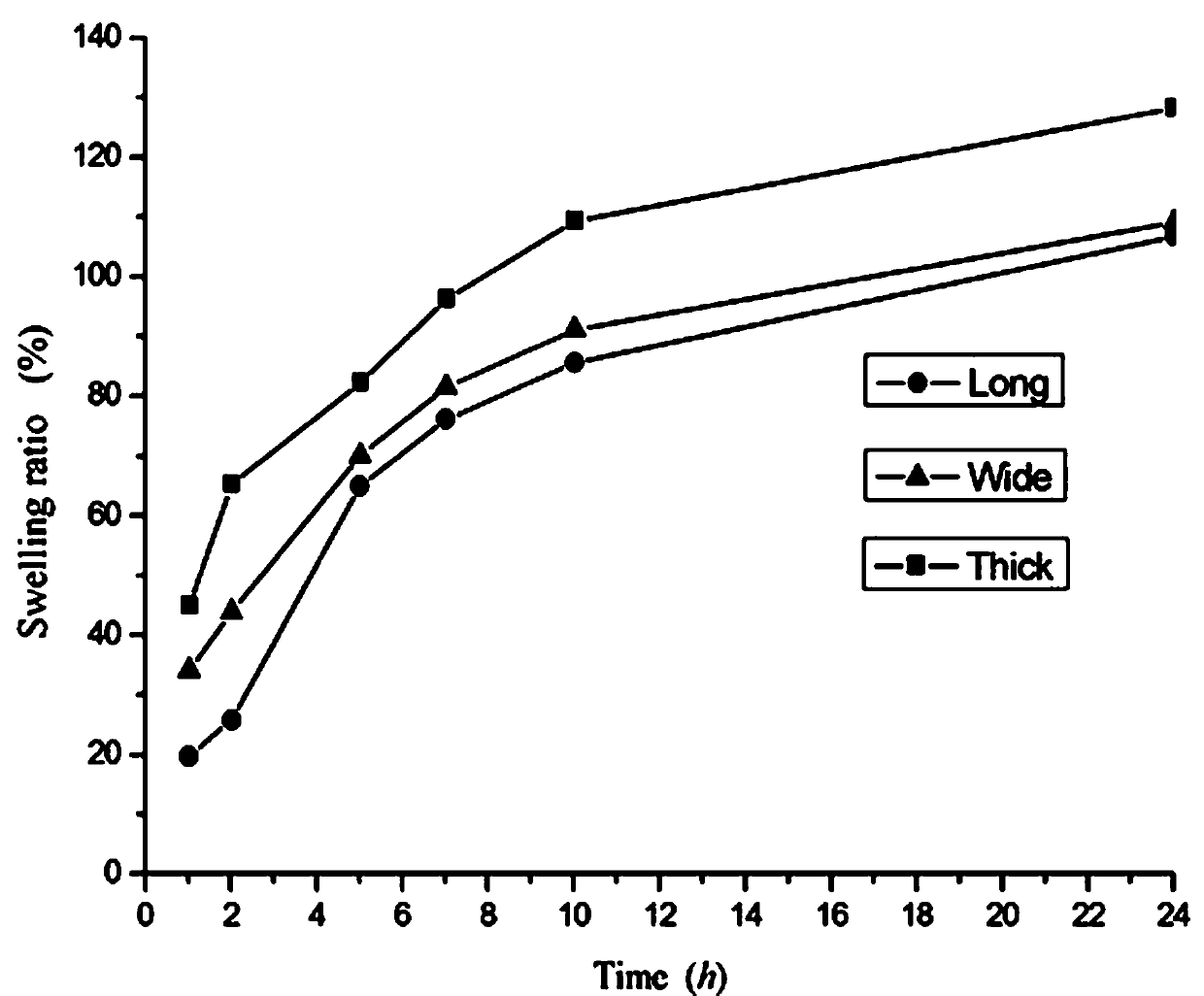

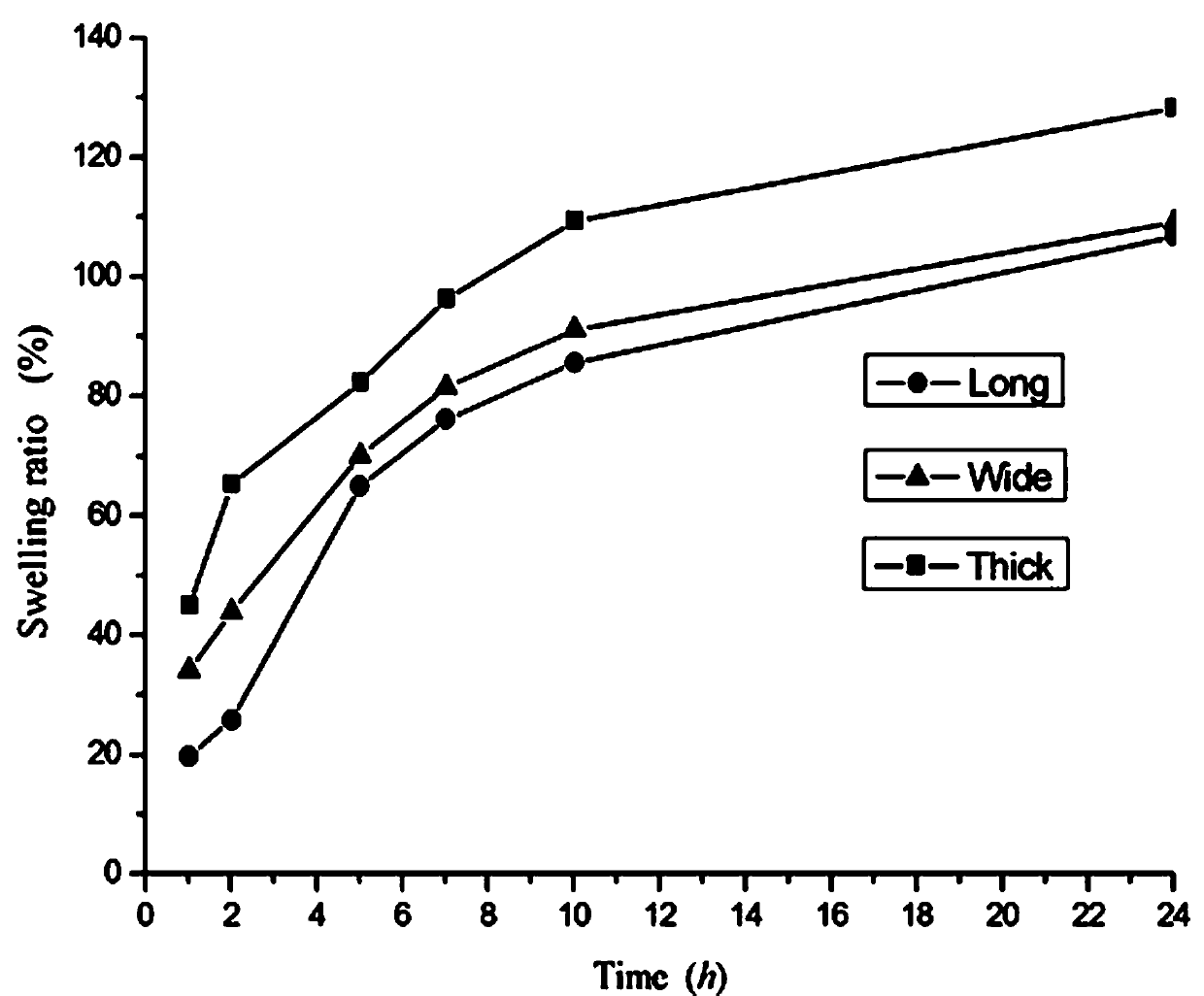

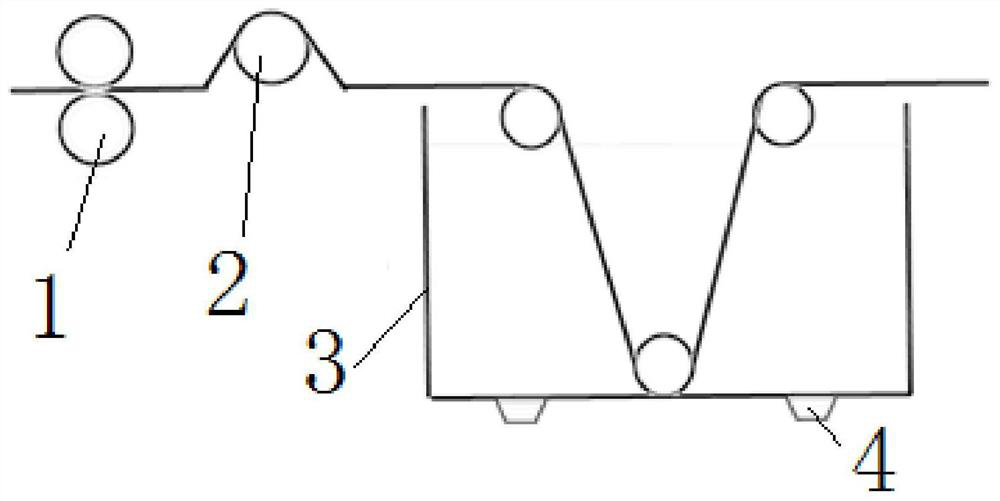

Pore forming agent removal method of battery diaphragm and preparation process of lithium ion secondary battery diaphragm

The invention discloses a pore forming agent removal method of a battery diaphragm and a preparation process of a lithium ion secondary battery diaphragm. The pore forming agent removal method of thebattery diaphragm comprises the following steps: pretreating a diaphragm substrate by virtue of a device, and removing at least a part of pore forming agent in the diaphragm substrate in advance; andextracting the pretreated diaphragm substrate by virtue of ultrasonic extraction, extracting the pore forming agent, and ensuring that the residual rate of the pore forming agent of the finally prepared battery diaphragm is less than 1 percent. By adopting the pore forming agent removal method of the battery diaphragm and the preparation process of the lithium ion secondary battery diaphragm, theextraction speed of the battery diaphragm can be increased on the premise of not increasing the length of a battery production line, not improving the device precision and not improving the personal skill; and moreover, the method is particularly suitable for extracting a thicker diaphragm substrate and solves the problem that the thicker substrate is difficult to extract.

Owner:四川卓勤新材料科技有限公司

Preparing method for acanthopanax senticosus extract

The invention relates to a preparing method for traditional Chinese medicine extract, in particular to a preparing method for acanthopanax senticosus extract. The preparing method comprises the steps that acanthopanax senticosus is subjected to countercurrent extraction through 40%-70% ethyl alcohol, line-sulfur treatment, alcohol precipitation, sterilization ultrafiltration belt type drying and other procedures, and the acanthopanax senticosus extract is prepared. By means of the method, impurities in the acanthopanax senticosus extract can be remarkably reduced, and the purity of effective ingredients in the acanthopanax senticosus extract and the safety and stability of the acanthopanax senticosus extract can be improved; meanwhile, the extraction cycle can be shortened, energy can be saved, high efficiency can be achieved, and the preparing method is especially suitable for industry production.

Owner:HARBIN ZHENBAO PHARMA

Method for extracting and separating tungsten from tungsten-containing aqueous solution through aqueous two-phase system

InactiveCN108220629AWide concentration rangeFast extraction rateProcess efficiency improvementTungstatePhase ratio

