Patents

Literature

37results about How to "Short assist time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

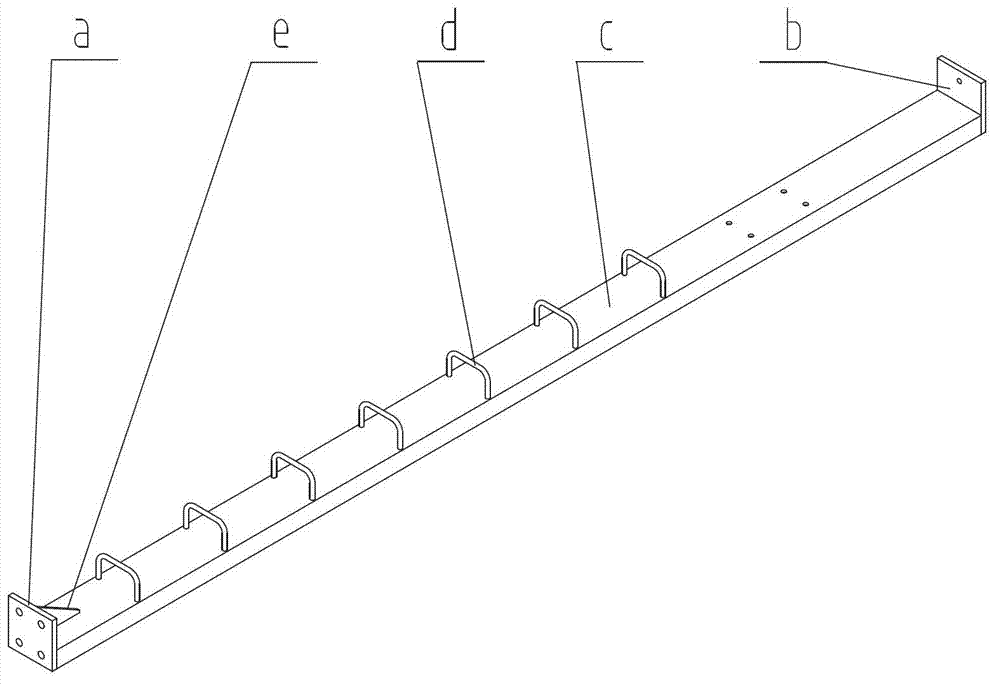

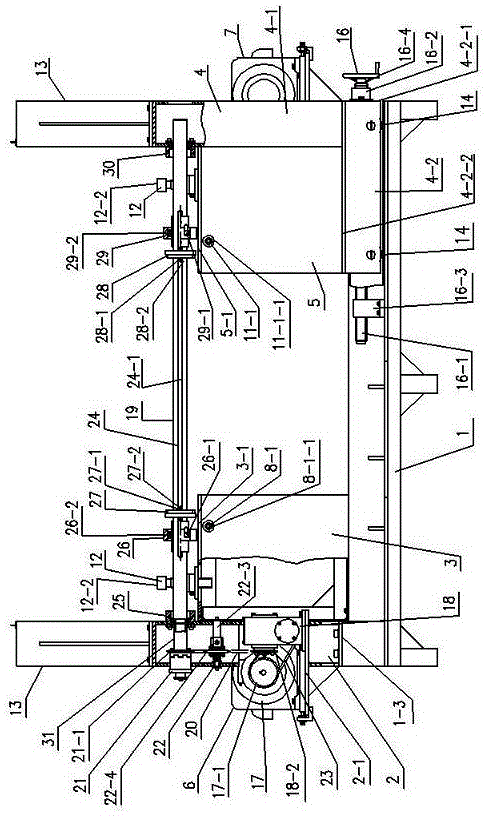

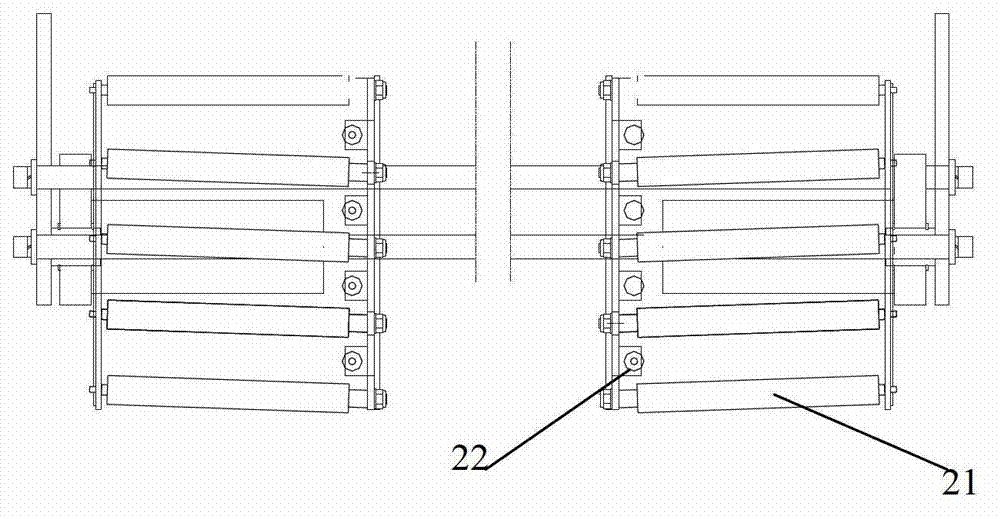

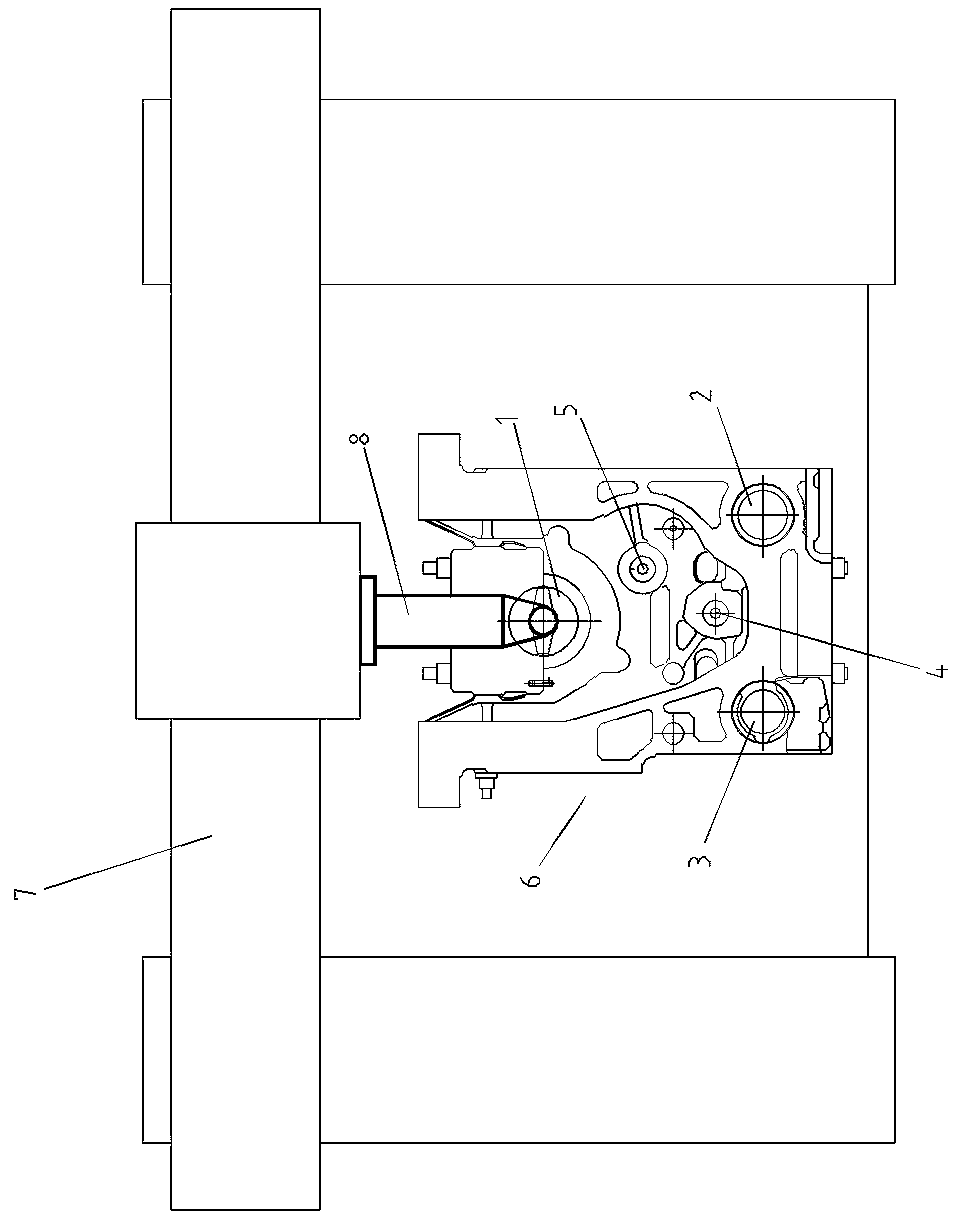

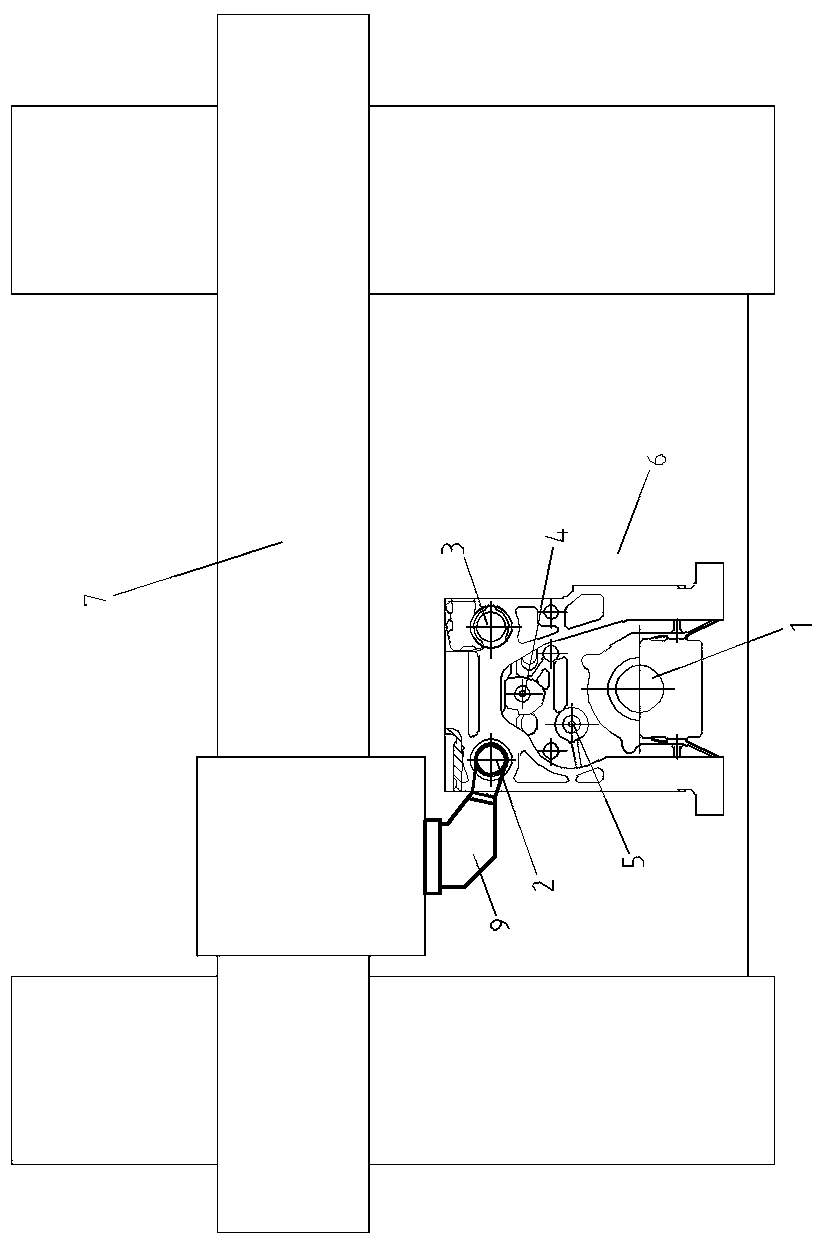

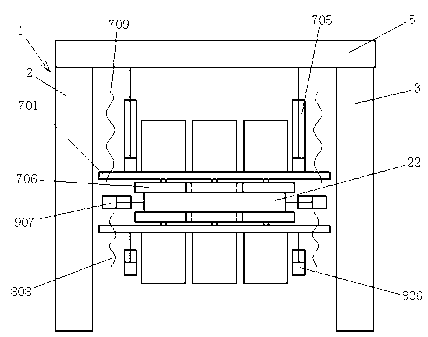

Standing column assembly welding tool

InactiveCN102825408AFast demouldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention provides a standing column assembly welding tool for welding a standing column of a mixing plant. The standing column assembly welding tool comprises a left and right limit mechanism, an up and down limit mechanism and side limit mechanisms. The left and right limit mechanism comprises a first end and a second end. A first connecting plate of the standing column is limited at the first end. A second connecting plate of the standing column is limited at the second end. The up and down limit mechanism is used for limiting fluctuation of a standing column body. The side limit mechanisms are disposed on sides of the standing column body and are used for limiting the forward and backward motions of the standing column body. By the aid of the limit mechanisms, all parts of the standing column can be limited. The standing column assembly welding tool has the advantages of high work efficiency, low labor intensity, high assembly precision.

Owner:SANY HEAVY IND CO LTD (CN)

