Pore forming agent removal method of battery diaphragm and preparation process of lithium ion secondary battery diaphragm

A preparation process and secondary battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of thick substrate extraction difficulties, achieve the effects of shortening extraction time, solving extraction difficulties, and accelerating extraction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for removing a pore-forming agent for a battery diaphragm, which is applied in the preparation process of a lithium-ion secondary battery diaphragm, and the steps of the method include:

[0029] The diaphragm substrate is pretreated by equipment, and at least a part of the pore-forming agent in the diaphragm substrate is removed in advance; in this embodiment, the pore-forming agent is white oil, but it is not limited thereto; when white oil is at 40°C, the kinematic viscosity 45-55mm 2 / s;

[0030] The pretreated separator substrate is extracted by ultrasonic extraction to extract the pore-forming agent, and ensure that the residual rate of the pore-forming agent in the final battery separator is less than 1%.

[0031] During the ultrasonic extraction process, the ultrasonic frequency is 17KHz, and the ultrasonic extraction time is 10min.

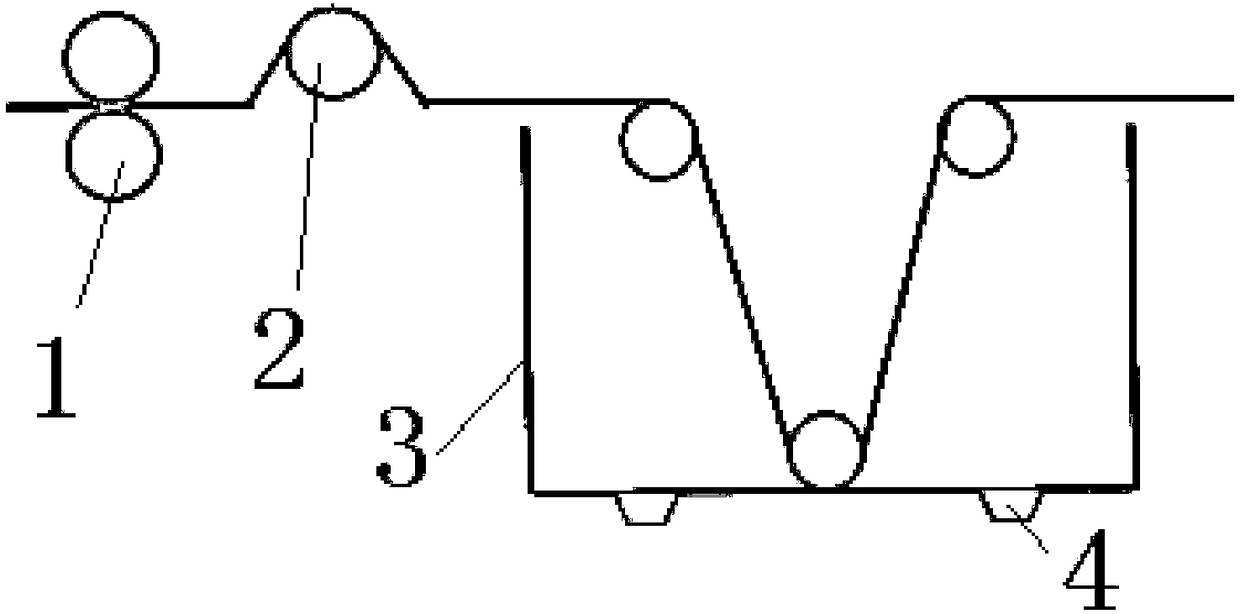

[0032] The equipment includes scraping roller set equipment with at least one pair of scraping roller sets 1 and vacuum...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, except that in the ultrasonic extraction process, the ultrasonic frequency is 28KHz, and the ultrasonic extraction time is 10 minutes.

Embodiment 3

[0048] This embodiment is basically the same as Embodiment 1, except that in the ultrasonic extraction process, the ultrasonic frequency is 17KHz, and the ultrasonic extraction time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com