The invention provides a method for extracting and separating tungsten from a tungsten-containing aqueous solution through an aqueous two-phase system. The method mainly comprises the steps that a non-ionic surfactant of the Twain series, the tungsten-containing aqueous solution, a saline solution and deionized water are evenly mixed and stirred, specifically, the mass fraction of the non-ionic surfactant is 10%-20%, the mass fraction of the tungsten is 0.1%-5%, and the mass fraction of salt is 6-12%; the pH value is adjusted to be 2-3, after being stirred for 10-60 min at the temperature of 30-60 DEG C, the mixture is subjected to standing for phase splitting, the phase splitting time is 10-60 min, and then the aqueous two-phase system with the upper phase being the tungsten-loaded non-ionic surfactant phase and the lower phase being the aqueous phase is obtained; and the back extraction temperature is 40-70 DEG C, the back extraction time is 20-60 min, the phase splitting time is 20-60 min, the phase ratio of the tungsten-loaded non-ionic surfactant phase to the ammonium carbonate aqueous solution phase is 1-4:1, and the back extraction product is ammonium tungstate. By the adoption of the method for extracting and separating the tungsten from the tungsten-containing aqueous solution through the aqueous two-phase system, the extraction speed is high, the phase splitting is good, the single-stage extraction rate of tungsten (VI) reaches 97% or over, and the single-stage back extraction rate of the tungsten (VI) reaches 96% or over.

Owner:YANSHAN UNIV

Method for extracting and separating tungsten in aqueous solution from aqueous two-phase system

ActiveCN108588415AWide concentration rangeFast extraction rateProcess efficiency improvementTungstatePolyethylene glycol

The invention relates to a method for extracting and separating tungsten in an aqueous solution from an aqueous two-phase system. The method is characterized in that polyethylene glycol, a tungsten-containing aqueous solution, a saline solution, and deionized water are mixed and uniformly stirred, the mass fraction of a nonionic surfactant is 10-20%, the mass fraction of tungsten is 0.1-5%, and the mass fraction of salt is 6-12%; a pH value is adjusted to 2-3, the material is stirred for 10-60 min at the temperature of 30-60 DEG C, standing is carried out for phase splitting for 10-60 min, andthe aqueous two-phase system having an upper phase being a nonionic surfactant phase loaded with phase and a bottom phase being an aqueous-phase; the back extraction temperature is 40-70 DEG C, the stirring time is 20-60 min, and the phase separating time is 20-60 min, the phase ratio (A:O) of the nonionic surfactant phase loaded with phase to an ammonium carbonate aqueous solution is 1:1-4:1, and the back-extraction product is ammonium tungstate. The method has the advantages of fast extraction rate and good phase separating, tungsten single-stage extraction yield can achieve more than 98%,and the tungsten single-stage back-extraction yield can achieve more than 97%.