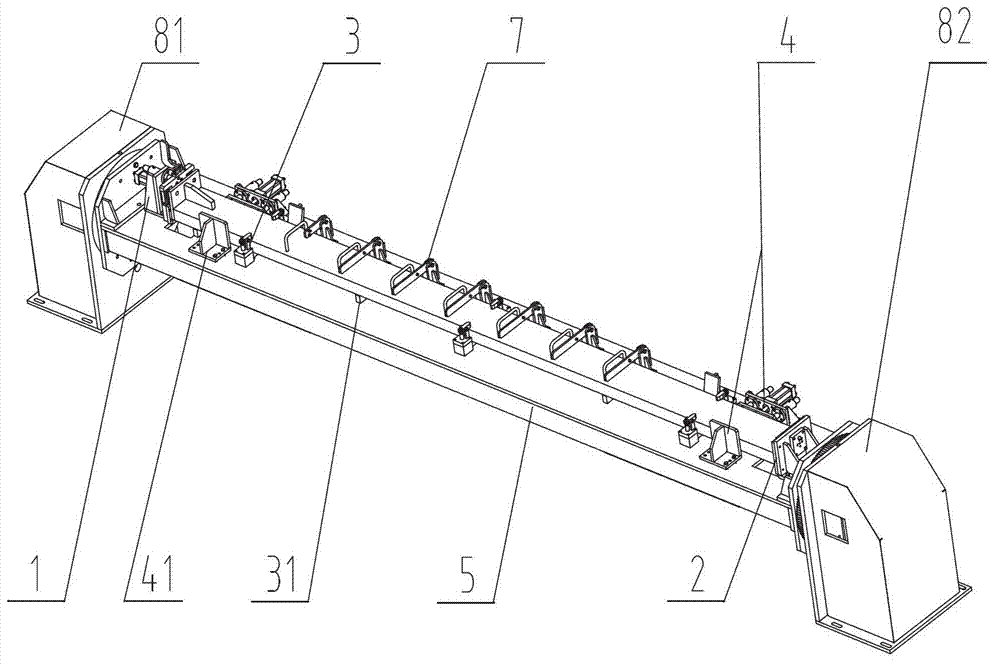

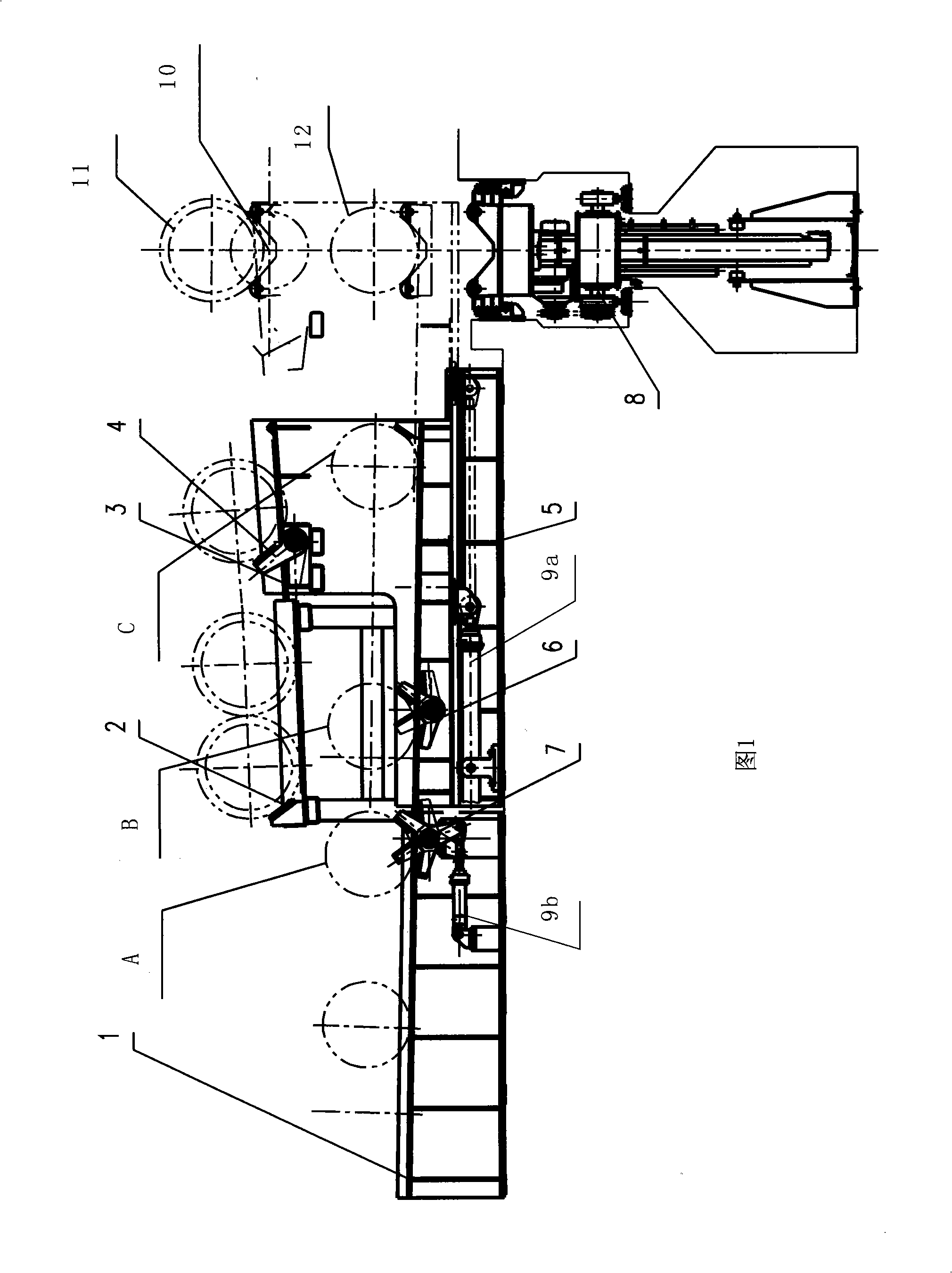

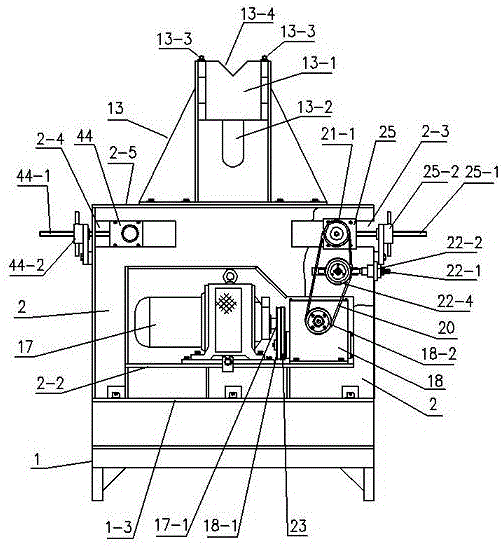

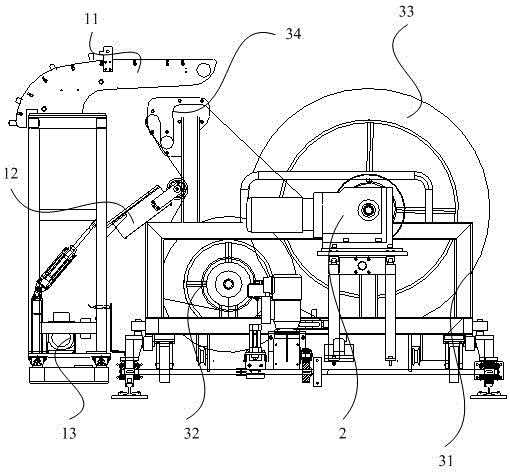

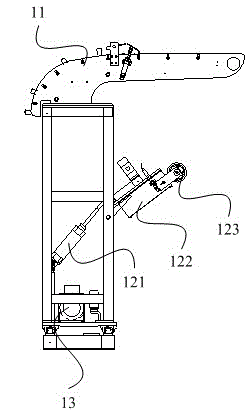

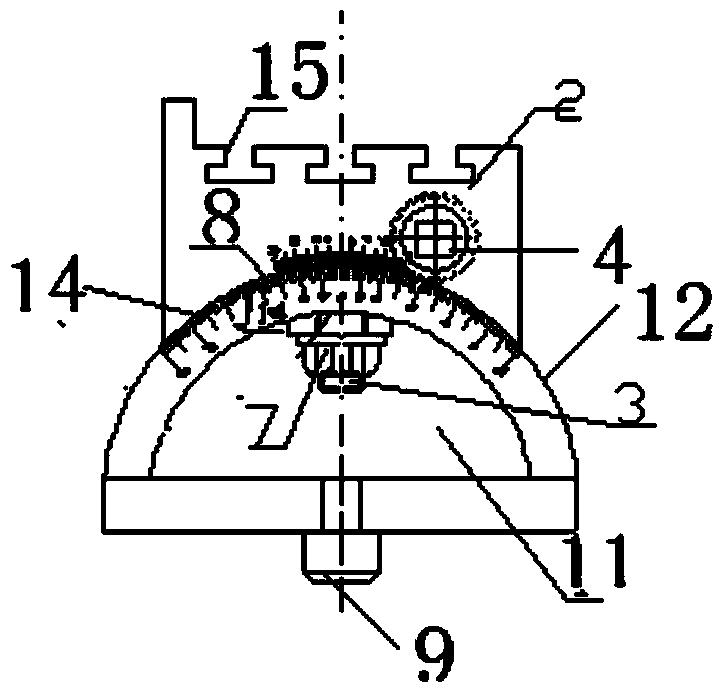

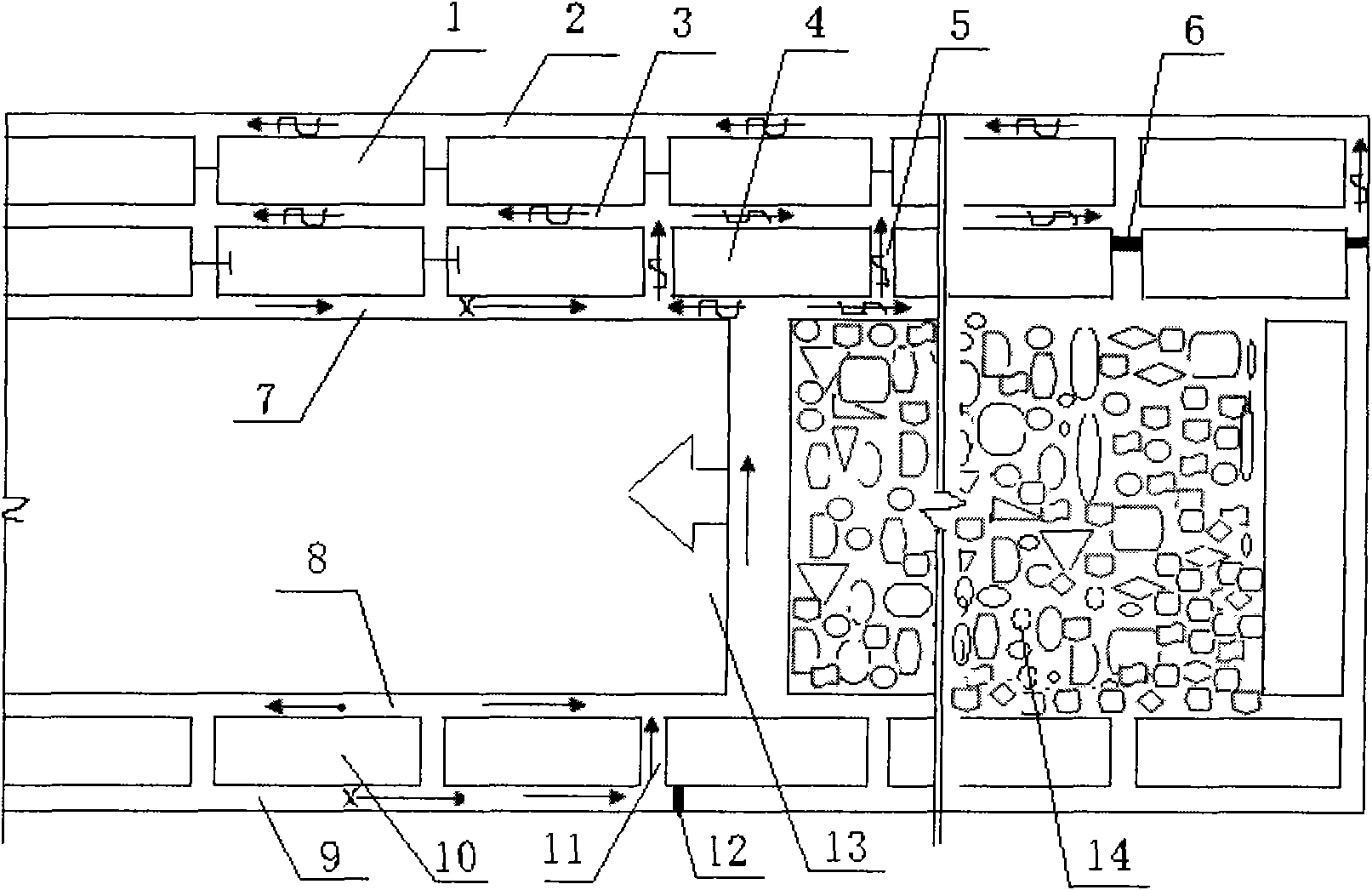

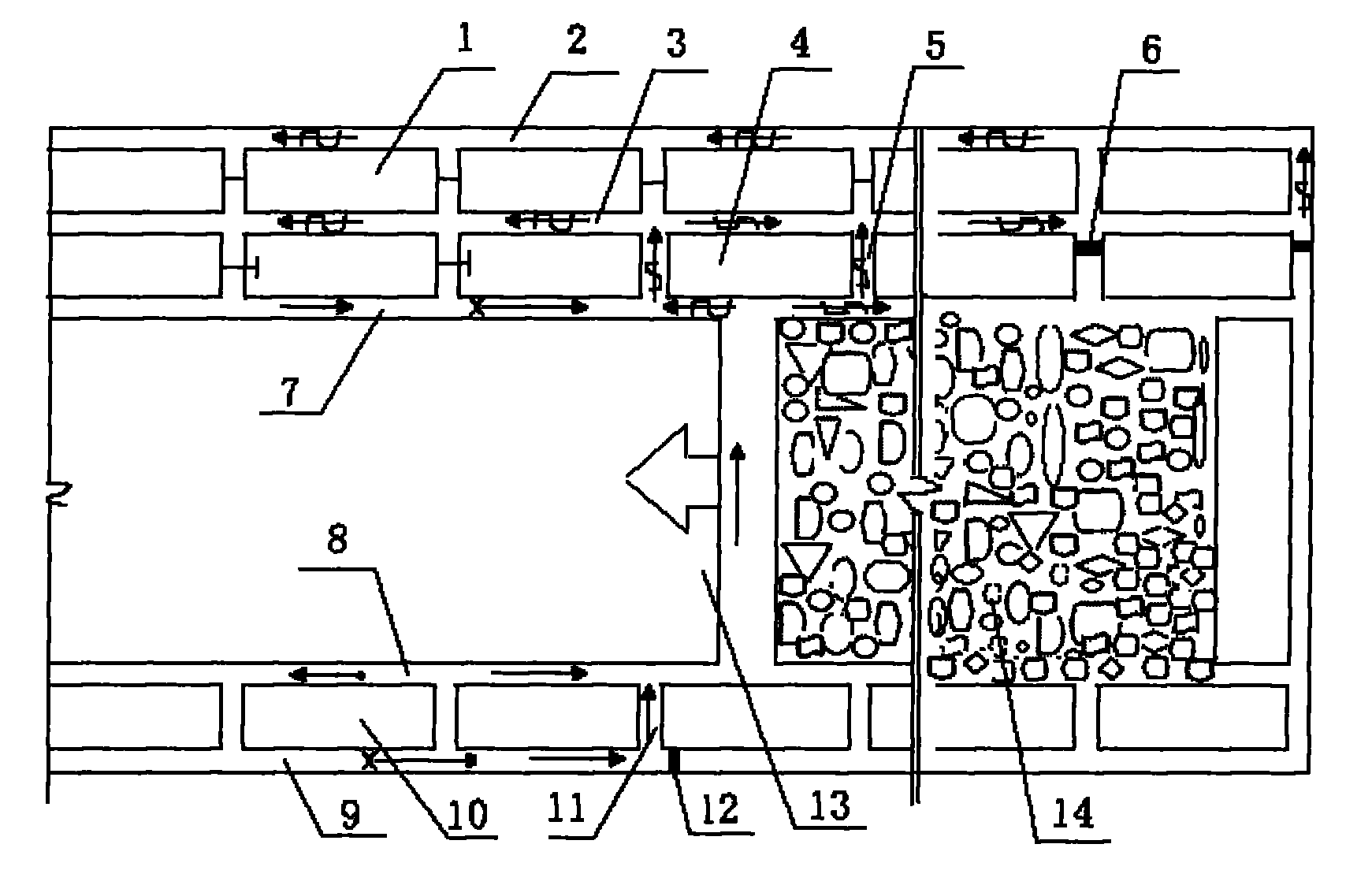

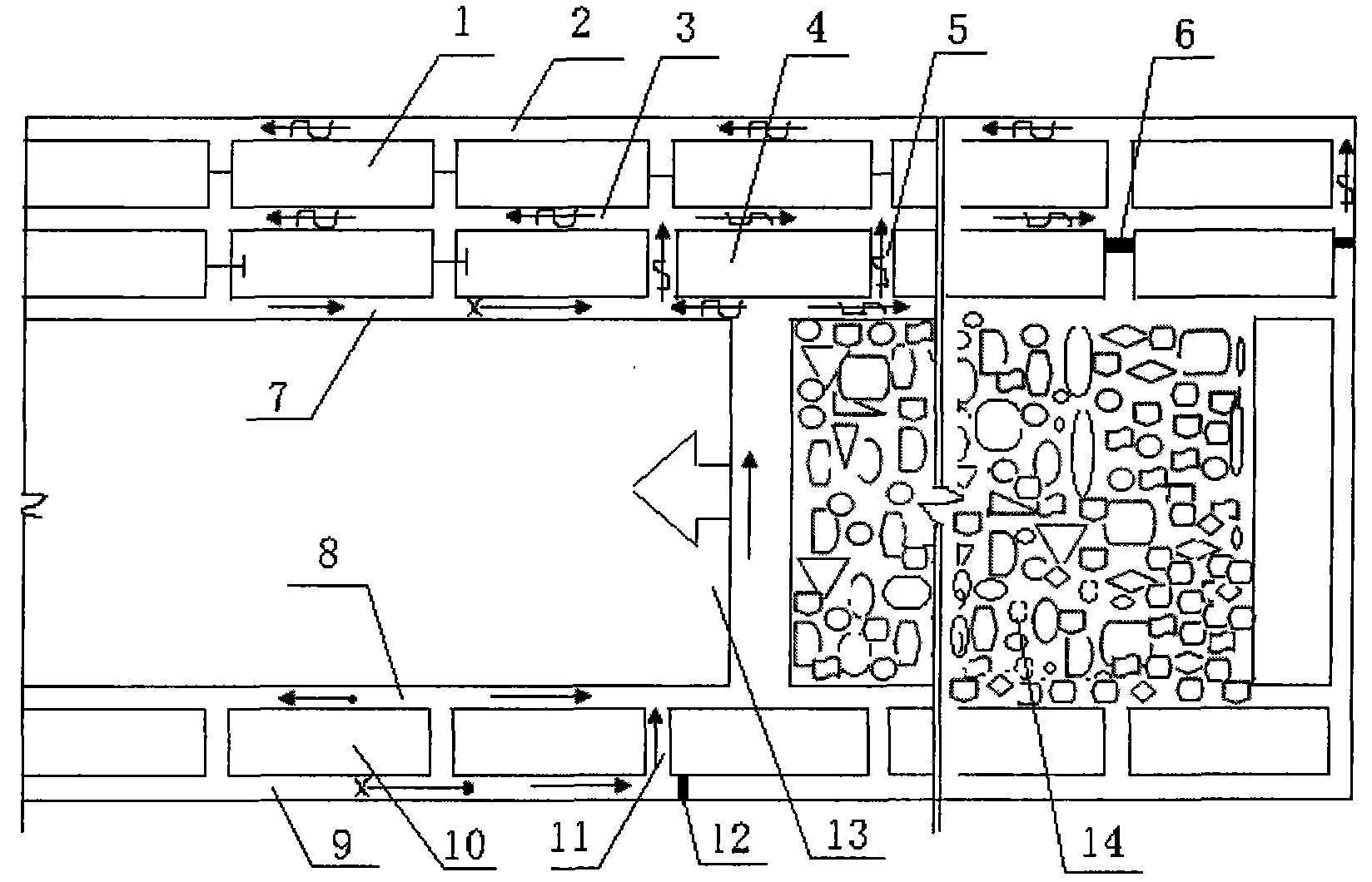

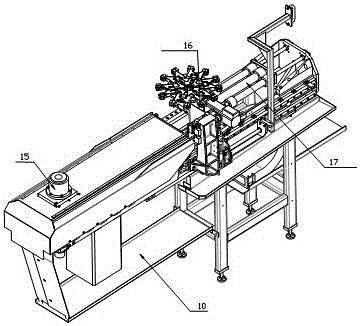

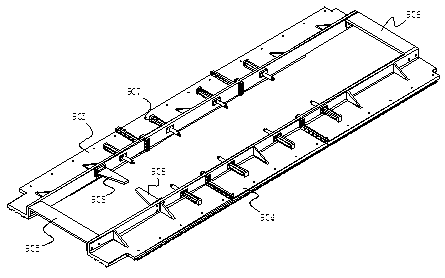

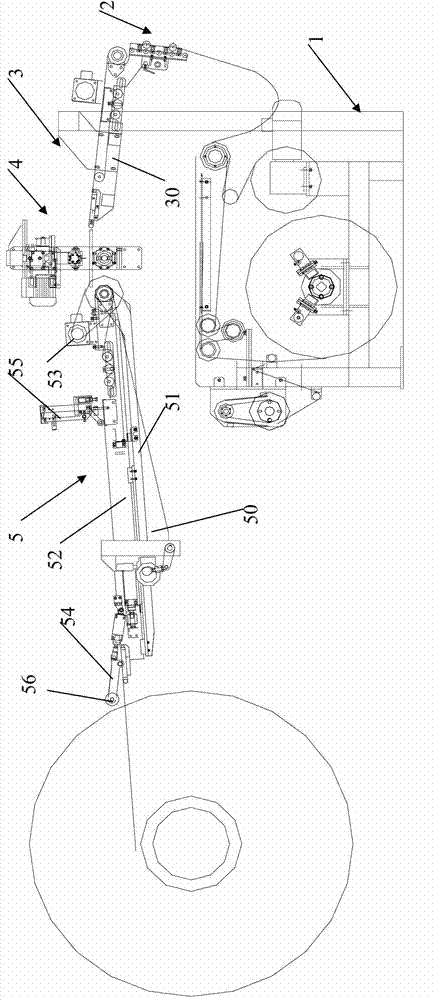

Novel method for discharging residual winding from sleeve barrel

InactiveCN101402109AMeet the requirements of actual productionReduce manufacturing costBogieSmall footprint

The invention discloses a method for a novel upper-sleeve coil stripper, which integrates an upper sleeve device and a coil stripper device into a whole. The method is as follows: the lower layer of the novel upper-sleeve coil stripper is provided with the upper sleeve device; one end of the novel upper-sleeve coil stripper is provided with a fixed sleeve storage platform (1) and a coil stripper stacking frame (2); the sleeve storage platform is provided with a striking fork c(7) for striking a sleeve; the middle of the novel upper-sleeve coil stripper is provided with a movable slide block (3) which is double-layered; a misshapen coil can be temporarily placed on the upper layer of the slide block, and the sleeve can be temporarily placed on the lower layer of the slide block; striking forks are arranged on the upper layer and the lower layer of the slide block respectively; the other end of the upper-sleeve coil stripper is provided with a coil stripping bogie (8); and the bottom of the slide block is slidably connected with a pedestal (5). The work flow of the novel upper-sleeve coil stripper is as follows: the coil stripping bogie (8) unloads the misshapen coil from a coiler (10); the slide block (3) moves to place the misshapen coil on the upper layer of the slide block; a striking fork b of the slide block strikes the sleeve (12) which is placed on the lower layer of the slide block from the B position to the C position; and the coil stripping bogie (8) moves upwards to support the sleeve. The method can well solve the problems, and has low manufacturing cost, small floor space, and short auxiliary time during the production process.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

