Method for preparing superfine high-purity cerium oxide by using rear earth ore sulfuric acid calcination products

A technology of sulfuric acid roasting and cerium oxide, which is applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult to meet the requirements of product use, low separation rate and efficiency, uneven particle size distribution, etc. , to achieve the effect of saving fractionation, extraction and separation operating unit devices, increasing extraction rate, and fast extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

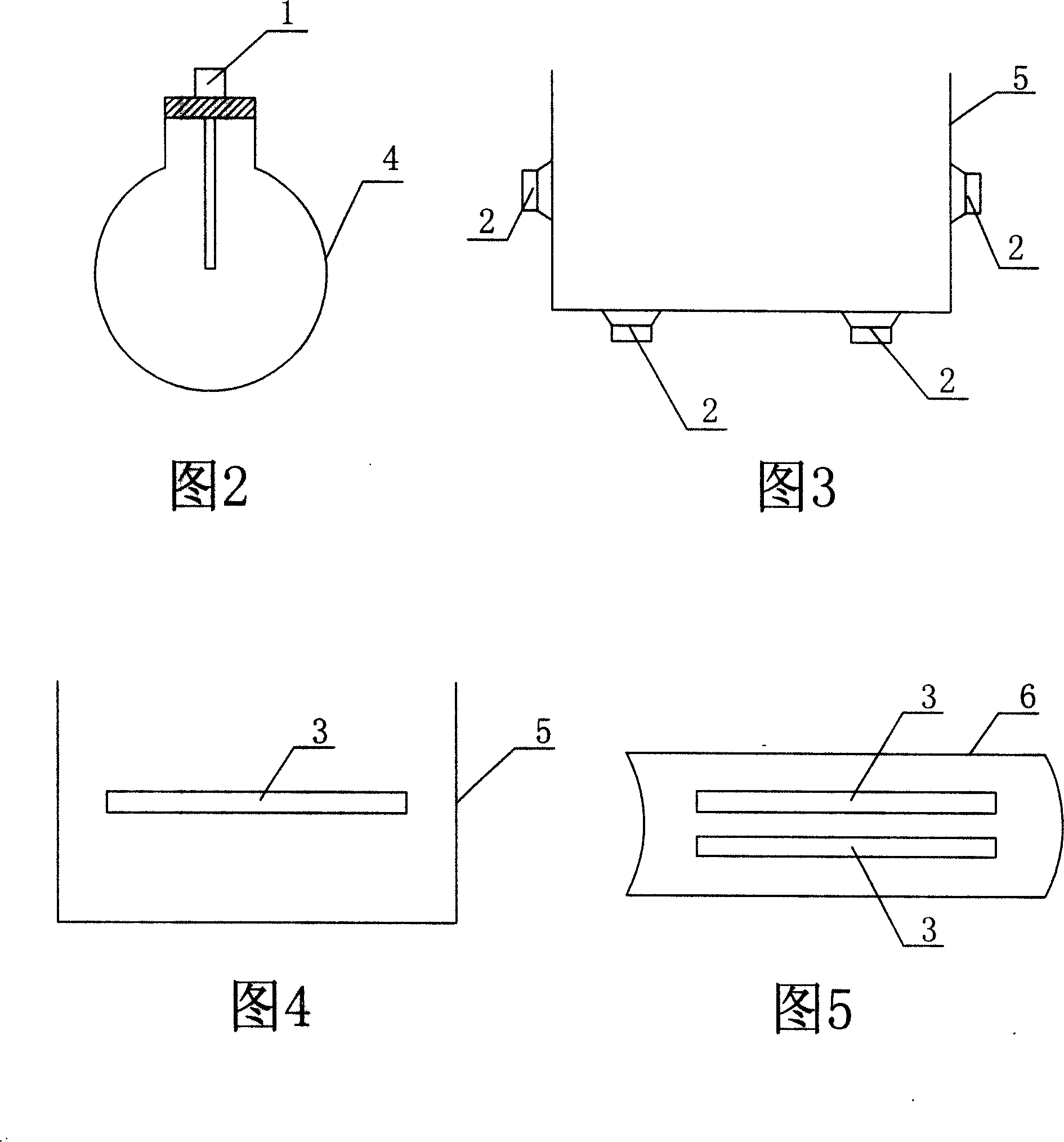

[0027] Main equipment: extraction kettle with probe-type ultrasonic generator, crystallization kettle with probe-type ultrasonic generator, fixed-bed electrochemical reactor.

[0028] Main raw materials: rare earth mineral sulfuric acid roasting product, P204 extractant, kerosene, NH 4 HCO 3 , NH 3 .