Owner:YANSHAN UNIV

Preparation method of agilawood wine

InactiveCN108165413ARapid catalytic hydrolysisIncrease filtration rateAlcoholic beverage preparationHydrogenRoom temperature

The invention discloses a preparation method of agilawood wine. The preparation method comprises the following specific preparation steps: step 1: preparing Maotai-flavor Baijiu: (1) taking completelyripe red sorghums and smashing for later use; (2) adding the smashed red sorghums into a fermentation tank filled with distilled water and sufficiently and uniformly mixing; (3) adding glucoamylase into the fermentation tank; meanwhile, controlling the inner temperature to be 55 to 65 DEG C and controlling the pH (Potential of Hydrogen) to be 4.0 to 4.5; (4) adding amylase into the fermentation tank; meanwhile controlling the inner temperature to be 75 to 85 DEG C and controlling the pH to be 6.0 to 7.2; (5) after fermenting the fermentation tank of step (4) under a room-temperature conditionfor 30 days, obtaining the Maotai-flavor Baijiu. The agilawood wine prepared by the preparation method has simple raw material components and a reasonable ratio; the agilawood wine disclosed by the invention has an elegant agilawood flavor, is mellow and abundant and has long aftertaste, good mouthfeel and rich aroma; the agilawood wine has no drug property and is suitable for a lot of drinkers to drink.

Owner:张雄汉

Method for preparing superfine high-purity cerium oxide by using rear earth ore sulfuric acid calcination products

InactiveCN100500568CIncrease speedImprove efficiencyRare earth metal compoundsProcess efficiency improvementSulfateRare earth

Owner:常州市西南化工研究所 +2

Method for extracting and separating molybdenum in aqueous solution through two- aqueous-phase system

ActiveCN108070718AWide concentration rangeFast extraction rateProcess efficiency improvementPhase splittingSingle stage

The invention relates to a method for extracting and separating molybdenum in an aqueous solution through a two-aqueous-phase system. The method mainly comprises the steps that a non-ionic surface active agent, a molybdenum containing aqueous solution, a saline solution and deionized water are mixed and stirred evenly, the mass fraction of the non-ionic surface active agent is 10%-20%, the mass fraction of the molybdenum (VI) is 0.1%-3%, and the mass fraction of salt is 8%-12%; the pH value is adjusted to be 1-7, after stirring is carried out for 10 min-60 min at 30 DEG C-60 DEG C, standing phase splitting is carried out, phase separation is carried out for 10 min-60 min, a non-ionic surface active agent phase with loaded molybdenum (VI) as an upper phase is obtained, and the two-aqueous-phase system with a water phase as a lower phase is obtained; the reextraction temperature is 40 DEG C-70 DEG C, the time is 20 min-60 min, phase separation is carried out for 20 min-60 min, the phaseratio of the non-ionic surface active agent phase with the loaded molybdenum (VI) to an ammonium carbonate aqueous solution phase is (1-4):1, and a reextraction product is ammonium molybdate. The method is high in extracting speed and good in phase separation, the single-stage extraction rate of the molybdenum (VI) reaches 94% or above, and the single-stage reextraction rate of the molybdenum (VI)reaches 95% or above.

Owner:YANSHAN UNIV

Preparation method of liquid ferment

InactiveCN105077250AAvoid inconvenienceHigh in nutrientsSugar food ingredientsYeast food ingredientsApple peelTherapeutic effect

The invention discloses a preparation method of a liquid ferment. The preparation method comprises the following steps: mixing mango kernels, loquat kernels, lychee kernels, peach kernels and longan kernels, grinding the mixture, soaking the mixture in an ethanol water solution for 8-10 hours, extracting a soak solution, adding water to dilute, and filtering to obtain first separation liquid; mixing shaddock peels, apple peels, guava peels, echeveria macdougallii leaves, sugar orange peels, melon peels, unpeeled pawpaw and a brown sugar water solution, carrying out braising and pulping to obtain syrup, fermenting to obtain a first fermented substance, and filtering, so as to obtain first fermentation liquid and first fermentation residues. The utilized raw materials of the liquid ferment include nutrient-rich fruits such as avocados, carambola, green plum pulp, haws, mulberries and the like and further include polygonatum sibiricum capable of well treating weakness of the spleen and the stomach, body fatigue and debility, strengthening bones and musculatures and benefiting marrow as well as radix stemonae capable of moistening lung, relieving cough and eliminating phlegm, and polygonatum sibiricum and radix stemonae are two Chinese herbal medicines with very high medicinal values, so that the liquid ferment has very good health efficacy.

Owner:南宁荣港生物科技有限公司

Decompressed microwave extraction device and method for extracting plant effective ingredient

InactiveCN100421759CAccelerated extraction and dissolutionReduce concentrationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveVapor–liquid separator

Owner:QILU UNIV OF TECH

Method for extracting and separating vanadium from aqueous solution

ActiveCN106756116AWide concentration rangeFast extraction rateProcess efficiency improvementActive agentAmmonium metavanadate

Provided is a method for extracting and separating vanadium from an aqueous solution. The method mainly comprises the steps that a non-ionic surface active agent with the concentration being 50-200 g / L, the vanadium-bearing aqueous solution with the concentration being 0.5-30 g / L, a saline solution with the concentration being 50-100 g / L and deionized water are mixed, the pH value is adjusted to be 1-3, the mixture is stirred for 10-60 min at the temperature of 25-80 DEG C, standing for phase splitting is conducted for 10-60 min, and a dual-water-phase system with the upper phase being the vanadium-bearing non-ionic surface active agent phase and the lower phase being the water phase is obtained; and an ammonium sulfate or ammonium nitrate or ammonium chloride aqueous solution is added to the vanadium-bearing surface active agent phase, the ratio of the vanadium-bearing non-ionic surface active agent phase (O) to the water phase (A) is 1-5, the pH value is adjusted to be 8-10 with ammonium hydroxide, and then the mixture is put into a constant-temperature water path boiler with the temperature being 25-80 DEG C to settle for 10-60 min. The method is high in extraction speed, phase separation is good, a third phase and emulsification are both avoided, the method is nontoxic and harmless relative to the environment, the dual-water-phase system is complete in phase splitting, the extraction rate of vanadium reaches 95% or over, and the deposition rate of ammonium metavanadate reaches 90% or over.