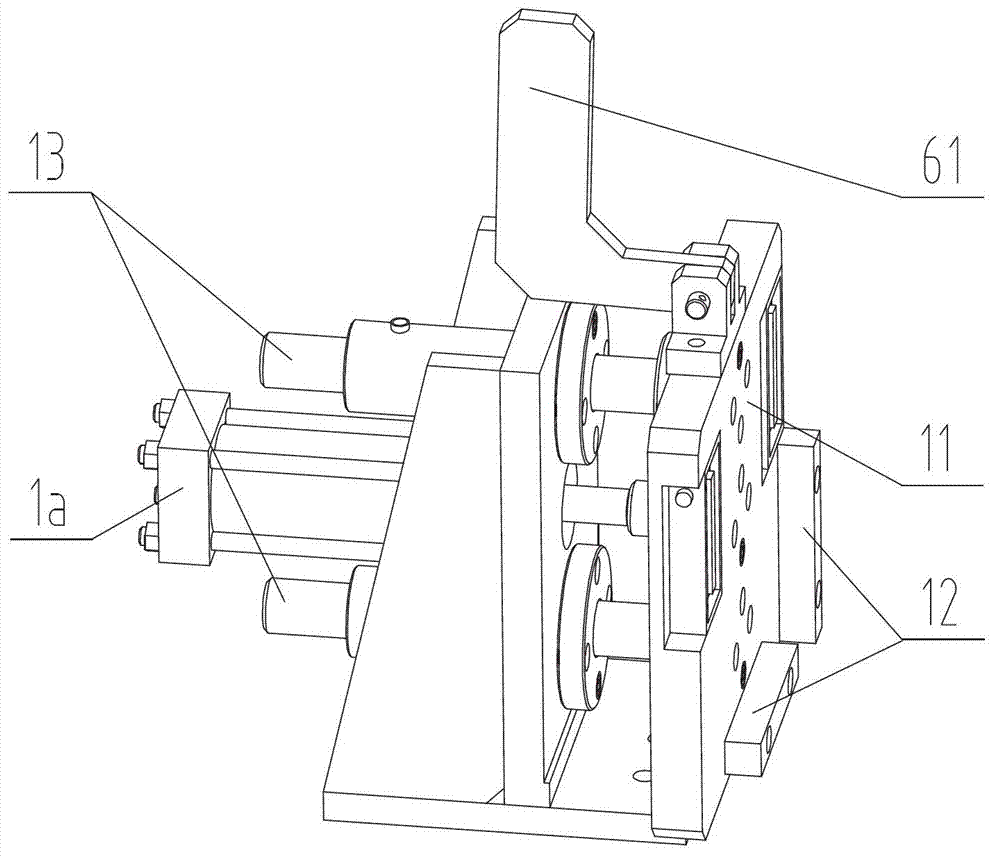

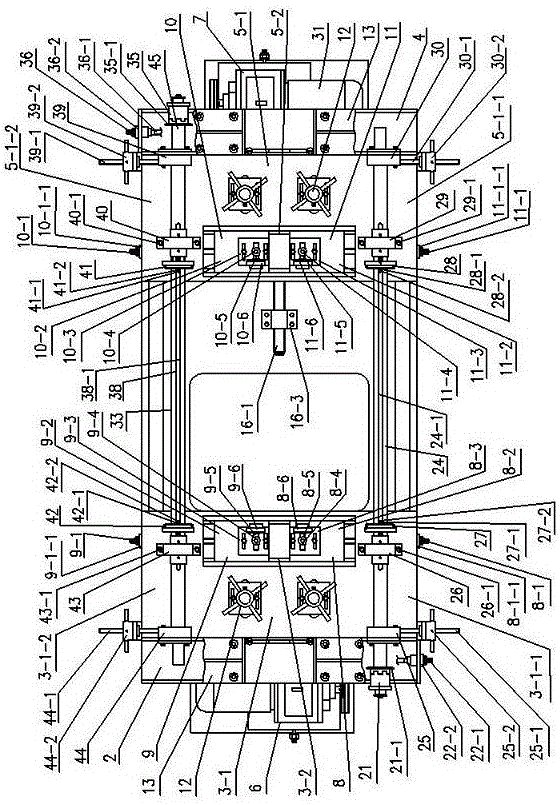

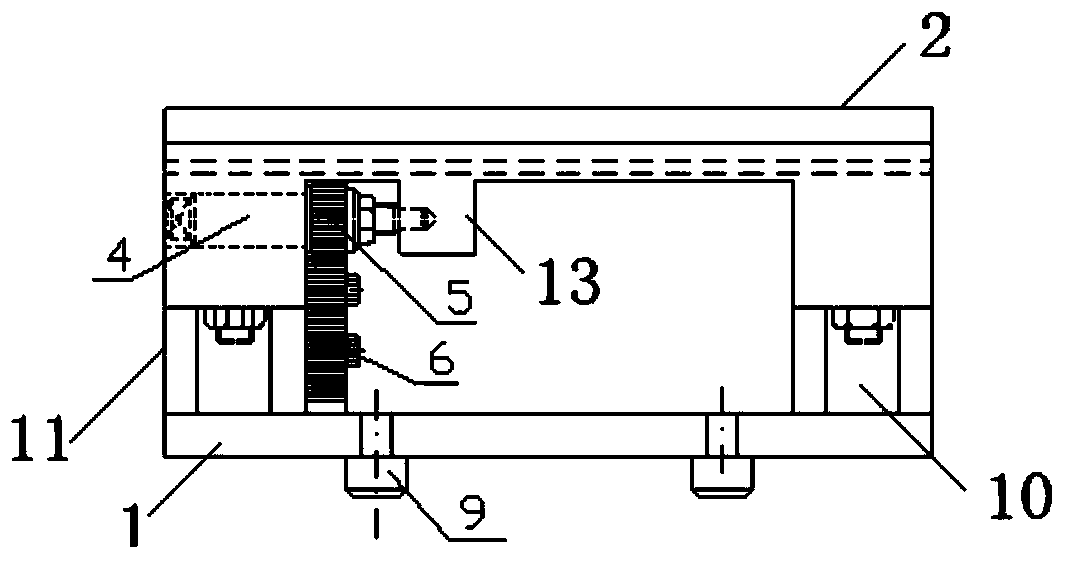

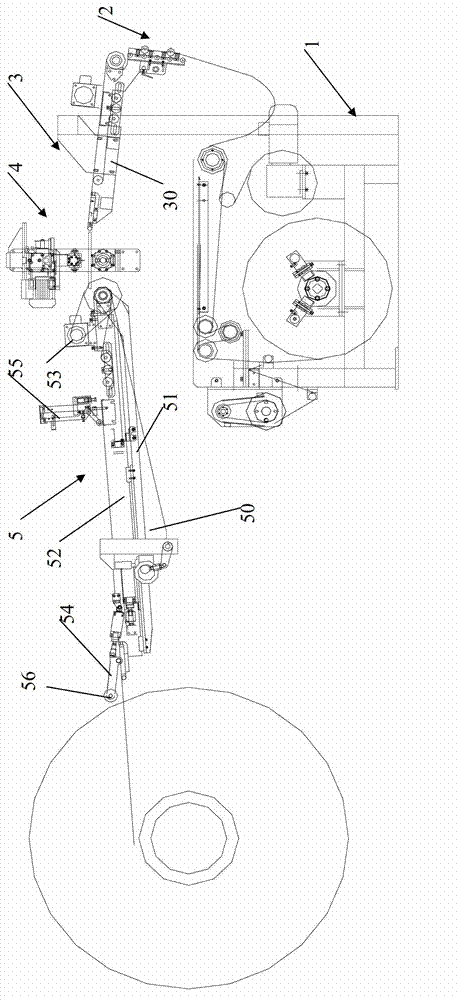

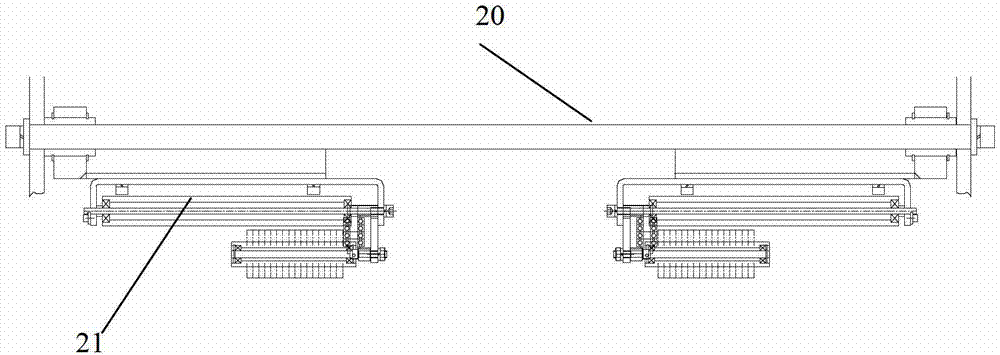

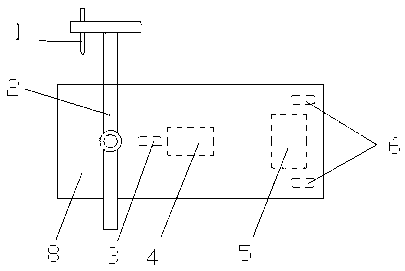

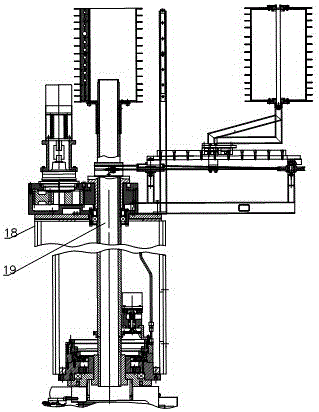

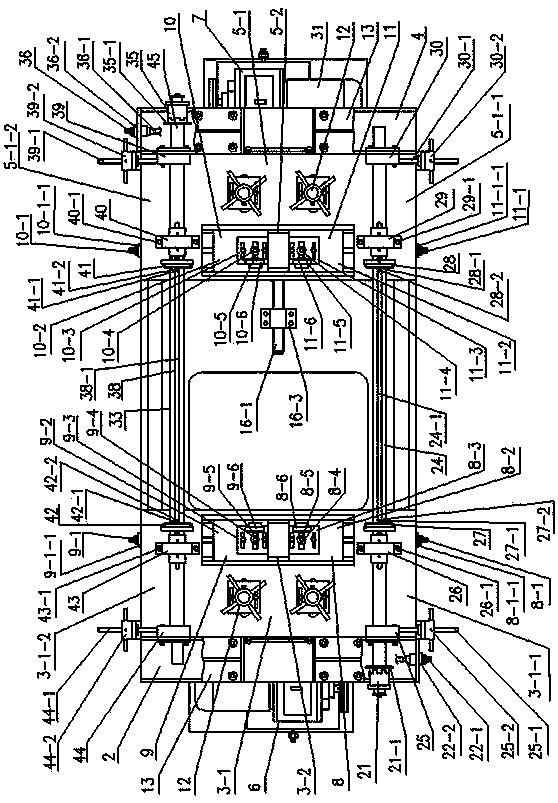

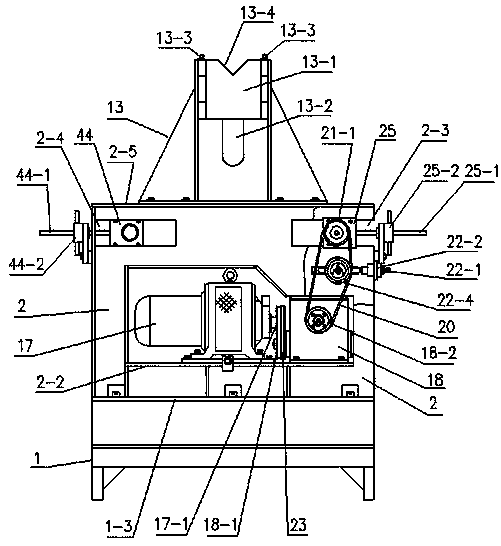

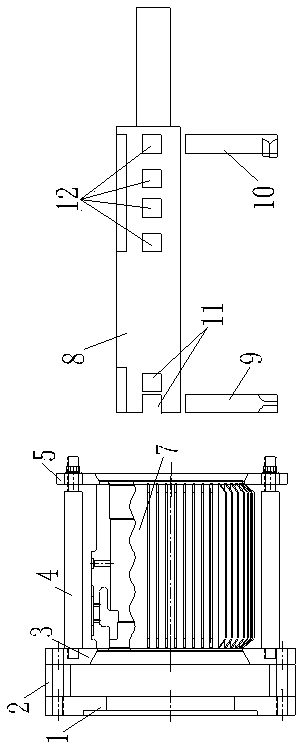

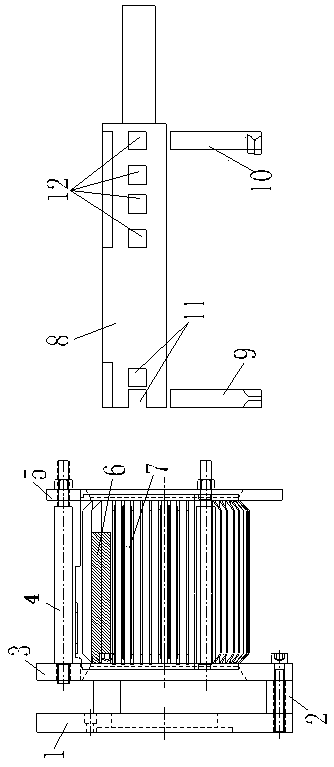

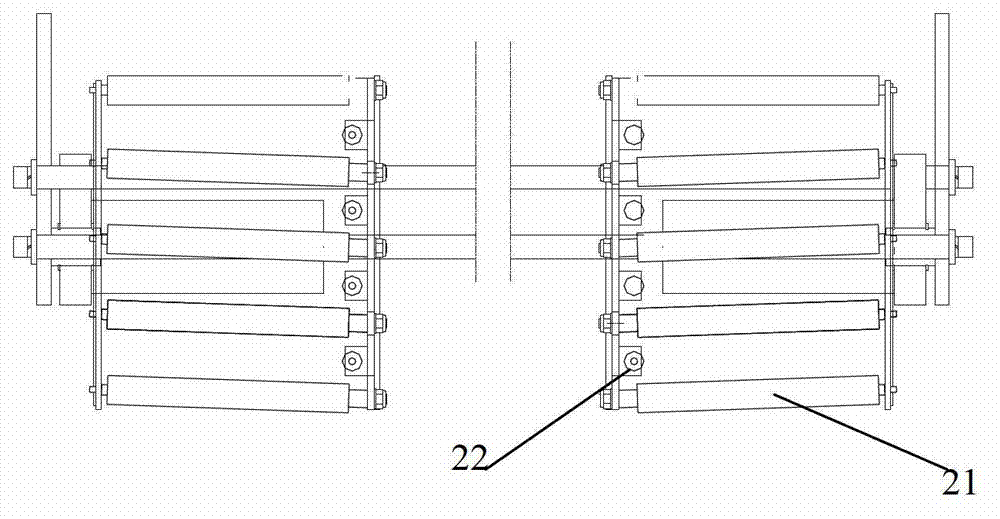

Double-station winding machine for high-tension coil of three-dimensional wound core dry type transformer

ActiveCN105006361AImprove winding efficiencyShort assist timeCoils manufactureWinding machineLow voltage

Provided is a double-station winding machine for a high-tension coil of a three-dimensional wound core dry type transformer. The winding machine comprises a base, a left wallboard, a left rack, a right wallboard, a right rack, a winding power device on the left wallboard, a left riding wheel supporting plate mechanism on the left rack, a right riding wheel supporting plate mechanism on the left rack, a winding power device on the right wallboard, a left riding wheel supporting plate mechanism on the right rack, a right riding wheel supporting plate mechanism on the right rack, an iron core support frame, and an iron core turnover support. Since the winding machine has two sets of independent winding power devices, the machine can wind two phases of coils of a transformer. Since positions of the right wallboard can be moved, the machine is suitable for installation of iron cores of transformers in different sizes. Since the main shaft of the main shaft mechanism of the winding power device can move parallelly, cooperation of a left gear and a right gear on the main shaft and riding wheels which are on the right rack and are corresponding to the left gear and the right gear is convenient and reliable, and a gap between a low-voltage inner wall of a transformer winding former and a core limb in rotation can be easily ensured. The device is simple in structure, convenient in operation, high in winding efficiency, and is safe and practical.

Owner:JIANGXI HANS POWER TECH

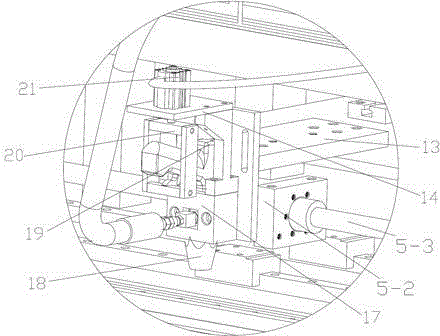

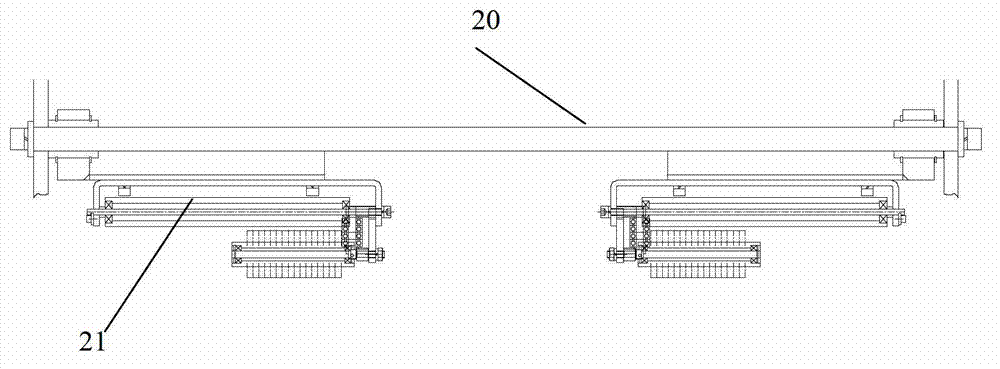

Cord fabric take-up device

InactiveCN106144704AShort assist timeHigh degree of automationWebs handlingEngineeringMechanical engineering

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

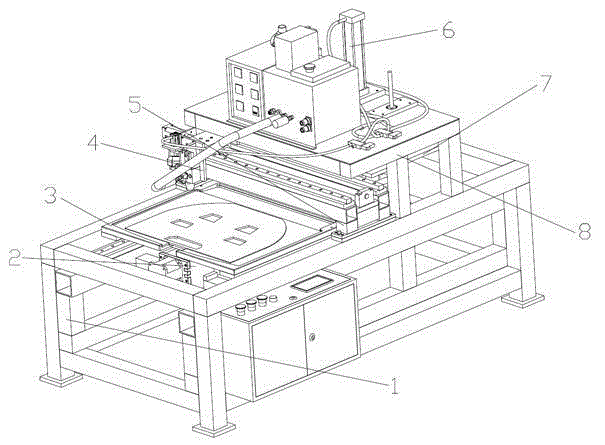

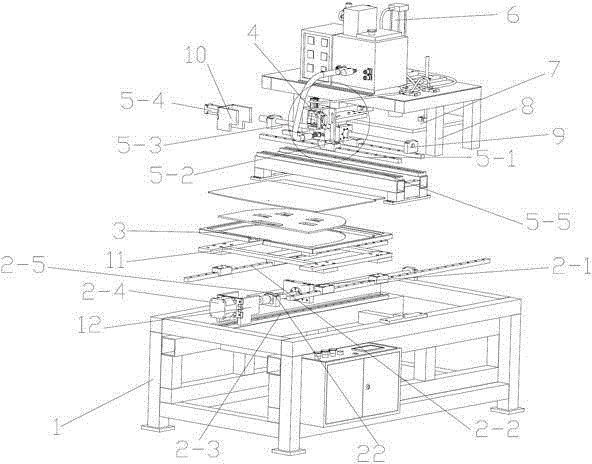

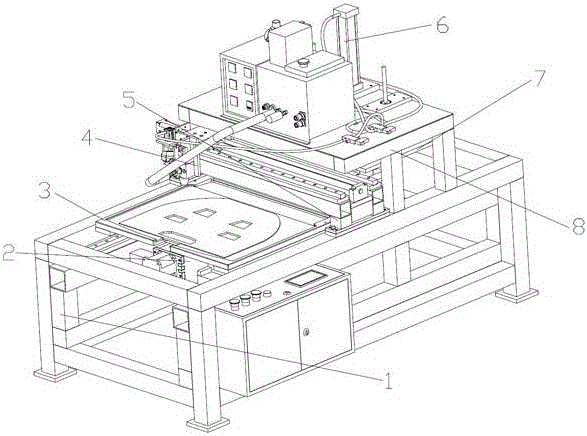

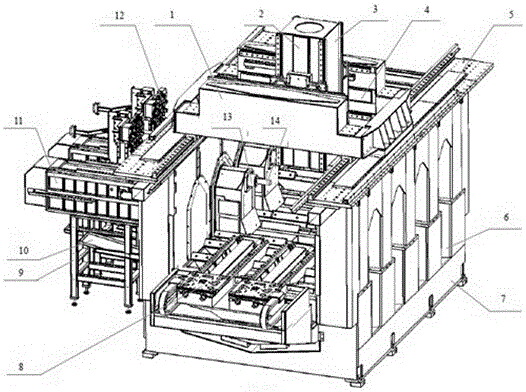

Automatic glue spraying and compounding all-in-one machine and manufacturing method for automobile trunk carpet production

ActiveCN104527203AConform to designFit for useLaminationLamination apparatusEngineeringVertical displacement

The invention discloses an automatic glue spraying and compounding all-in-one machine and a manufacturing method for automobile trunk carpet production. A template of the automatic glue spraying and compounding all-in-one machine is moved by a horizontal sliding mechanism so that the purpose of horizontal displacement glue spraying of a polypropylene cellular board on the template can be achieved through a glue spraying device. The glue spraying device is moved by a vertical sliding mechanism so that the purpose of vertical displacement glue spraying of the polypropylene cellular board on the template can be achieved through the glue spraying device. Meanwhile, the glue sprayed polypropylene cellular board on the template is glued to a sound insulation felt. The glued sound insulation felt and the polypropylene cellular board on the template are quickly transferred to the position below a pressing plate by the horizontal sliding mechanism. The pressing plate is automatically activated and quickly pushed by a power unit so that further pressing, compounding and molding can be carried out on the glued sound insulation felt and the polypropylene cellular board. According to the automatic glue spraying and compounding all-in-one machine and the manufacturing method for the automobile trunk carpet production, the compounding fastness and the production efficiency of an automobile trunk carpet are improved, and the compounded and molded automobile trunk carpet is good in operation performance.

