Method for determining content of heavy component in coal liquefaction products

A determination method and heavy component technology are applied in the field of determination of heavy component content in coal liquefaction products, which can solve problems such as long time consumption, and achieve the effects of shortening extraction time, improving extraction efficiency, and improving measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

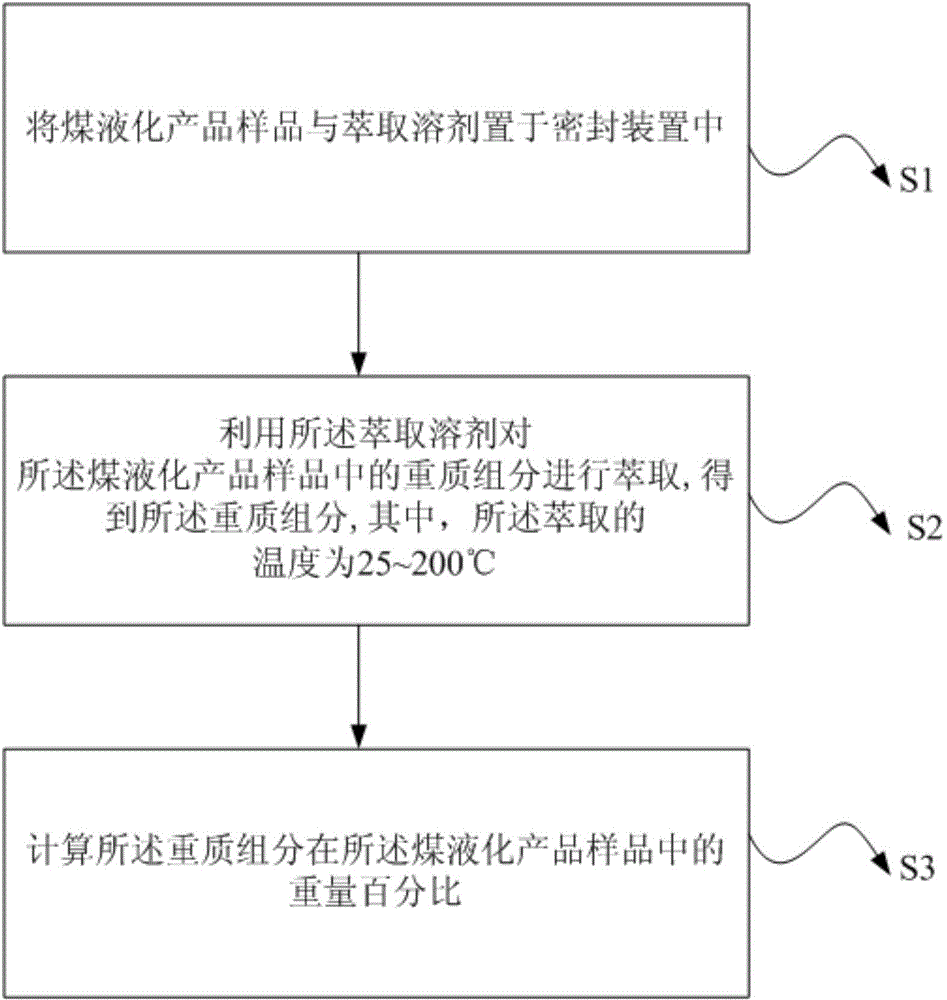

Method used

Image

Examples

Embodiment 1

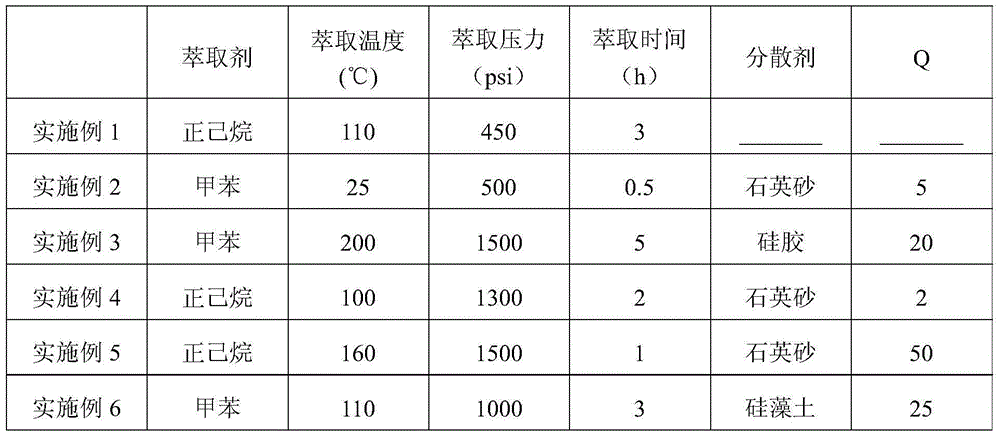

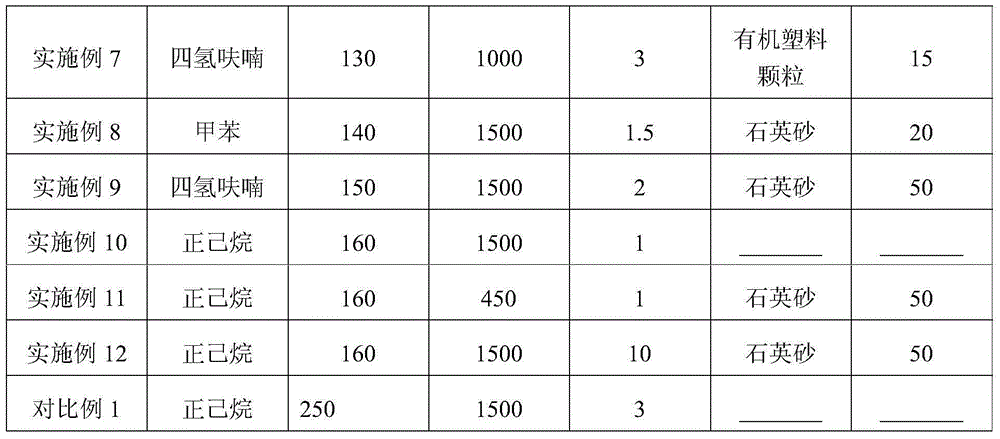

[0035]Put 3.12g of the coal direct liquefaction residue sample in a sealed container, put n-hexane as the extraction solvent in the sealed container, heat the sealed container to 110°C, pressurize to 450psi, and extract for 3 hours to obtain n-hexane The alkane soluble matter is 0.336g, and the weight percent of n-hexane soluble matter in the coal direct liquefaction residue sample is 10.77% through calculation. The process parameters of the specific extraction process are shown in Table 1, and the measurement results are shown in Table 2.

Embodiment 2

[0037] 3.12g of coal direct liquefaction residue sample and 15.60g of quartz sand are placed in a sealed container, and toluene is placed in a sealed container, and the sample is extracted by the same extraction method as in Example 1. The specific extraction process is The parameters are shown in Table 1, and the measurement results are shown in Table 2.

Embodiment 3

[0039] 3.12g of coal direct liquefaction residue sample and 60.24g of silica gel are placed in a sealed container, and toluene as an extraction solvent is placed in a sealed container, and the sample is extracted by the same extraction method as in Example 1. The specific extraction The technological parameters of the process are shown in Table 1, and the measurement results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com