Owner:YANSHAN UNIV

Method for extracting molybdenum (VI) in water solution

The invention provides a method for extracting molybdenum (VI) in a water solution. The method mainly comprises the following steps: uniformly mixing and stirring a nonionic surfactant, a molybdenum containing water solution, a salt solution and deionized water, wherein the nonionic surfactant belongs to a Tween series and is at a concentration of 50-300g / L, the molybdenum concentration is 1-40g / L, and the salt concentration is 50-300g / L; regulating a pH value to 1-4, standing for phase separation after carrying out stirring at 25-50DEG C for 10-30min, and carrying out phase separation for 30-60 minutes so as to obtain a double-water-phase system, wherein the upper phase is a molybdenum-loaded nonionic surfactant phase, the concentration of molybdenum in the upper phase is 2-80g / L, and the lower phase is a water phase; and mixing the molybdenum-loaded nonionic surfactant phase with an ammonium sulfate water solution according to a phase ratio of 1-5, regulating the pH value to 7-10, carrying out reversed extraction at 25-50DEG C for 20-40 minutes, standing for phase separation, carrying out phase separation for 30-60 minutes, and obtaining a product, namely ammonium molybdate. The extracting rate is high, and phase separation is great. The molybdenum extracting rate reaches more than 92%, and the molybdenum reversed extracting rate reaches more than 90%.

