Method for extracting vanillic acid by using deep-eutectic solvent/normal propyl alcohol aqueous two-phase system

A low eutectic solvent, two-phase system technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, to achieve the effects of fast extraction rate, simple synthesis process, and wide range of synthetic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

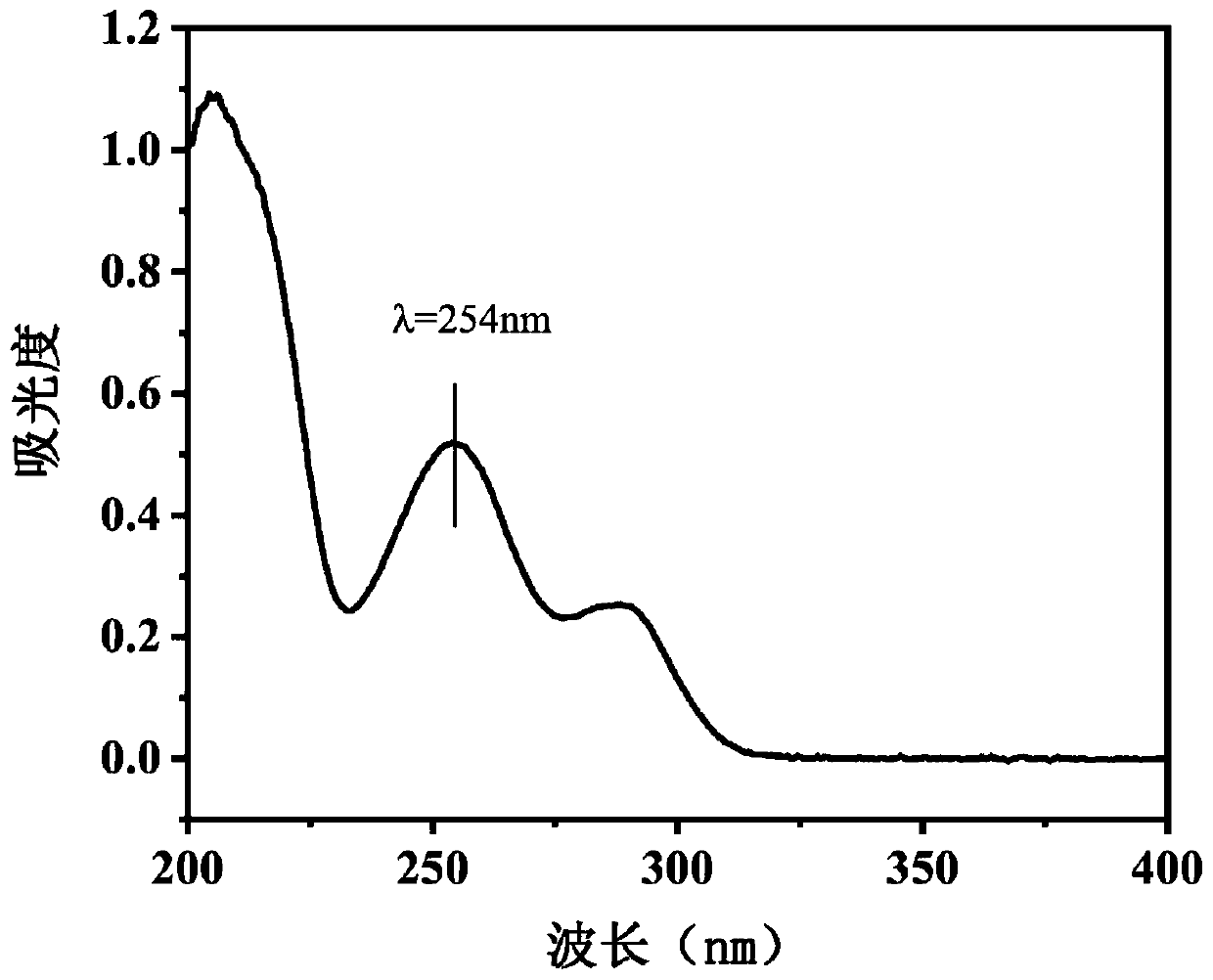

