Novel method for discharging residual winding from sleeve barrel

A technology of residual coils and sleeves, which is applied in the field of plate and strip finishing devices, and can solve the problems of large footprint, long auxiliary time, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

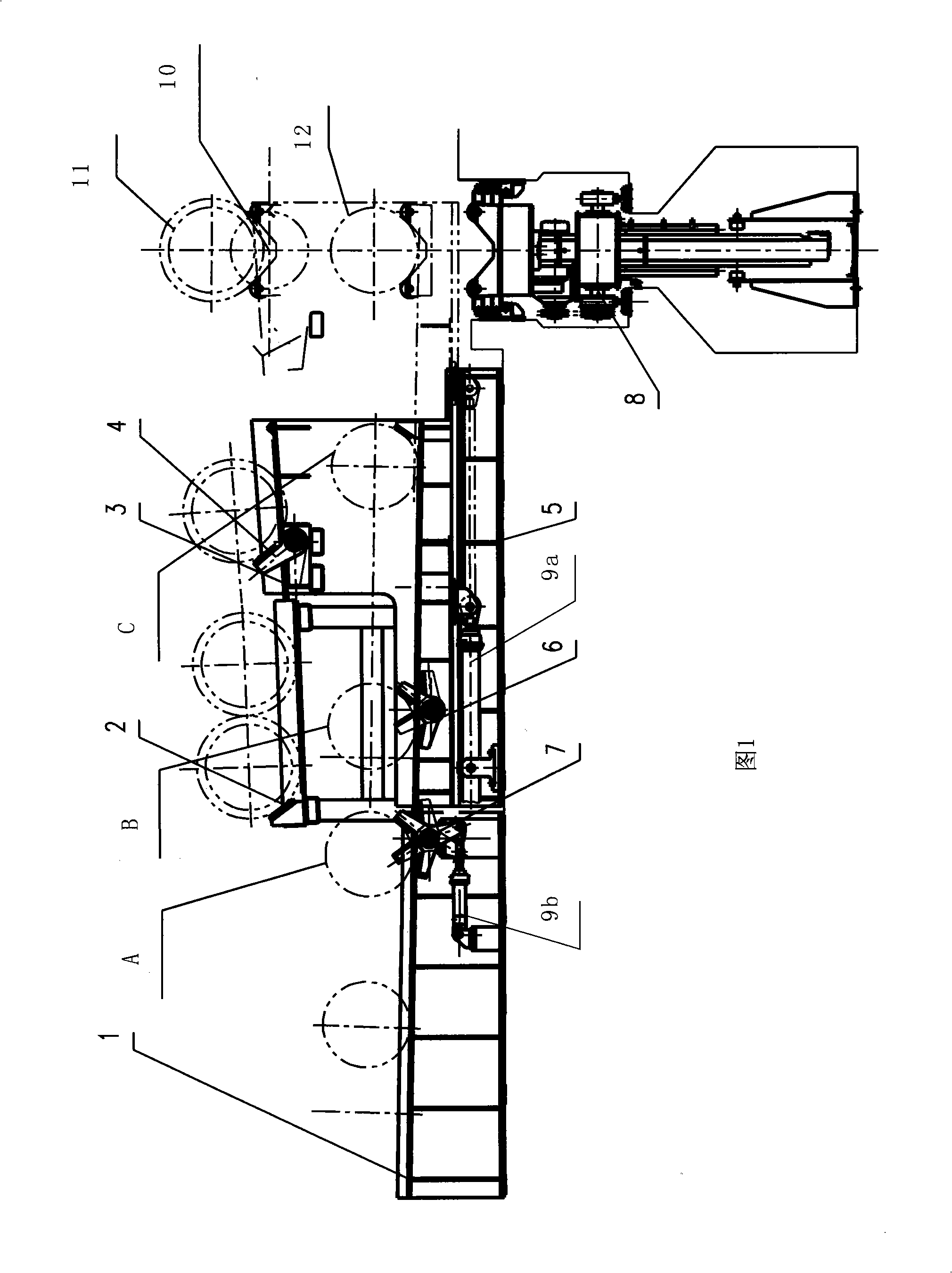

[0024] As shown in Figure 1: A new method for unloading residual rolls on the upper sleeve is to combine the upper sleeve device and the unloading residual roll device into one, and its manufacturing method is as follows:

[0025] A double-layer structure is adopted, the lower layer is the upper sleeve device, and the upper layer is the unloading device; one end of the upper sleeve device and the unloading device is a fixed sleeve storage table (1) and a remnant stacking rack (2) , the middle is a movable carriage (3), the other end is an unloading trolley (8), the bottom of the carriage is slidingly connected with the base (5); the carriage (3) is composed of two layers, and the upper layer of the carriage can be temporarily unloaded For the remnant roll, the lower layer of the carriage can temporarily place the sleeve to be loaded, and the upper and lower layers of the carriage are respectively provided with shift fork a.(4) and shift fork b(6) to move the remnant roll or sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com