Owner:YANSHAN UNIV

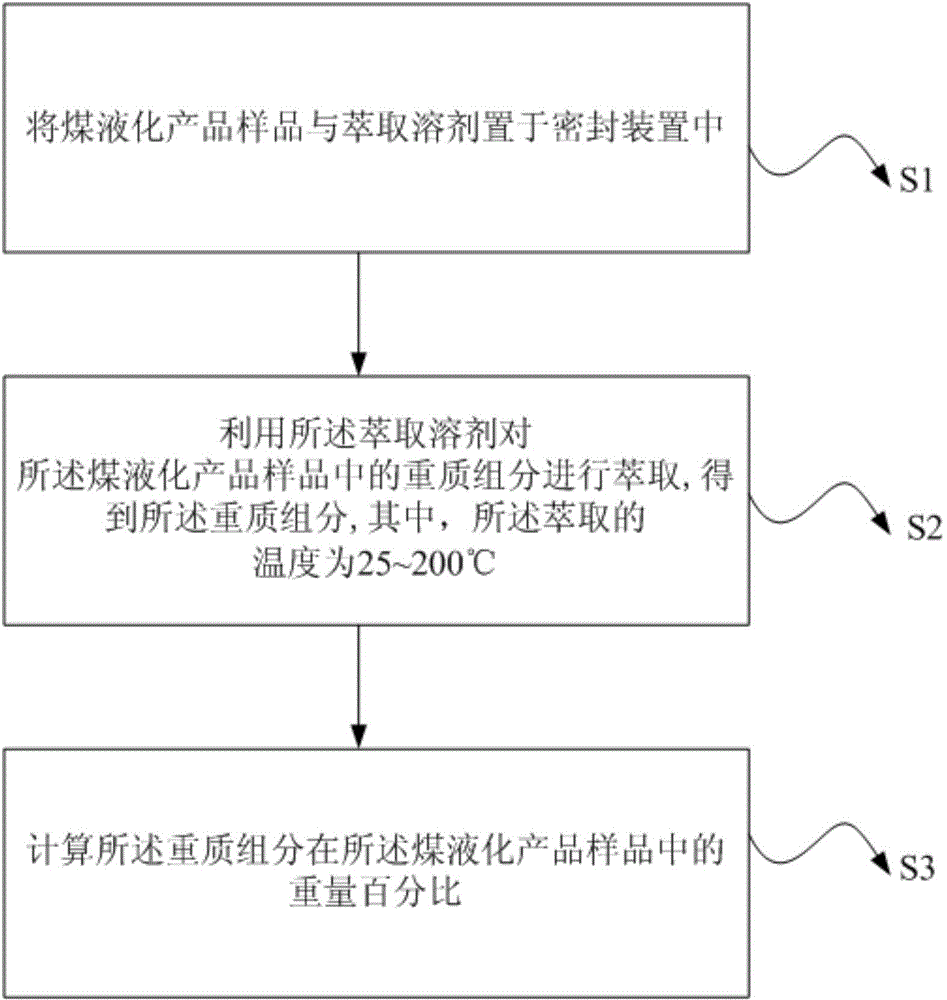

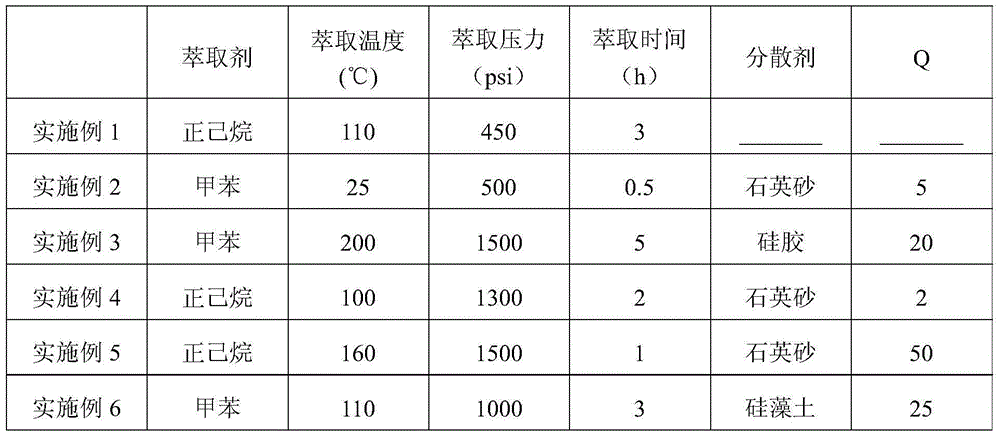

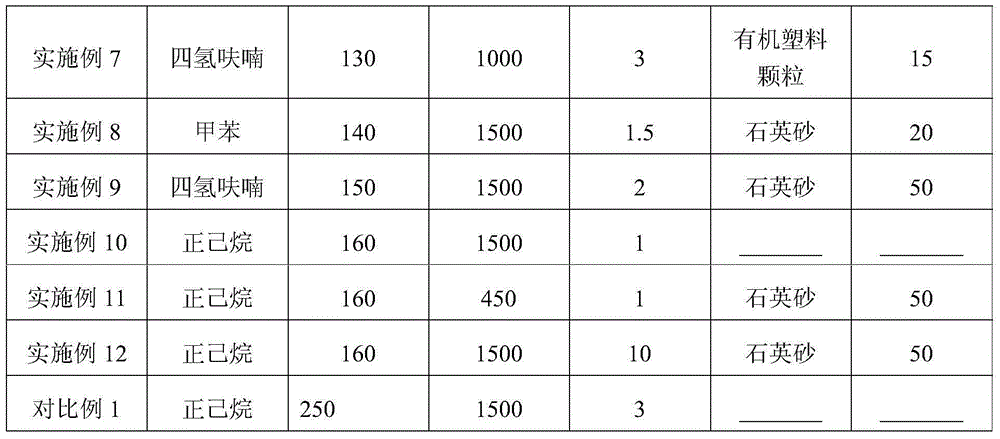

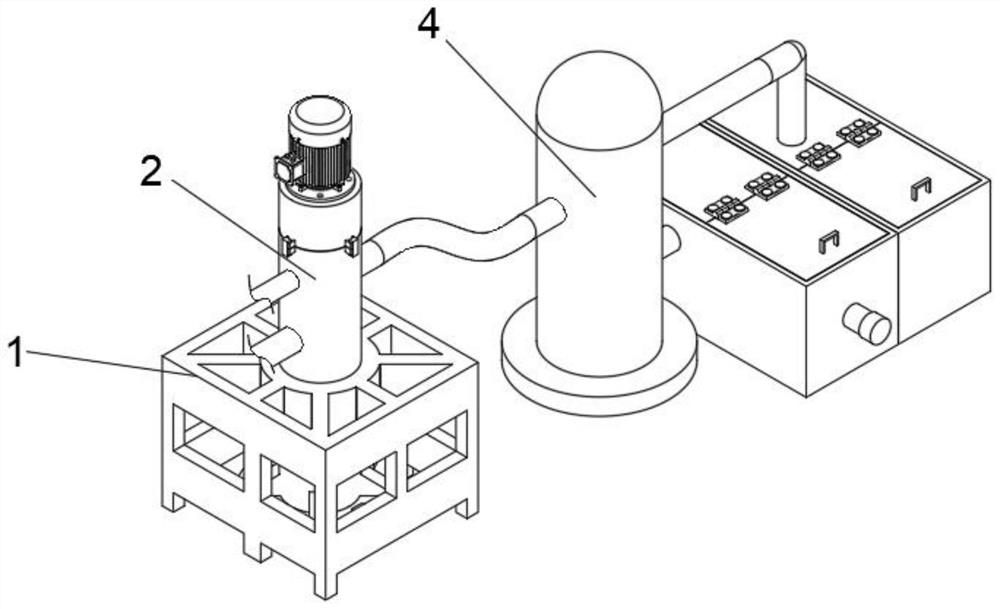

Method for determining content of heavy component in coal liquefaction products

InactiveCN104865113AFast extraction rateShorten extraction timePreparing sample for investigationSolventChemistry

The invention provides a method for determining the content of a heavy component in coal liquefaction products. The determination method comprises the following steps: S1, putting a coal liquefaction product sample and an extraction solvent into a seal device; S2, extracting the heavy component in the coal liquefaction product sample by utilizing the extracting solvent so as to obtain the heavy component at the extracting temperature of 25-200 DEG C; and S3, calculating the weight percentage of the heavy component in the coal liquefaction product sample. The method can be used for rapidly and accurately determining the content of the heavy component in the coal liquefaction products.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for extracting and separating tungsten from aqueous solution containing tungsten

InactiveCN108251662AImprove extraction efficiencySimple processProcess efficiency improvementPhase splittingSingle stage

Provided is a method for extracting and separating tungsten from an aqueous solution containing tungsten. Mainly, a nonionic surface active agent, the aqueous solution containing tungsten, a brine solution and deionized water are mixed and stirred uniformly; the mass fraction of the nonionic surface active agent is 10-20%, the mass fraction of tungsten is 0.1-3%, and the mass friction of salt is 6-12%; the pH value is adjusted to 2-3, after stirring is performed at 30-60 DEG C for 10-60 min, standing and phase splitting are performed, phase separation is performed for 10-60 min, and a dual-water-phase system with the upper phase being a nonionic surface active agent phase loaded with tungsten and the lower phase being a water phase is obtained; the reextraction temperature is 40-70 DEG C,time is 20-60 min, phase separation is performed for 20-60 min, the phase ratio of the nonionic surface active agent phase loaded with tungsten and the ammonium carbonate aqueous solution phase is 1-4: 1, and reextraction products are ammonium tungstate. The method is high in extraction speed and good in phase separation, the tungsten single-stage extraction rate reaches 98% or above, and the tungsten single-stage reextraction rate reaches 97% or above.