Owner:NINGBO SUNLIGHT MOTOR PARTS

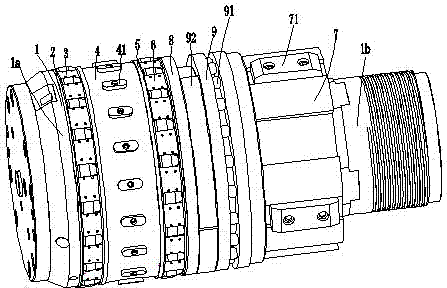

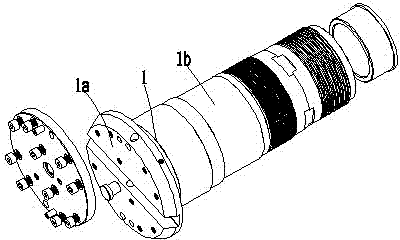

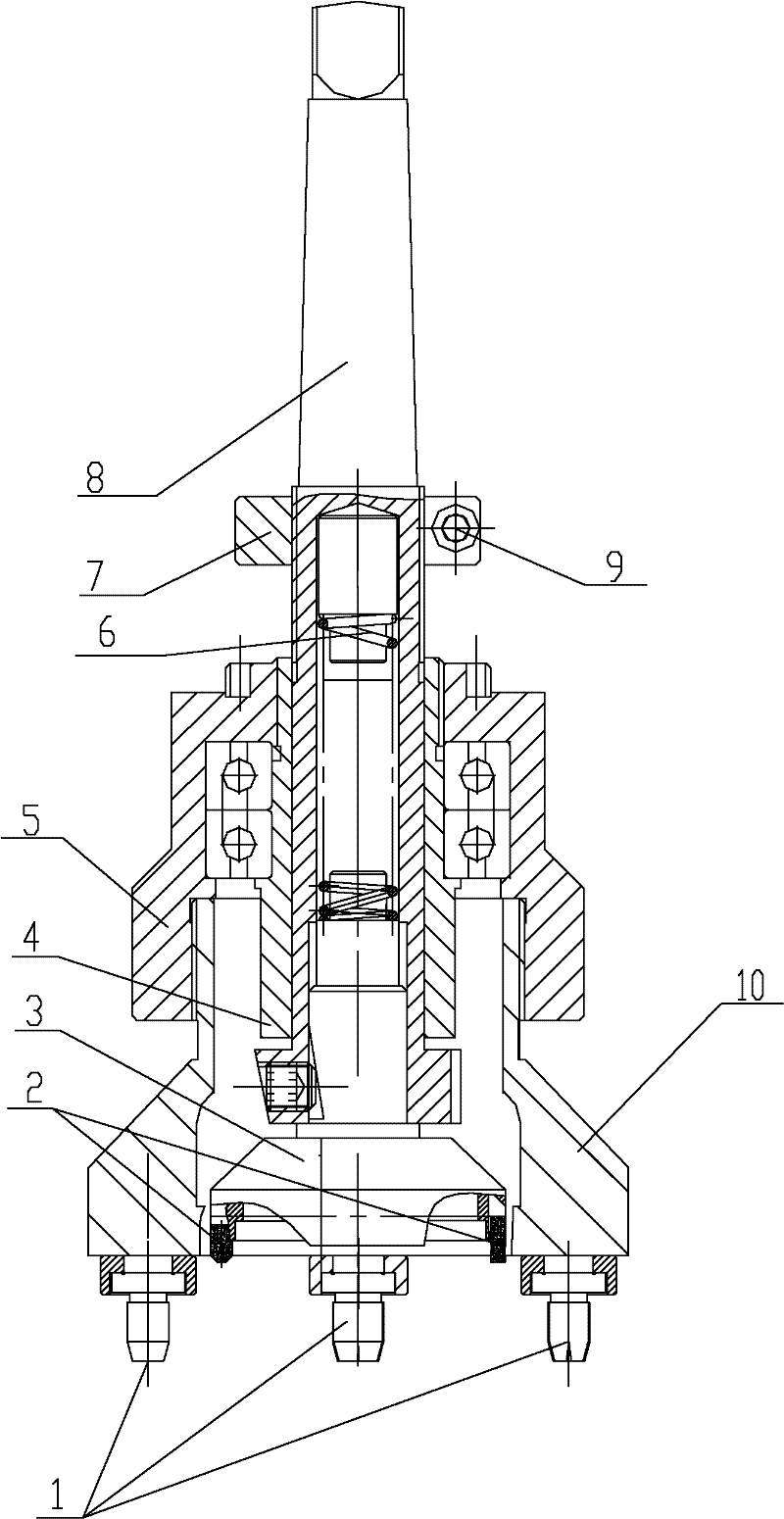

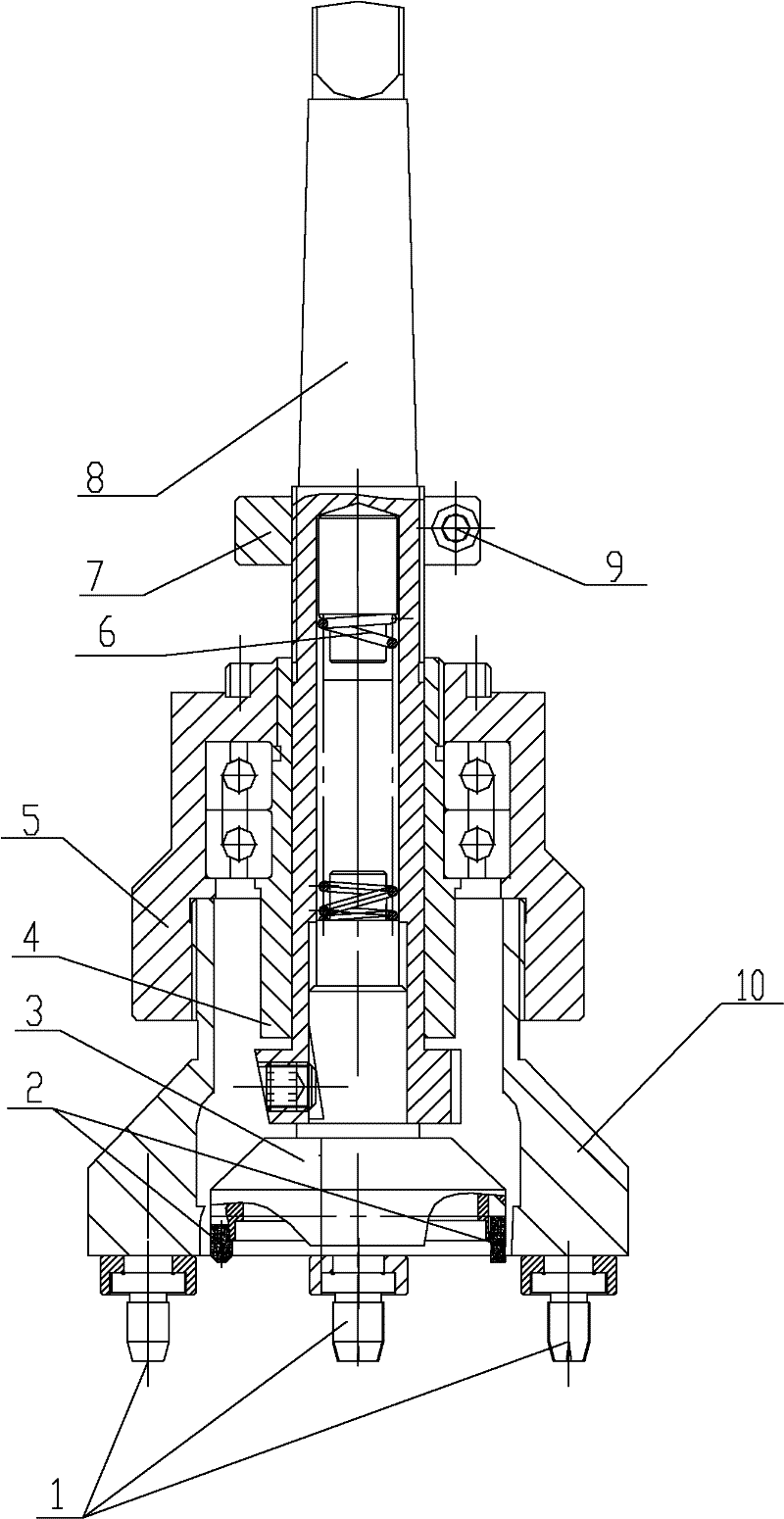

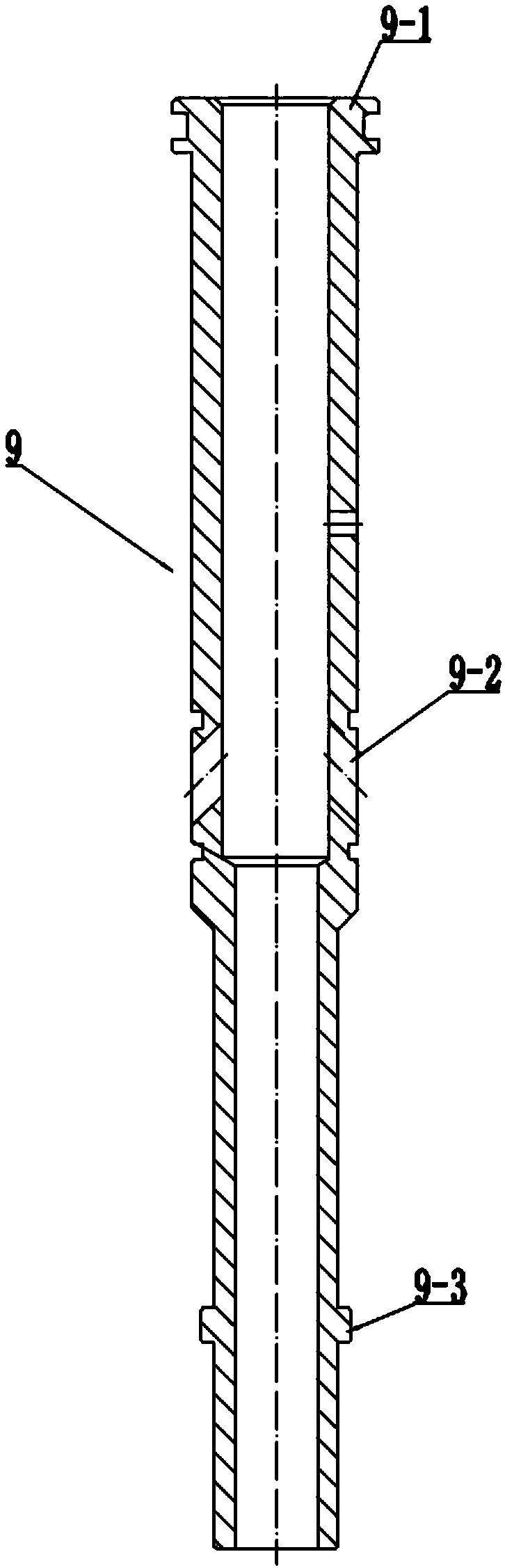

Boring and Rolling Compound Tool

ActiveCN102294495AImprove work performanceImprove fatigue strengthTurning toolsSurface roughnessEngineering

The invention discloses a boring and rolling combined cutting tool, which comprises a rolling part and a boring cutter part, wherein the boring cutter part comprises a core shaft, the front end of the core shaft is provided with a cutterhead body for assembling a boring cutter, and the rear end of the core shaft is provided with a circular shaft extending cylinder; the rolling part comprises a front raceway, a front retainer, a middle sleeve, a rear raceway and a rear retainer which are sequentially arranged, and the front raceway, the front retainer, the middle sleeve, the rear raceway and the rear retainer are all matched with a front outer ring of the shaft extending cylinder in a buckle mode; the middle part of the shaft extending cylinder is connected with a supporting sleeve in a screwed mode, and the front raceway, the front retainer, the middle sleeve, the rear raceway and the rear retainer are controlled to be fixed in the axial position on the front outer ring of the shaft extending cylinder by the screwed supporting sleeve; in rolling processing, a rolling tool applies certain pressure on the surface of a workpiece, and microcosmic crests and microcosmic troughs originally remained on the surface of the workpiece are rolled to be flat to reduce surface roughness; in boring and rolling combined rolling, the boring process and the rolling process are combined to make boring more stable; and the assisting time is short, and the production efficiency is high.

Owner:宁波市精恒凯翔机械有限公司

Tool clamp of free rotating indexing table

InactiveCN104029046ASimple structureReduce manufacturing costPrecision positioning equipmentPositioning apparatusEngineeringMachine tool

The invention discloses a tool clamp of a free rotating indexing table. The tool clamp of the free rotating indexing table is simple in structure, fast in clamping, safe, reliable, easy to operate, high in work efficiency, short in auxiliary time and low in manufacturing cost. According to the technical scheme, a top face arc and a guide rail groove are arranged on two side stand plates, mounting seats of the two side stand plates are symmetrically distributed, and the indexing table with a bottom face arc and a guide rail sliding block at the two ends is assembled in the top face arc and the guide rail groove in the same arc. A bottom face fixed connecting plate of the indexing table is fixedly connected with a handle of one side stand plate, a driving gear assembled on a handle connecting rod is meshed with a semi-arc fixed gear fixedly connected with the inner side face of the one stand plate to form an indexing transmission mechanism, and therefore the clamp tool of the free rotating indexing table which can freely rotate within the range of + / -50 degrees is formed. The defects that an existing machine tool rotary workbench can only carry out clockwise and anticlockwise rotary machining, and parts in angle machining with a main shaft cannot be unbound are overcome.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

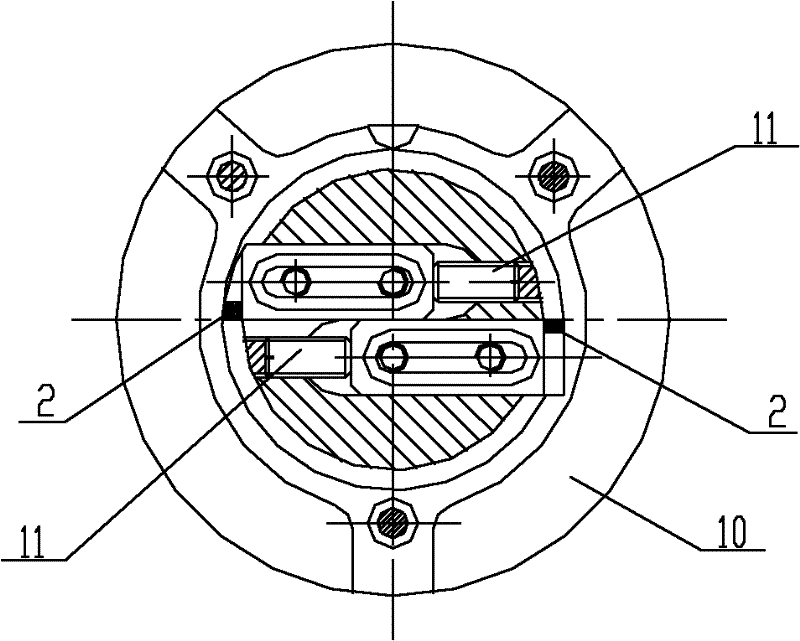

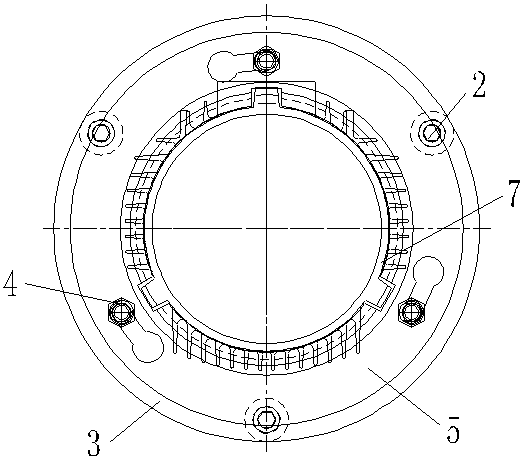

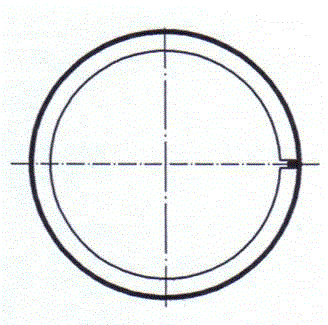

Annular groove machining cutter tool used for vertical drilling machine

InactiveCN102248214AImprove consistencyAccuracy controllableMilling cuttersMilling equipment detailsEngineeringUltimate tensile strength

The invention discloses an annular groove machining cutter tool used for a vertical drilling machine, comprising a cutter bar, wherein a limiting locknut is connected in the middle of the cutter bar; a spindle sleeve is fixedly connected at the lower part of the cutter bar; a cutter disc is installed at the bottom of the cutter bar; cutter bits arranged symmetrically are installed at the bottom of the cutter disc; an outer sleeve is supported on an excircle of the spindle sleeve through a bearing; and three claw locating sleeves are fixedly connected at the bottom of the outer sleeve. By adopting the annular groove machining cutter tool, machining of annular grooves of six sizes can be completed in one step, the sizes are favorable in consistency, and the precision is easy to control; a processed part is convenient to replace, and the auxiliary time of replacing the processed part is short; the annular groove machining cutter tool is located conveniently and accurately; the groove depth is not influenced by the overall thickness of a hydraulic valve plate; the labor intensity is low and the production efficiency is high. Compared with the annular groove machined on a lathe, the annular groove has the quality which is easily ensured and the production efficiency which can be improved by 2-3 times.

Owner:TIANJIN TIANDA YINTAI RAPID MFG PRODIVITY PROMOTION CENT

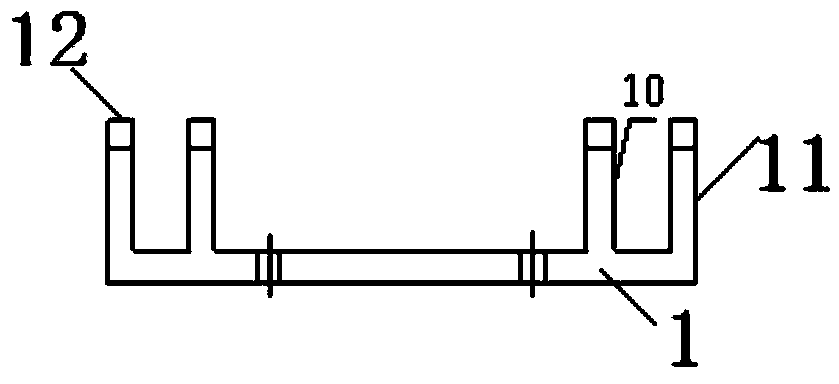

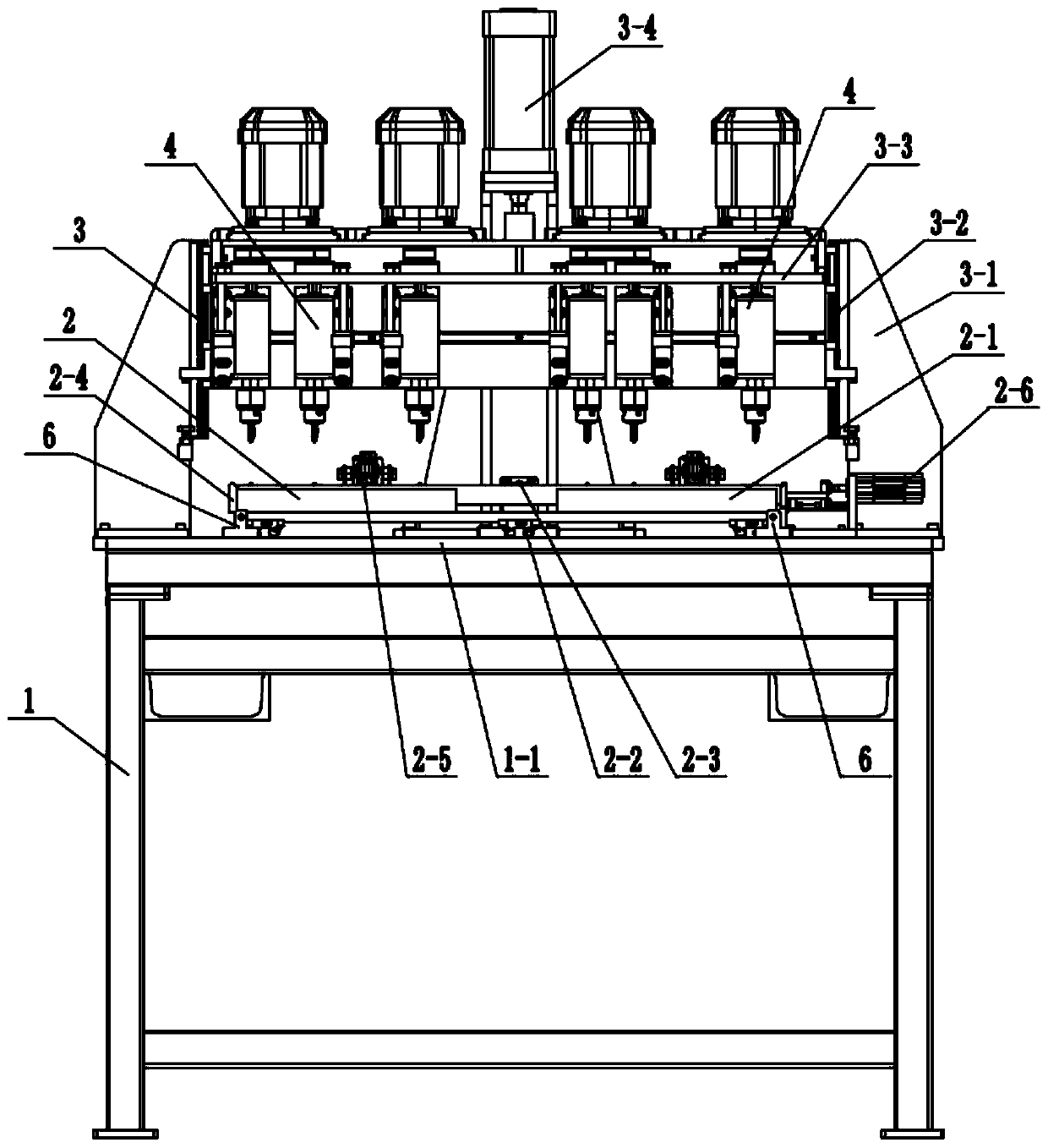

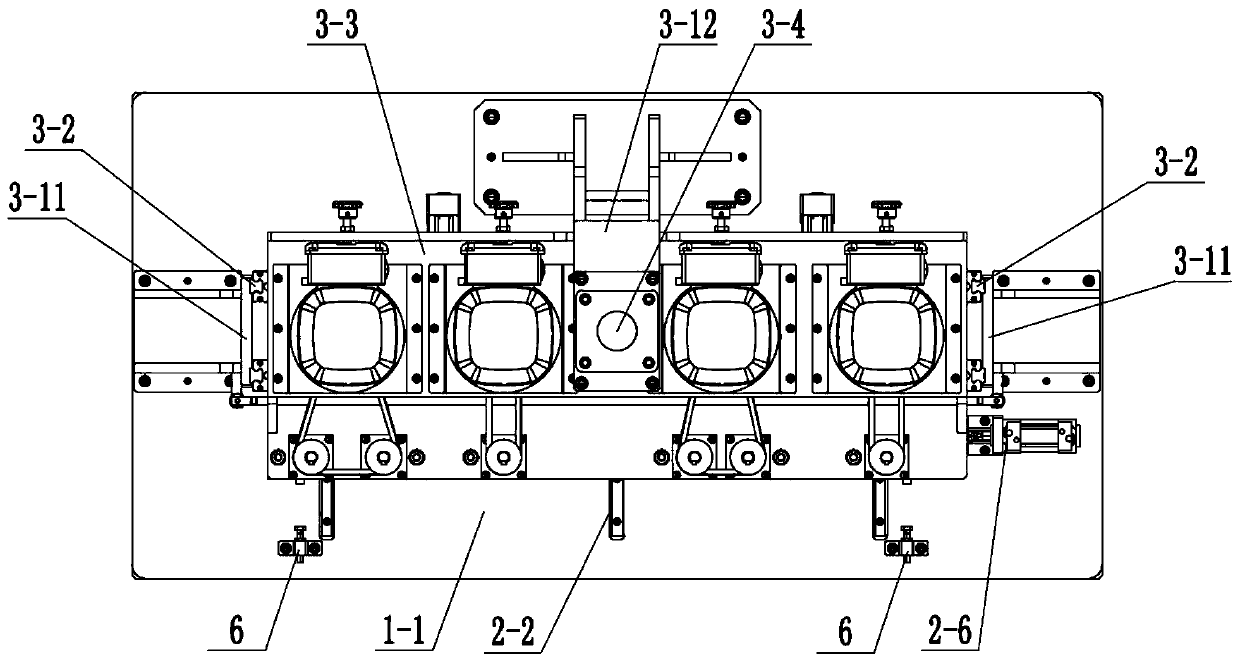

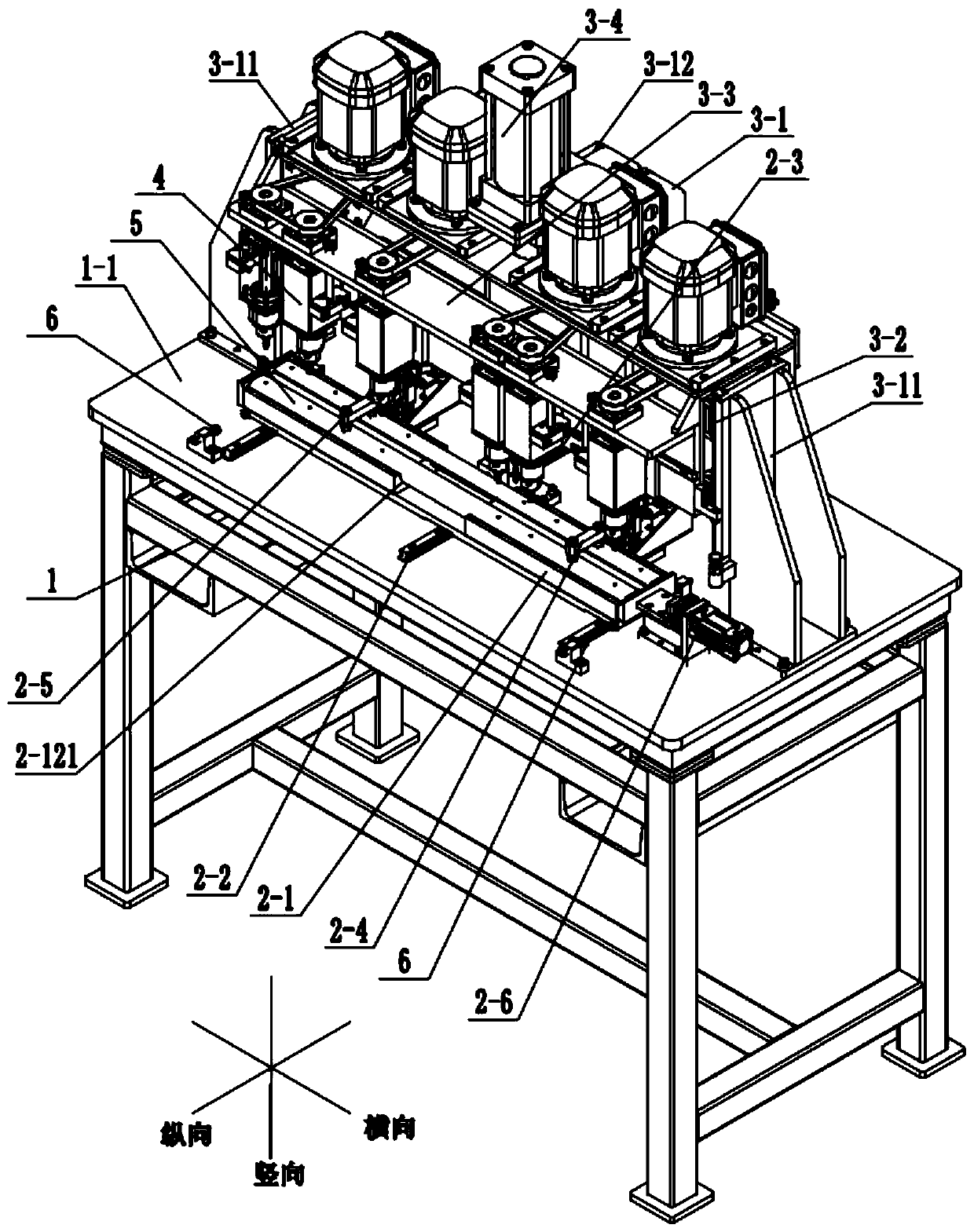

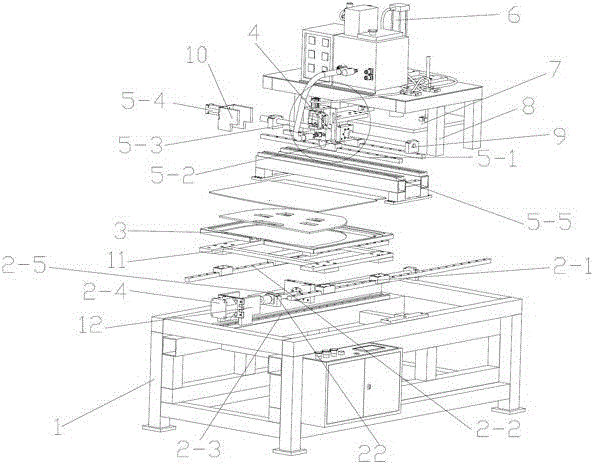

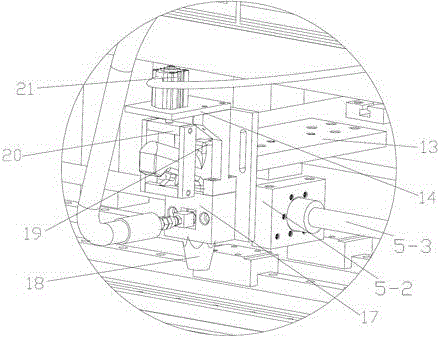

Multi-station automatic drilling equipment for aluminum alloy sections

InactiveCN111014769AIncrease productivityShort assist timePositioning apparatusMetal-working holdersLateral positionedEngineering

The invention discloses multi-station automatic drilling equipment for aluminum alloy sections. The equipment is characterized by comprising a rack (1), an aluminum alloy profile positioning clamp (2), a lifting mechanism (3) and a plurality of drilling machines (4), wherein the rack (1) is provided with a horizontal workbench (1-1), the aluminum alloy profile positioning clamp (2) comprises a positioning base (2-1), a longitudinal guide rail (2-2), a longitudinal air cylinder (2-3), a transverse positioning baffle (2-4), a first pressing mechanism (2-5) and a second pressing mechanism (2-6),the lifting mechanism (3) comprises a bracket (3-1), a vertical guide rail (3-2), a lifting seat (3-3) and a lifting driving cylinder (3-4), the drilling machines (4) are installed on the lifting base(3-3) and distributed side by side at intervals in the transverse direction. The equipment is advantaged in that multi-hole-site automatic drilling machining can be conducted on the two aluminum alloy sections, and working efficiency can be improved exponentially.

