Automatic glue spraying and compounding all-in-one machine and manufacturing method for automobile trunk carpet production

A suitcase and all-in-one technology, applied in chemical instruments and methods, layered products, lamination devices, etc. Problems such as long distribution path can be achieved to reduce melting and spraying temperature, reduce the influence of thermal deformation, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

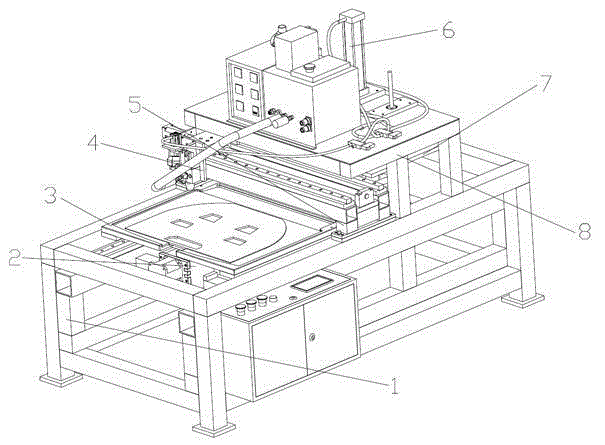

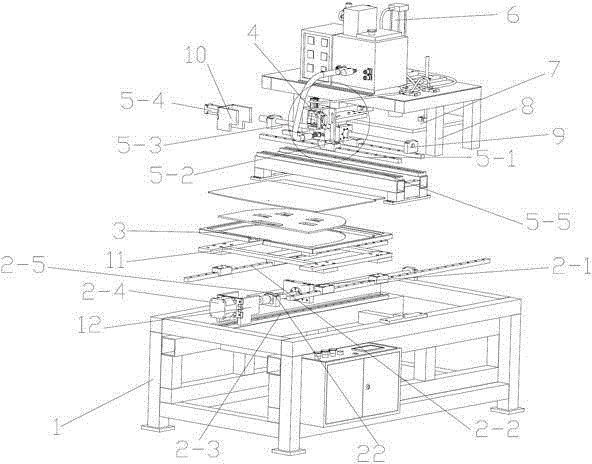

[0024] like figure 1 As shown, the automatic glue-spraying all-in-one machine for automobile trunk carpet production described in this embodiment includes an upper frame 8, a lower frame 1 and a pressing plate 7, and the upper frame 8 is fixed on the lower frame 1 , the lower frame 1 is provided with a transverse sliding mechanism 2 for realizing lateral displacement and a longitudinal sliding mechanism 5 for realizing longitudinal displacement, and the longitudinal sliding mechanism 5 is arranged above the transverse sliding mechanism 2, and the transverse sliding mechanism 2 is fixed with Template 3, the glue spraying device 4 corresponding to the template 3 is fixed on the longitudinal sliding mechanism 5, and the glue spraying port of the glue spraying device 4 is facing the template 3, and the upper frame 8 is provided with the pusher. The power mechanism 6 of the pressure plate 7, and the pressure plate 7 is fixed on the push rod of the power mechanism 6, and the pressur...

Embodiment 2

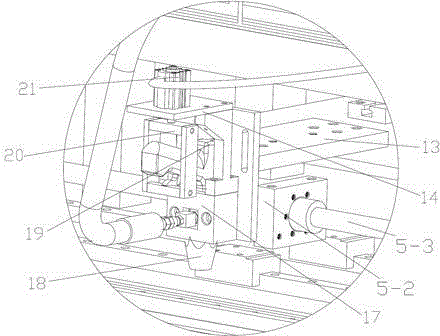

[0036] like image 3 As shown, the automatic glue-spraying all-in-one machine for the car trunk carpet described in this embodiment is different from Embodiment 1 in that: the glue-spraying device 4 is fixed on the longitudinal sliding mechanism 5 through the fixing plate 13, so The glue spraying device 4 includes a fixed frame 14, a hot melt glue gun 19, a nozzle 18, a hot melt glue gun switch 20 and a cylinder 21, the fixed frame 14 is fixed on the fixed plate 13, and the hot melt glue gun 19 is embedded in the fixed frame 14 In the groove for fixing the hot melt gun 19, and the lower opening of the groove of the fixed frame 14 is fixed with a fixed seat 17, the gun head of the hot melt gun 19 passes through the fixed seat 17 and is sealed with the nozzle 18, and the nozzle 18 is facing the template 3, the hot melt glue gun switch 20 is buckled on the wrench of the hot melt glue gun 19, the piston rod of the cylinder 21 and the hot melt glue gun switch 20 are fixed to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com