Owner:YANSHAN UNIV

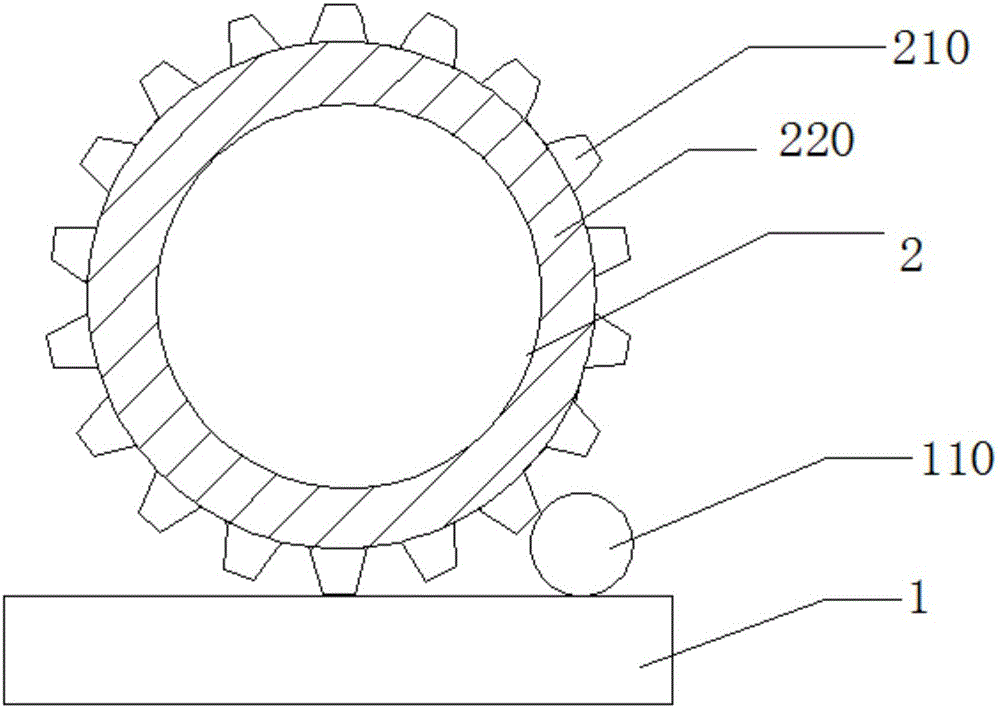

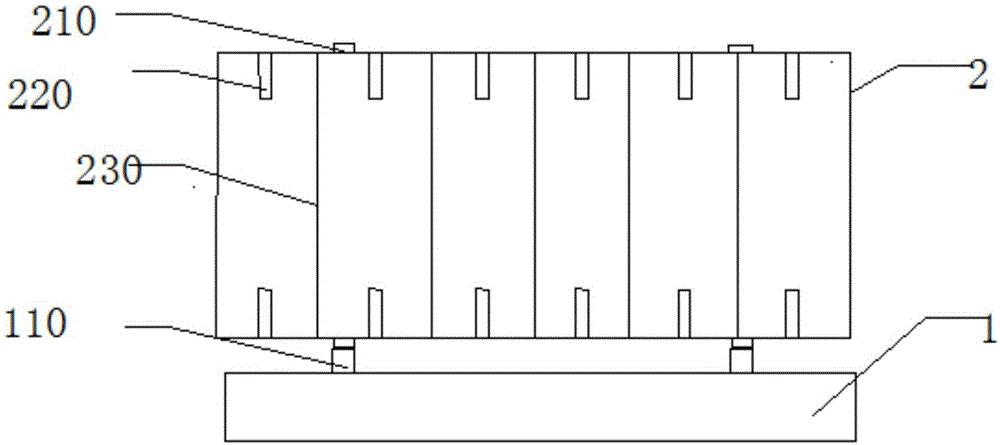

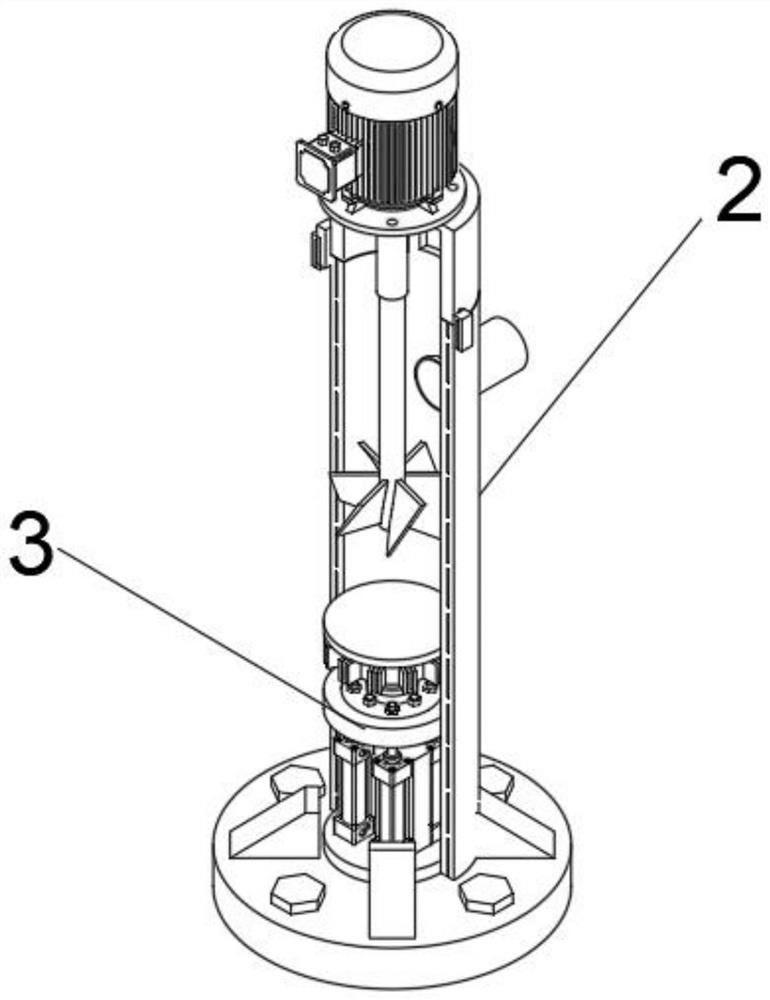

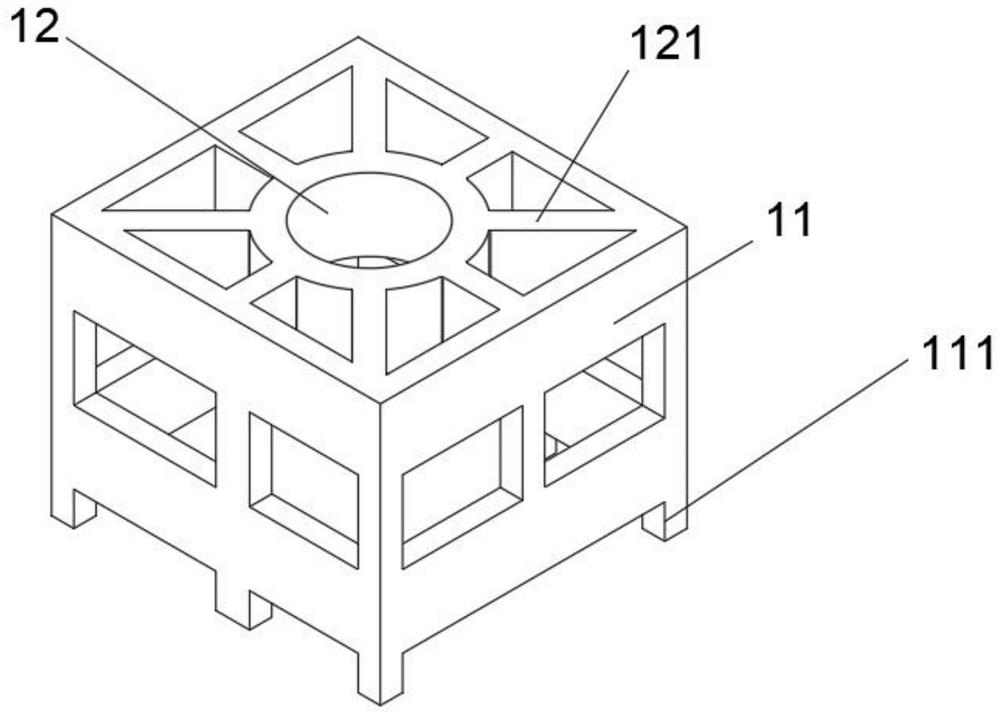

Refining equipment based on waste mineral oil solvent extraction

PendingCN112812815AEasy to replaceAvoid damageHollow article cleaningHydrocarbon oils refiningElectric machineryProcess engineering

The invention relates to the technical field of waste mineral oil solvent extraction, in particular to refining equipment based on waste mineral oil solvent extraction. The equipment comprises a reinforcing device, an extraction device is arranged at the top of the reinforcing device, a cleaning device is arranged at the circle center of the bottom in the extraction device, a discharging device is arranged on one side of the extraction device, the extraction device comprises a mixed extraction tower with an annular interlayer arranged on the inner wall, and a clamping device is arranged at the top of the mixed extraction tower, a stirring device is arranged at the top of the clamping device and comprises a stirring motor, a heating device is arranged at an interlayer of the inner wall of the mixed extraction tower, an existing waste mineral oil extraction device cannot treat an extraction agent, the utilization rate of the extraction agent is low, and the extraction efficiency is low, and the extraction agent needs to be treated to be fully mixed with waste mineral oil to play a role, and the existing waste mineral oil is easily adhered to the inner wall of the extraction device and is difficult to clean, so that the service life of the device is shortened.