Owner:重庆新美鱼博洋铝业有限公司

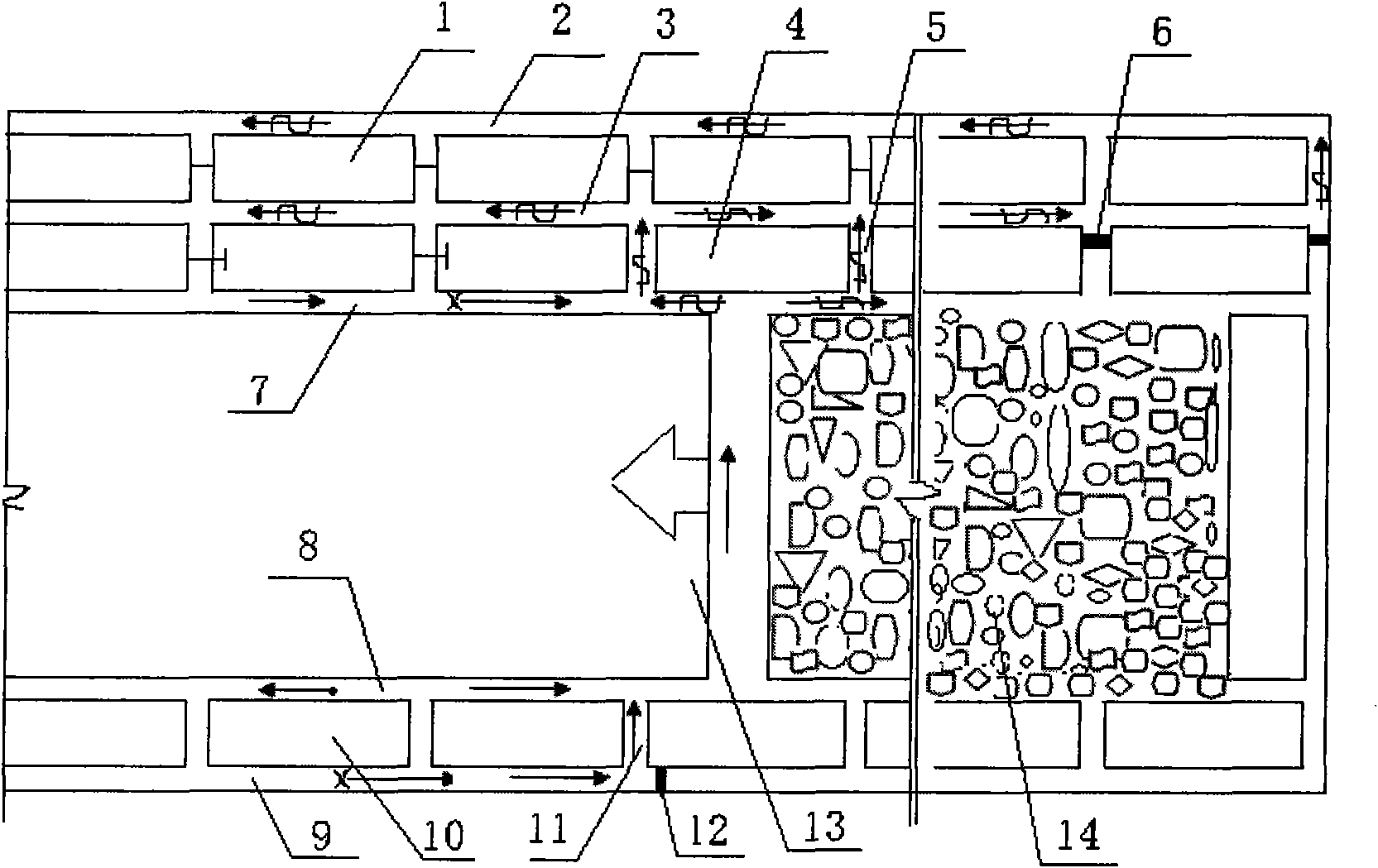

U+H type ventilation system

InactiveCN101871356ASuitable for miningLow ventilation resistanceTunnel/mines ventillationConventional ventilationAir volume

The invention relates to a ventilation arrangement system in coal mining, in particular to a U+H type ventilation system which is suitable for a highly gassy mine and solves a plurality of problems of the conventional ventilation system in the coal mine working face mining process. Five tunnels are arranged to form a working face tunnel, wherein three air inlet tunnels and two air return tunnels forms an U+H ventilation system. The invention has small ventilation resistance and large wind-crossing section, air volume and windblown mine gas capacity and is suitable for the mining of the highly gassy mine.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

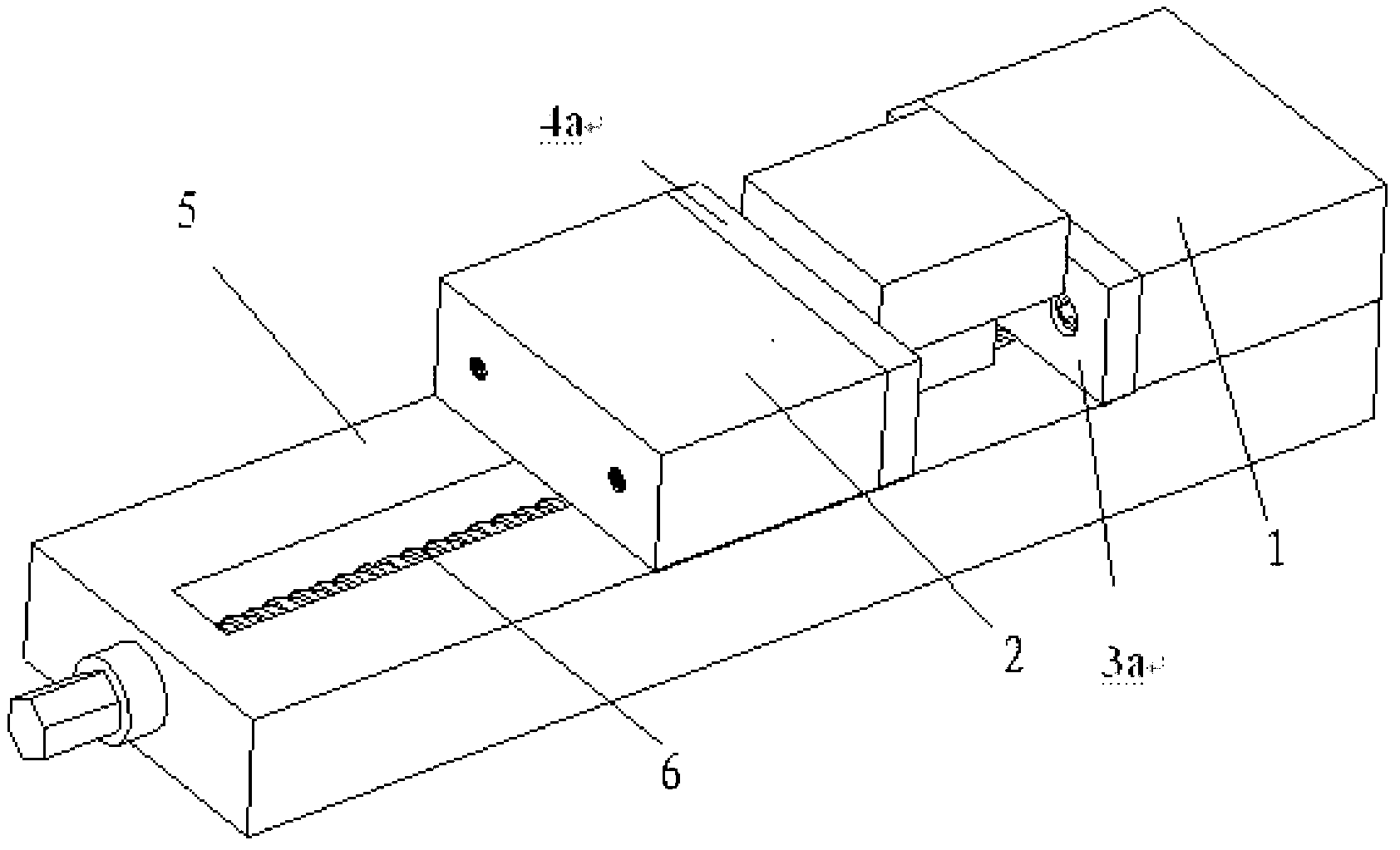

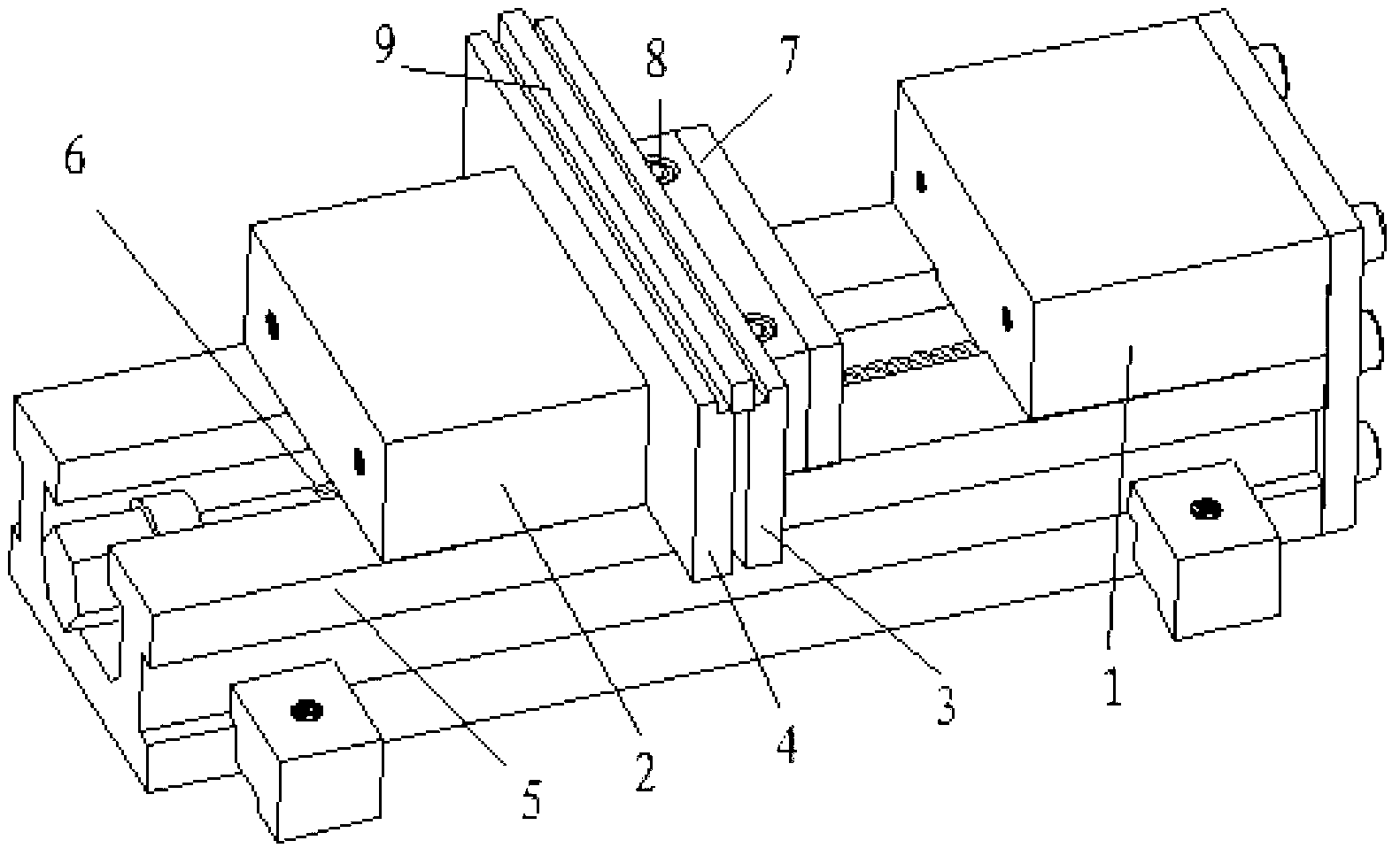

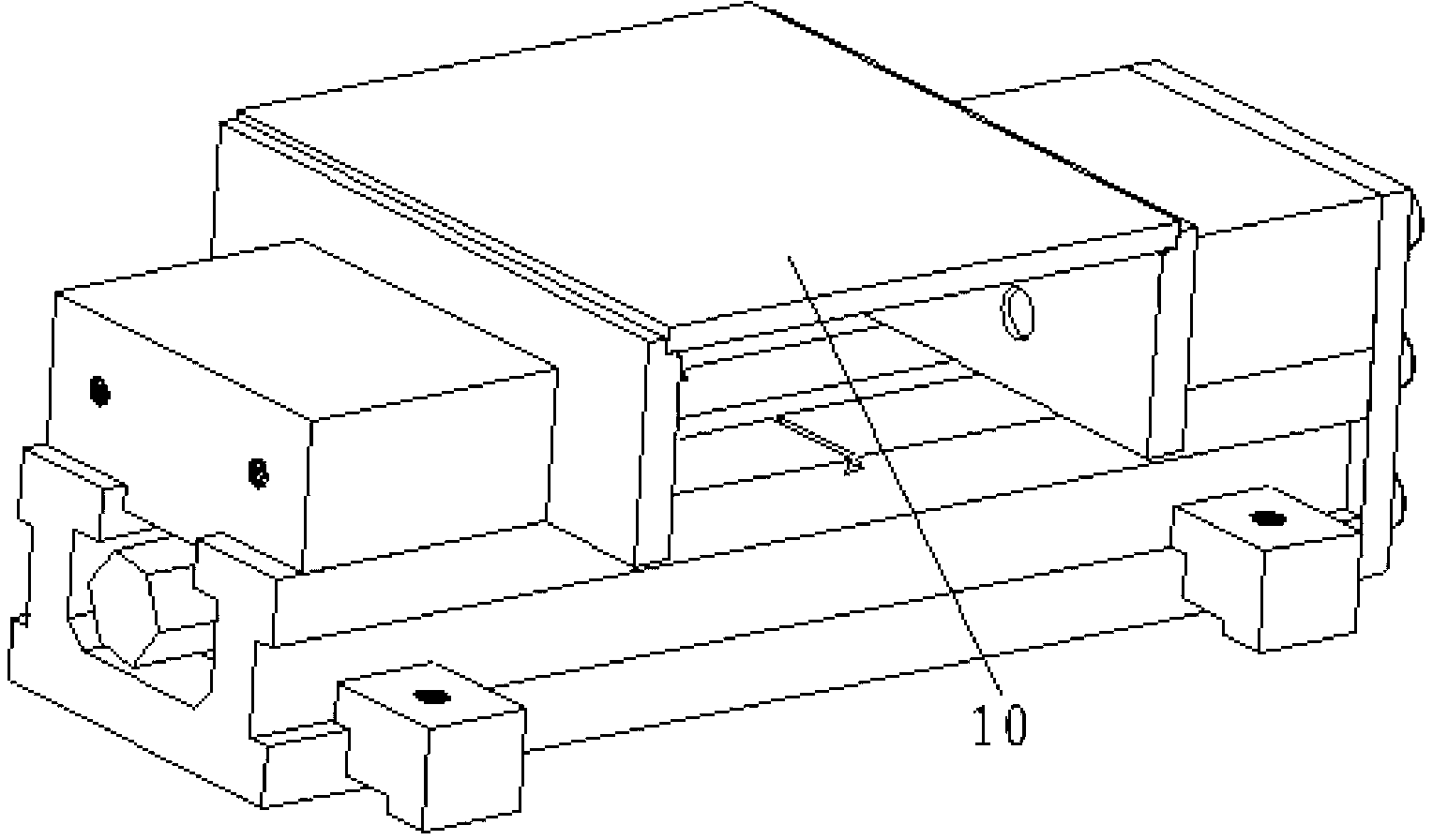

Flat tongs capable of clamping slender and thin-wall workpieces

InactiveCN103223602AAchieve clampingClamp firmlyPositioning apparatusMetal-working holdersEngineeringProcessing accuracy

The invention discloses a pair of flat tongs capable of clamping slender and thin-wall workpieces. The pair of flat tongs comprises a fixed jaw, a movable jaw, a fixed tong body, a second fixed jaw plate and a second movable jaw plate, wherein the movable jaw is slidingly connected with the fixed tong body through a screw rod, and can be pushed to move along the fixed tong body by the screw rod; the fixed jaw is connected with the fixed tong body in a fastening manner; the second fixed jaw plate and the second movable jaw plate are fixed on the fixed jaw and the movable jaw respectively through inner hexagon bolts; and at least two steps perpendicular to each other are arranged on the inner sides of the end parts of the second fixed jaw plate and the second movable jaw plate. According to the pair of flat tongs, at least two steps perpendicular to each other are arranged on the inner sides of the end parts of the second fixed jaw plate and the second movable jaw plate, so that the slender and thin-wall workpieces can be clamped by the combination of the steps, and the pair of flat tongs clamps stably and reliably, and is short in auxiliary time and high in processing accuracy.