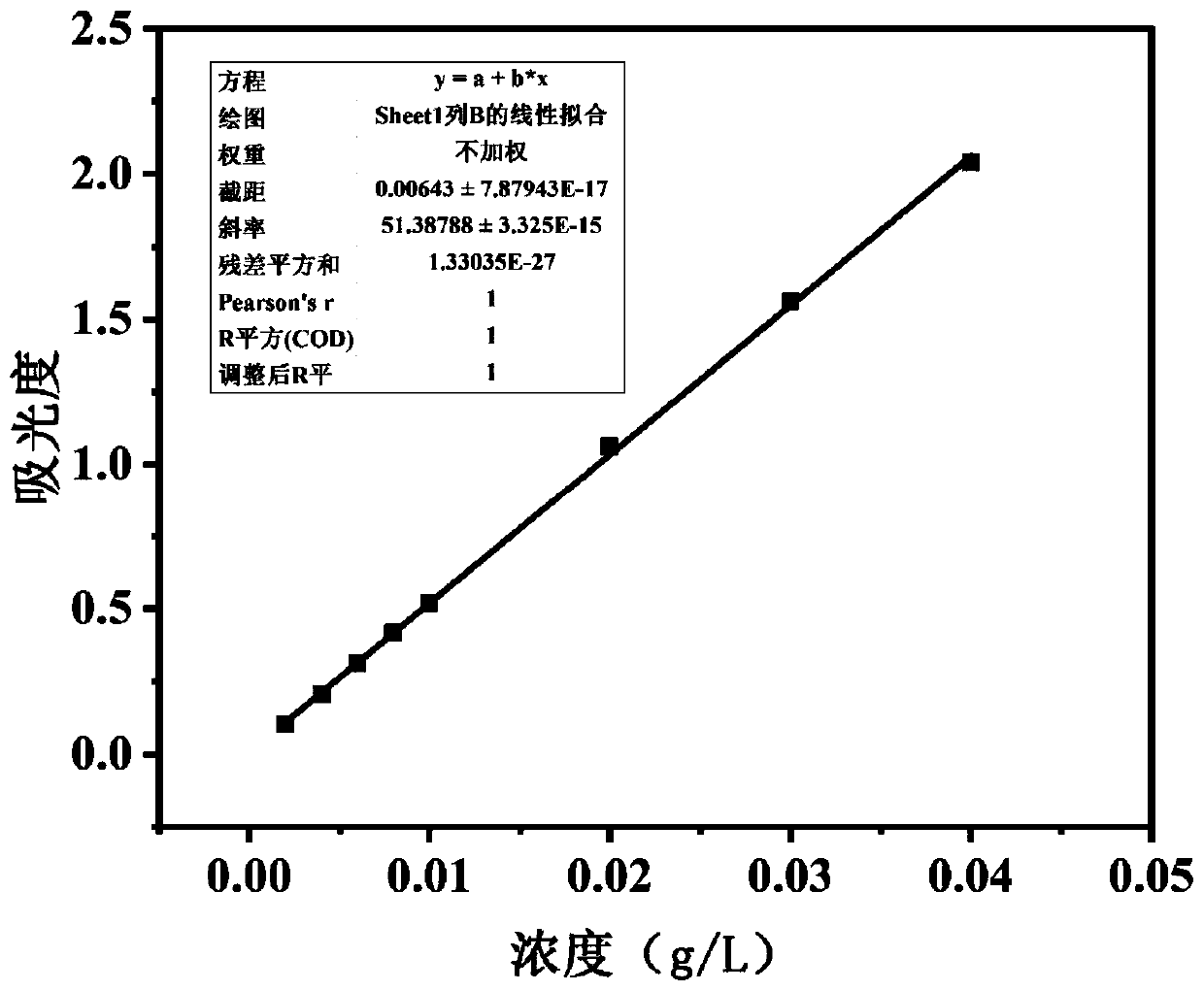

[0032] (1) Weigh 7.1724g of betaine and 10.8096g of glucose into a round bottom flask, heat in an 80°C oil bath, and stir with a magnet until a clear and transparent solution is formed, and store for later use. Weigh 0.2g of vanillic acid powder into a 200mL volumetric flask to prepare a 1g / L vanillic acid aqueous solution and store it for future use.

