A multifunctional machine tool

A multifunctional machine tool and machine body technology, applied in the field of multifunctional machine tools, can solve the problems of inability to process workpieces, multiple positioning and processing of workpieces, and small tool magazine capacity, so as to achieve short auxiliary time, increase tool change space, and improve processing efficiency. and the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

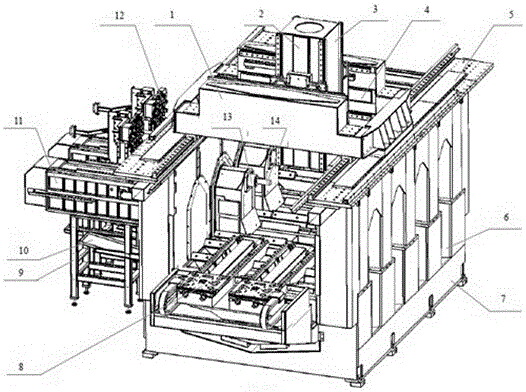

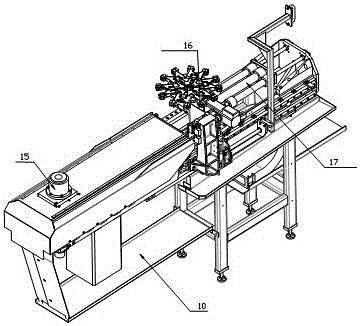

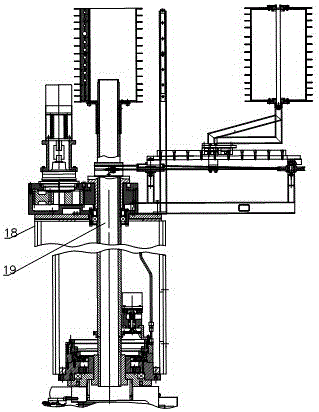

[0023] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a body 7, which is characterized in that: a plurality of internal and external transparent tunnels 6 are arranged on both sides of the body 7, and a main shaft support 9 is provided on the outside of the tunnel 6, and a line rail is provided on the main shaft support 9, The line rail is equipped with a detachable spindle tool module that enters and exits along the tunnel. The upper part of the body 7 is provided with a driving device that drives the workpiece to move along the X, Y, and Z axes. The lower part of the driving device is connected to the workpiece through a double-rotary clamping mechanism. Fixture, the double-rotary clamping mechanism drives the workpiece to rotate along the horizontal axis and the vertical axis. The lower part of the machine body is provided with two rows of feeders 8. The spindle tool module includes a horizontal spindle tool module an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com