Owner:SUZHOU VOCATIONAL UNIV

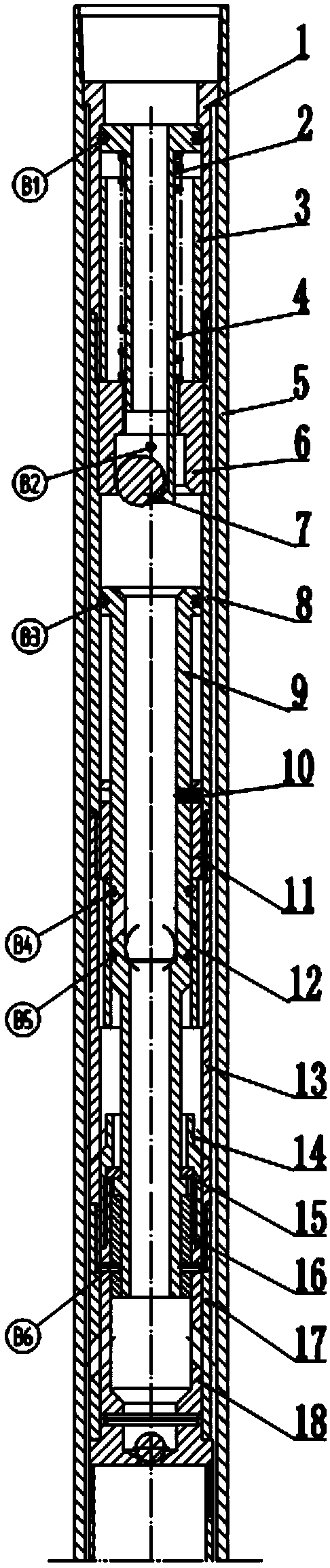

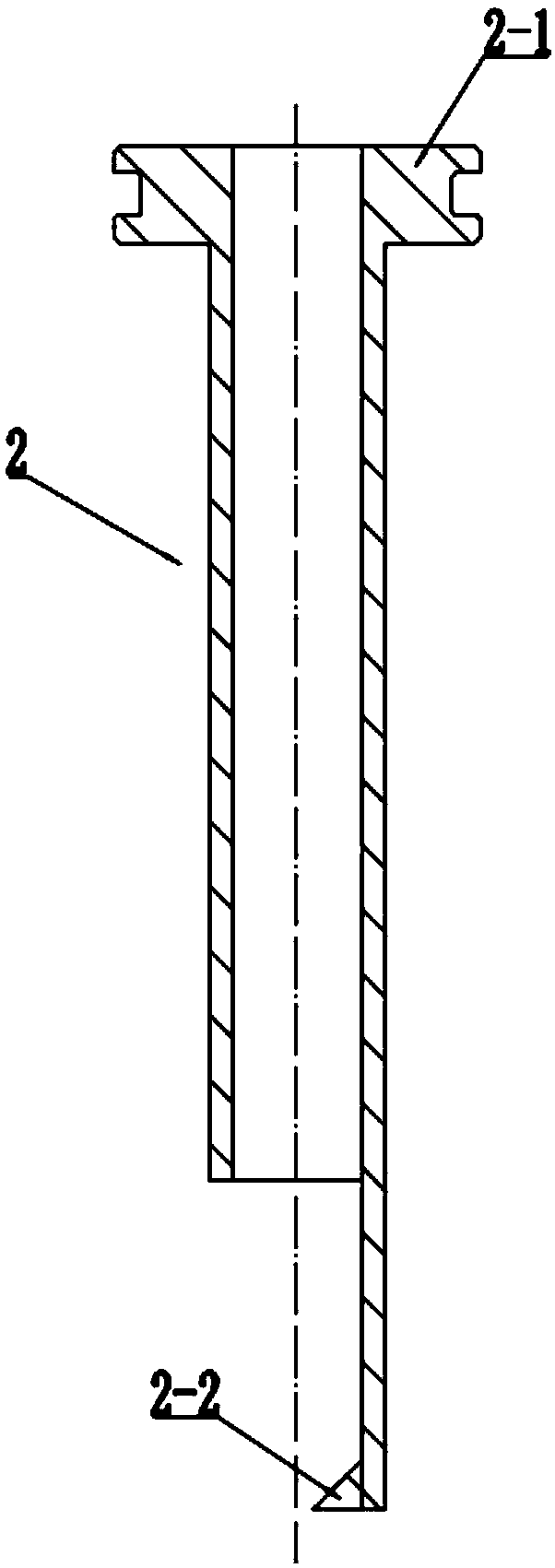

Hydraulic differential mechanism with built-in steel ball

PendingCN109025875AAvoid cumbersome workmanshipIncrease adoption rateCore removalPistonHollow cylinder

The invention provides a hydraulic differential mechanism with a built-in steel ball. The mechanism comprises a ball throwing part and a differential part. The ball throwing part is arranged on the differential part. A ball throwing piston cover, a ball throwing piston, a ball throwing piston limiting sleeve, a ball throwing spring, a steel ball chamber and a pressure building steel ball. The ballthrowing piston cover is embedded in the inner wall of the outer pipe of a rope wire line core driller. The ball throwing piston is arranged in the ball throwing piston cover and is of a hollow cylinder. A first pressure bearing disc is arranged on the upper end of the ball throwing piston and the lower end of the ball throwing piston passes through the steel ball chamber. An inward wedge-shapedboss is arranged at the bottom of the ball throwing piston. The ball throwing spring is assembled between the first pressure bearing disc and the steel ball chamber in a pre-compression manner. The ball throwing piston limiting sleeve sleeves the exterior of the ball throwing spring. According to the invention, by combining the way of internally arranging of the steel ball and the ball throwing pressure building, compulsory coring working is finished. The objectives of improving recovery factor and drilling-in and coring efficiency of complex stratums which are loosened, broken, poor in cementing properties, weak and easy to wawshout during drilling-in coring are achieved.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI

Automatic glue spraying and compounding machine for automobile trunk carpet production and production method

ActiveCN104527203BReduce meltingReduce the temperatureLaminationLamination apparatusEngineeringVertical displacement

The invention discloses an automatic glue spraying and compounding all-in-one machine and a manufacturing method for automobile trunk carpet production. A template of the automatic glue spraying and compounding all-in-one machine is moved by a horizontal sliding mechanism so that the purpose of horizontal displacement glue spraying of a polypropylene cellular board on the template can be achieved through a glue spraying device. The glue spraying device is moved by a vertical sliding mechanism so that the purpose of vertical displacement glue spraying of the polypropylene cellular board on the template can be achieved through the glue spraying device. Meanwhile, the glue sprayed polypropylene cellular board on the template is glued to a sound insulation felt. The glued sound insulation felt and the polypropylene cellular board on the template are quickly transferred to the position below a pressing plate by the horizontal sliding mechanism. The pressing plate is automatically activated and quickly pushed by a power unit so that further pressing, compounding and molding can be carried out on the glued sound insulation felt and the polypropylene cellular board. According to the automatic glue spraying and compounding all-in-one machine and the manufacturing method for the automobile trunk carpet production, the compounding fastness and the production efficiency of an automobile trunk carpet are improved, and the compounded and molded automobile trunk carpet is good in operation performance.

Owner:NINGBO SUNLIGHT MOTOR PARTS

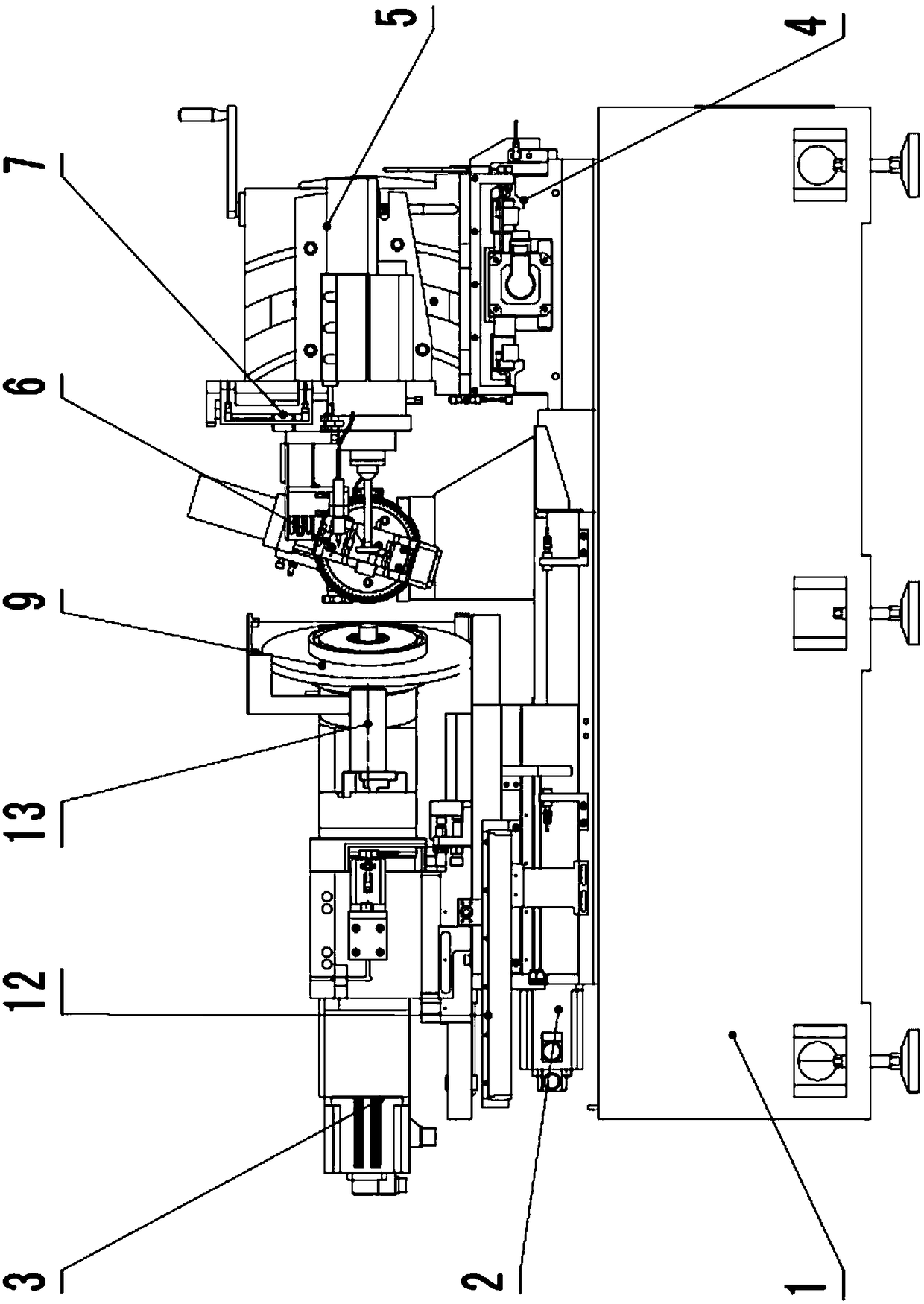

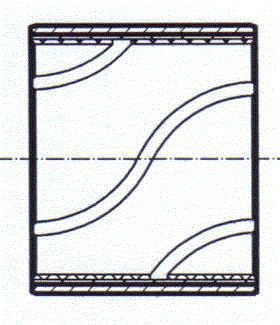

Composite grinding device of ball screw nuts

ActiveCN109227249AReduce installation concentricity errorIncrease productivityGrinding carriagesThread cutting machinesGratingBall screw

The invention discloses a composite grinding device of ball screw nuts. The composite grinding device comprises a lathe bed, a workpiece drive unit, an outer diameter end face grinding wheel dressingunit, an outer diameter end face grinding wheel shaft unit, an inner thread grinding wheel shaft unit, a measuring unit, a workpiece rotary circular grating and a workpiece carriage linear grating. Aworkpiece carriage unit, an outer diameter end face grinding wheel shaft carriage unit, an inner thread grinding wheel shaft carriage unit and an inner thread grinding wheel dressing unit are arrangedon the lathe bed. The measuring unit is arranged on the inner thread grinding wheel shaft unit. The workpiece rotary circular grating is arranged at the front end of the workpiece drive unit. The workpiece carriage linear grating is arranged at the front end of the workpiece carriage unit. The composite grinding device is simple in structure and convenient to operate, inner thread grinding and outer diameter grinding of the ball screw nuts are integrated, all auxiliary time in the machining process can be shortened to be minimal, the mounting coaxiality errors of the outer diameters and innerthreads of the ball screw nuts are greatly reduced, the production efficiency of the lathe bed is greatly improved, and the production cost can be greatly reduced.

Owner:上海莱必泰数控机床股份有限公司

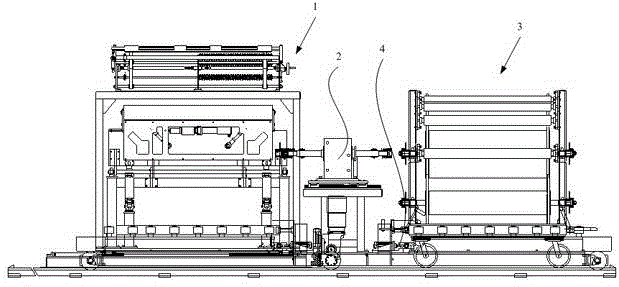

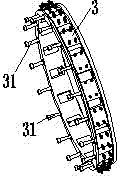

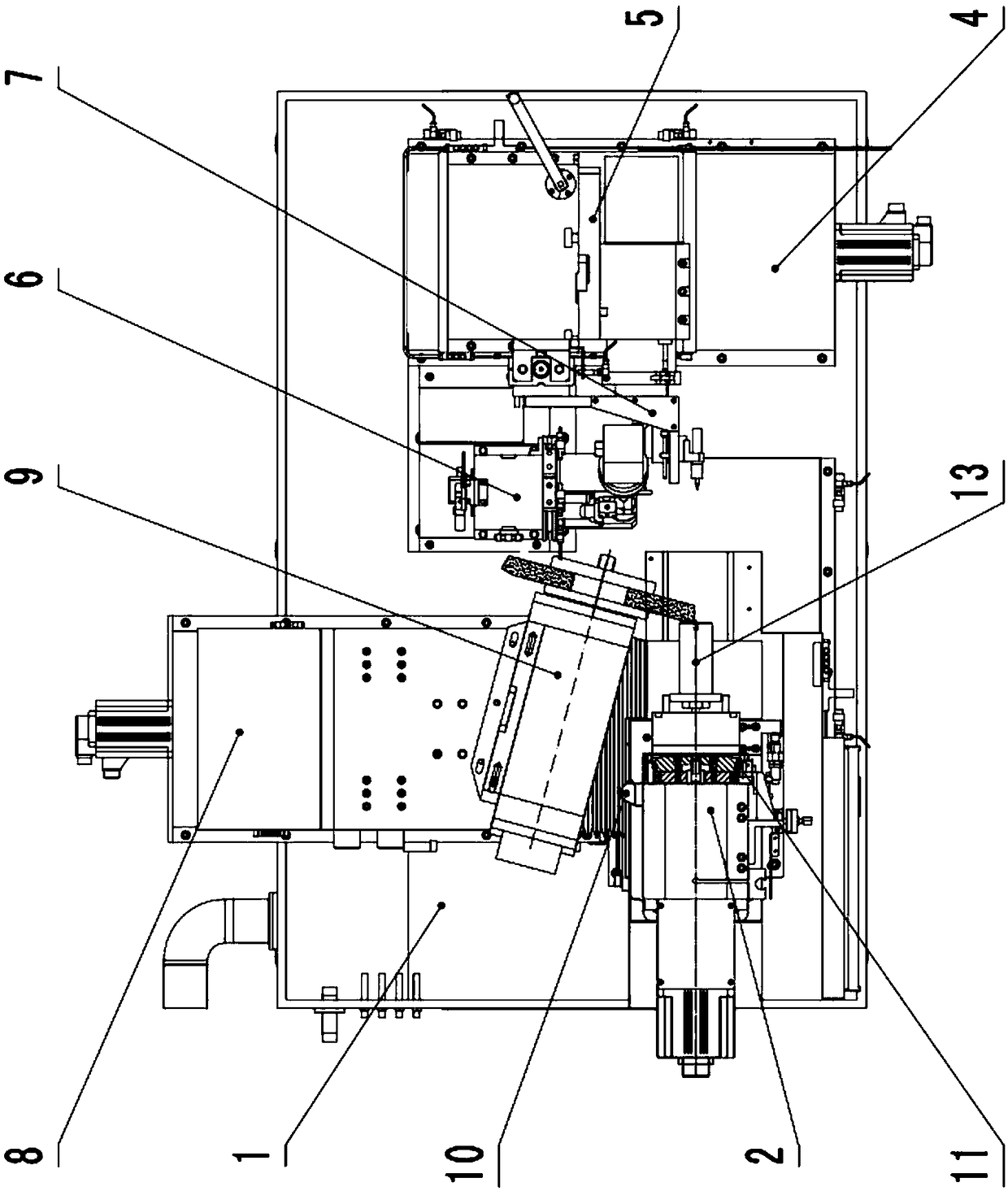

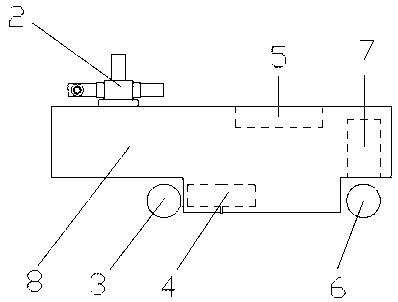

Bead fabric supply frame of forming machine

ActiveCN102862858AReduce stretchQuality improvementArticle deliveryWebs handlingSize changeEngineering

The invention discloses a bead fabric supply frame of a forming machine. The bead fabric supply frame comprises a bead fabric guiding and opening device, a rear supply mechanical edge positioning device, a rear supply conveying device, a cutting device and a feeding conveying device which are arranged sequentially, the rear supply feeding device comprises a frame, a transmission and a conveying belt, the transmission is fixedly arranged on one side of the frame, and the conveying belt is disposed on the frame, is driven by the transmission and is used for forwardly conveying bead fabrics. Bead fabrics are automatically guided to be opened by the bead fabric supply frame at first, and then are automatically conveyed, rubber is automatically cut off according to the requirement on length, and finally automatically fit to a rubber drum, required auxiliary time is short, and labor intensity of workers is reduced. Besides, various steps are carried out synchronously, a supply process is reliable in coordination and high in precision, stretching of the bead fabrics is greatly reduced, fitting quality of the bead fabrics is improved, the bead fabric supply frame is adjusted conveniently and quickly during size change, the bead fabrics are fed into a rear supply frame after being guided to be opened, and fitting precision of the bead fabrics is guaranteed due to the fact that a mechanical centering device is arranged in front of the rear supply frame.

Owner:TIANJIN SAIXIANG TECH

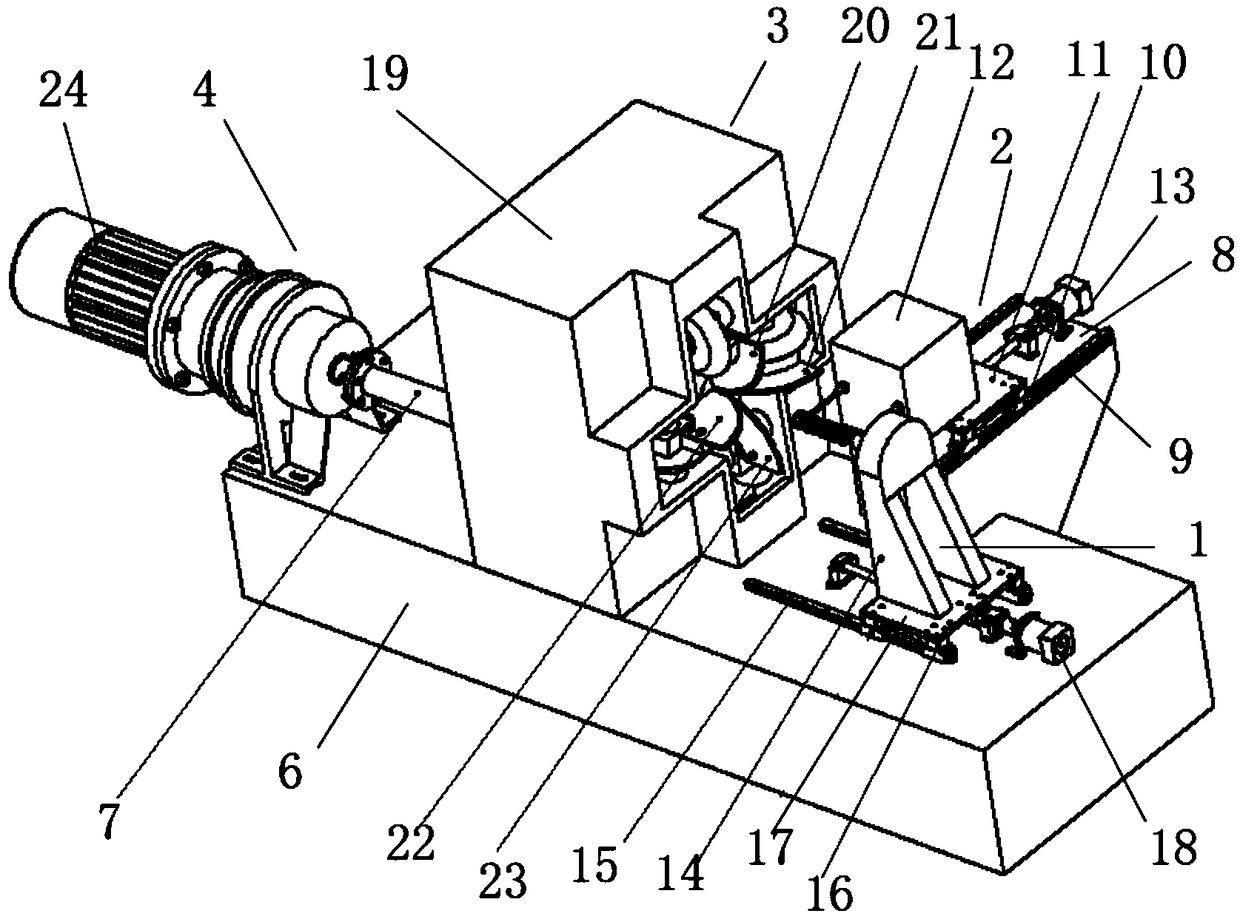

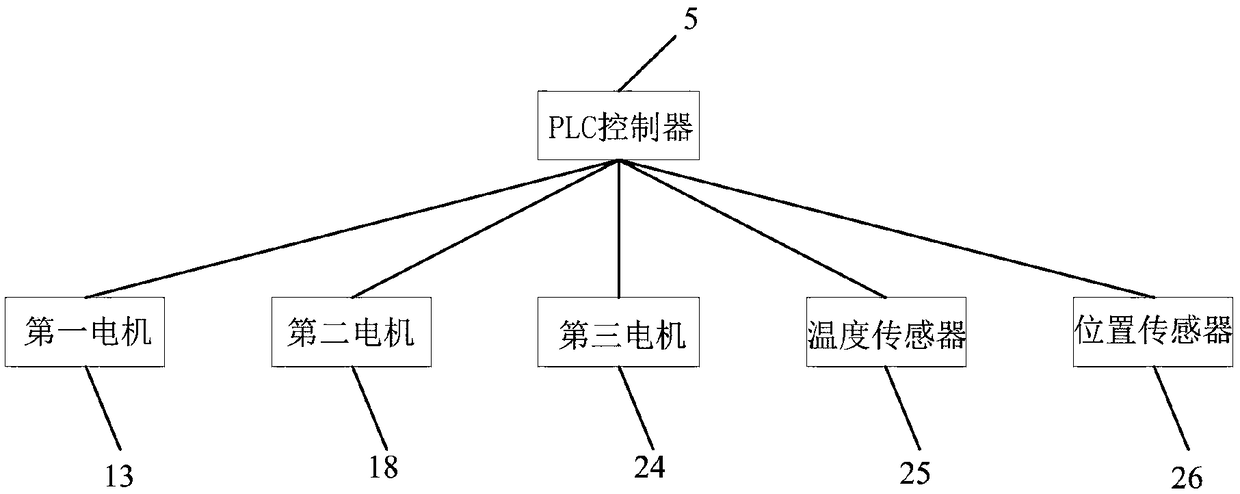

Device for processing straight groove tap groove and processing method of device

PendingCN108637162AEasy to controlImprove work efficiencyMetal-working apparatusDrive shaftComputer engineering

The invention discloses a device for processing a straight groove tap groove. The device for processing the straight groove tap groove comprises a feeding device, a heating device, a processing device, a driving device and a PLC. The driving device, the processing device and the feeding device are all installed on a base and positioned on the same horizontal line. The heating device is installed on the base through a bracket. The top end of the heating device and the top end of a conveying device are positioned on the same horizontal line. The conveying device is positioned in front of the processing device and can move along a guide rail to convey a tap into the processing device. The driving device is arranged on the rear side of the processing device. The driving device is connected with the processing device through a driving shaft. The feeding device, the heating device, the processing device and the driving device are all connected with the PLC. The device solves the problems ofsingle process and low processing efficiency of existing processing of the tap groove.