Owner:湖南两山环境科技有限公司

Method for extracting and separating tungsten and molybdenum from aqueous solution

ActiveCN112899500AEfficient separationImprove separation efficiencyProcess efficiency improvementIon speciationMOLYBDATE ION

The invention relates to the technical field of metallurgy, and provides a method for extracting and separating tungsten and molybdenum from an aqueous solution. According to the method, a tungsten-molybdenum mixed aqueous solution, a nonionic surfactant, a complexing agent, sodium sulfate and water are mixed, the pH value of the mixed solution is adjusted to be smaller than or equal to 3, an aqueous two-phase extraction system is obtained, an upper phase and a lower phase are obtained through stirring and standing phase splitting, the upper phase is a tungsten-rich nonionic surfactant phase, and the lower phase is a molybdenum-rich aqueous phase. Under the acidic condition, tungsten mainly exists in the form of paratungstate B anions, molybdenum exists in the form of paramolybdate ions, a hydrophilic complex is formed by the complexing agent and the paramolybdate ions, therefore, molybdenum is left in the aqueous phase, the paratungstate B anions enter the nonionic surfactant phase by means of the high hydrophobicity of the paratungstate B anions, and efficient separation of tungsten and molybdenum is achieved. The method provided by the invention has the advantages of high extraction rate, high separation efficiency, no emulsification phenomenon, no use of any toxic, harmful, flammable, explosive and volatile organic solvents, simple operation and environmental protection.

Owner:YANSHAN UNIV

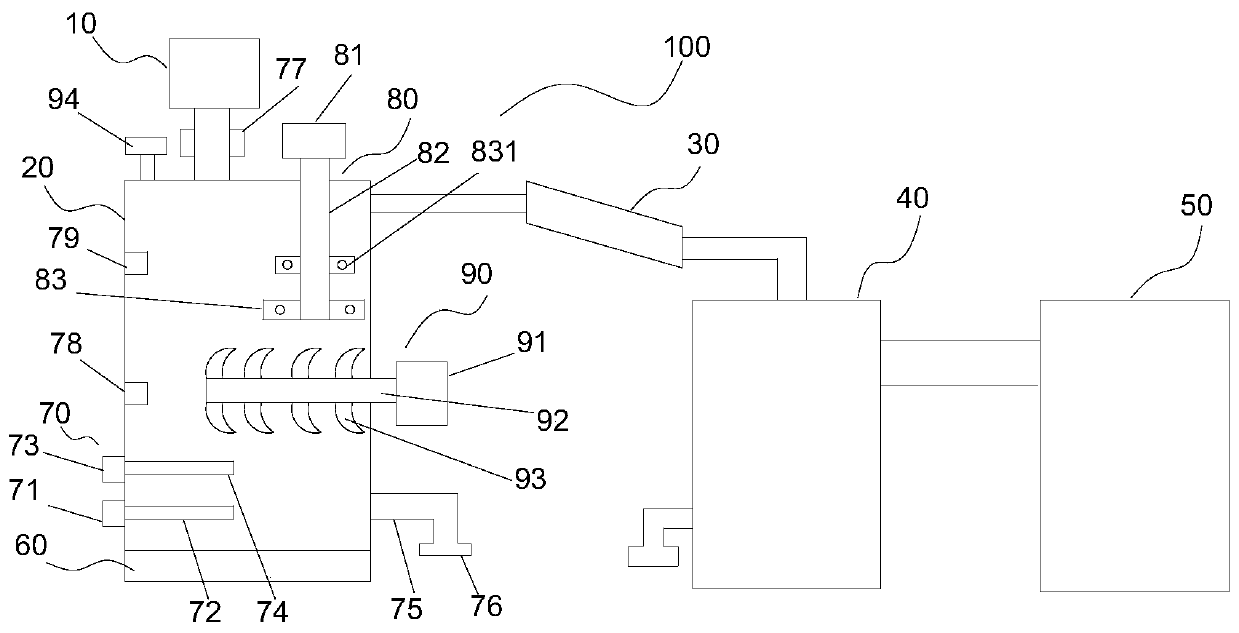

Western medicine component extraction device

InactiveCN110935193AHigh activityFast extraction rateLiquid solutions solvent extractionWestern medicineLiquid storage tank

The invention discloses a western medicine component extraction device. An outlet end of a liquid storage tank communicates with an inlet end of the extraction tank through a pipe. A condensing memberis arranged obliquely, an inlet end of the condensing member communicates with a gas outlet end of the side wall of the extraction tank through a pipe, and an outlet end of the condensing member communicates with an liquid inlet end of a collecting tank through a pipe. The gas outlet of the collection tank communicates with the pump body through a pipeline. A heating element is fixedly connectedwith the extraction tank. A first ultrasonic control element is fixedly connected to the extraction tank. A first ultrasound sheet is fixedly connected to the extraction tank. One end of the liquid outlet pipe communicates with the extraction tank, and is located on a side wall at the bottom end of the extraction tank. The other end of the liquid outlet pipe is fixedly connected with a switch valve. The device achieves the objects of improving extraction effect and efficiency of western medicine component extraction.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