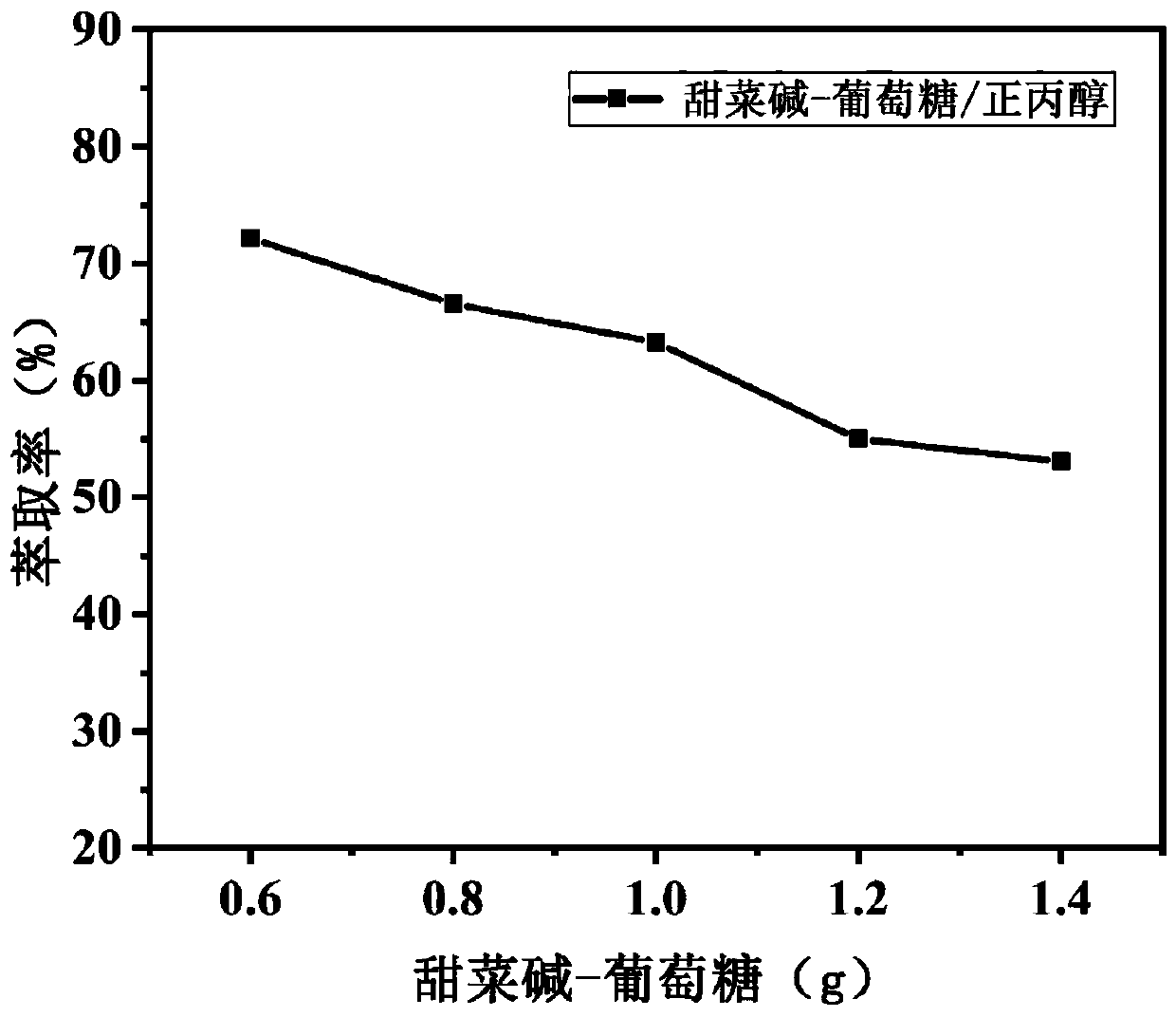

[0033] (2) Weigh 1g of vanillic acid aqueous solution in a 10mL centrifuge tube, add 0.6, 0.8, 1.0, 1.2, 1.4g of betaine-glucose deep eutectic solvent respectively, then add 1g of n-propanol, and vibrate with a vortex shaker to obtain mixture.

[0034] (3) Put the mixed solution in step (2) into a constant temperature shaker to vibrate, set the temperature at 25°C, and shake for 30 minutes. After shaking, place it in a constant temperature water bath at 25°C and let it stand for 4 hours to obtain the above The phase is a n-propanol phase rich in vanillic acid, and the lower phase is a two-phase system of a deep eutectic solven...

Embodiment 2

[0038](1) Weigh 7.1724g of betaine and 22.3078g of sorbitol in a round bottom flask, heat in an 80°C oil bath, and stir with a magnet until a clear and transparent solution is formed, and store for later use. Weigh 0.2g of vanillic acid powder into a 200mL volumetric flask to prepare a 1g / L vanillic acid aqueous solution and store it for future use.

[0039] (2) Weigh 1g of vanillic acid aqueous solution in a 10mL centrifuge tube, add 0.6, 0.8, 1.0, 1.2, 1.4g of betaine-sorbitol deep eutectic solvent, then add 1g of n-propanol, and vibrate with a vortex shaker to obtain mixture.

[0040] (3) Put the mixed solution in step (2) into a constant temperature shaker to vibrate, set the temperature at 25°C, and shake for 30 minutes. After shaking, place it in a constant temperature water bath at 25°C and let it stand for 4 hours to obtain the above The phase is a n-propanol phase rich in vanillic acid, and the lower phase is a two-phase system of a deep eutectic solvent-rich phase. ...

Embodiment 3

[0044] (1) Weigh 7.1724g of betaine and 18.6306g of xylitol in a round bottom flask, heat in an 80°C oil bath, and stir with a magnet until a clear and transparent solution is formed, and store for future use. Weigh 0.2g of vanillic acid powder into a 200mL volumetric flask to prepare a 1g / L vanillic acid aqueous solution and store it for future use.

[0045] (2) Weigh 1g of vanillic acid aqueous solution in a 10mL centrifuge tube, add 0.6, 0.8, 1.0, 1.2, 1.4g of betaine-xylitol deep eutectic solvent, then add 1g of n-propanol, vibrate with a vortex shaker, A mixed solution was obtained.

[0046] (3) Put the mixed solution in step (2) into a constant temperature shaker to vibrate, set the temperature at 25°C, and shake for 30 minutes. After shaking, place it in a constant temperature water bath at 25°C and let it stand for 4 hours to obtain the above The phase is a n-propanol phase rich in vanillic acid, and the lower phase is a two-phase system of a deep eutectic solvent-ric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com