Owner:辽宁科莱电力工程技术有限公司

Ventilating system arranged in U+H shape under coal mine

ActiveCN101718208BSuitable for miningLow ventilation resistanceTunnel/mines ventillationCoalH shaped

The invention relates to a ventilating system arranged in U+H shape under the coal mine, in particular to a ventilating systems arranged in U+H shape under the high methane coal mine, aiming at solving the problem of the ventilating system in the process of stoping the face of the coal mine. The ventilating system comprises a stoping face. One side of the stoping face is provided with a belt conveying and air intaking way and an auxiliary conveying and air intaking way in sequence, and the other side is provided with an auxiliary conveying and air intaking way, a first air returning way and asecond air returning way in sequence. The belt conveying and air intaking way and the two auxiliary conveying and air intaking ways intake air and return air after being communicated with the first air returning way and the second air returning way through a channel arranged in front of the stoping face. Therefore, the ventilating system which is arranged in U+H shape and intakes air for three times and returns air for two times is formed.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

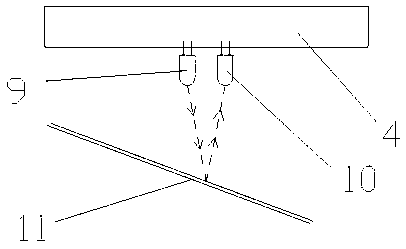

Automatic tracking flame cutting machine

The invention relates to an automatic tracking flame cutting machine. The automatic tracking flame cutting machine is composed of a cutting nozzle, a cutting torch frame, a universal wheel, a trackingmodule, a driving module, driving wheels, direct current motors, a vehicle body, an infrared emitting tube and an infrared receiving tube. The automatic tracking flame cutting machine is compact in structure, small in size, convenient to carry, convenient to operate, safe to use, short in required auxiliary time, and free of use of rails; and the cutting machine can move along any drawn white line on a metal plate or the flat ground, the movement is stable and accurate, and the turning is smooth.

Owner:哈尔滨市黎明锅炉容器封头有限公司

A multifunctional machine tool

InactiveCN104400564BNo lift timeNo repetition step upLarge fixed membersPositioning apparatusComputer moduleLinear motor

The invention relates to a multifunctional machine tool, and is applied to a machining process. The multifunctional machine tool comprises a bracket, and is characterized in that multiple through pits are formed in the two sides of a machine body, wherein a main shaft bracket is arranged at the outer sides of the pits; a guide rail is arranged on the main shaft bracket; detachable main shaft cutter modules accessing along the pits are arranged in the guide rail; a driving device for driving workpieces to move along X, Y and Z axles is arranged at the upper part of the machine body; the lower part of the driving device is connected with a workpiece fixture through a double-rotation clamping mechanism; the double-rotation clamping mechanism drives the workpieces to rotate along a horizontal shaft and a vertical shaft; and two material dischargers are arranged between a machining area and an operation area of the machine body. The multifunctional machine tool has the following beneficial effects: as a tool changing space is increased, multiple pits and multiple main shafts are arranged, and the double-linear motor driving is performed along the X, Y and Z axles, no tool changing time, no lifting time of main shafts and no repeated clamping of the workpieces can be realized, the assisting time is short, the machining of multiple surfaces is finished once, and the processing efficiency and the processing precision are improved.

Owner:SHANDONG NEW ANKAI KITCO SCI&TECH

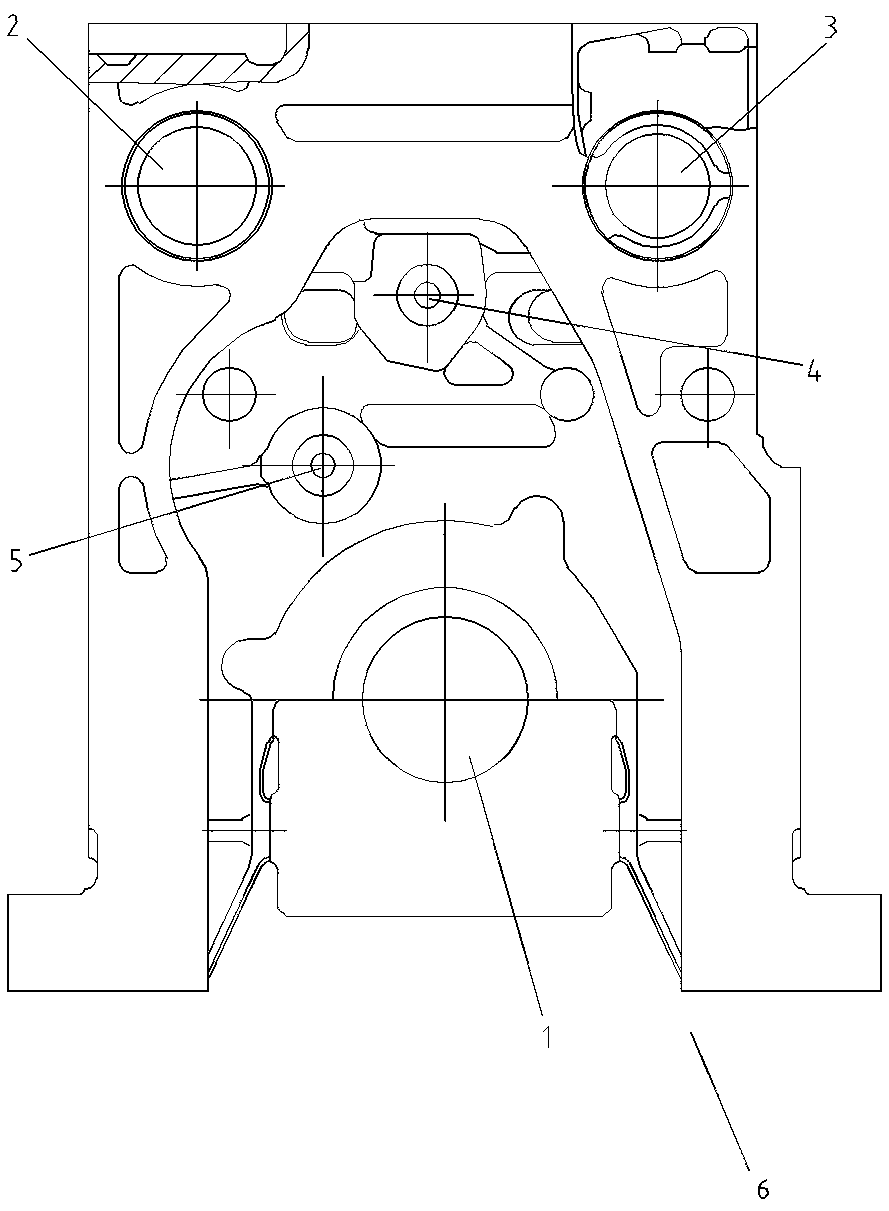

Machining Method of Drive Gear Hole System for Medium Speed Diesel Engine Frame

ActiveCN110293239BShort assist timeImprove work efficiencyBoring/drilling machinesGear wheelDieseling

The invention discloses a medium-speed diesel engine frame transmission gear hole system machining method. The method comprises the following steps that (1) the bottom face of a diesel engine frame ismade to face upwards, and all gears of main bearing holes are machined through a first special accessory; (2) the top face of the diesel engine frame is made to face upwards, and all gears of oil injection camshaft holes are machined through a second special accessory; (3) all gears of air exhaust cam shaft holes are machined through the second special accessory; (4) actual position coordinates of the oil injection camshaft holes and the air exhaust cam shaft holes are found through a third special accessory, the coordinate value of a transition gear is worked out, and a transition gear holeis machined through the third special accessory; and (5) the transition gear hole and the main bearing holes serve as the criterion, the coordinate value of an intermediate gear hole is worked out, and the intermediate gear hole is machined through the third special accessory. According to the medium-speed diesel engine frame transmission gear hole system machining method, the auxiliary time is short, the working efficiency is high, the labor intensity is low, in addition, the accumulative error of clamping and aligning is small, the machining error is small, the positioning dimension precision between the holes is ensured, and accordingly, the product machining quality is ensured.

Owner:CSSC MARINE POWER

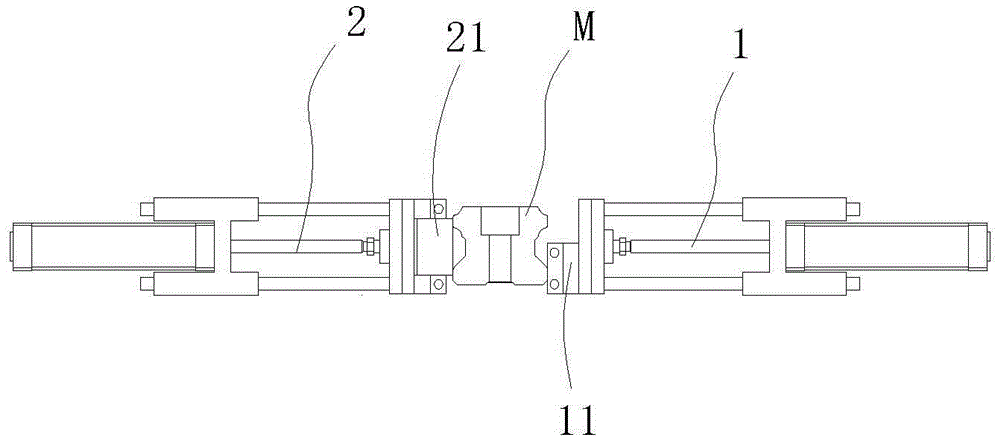

Method and device for installation and correction of linear rolling guide rail of grinding machine

ActiveCN103934749BEasy to operateShort assist timeGrinding carriagesGrinding feed controlEngineeringInstallation Error

The invention discloses a method and device for installing and correcting a grinder linear rolling guide rail. The device comprises a pressing cylinder and a standard cylinder. The pressing cylinder and the standard cylinder are arranged on a left grinding wheel spindle and a right grinding wheel spindle of a grinder respectively. A locating block of the standard cylinder abuts against the standard side face of the guide rail, a roller of the pressing cylinder on the other side tightly presses the other side face of the guide rail, a workpiece correcting device is moved, if certain deviation of the installing direction of the linear guide rail exists, the guide rail can be slightly moved to correct installation errors in the moving process, after the first time of moving and attraction force of a magnetic work table is increased, the second time of moving is executed to further correct the position of a workpiece, and therefore the standard side face of the linear guide rail is parallel to the longitudinal moving direction of the work table. The correcting device is used for correcting the standard side face of the linear guide rail to be parallel to the longitudinal moving direction of the work table, and the device has the advantages of being simple in operation, short in auxiliary time, high in correction precision, and the like.

Owner:安徽省安达兴智能装备有限公司

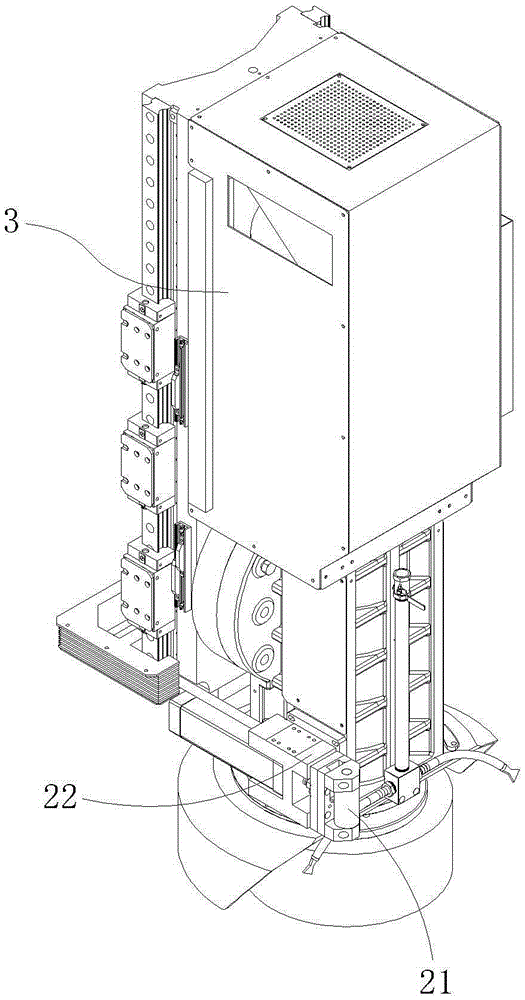

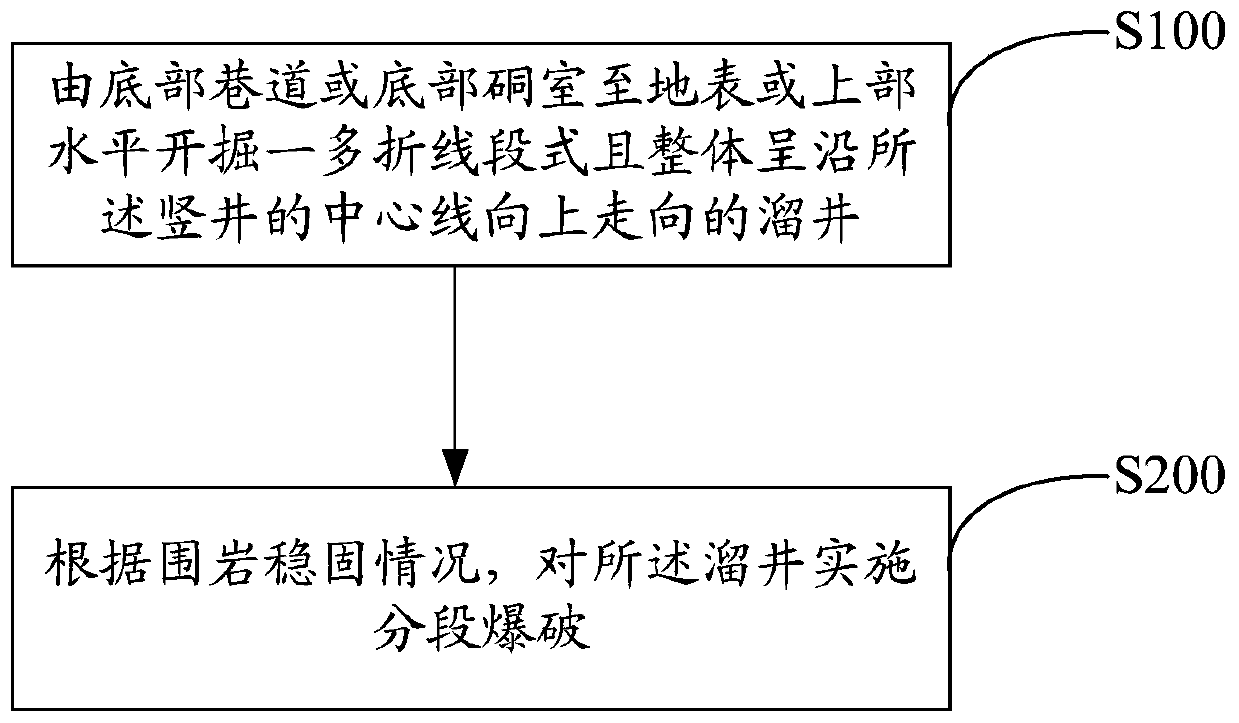

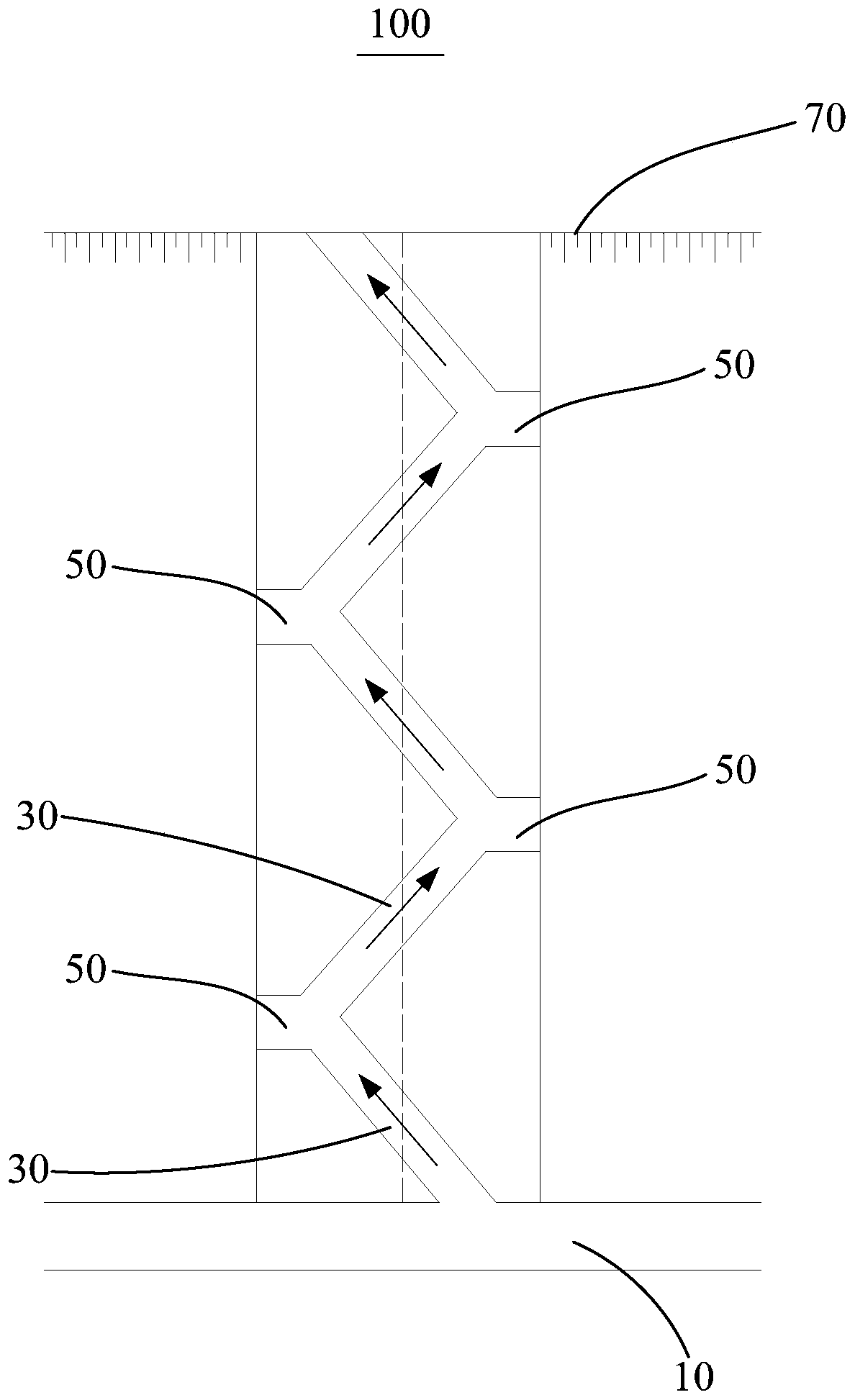

Shaft construction method and construction structure

Owner:湖北三宁矿业有限公司

Indexing regulating device

InactiveCN104175177ACompact structureHigh precisionPrecision positioning equipmentEngineeringMachine tool

The invention discloses an indexing regulating device which comprises an index plate, a spindle, a body, a machine table, a collet chuck, a pull rod and a hand wheel, wherein the index plate is connected with the spindle through a nut, the spindle is connected with the body which is connected with the machine table through a bolt, the collet chuck is matched and connected with the spindle and connected with the pull rod, and the pull rod is equipped with the hand wheel. With the adoption of the scheme, the indexing regulating device is simple and compact in structure and high in accuracy and processing efficiency, and needs short auxiliary time.

Owner:WUXI TIANHONG MACHINERY MFG

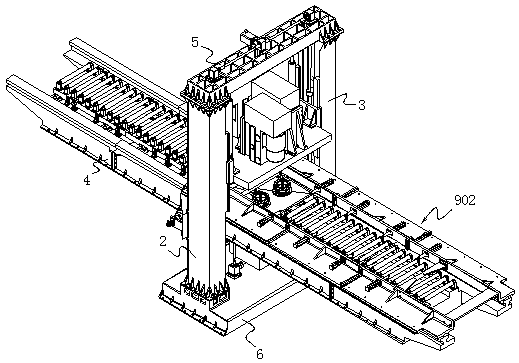

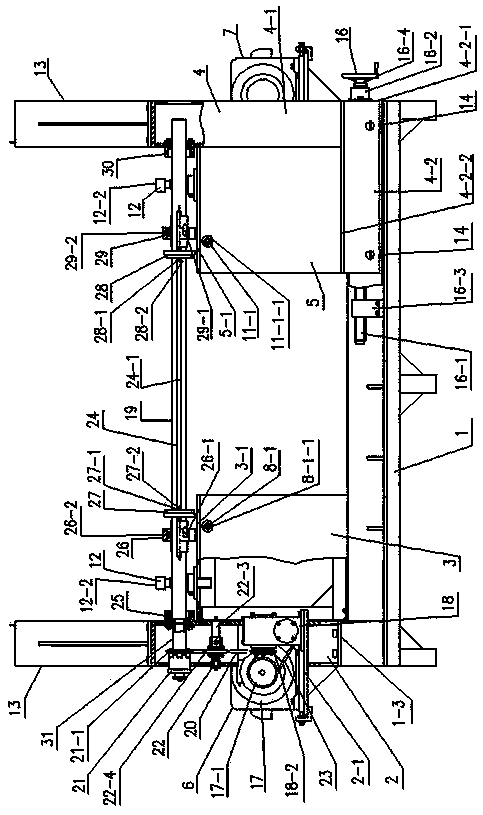

Vertical double-sided milling machine of gantry

InactiveCN102500801BShort assist timeImprove efficiencyMilling machinesLarge fixed membersMilling cutterReciprocating motion

The invention relates to a vertical double-sided milling machine of a gantry, which comprises a gantry frame (1) and a milling machine body (4) which is fixed on the gantry frame (1), wherein an upper milling mechanism (7) and a lower milling mechanism (8) for milling workpieces are arranged above and below the milling machine body (4) respectively; the milling machine body (4) is also provided with a work bench (902) which is used for machining the workpieces and can be driven by a work bench drive mechanism (9) on the gantry frame (1) to move forwards and backwards in a reciprocating manner; the gantry frame (1) is also provided with an upper milling drive mechanism capable of driving the upper milling mechanism (7), an upper milling support mechanism for supporting the upper milling drive mechanism, a lower milling drive mechanism capable of driving the lower milling mechanism (8), and a lower milling support mechanism for supporting the lower milling drive mechanism. The vertical double-sided milling machine for the gantry has the advantages that: two large surfaces of a large panel can be machined simultaneously; each surface is milled by three milling cutters, so that one surface can be milled at a time; and the vertical double-sided milling machine of the gantry is high in efficiency.

