Pore-forming agent removal method for battery separator and preparation process for lithium-ion secondary battery separator

A preparation process and secondary battery technology, applied in separators/films/diaphragms/spacers, battery components, circuits, etc., can solve problems such as extraction difficulties of thick substrates, shorten extraction time, and solve extraction difficulties , The effect of speeding up the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for removing a pore-forming agent for a battery diaphragm, which is applied in the preparation process of a lithium-ion secondary battery diaphragm, and the steps of the method include:

[0029] The diaphragm substrate is pretreated by equipment, and at least a part of the pore-forming agent in the diaphragm substrate is removed in advance; in this embodiment, the pore-forming agent is white oil, but it is not limited thereto; when white oil is at 40°C, the kinematic viscosity 45-55mm 2 / s;

[0030] The pretreated separator substrate is extracted by ultrasonic extraction to extract the pore-forming agent, and ensure that the residual rate of the pore-forming agent in the final battery separator is less than 1%.

[0031] During the ultrasonic extraction process, the ultrasonic frequency is 17KHz, and the ultrasonic extraction time is 10min.

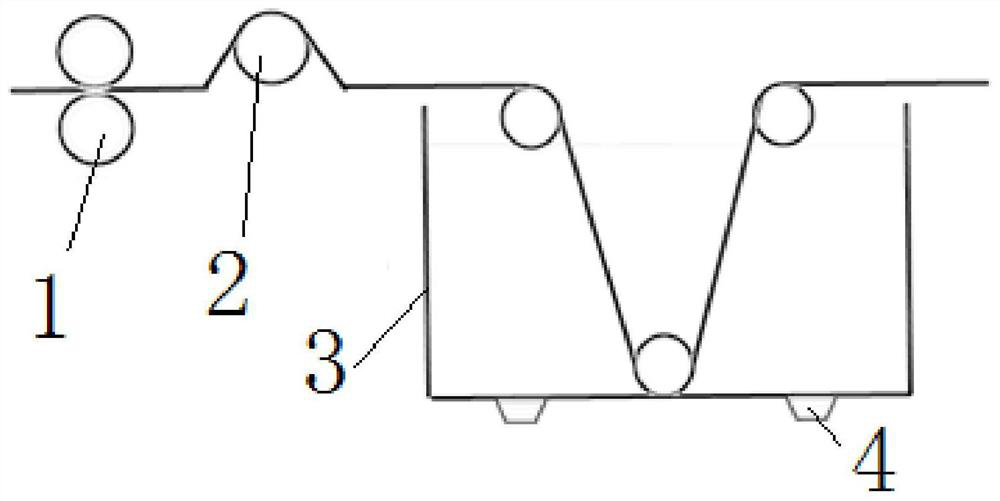

[0032] The equipment includes scraping roller set equipment with at least one pair of scraping roller sets 1 and vacuum...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, except that in the ultrasonic extraction process, the ultrasonic frequency is 28KHz, and the ultrasonic extraction time is 10 minutes.

Embodiment 3

[0048] This embodiment is basically the same as Embodiment 1, except that in the ultrasonic extraction process, the ultrasonic frequency is 17KHz, and the ultrasonic extraction time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com