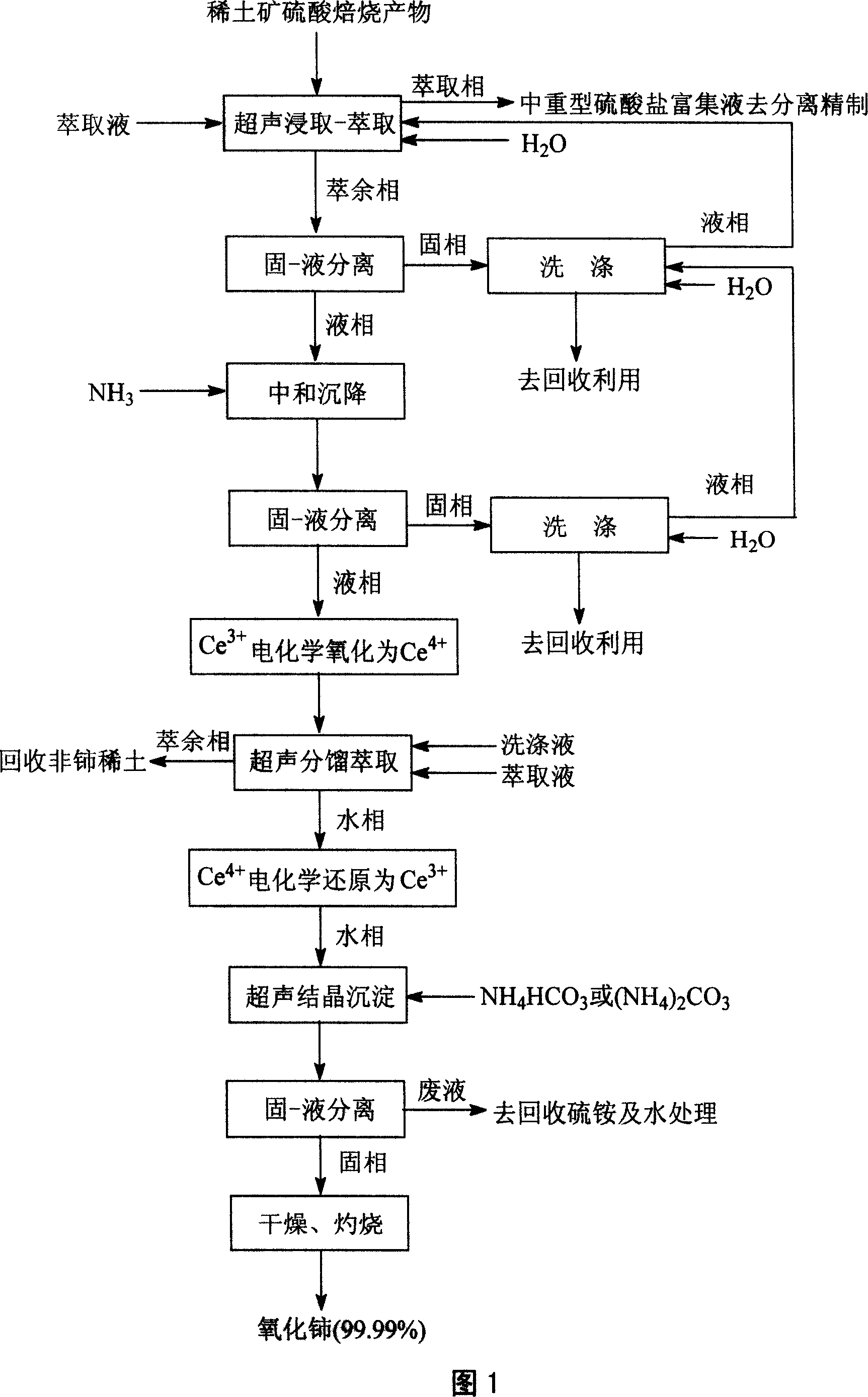

[0029] As shown in Fig. 1 and Fig. 2, a kind of method for preparing superfine high-purity cerium oxide by roasting product of sulfuric acid of rare earth mine is to be raw material by roasting product of sulfuric acid of rare earth mine, and described method step is as follows:

[0030] (1) Ultrasonic leaching-extraction: In the extraction kettle with a probe-type ultrasonic generating device, add the roasted product of rare earth ore sulfuric acid, leaching solution, and extraction solution. The proportion of the three materials is 1000g: 2L: 1L, and the operation The condition is that the ultrasonic frequency is 19kHz, and the ultrasonic action intensity is 0.2W / cm 2 , th...

Embodiment 2

[0041] Main equipment: extraction tank with vibrator-type ultrasonic generator, crystallization tank with vibrator-type ultrasonic generator, fluidized bed electrochemical reactor.

[0042] Main raw materials: rare earth mineral sulfuric acid roasting product, P204 extractant, sulfonated kerosene, (NH 4 ) 2 CO 3 , NH 3 .

[0043]As shown in Fig. 1 and Fig. 3, a kind of method for preparing superfine high-purity cerium oxide by roasting product of sulfuric acid of rare earth mine is to be raw material by roasting product of sulfuric acid of rare earth mine, and described method step is as follows:

[0044] (1) Ultrasonic leaching-extraction: In the extraction tank with a vibrator-type ultrasonic generator, add the roasted product of rare earth ore sulfuric acid, leaching solution, and extraction solution. The ratio of the three materials is 1000g: 25L: 10L, and the operation The condition is that the ultrasonic frequency is 80kHz, and the ultrasonic action intensity is 20.0...

Embodiment 3

[0055] Main equipment: extraction tube with vibrating plate ultrasonic generator, crystallization tube with vibrating plate ultrasonic generator, fixed bed electrochemical reactor.

[0056] Main raw materials: rare earth mineral sulfuric acid roasting product, P204 extractant, kerosene, NH 4 HCO 3 , NH 3 .

[0057] As shown in Fig. 1 and Fig. 5, a kind of method for preparing superfine high-purity cerium oxide by roasting product of sulfuric acid of rare earth mine is to be raw material by roasting product of sulfuric acid of rare earth mine, and described method step is as follows:

[0058] (1) Ultrasonic leaching-extraction: In the extraction tube with a vibrating plate type ultrasonic generating device, add the roasted product of rare earth ore sulfuric acid, leaching solution, and extraction solution. The proportion of the three materials is 1000g: 15L: 5L, and the operation The condition is that the ultrasonic frequency is 25kHz, and the ultrasonic action intensity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com