Owner:WUHAN UNIV

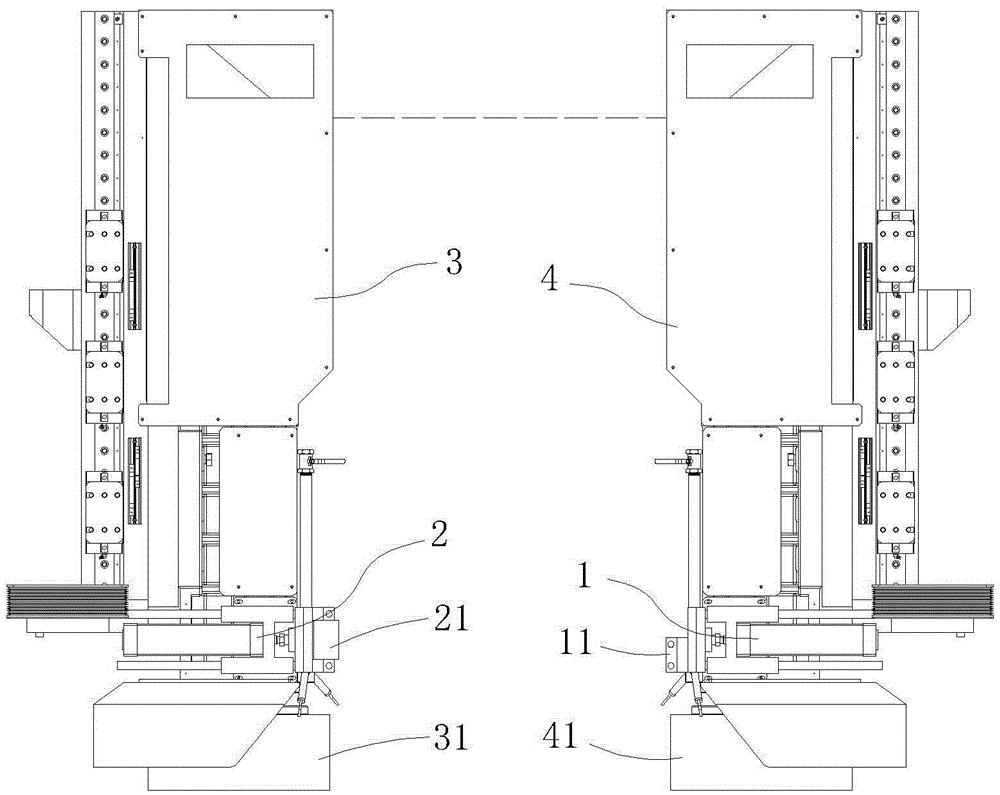

Three-dimensional wound core dry-type transformer high-voltage coil double-position winding machine

ActiveCN105006361BImprove winding efficiencyShort assist timeCoils manufactureWinding machineLow voltage

Provided is a double-station winding machine for a high-tension coil of a three-dimensional wound core dry type transformer. The winding machine comprises a base, a left wallboard, a left rack, a right wallboard, a right rack, a winding power device on the left wallboard, a left riding wheel supporting plate mechanism on the left rack, a right riding wheel supporting plate mechanism on the left rack, a winding power device on the right wallboard, a left riding wheel supporting plate mechanism on the right rack, a right riding wheel supporting plate mechanism on the right rack, an iron core support frame, and an iron core turnover support. Since the winding machine has two sets of independent winding power devices, the machine can wind two phases of coils of a transformer. Since positions of the right wallboard can be moved, the machine is suitable for installation of iron cores of transformers in different sizes. Since the main shaft of the main shaft mechanism of the winding power device can move parallelly, cooperation of a left gear and a right gear on the main shaft and riding wheels which are on the right rack and are corresponding to the left gear and the right gear is convenient and reliable, and a gap between a low-voltage inner wall of a transformer winding former and a core limb in rotation can be easily ensured. The device is simple in structure, convenient in operation, high in winding efficiency, and is safe and practical.

Owner:JIANGXI HANS POWER TECH

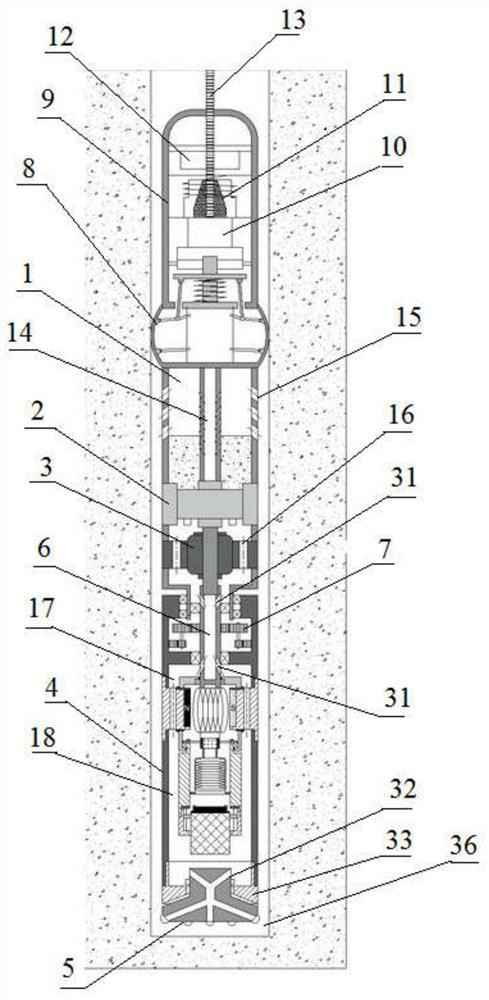

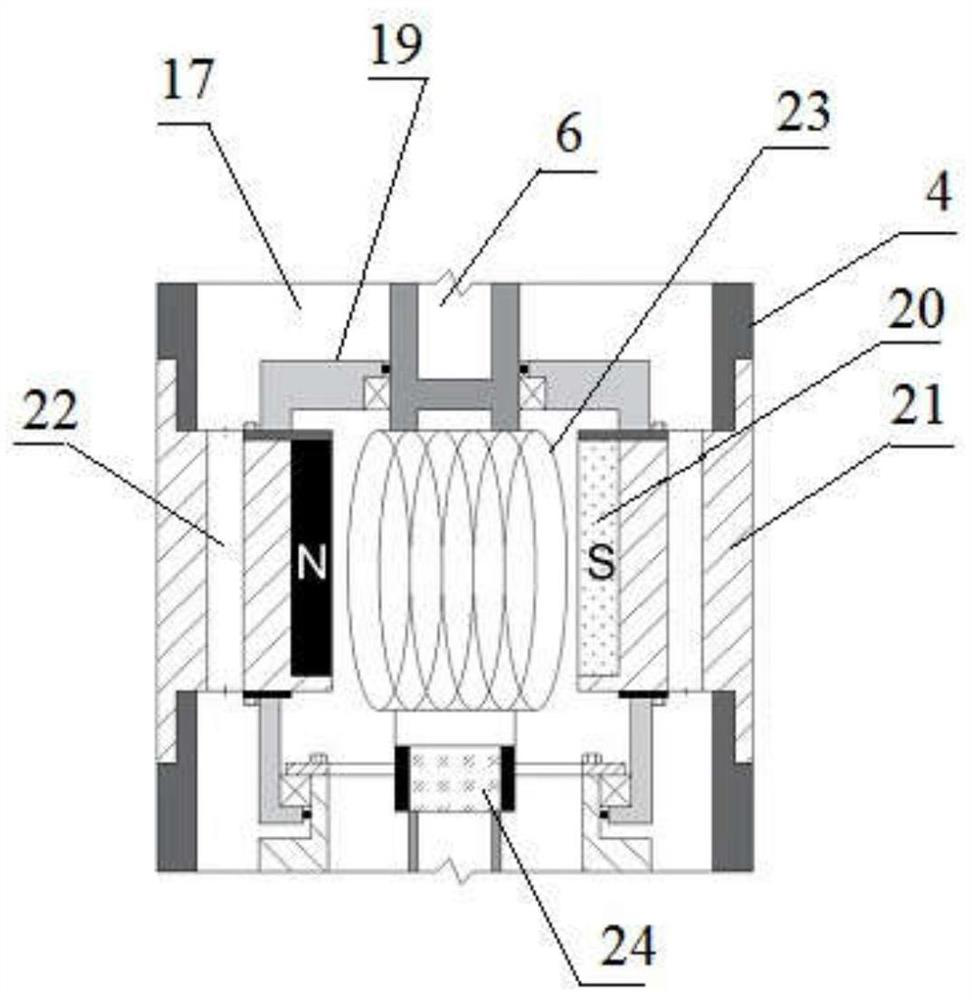

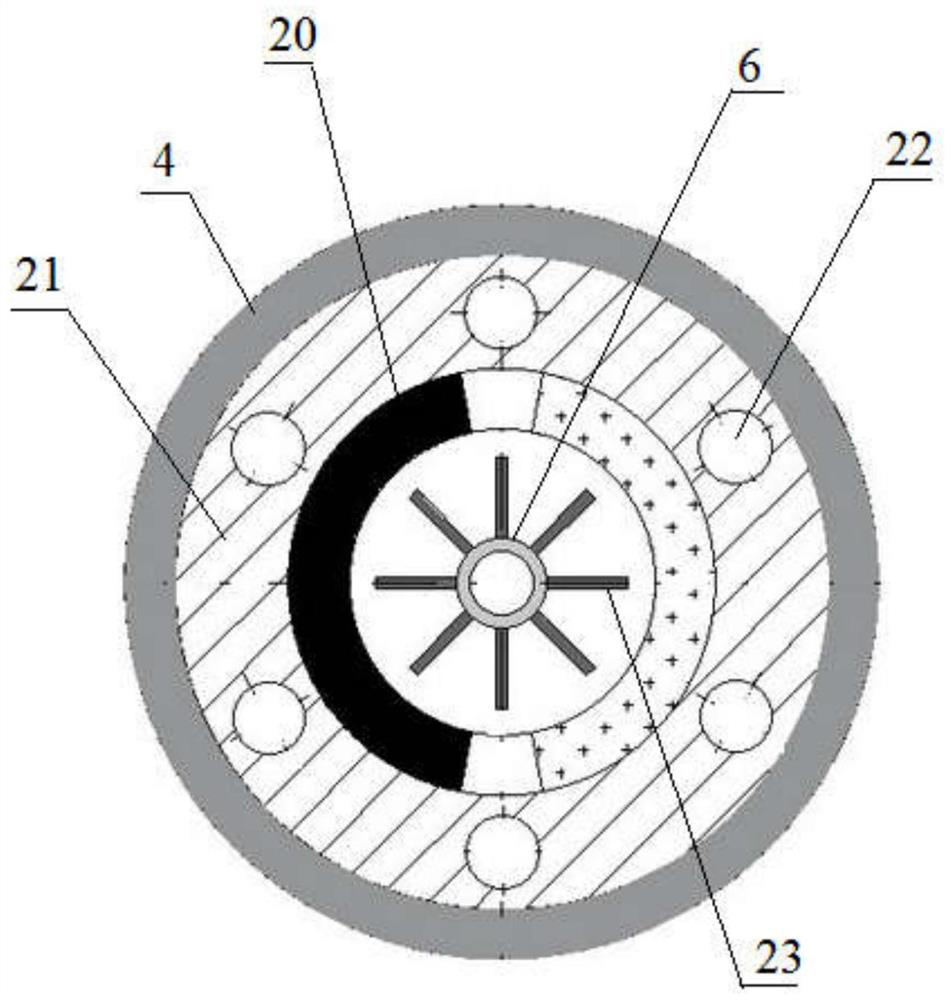

An armored cable electromagnetic percussion rotary drilling tool for bedrock under polar ice

ActiveCN113565433BMake up for the disadvantage of not being able to drill into rock formationsNot easy to damageEarth drilling toolsIce drillingReduction driveDrive shaft

The invention discloses an armored cable type electromagnetic impact rotary drilling tool for polar subglacial bedrock, which includes a cuttings chamber, a water pump, a driving motor, an electromagnetic impact system, an outer pipe of the drilling tool and a drill bit, wherein the cuttings chamber is assembled on On the upper part of the water pump, the liquid outlet of the cuttings chamber is set corresponding to the liquid inlet of the water pump. The driving motor is arranged at the lower part of the water pump. The bottom is connected with the electromagnetic impact system, and the electromagnetic impact system is driven by the hollow shaft to work. Both the hollow shaft and the electromagnetic impact system are assembled in the inner cavity of the outer tube of the drilling tool, and the hollow shaft and the outer tube of the drilling tool are connected through a reducer , the bottom of the outer tube of the drilling tool is connected to the drill bit, beneficial effects: the electromagnetic impact system is added, which effectively makes up for the shortcomings of the traditional armored cable-type electric mechanical drilling tool that cannot drill into the rock formation due to insufficient drilling pressure and torque, and reduces the risk of broken rock difficulty.

Owner:JILIN UNIV

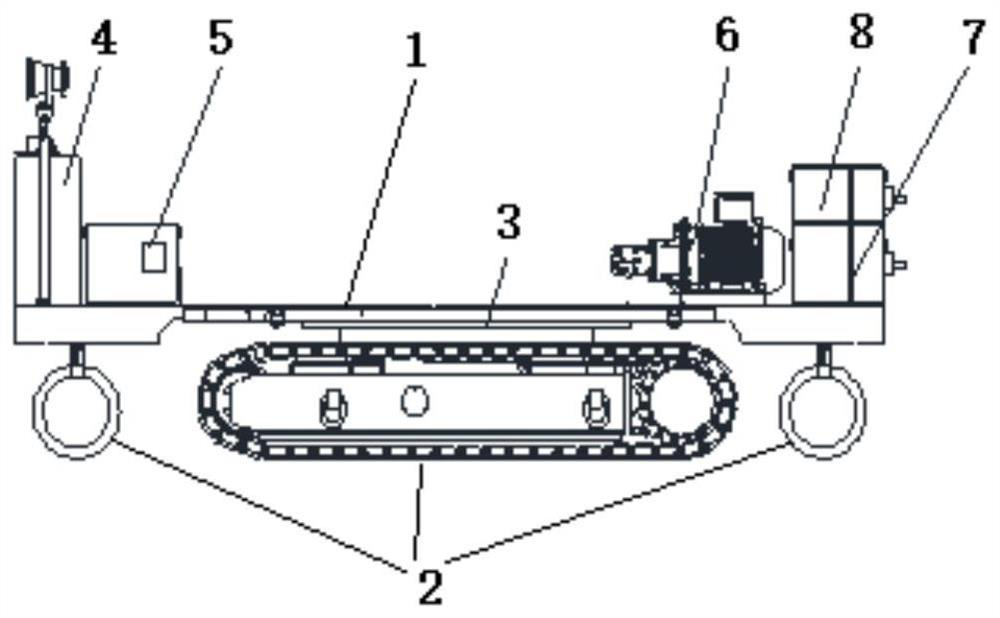

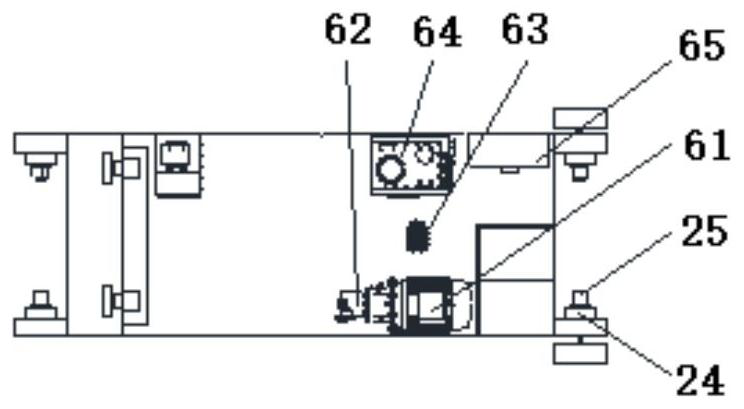

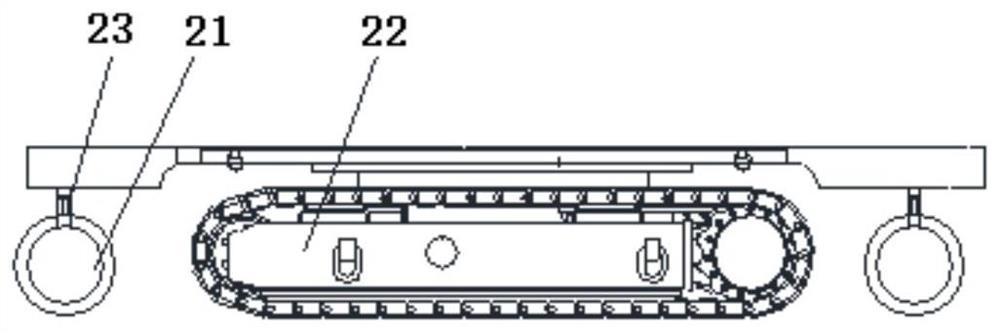

Coal mine underground autonomous mobile platform and method capable of realizing remote interaction

ActiveCN112849283BImprove operational efficiencyFast shippingProgramme controlComputer controlDecision controlControl engineering

The invention discloses a coal mine underground autonomous mobile platform capable of realizing remote interaction and a method thereof, including a car body platform, a slewing support, a transmission device, a main power box, an auxiliary power box, a walking drive device, an intelligent control system, a detection device, and a detection device Obtain multi-source information data such as coal mine roadway environment images, obstacle information, and platform operating parameters, and transmit them to the intelligent control system. The intelligent control system performs calculation and analysis based on the obtained information, and independently decides to select the appropriate operating mode and optimize the working path or operator. Carry out long-distance interactive control, and transmit the precise position, operation mode and optimized path of the autonomous mobile platform to the walking drive device. The invention has high operating efficiency, wide adaptability to construction equipment, remote interaction or independent decision-making control, high-precision autonomous navigation of the platform, unmanned transportation process, short auxiliary time, and can replace manual work to complete the autonomous obstacle-avoiding movement of construction equipment and materials and long-distance transportation.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Faceplate Tooling for Machine Base Finishing

ActiveCN105058129BGuaranteed parallelismIncreased direct benefitsTool holdersPositioning apparatusEngineeringMachine

Owner:HANGZHOU JIANGCHAO ELECTRICAL MACHINERY

Automatic feeding plate slot milling machine with magnetic sucking cup

ActiveCN104139201ALow technical requirementsReduce labor intensityMilling equipment detailsMilling cutterEngineering

The invention discloses an automatic feeding plate slot milling machine with a magnetic sucking cup. The automatic feeding plate slot milling machine comprises a machine frame, and the machine frame is fixedly connected with a deck plate. The automatic feeding plate slot milling machine with the magnetic sucking cup is characterized in that the left end and the right end of the deck plate are respectively and fixedly connected with a slide rail base, the slide rail bases are fixedly connected with two parallel slide rails of the same height, each slide rail is sleeved with a bearing pedestal, a sliding bearing is fixed in each bearing pedestal, an upper plate is fixed on the bearing pedestals, an adjusting panel is fixed on the upper plate, a plane electromagnetic sucking cup is fixed on the adjusting panel, the electromagnetic sucking cup is connected with a piston rod of an oil cylinder at one end of the corresponding bearing pedestal, the piston rod is telescopic to drive the electromagnetic sucking cup to move left and right, the front side and the rear side of the electromagnetic sucking cup on the deck plate are respectively and fixedly connected with a cutter base, a cutter shaft is mounted between the two cutter bases, saw blade milling cutters are mounted on the cutter shaft above the electromagnetic sucking cup, one end of the cutter shaft is driven by a motor to rotate, and the milling cutters conduct groove milling on plates which are attracted on the electromagnetic sucking cup. The production efficiency is 5-8 times the efficiency for turning oil storage grooves in a lathe originally.

Owner:ZHEJIANG SF OILLESS BEARING

Bead fabric supply frame of forming machine

ActiveCN102862858BReduce stretchQuality improvementArticle deliveryWebs handlingSize changeEngineering

The invention discloses a bead fabric supply frame of a forming machine. The bead fabric supply frame comprises a bead fabric guiding and opening device, a rear supply mechanical edge positioning device, a rear supply conveying device, a cutting device and a feeding conveying device which are arranged sequentially, the rear supply feeding device comprises a frame, a transmission and a conveying belt, the transmission is fixedly arranged on one side of the frame, and the conveying belt is disposed on the frame, is driven by the transmission and is used for forwardly conveying bead fabrics. Bead fabrics are automatically guided to be opened by the bead fabric supply frame at first, and then are automatically conveyed, rubber is automatically cut off according to the requirement on length, and finally automatically fit to a rubber drum, required auxiliary time is short, and labor intensity of workers is reduced. Besides, various steps are carried out synchronously, a supply process is reliable in coordination and high in precision, stretching of the bead fabrics is greatly reduced, fitting quality of the bead fabrics is improved, the bead fabric supply frame is adjusted conveniently and quickly during size change, the bead fabrics are fed into a rear supply frame after being guided to be opened, and fitting precision of the bead fabrics is guaranteed due to the fact that a mechanical centering device is arranged in front of the rear supply frame.

Owner:TIANJIN SAIXIANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com