A system and method for measuring furnace temperature distribution by using ccd camera

A technology of furnace temperature and camera, which is applied in the field of radiation temperature measurement, can solve the problems of measurement error and other problems, and achieve the effects of accurate flame boundary, good photosensitive performance and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

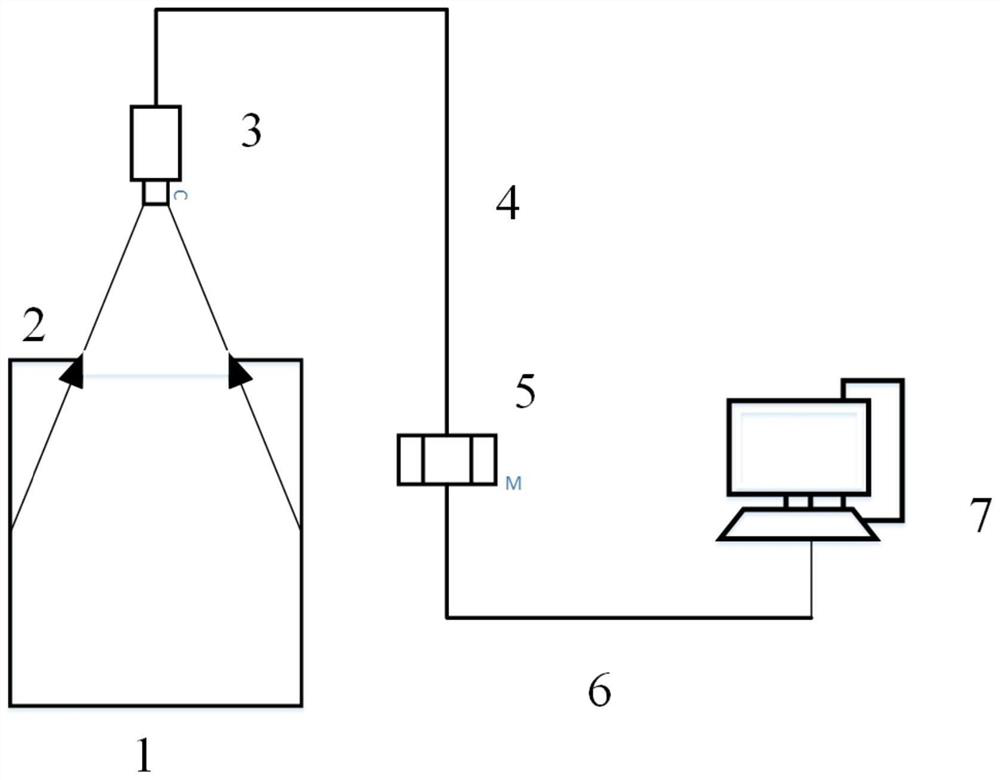

[0053] Such as figure 1 As shown, a system using CCD camera to measure the temperature distribution of the furnace, according to the direction of the optical path, includes: boiler 1, furnace detection port 2, CCD camera 3, data line 4, signal acquisition device 5, BNC line 6 and computing processing system 7. The top of the boiler 1 is provided with a furnace detection port 2, the CCD camera 3 is arranged above the furnace detection port 2, and the signal acquisition device 5 is electrically connected to the CCD camera 3 and the operation processing system 7 respectively. The computing processing system 7 uses a computer to perform image processing, generate an image matrix, form a projected grayscale image, and reconstruct the temperature field.

[0054] Specifically, the CCD camera 3 is connected to the signal acquisition device 5 through the data line 4; the signal acquisition device 5 is connected to the arithmetic processing system 7 through the BNC line 6, and the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com