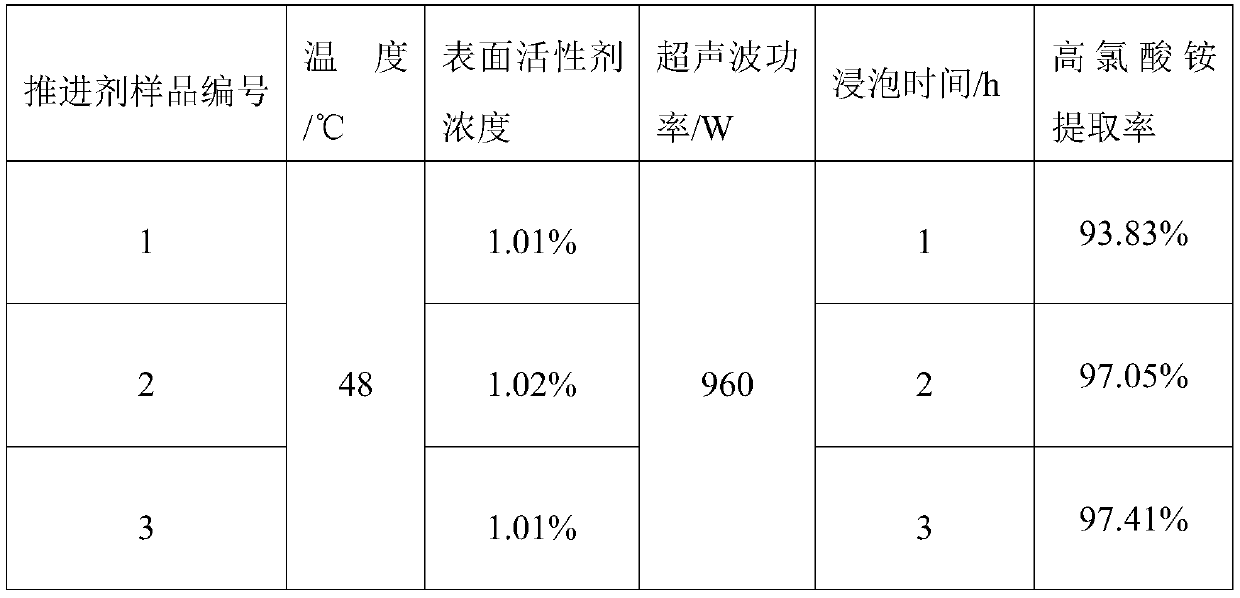

Method for extracting ammonium perchlorate in scrapped four-component HTPB propellant through ultrasonic assistance

ActiveCN109956455ASafe and efficient extractionQuick extractionPerchloratesFiltrationSODIUM DODECYL BENZENE SULFONATE

The invention discloses a method for extracting ammonium perchlorate in scrapped four-component HTPB propellant through ultrasonic assistance, and relates to the technical field of scrapped propellantcomponent recovery. The method comprises the following steps: (1) crushing a propellant; (2) soaking and swelling the propellant at 33-48 DEG C in a mixed solution of water, anhydrous ethanol and petroleum ether according to the volume ratio of 1:1:1 for 10-24 h; (3) then performing suction filtration of the mixed solution, adding distilled water to the propellant, wherein the mass ratio of the propellant to the distilled water is 1:(10-15), then adding sodium dodecyl benzene sulfonate accounting for 1-1.5 wt% of the distilled water, carrying out stirring extraction for 1-3 hours and soakingextraction for 1-3 hours, and finally extracting the mixed solution in 720-960 W ultrasonic wave for 1-3 hours, wherein the water temperature in the extraction process is 48 DEG C; and (4) after extraction, carrying out suction filtration on the mixed solution, mixing and swelling the mixed solution and the filtrate obtained after extraction, and carrying out secondary filtration and evaporative crystallization to obtain ammonium perchlorate. The method has the advantages of high extraction rate of ammonium perchlorate, rapidness in extraction, safety, environmental protection and low cost. Common reagents and instruments are needed in the method, and the operation method is simple and easy to implement and suitable for large-scale application.

Owner:中国人民解放军32181部队

Preparation method of auricularia auricular polysaccharides

The invention discloses a preparation method of auricularia auricular polysaccharides. The method adopts agarics as raw materials, and extracts auricularia auricular polysaccharides with a method for combining the polyethylene glycol / ammonium sulfate two aqueous phase extraction and the hollow fiber membrane separation by stewing at high temperature; and the extracted polysaccharides are spray-dried to obtain the solid powder auricularia auricular polysaccharides. The method can obtain high-purity soluble auricularia auricular polysaccharides. Meanwhile, the method can combines the membrane separation with the two aqueous phase extraction, thus greatly fastening the extraction mass transfer rate. The two aqueous phase system is separated by the membranes so as to avoid the emulsification resulted from small interfacial tension of the two aqueous phase system, and greatly reduce the dosage of organic solvents.

Owner:LONGHAI YINGXIN AGRI TECH

Pore-forming agent removal method for battery separator and preparation process for lithium-ion secondary battery separator

ActiveCN108183190BReduce residual rateSolve the problem of difficult extractionCell seperators/membranes/diaphragms/spacersPhysical chemistryBattery cell

Owner:四川卓勤新材料科技有限公司

A kind of method for extracting molybdenum (VI) in aqueous solution

Owner:YANSHAN UNIV

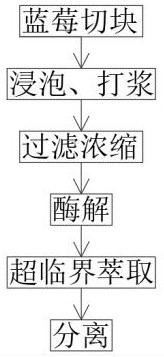

Technological process for blueberry essence extraction

InactiveCN112295262AQuality improvementPrevent outflowOrganic chemistryLiquid solutions solvent extractionProcess engineeringHeating effect

The invention relates to the technical field of blueberry essence extraction, and discloses a technological process for blueberry essence extraction, which comprises the following steps of: dicing blueberries, soaking, pulping, filtering and concentrating, carrying out enzymolysis, carrying out supercritical extraction, and separating. According to the technological process for blueberry essence extraction, supercritical CO2 fluid in the preparation process can be detected in real time, the defect that traditional extraction liquid is not easy to take out for detection is overcome, the prepared blueberry essence can be better in quality, the situation that a device is heavy and not easy to carry is avoided, the device is placed stably, the extraction rate can be increased, materials can beprevented from being mixed unevenly, waste caused by the fact that extracted supercritical CO2 fluid adheres to the inner wall of an inner reaction tank and cannot be discharged completely is avoided, the economic cost is saved, the device is convenient to clean after preparation, liquid oil overflowing due to excessive added oil can be prevented, and poor oil bath heating effect due to small oilamount can be prevented.

Owner:青岛成群兴盛商贸有限公司

A method for extracting and separating vanadium in aqueous solution

ActiveCN106756116BWide concentration rangeFast extraction rateProcess efficiency improvementWater bathsAmmonium metavanadate

A method for extracting and separating vanadium in aqueous solution, which mainly comprises mixing non-ionic surfactant, vanadium-containing aqueous solution, saline solution and deionized water, the concentrations of which are respectively 50-200g / L, 0.5-30g / L, 50- 100g / L, adjust the pH value to 1~3, stir it at 25~80°C for 10~60min, stand still and separate the phases for 10~60min, the upper phase is the nonionic surfactant phase loaded with vanadium, and the lower phase is water Phase two-phase system, adding ammonium sulfate, ammonium nitrate or ammonium chloride aqueous solution to the loaded vanadium surfactant phase, so that the ratio of the vanadium-loaded nonionic surfactant phase (O) to the aqueous phase (A) is 1 to 5, adjust the pH value to 8 to 10 with ammonia water, and then place it in a constant temperature water bath at 25 to 80°C for precipitation for 10 to 60 minutes. The invention has fast extraction rate, good phase separation, no formation of third phase and no emulsification problem, non-toxic and harmless to the environment, complete phase separation of the two-phase system, vanadium extraction rate of over 95%, and ammonium metavanadate precipitation rate Reach more than 90%.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com