Method for extracting nicotine from molecularly imprinted polymer

A technology of molecular imprinting and polymers, applied in chemical instruments and methods, other chemical processes, organic chemistry, etc., can solve the problems of high cost, low product purity, complicated steps, etc., achieve long service life, high selectivity, reduce Effect of Solvent Dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

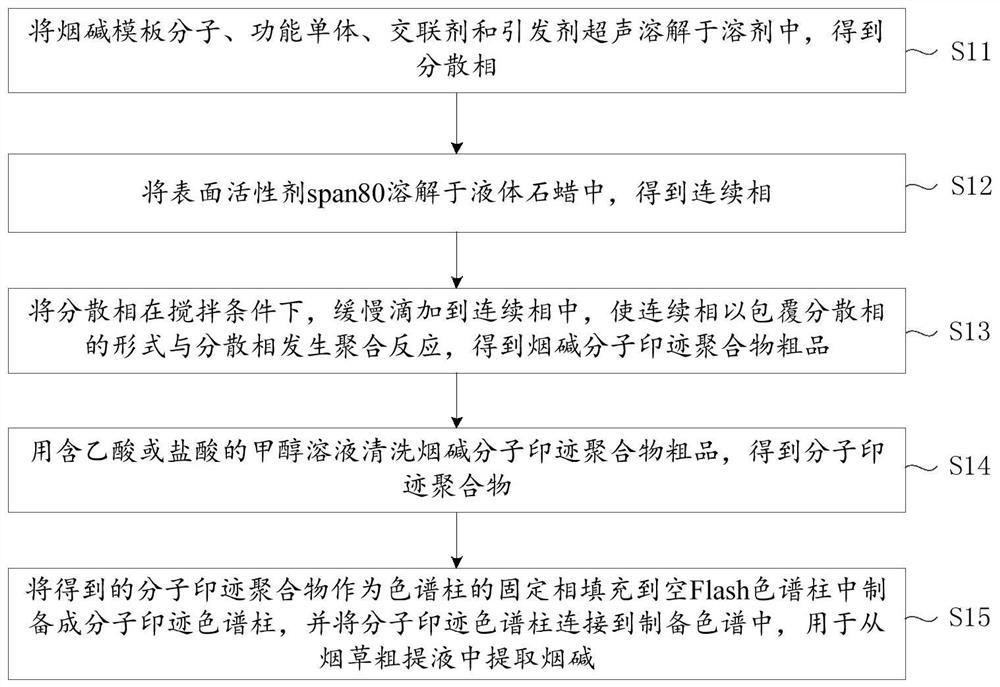

[0065] 1. Preparation of molecularly imprinted polymers (prepared by reverse suspension polymerization):

