Double-station winding machine for high-tension coil of three-dimensional wound core dry type transformer

A technology of dry-type transformers and high-voltage coils, which is applied in coil manufacturing and other directions, and can solve the problems of low winding efficiency, long auxiliary time, and tediousness of single-phase winding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

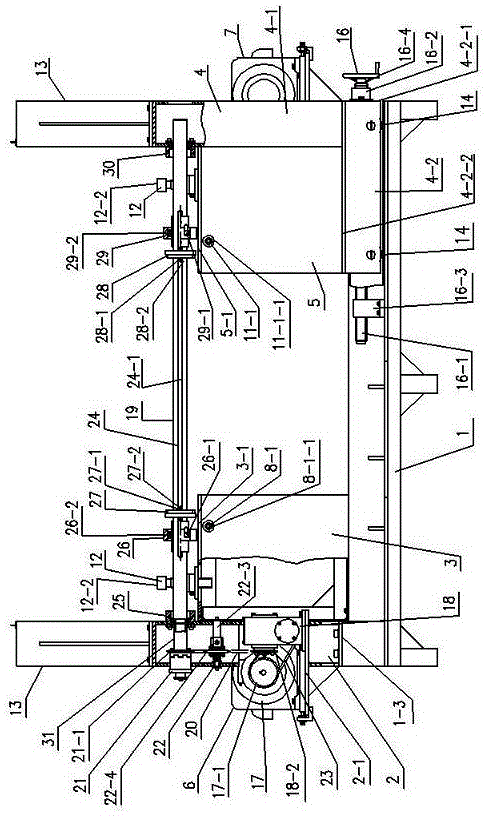

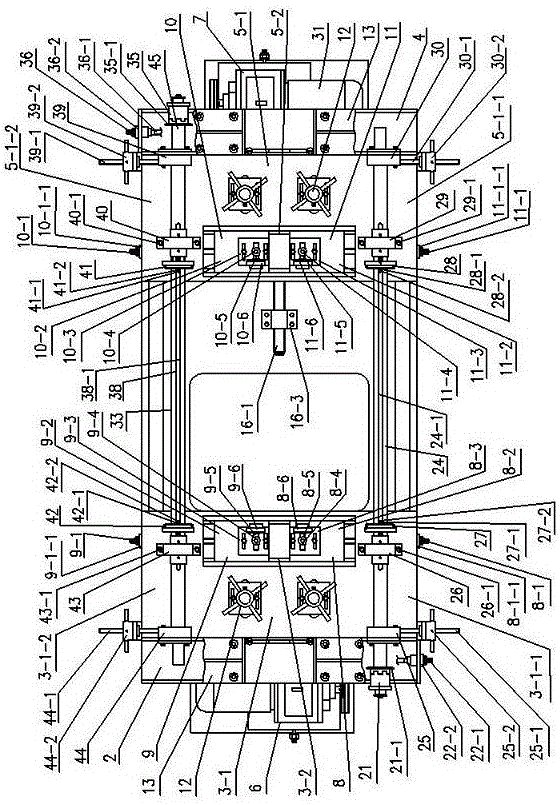

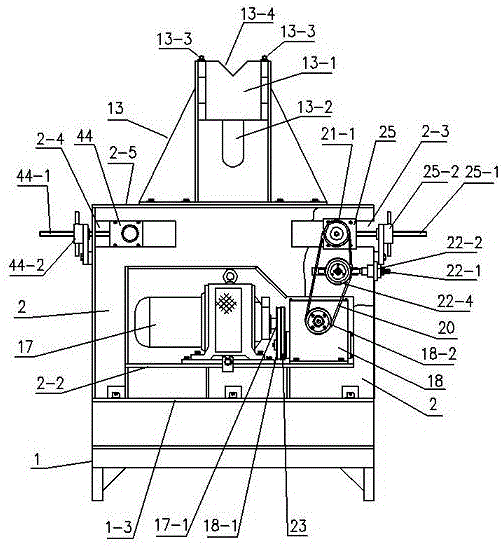

[0119] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0120] Such as Figure 1 to Figure 4 As shown, a three-dimensional three-dimensional wound core dry-type transformer high-voltage coil double-position winding machine includes a base 1, a left wall board 2, a left stand 3, a right wall board 4, a right stand 5, and a left wall board 2. The winding power device 6, the left supporting wheel dragging mechanism 8 on the left platform 3 tables, the right supporting wheel supporting mechanism 9 on the left platform 3 tables, the winding power device 7 on the right wallboard 4, the right The left supporting wheel dragging mechanism 10 on the platform of platform 5, the right supporting wheel supporting mechanism 11 on the platform of right platform 5, the iron core supporting frame 12 and the iron core turning bracket 13, wherein:

[0121] Such as Figures 5 to 7As shown, the base 1 is a rectangular frame, the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com