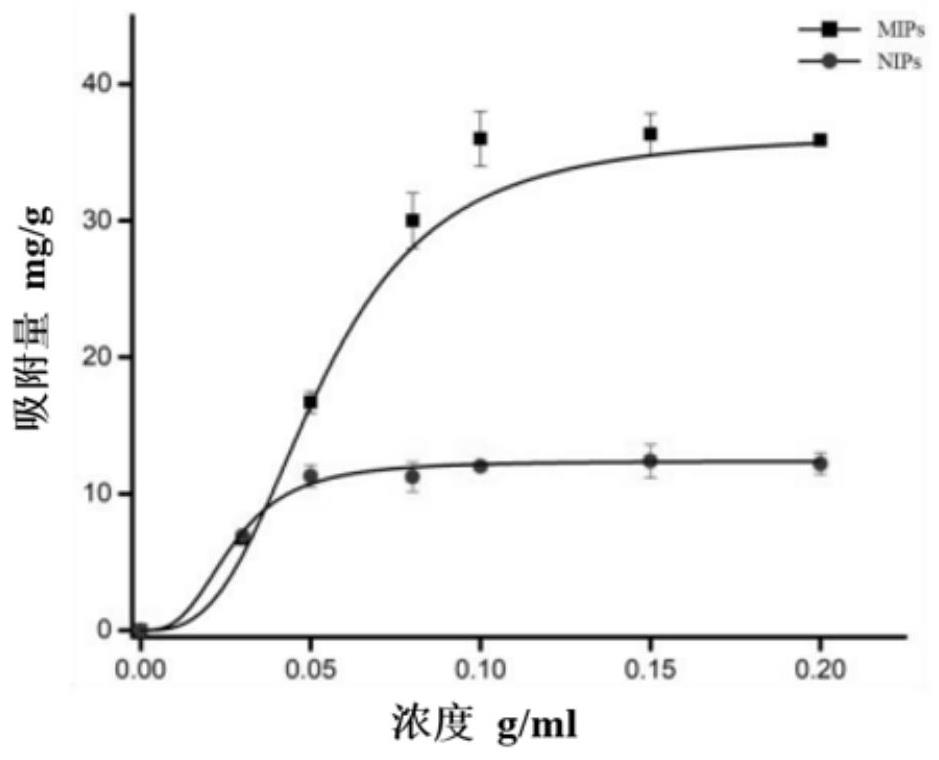

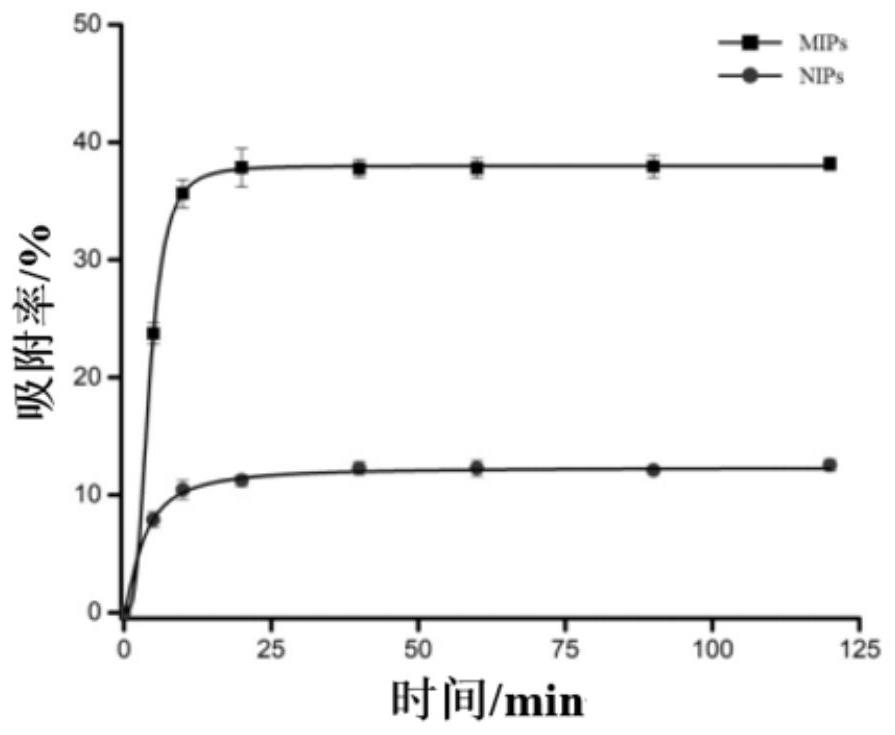

[0066] In an inert gas environment, 40.5 mg of nicotine template molecules, 43 mg of methacrylic acid (MAA), 36 mg of acrylic acid (AA), 385 mg of N,N-methylenebisacrylamide (BIS), 30 mg of ammonium persulfate ( APS) was dissolved in 10ml / 1ml of water / ethanol to obtain a dispersed phase; 10.3g of Span 80 was dissolved in 352ml of liquid paraffin to obtain a continuous phase; The dispersed phase was slowly added dropwise to the continuous phase to undergo a polymerization reaction. After 6 hours, the mixed solution was filtered to obtain a crude molecularly imprinted polymer, and the molecularly imprinted polymer was cleaned with a mixed solution containing acetic acid and methanol at a volume ratio of 1:9. Crude, the molecularly imprinted polymer MIP1 was obtained.

[0067] The difference between the preparation of non-imprinted polymer NIPs (Nonimprinted Polymers) and E...

Embodiment 2

[0101] In an inert gas environment, dissolve 40.5mg of nicotine template molecules, 129mg of MAA, 385mg of BIS, and 30mg of APS in 10ml / 1ml of water / ethanol to obtain a dispersed phase; dissolve 2.88g of Span 80 in 88ml of liquid In paraffin wax, the continuous phase is obtained; then at 70°C and 400rpm (rotational speed) mechanical stirring speed, the dispersed phase is slowly added dropwise to the continuous phase to undergo polymerization reaction, and after 6 hours, the mixed solution is filtered to obtain the molecularly imprinted polymer The crude product was washed with a mixed solution containing acetic acid and methanol at a volume ratio of 1:9 to obtain the molecularly imprinted polymer MIP2.

[0102] The adsorption and characterization results of molecularly imprinted polymers in this example, as well as the Flash chromatography column prepared by molecularly imprinted polymers and the performance test results are the same as those in Example 1, and will not be repea...

Embodiment 3

[0104] In an inert gas environment, dissolve 40.5mg of nicotine template molecules, 86mg of MAA, 385mg of BIS, and 30mg of APS in 10ml / 1ml of water / ethanol to obtain a dispersed phase; dissolve 2.88g of Span 80 in 88ml of liquid In paraffin wax, the continuous phase is obtained; then at 70°C and 400rpm (rotational speed) mechanical stirring speed, the dispersed phase is slowly added dropwise to the continuous phase to undergo polymerization reaction, and after 6 hours, the mixed solution is filtered to obtain the molecularly imprinted polymer The crude product was washed with a mixed solution containing acetic acid and methanol at a volume ratio of 1:9 to obtain the molecularly imprinted polymer MIP3.

[0105] The adsorption and characterization results of molecularly imprinted polymers in this example, as well as the Flash chromatography column prepared by molecularly imprinted polymers and the performance test results are the same as those in Example 1, and will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com